Do-it-yourself impulse electronic load. Do-it-yourself electronic load: diagram. Homemade electronic load on a field effect transistor. General information about electronic loads

Eugene.A: Moreover, it is also meaningless. Modern electric meters do not spin in the opposite direction.

But there is almost nothing to warm up.

Eugene.A: About the transformation - some kind of rectal method. For lovers of perversion. Retired. Instead of watching porn.

...

You just need more nichrome, constantan, manganin and a switch to adjust the current, if there is such a need.

Or maybe I'm a pervert? True, there are no pensions, but it is not far off ... No, you can’t watch porn, it discourages you from doing it yourself - a scientifically proven fact!

And now let's compare the methods proposed by you and mine.

You offer the old fashioned way: more nichrome, constantan, manganin and a switch - this is rather cumbersome, not technologically advanced and not very accurate. I am already silent if a small step of adjusting the load current is required.

I suggest using one piece of nichrome, constantan or manganin and no switches at all.

Moreover, these pieces are not needed either. You can just take an iron, an electric heater, an electric stove ... whatever is at hand, and stick it with your own plug into a block called "electronic load". On the block there is a load current regulator in the form of a variable resistance, an encoder or buttons with a keyboard - according to taste and capabilities, and a display showing the current values of voltage, current and power ...

Unlike your method, I will be able to regulate the load current not discretely

and pla-a-a-vnenko, and even stabilize the set value.

And the accuracy will not be much better than your method.

The load current is I=k*ktr*Rn, where:

k - duty cycle of PWM pulses,

ktr - transformation ratio of the used transformer,

Rн - resistance of the iron, electric heater or electric stove.

It is enough to accurately measure the resistance of the iron ...

Actually, why? It is enough to enter the calibration mode when working with the device - with an iron, electric heater or electric stove connected, apply (inside the device) a calibrated voltage to its input and set the maximum current value with a calibration trimmer at the maximum fill factor. You can even automate this operation if the MK is worth it.

Everything.

The adjustment turns out to be linear, therefore, by tying the maximum value of the load current of 20A by calibration to a duty cycle of 0.9, with a coefficient of 0.1 we get a current of 2.2A.

To expand the limits, you can put a switch or relay and switch the taps of the converter transformer. We get several consistent subranges for adjusting the current (resistance) of the load.

I forgot to say - the transformer is better because of the easier coordination with calibrated loads such as an iron, electric heater or electric stove.

The transformer comes from a computer PSU (power). He has a lot of takeaways...

And now, Eugene.A, please explain to me - a pervert and almost a penisoner - why your method is not rectal, but mine is rectal, despite the fact that it is better, more technologically advanced, more versatile, more accurate and performs the same task?

First, let's take a look at the schema. I do not pretend to originality, as I spied on the constituent elements and adapted them to what I had from the details.

The protection circuit is made up of a fuse FU1 and a diode VD1 (perhaps it is superfluous). The load is made on four 818 transistors VT1…VT4. They have acceptable current and power dissipation characteristics, and they are not expensive and are not in short supply. VT5 control on an 815 transistor, and stabilization on operational amplifier LM358. Ammeter, showing the current passing through the load, I installed separately. Because if you replace the resistors R3 R4 with an ammeter (as in the circuit at the link above), then, in my opinion, part of the current that flows through VT5 will be lost and the readings will be underestimated. And judging by how the 815 heats up, a decent current flows through it. I even think that between the VT5 emitter and the ground it is necessary to put another Ohm resistance, so 50 ... 200.

Separately, it is necessary to talk about the circuit R10 ... R13. Since the adjustment is not linear, it is necessary to take one variable resistance of 200 ... 220 kOhm with a logarithmic scale, or set two variable resistors that provide smooth regulation over the entire range. Moreover, R10 (200 kOhm) regulates the current from 0 to 2.5A, and R11 (10 kOhm) with R10 turned to zero regulates the current from 2.5 to 8 A. The upper current limit is set by resistor R13. When setting up, be careful if the supply voltage accidentally falls on the third leg of the operational amplifier, the 815 opens completely, which will most likely lead to the failure of all 818 transistors.

Now a little about the power supplies for the load.

No, this is not perversion. I just didn’t have a small-sized 12-volt transformer at hand. I had to make a multiplier and increase the voltage from 6 volts to 12 for the fan and install a stabilizer to power the load itself and the alarm.

Yes, I inserted a simple temperature alarm into this device. I looked at the diagram. When the radiator heats up above 90 degrees, the red LED turns on and the buzzer with an integrated generator turns on, which makes a very unpleasant sound. This indicates that it is time to reduce the current in the load, otherwise you can lose the device due to overheating.

It would seem that with such powerful transistors that can withstand up to 80 volts and 10 A, the total power should be at least 3 kW. But, since we are making a “boiler” and all the power of the source goes into heat, the limitation is imposed by the dissipated power of the transistors. According to the datasheet, it is only 60 W per transistor, and given that the thermal conductivity between the transistor and the heatsink is not ideal, the actual power dissipation is even less. And therefore, in order to somehow improve the heat dissipation, I screwed the VT1 ... VT4 transistors directly to the radiator without gaskets for heat-conducting paste. At the same time, I had to organize special linings for the radiator so that it would not close to the case.

Unfortunately, I did not have the opportunity to test the operation of the device in the entire voltage range, but at 22V 5A the load works without overheating stably. But as always, there is a fly in the ointment in a barrel of honey. Due to the insufficient area of the radiator I took, with a load of more than 130 watts, after some time (3 ... 5 minutes), the transistors begin to overheat. What does the alarm indicate? Hence the conclusion. If you do a load, take the radiator as large as possible and provide it with reliable forced cooling.

Also, a small drift in the direction of reducing the load current by 100 ... 200 mA can be considered a fly in the ointment. I think this drift is due to the heating of resistors R3, R4. So, if you can find 0.15 ohm resistors for 20 watts or more, then it is better to use them.

In general, the scheme, as far as I understand, is not critical to the replacement of parts. Four 818 transistors can be replaced by two kt896a, kt815g can, and perhaps should be, replaced by kt817g. I think you can also take another operational amplifier.

I want to emphasize that it is imperative to set the R13 resistor at least 10 kOhm during setup, then, as you understand what current you need, reduce this resistance. I do not lay out the printed circuit board, because the installation of the main part of the load is made hinged.

Addition.

As it turned out, I have to use the load regularly, and in the process of using it, I realized that, in addition to the ammeter, I also need a voltmeter to control the source voltage. On Ali, I came across a small device that combines a voltmeter and an ammeter. Priborchik 100 V / 10 And it cost me 150 rubles with shipping. As for me, this is a penny. half a beer costs about the same. Without thinking twice, I ordered two.

November 8, 2017, 02:47I have already written at least three reviews of electronic loads, both completely home-made and assembled from a “designer”, as well as factory-made. In this case, both options are more likely to belong to the class of "designers", since they are not a functionally finished product, although they can work on their own, they require at least a power supply.

I saw them almost a year ago, became interested, and so I decided to buy it, and at the same time check how it is to “buy on Tao”.

In general, those who are interested in this topic, I think they will find a lot of interesting things for themselves.

Partly the prerequisite for buying was the difficulty with checking powerful PSUs, when my 300-400 watts was not enough at all, partly broadening my horizons, well, and not the last on the list was an attempt to buy on Taobao, because very interesting things come across there.

There were no problems with the purchase, and as a result, after a while I received a rather voluminous package. Here I made small mistake, shipping is quite expensive, and my pieces of iron are quite weighty.

Everything was packed just fine, but this was also a small minus, since the more packaging material, the higher the shipping cost goes :(

In the second photo you see not two products, but one. In this case, on the right is one of the loads, and on the left is what it was packed into.

The second load was packed even better, but in this case it was the seller's packaging, such a soft box.

No, everything is cool, the intermediary not only packed well, but also sent a letter before that, they say, dear Kirich, we got two obscure pieces of iron here, but we don’t even have a clue how to check them, we don’t even know what it is ...

To which I replied, calmly, don’t panic, compare with the photo in the store, if it’s approximately similar, then send it :)

In general, I got to the bottom of my order and as a result, there were only two electronic loads on the table.

I'll show you the "stupid" one first. without the ability to connect to a computer, just a load.

Declared power - up to 300 watts

Voltage - up to 150 Volts

Current - up to 40 Amps

Modes - CC\CV

There were many in the range different options, which conditionally differ in voltage 150/60 Volts, as well as current 10/20/30/40 Amperes, as well as the adjustment design - a connector on the board, a trimming resistor on the board or an external variable resistor.

I immediately chose the most "fancy" option and at the same time the most powerful, i.e. 150 volts, 40 amps, 300 watts with external resistor.

As you can see, the design consists of essentially two identical modules connected together. There is also a version with a power of 150 watts, consisting of a single module.

An external resistor is a regular variable resistor on a small circuit board. I’ll run a little ahead right away, there’s no point in ordering like that, for convenient control you must either order a load with a range of 60 volts, or even better - put a multi-turn resistor.

The design of the cooling system (actually the heaviest part), consists of two fans and a special aluminum radiator through which air is blown.

For the design of 5 points, where to get hold of a similar aluminum profile, even better if the size is not 50x50mm, but for example 80x80, well, at least 60x60.

A pair of rather powerful, but also very noisy fans, covered with protective grilles. At first I thought, here are the economists, they put only two screws on the grill, then it turned out that there was simply nowhere to screw the second pair of screws. No, they're still economists :)

Two control boards are connected together, although it is more correct to say that they are not disconnected, since they usually go that way during manufacture.

Postings are stretched from one board to another and the idea is clearly traced when one board becomes the leader and the second the slave.

Most of the connectors are missing, but I'll try to explain what's what.

Ref - adjustment by external voltage 0-5 Volts.

Potentiometer - external variable resistor, the middle contact is connected to the same Ref, i.e. changes the voltage in the range of 0-5 volts.

Fan - fan connection, the wires are simply soldered without any connectors.

Con 1, a connector is soldered in the left board - power supply 12-15 Volts.

There is also room for a 74HC connector. In general, this is usually the designation of a series of logical microcircuits, but I don’t know what in this case. One pin goes to ground, four - to the microcontroller.

Con 4 - temperature sensor.

At the other end of the board, there are power connectors for connecting the load, as well as:

Con 2 - in fact, it is in series with the Vin power connector, most likely a fuse should be placed there, some kind of plate is actually soldered there. As an option, connect an ammeter, but the connector is kind of frail for a current of 20 Amperes.

Con 3 - ground, +12 Volts and input voltage Vin are connected to this connector. You can connect a voltmeter here.

Fan 2 - Connection of the second fan (working for blowing), connected in parallel with the first one.

Four IRFP460A field-effect transistors work as the actual load. It turns out 75 watts per TO-247 case, in my opinion this is a lot, a lot, the power is exceeded by at least 1.5 times. This is due to the fact that field-effect transistors work much harder in linear mode. Actually, therefore, in my home-made for a power of 400 watts, 8 transistors are installed, 50 watts per case, and that's a bit too much.

But the fact that the transistors are connected correctly, I cannot help but note that each transistor has not only its own shunt, but also its own operational amplifier. I used exactly the same solution in my version.

The board is screwed with four screws through the racks, the transistors have their own fasteners, and they didn’t forget not only the thermal paste, but also the correct screws with a flat washer + Grover’s washer.

When I took it apart, I subconsciously expected that the radiators would fall apart, but no, everything worked out, the radiators seem to be glued together.

But here the racks could be twisted and stronger ...

Below you can more clearly see how the boards are connected to each other. By the way, for a more correct connection of the power wires, you need to connect the plus to one board, and the minus to the other.

If there are no particular questions about connecting the power connectors, then the wires in varnish insulation for connecting the power supply of the modules look somehow completely wrong. I understand that they are simply hidden there, but one wire touched the rack and over time, due to vibration, it would scrape the insulation. Of course, you may ask where the vibration comes from. This is how two rather powerful fans work, and more similar wires are not needed.

One of the "halves" closer.

1. The power input is protected not only by a 1 amp fuse, but also a reverse polarity protection diode. But in addition, they put a bunch of capacitors in the power circuit, even surprising :)

2. Although the load is “stupid”, it still contains a microcontroller. In this case, it controls the operating modes, overpower protection, and the fan.

3, 4. Three operational amplifiers LM321. A pair serves current sensors and transistor controls, and one (as I understand it) is CV mode.

Speaking of fan control. Made very thoughtfully. If the load is cold, the fan is off. It turns on stepwise when the power exceeds 20-30 watts per module, gradually increasing the blowing power.

If you turn off the load when the radiators are cold, the fans turn off immediately. But if you first warm up, they will turn off only when the temperature drops to about 35 degrees.

Those. fans are controlled stepwise and depending on power and temperature.

A ceramic capacitor is installed in parallel with the input, power terminals. My old one also has a capacitor, but with a noticeably larger capacity, so sometimes it sparks a little when power is applied to the input.

The less powerful and more “smart” load had noticeably fewer choices, 60/150 Volts and 5/10/20 Amps. And again, I chose the most powerful and high-voltage option, and in this case it may have been a mistake.

Below is the SPI connector, as I understand it, it is more needed to connect the programmer.

Even lower is a long row of contacts, microcontroller ports and power are brought here.

But what is SWIM, a little to the right and above, I did not understand. It looks like some kind of jumper is put there, the middle output goes to the microcontroller, the extreme ones go to ground and power. Those. in this way, you can set three signals - 1, 0 and Z. I tried all the options in the process, but did not notice any difference.

If everything was relatively simple in the previous load, then there are more components here.

1. Actually "brains", in the form of a microcontroller from STM.

2. Measuring Ultralow Offset opamp OP07, amplifies the signal from the main shunt.

3. Also on the board is a voltage converter LMC7660, it is needed to form a negative power pole for operational amplifiers. I did something similar in my electronic load, there was also a bunch of OP07 + 7660 in the current measurement circuit.

4. The board also has two OPA2277 precision dual operational amplifiers.

And this is where the little oddities begin.

There is a place on the board for two operational amplifiers, while all their wiring is even soldered, i.e. just solder a couple more OPA2277.

But the most incomprehensible thing is that the first pair of op-amps serves three transistors, and since the op-amps are dual, one still remains. I did not understand the rest, most likely it is used either to measure voltage or to control three subsequent op-amps.

There is one “half” for each transistor, since there are three transistors installed (I will show below). There is also room for a couple more transistors, but one dual op amp is enough for them, why do they need another one, and even with a soldered piping identical to the first? Mystery...

The input power protection circuit is solved as on the previous load, a polyswitch, a polarity reversal diode and a bunch of capacitors.

And here are the three transistors that I wrote about above. the board is designed for five transistors, and you can even see two thermal sensors placed between the first and second, as well as between the fourth and fifth transistors. Both temperature sensors are seen in the control program. In general, the decision is very correct, the manufacturer clearly decided to play it safe.

But here are three transistors from completely different batches, original :)

On the right you can see the place under the connector for the second fan.

As I wrote above, shunts are installed on the left side of the board. A pair of U-shaped - measuring for the controller itself, the data from these shunts are displayed in the program. There are two shunts out of five, five are used most likely in the 50 Amp version.

To the right, three M-shaped pieces are shunts in the power transistor circuit, they are used to equalize the current for each transistor separately. In this case, each shunt is in a circuit with an operational amplifier and the current is aligned very accurately. I used exactly the same solution in my powerful load, only there are 8 transistors, 8 shunts and 4 op-amps. This solution is the most correct, because it provides a uniform distribution of current between the elements. You can even use different transistors in general, the current will still be distributed evenly.

At the same time, interestingly, there are photos on the product page and a funny combination is shown, all the op amps are soldered, a wide cable is applied, i.e. it is assumed that 5 transistors are installed, but there is only one measuring shknt, and two balancing ones.

As part of the review of a more powerful load, I did not remove the fans, but judging by the appearance, they are the same. Pretty powerful 50mm fans with a power of almost 3 watts from Delta.

The fans themselves are the main consumers, therefore, for this load, a 12 Volt 0.3-0.35 Amp power supply is enough, and for a powerful version of 12 Volt 0.6 Ampere.

Before proceeding to the tests, I weighed both devices. Most likely you will ask why, if they are clearly not portable.

Since they were ordered through an intermediary, the weight begins to play a rather large role.

The total "useful weight" was 1218 grams, the entire package weighed 318 grams, total total weight The parcel was 1536 grams. By the way, in the process, I exceeded the estimated weight, and a debt of 1.3 bucks formed, but the intermediary sent the parcel anyway. To the question - what to do with the debt, they answered me - this will be taken into account with the next purchase.

Since I was the first to examine a powerful version, I will be the first to check it.

We connect the power supply and proceed to the tests.

First, a few words about management.

Each module is controlled by its own button. Short press - turn on / off, long - switch the operating mode. Wherein:

1. If you hold the button for a long time in the off mode, then the second mode will turn on when you turn it on.

2. The load "remembers" the last used mode.

The first photo shows the correct combination, green-green, in this mode the SS mode works.

If you turn on only the second load, then nothing will happen, it does not work by itself.

The next two combinations can work, but very incorrectly, so you can’t use them, but I’d better show you further with examples.

1. We connect to a laboratory PSU and set the output to 30 Volts, the load is turned off.

2. Turn on the lead (on the left), set the load current at 1 Ampere.

3. We turn on the slave, the current has become 1.84 Amperes, and not 2, as expected, there is an incorrect calibration.

4. Turn off the master, the current drops to zero, the slave itself cannot work.

For the sake of interest, I checked the minimum drop on the load, even taking into account the cable, it was 0.64 Volts at a current of 5.1 Amperes. Somehow I didn’t think to measure how much is real, but according to calculations, it comes out to be about 0.5-0.6 Volts.

CV mode. Actually it was one of important reasons why I bought these loads. This mode is not needed very often, but it cannot be replaced by CC mode.

Let me explain, if you check the power supply, then it works in CV mode (stabilized voltage) and you need to load it in CC mode (stabilized current). But if you check the charger, then the situation is reversed here, it works in CC mode, and it must be loaded accordingly with a load operating in CV mode.

This mode is more like an analogue of a powerful zener diode, or, well, the equivalent of a battery connected to the charger under test.

Yes, by charger, I mean the charger, and not power supplies with a USB output, which are mistakenly called chargers.

And so, what did I find out.

1. We set the voltage at the output of the power supply to 50-60 Volts, in this case it was 54 Volts.

2. We bring the load regulator to the extreme right position and by gradual rotation to the left we achieve until the PSU enters the current stabilization mode. Everything, the load operates in CV mode, stabilizing the voltage at a level of 52 Volts. If it were not a laboratory PSU, but an ordinary one, then it would simply go into defense, since the load would by all means prevent its normal operation.

3. By turning the resistor to the left, we reduce the voltage even lower, for example, to 16 volts. There are different currents in the photo, this is not a glitch, just the photos were collected in the course of different experiments and the setting of the laboratory PSU changed during the experiments.

4. But the first problem turned out - if you turn on the driven load, then the voltage drops to zero. It turns out that they cannot work together in this mode.

5, 6. I managed to start the slave load in this mode, but in fact it did not work, it was even evident from the fact that its fan did not start. In addition, the slightest change and it again fell into short circuit mode.

It turns out that only the driving load works in CV mode, because the power is limited to 150 watts, and not 300, as in CC mode.

The second problem was that the load is designed for 150 volts and this entire range is contained in an incomplete turn of the variable resistor, so there is no need to talk about the accuracy of the adjustment, it is very rude. A 60 volt version would be more accurate, but here you will most likely have to replace the resistor with a multi-turn one.

In addition, I just played with different power, 250-300 watts in SS mode dissipates the load without any problems at all, it makes really loud noise. By the way, the fans are controlled independently, and sometimes you can hear how one has reduced the speed, and the second is running at full speed.

In CV mode, I managed to load 160-162 watts, then there was a short squeak from the speaker and the load turned off. Stable work was around 155 watts.

For the next experiment, everything was used as above, plus a USB-RS485 converter and a connecting cable.

I didn’t take pictures especially in the process, and in fact there was nothing special to photograph, therefore, there will be a number of screenshots, tests and some explanations and descriptions of the problems that I met along the way.

On the product page there was a link to the Chinese “baida”, where all the necessary software for working with this module was posted.

I changed the name of the main program to a more intelligible one - DCL, otherwise "as is".

The same, but with the original file name and additional information. As you can see, they gave a lot of things, but there is one problem, the antivirus and the Win 10 OS protection system (I tried with Win 7, 8, 10) swear at the trojan in two files (they both have the same icon in the form of a red square above). Since I still wanted to try, I had to disable the antivirus and run everything at my own peril and risk.

As a result, such software was launched. Rather, this is how it should be. I tried to follow the link to the developer's page, it says that the software is in an "experimental" version, so glitches are possible. In general, the manufacturer is engaged in the manufacture of various measuring modules, but more on this closer to the end of the review, it will be more logical.

And so the explanations of what and where in this software, some became clear immediately, some were already in the process of experiments, and the last part was generally after translation from Chinese.

1. Parameter entry window.

2. Buttons for setting the parameter value, respectively with a step of 100, 10, 1, 0.1 and 0.01. The first and last are usually not used. The top buttons increase, the bottom ones decrease, everything is quite logical.

3. Buttons for switching to calibration mode, I understood the purpose by accident, I'll tell you below.

4. Setting the operating mode - CC, CV, CW, CR

5. Select the COM port and device number on this port (RS485 supports multiple devices on the same line).

6. Turn on/off the load.

7. And here I had to ask the Chinese managers I know, who at the same time know a language that is more understandable to me :). This is a record of the results of work in a file.

When I launched the software on my computer, everything was more incomprehensible, and it was with this software that I figured out what and why.

And exactly the same picture was observed on all home computers and tablets.

I especially hung when I saw a current of 655 amperes.

But let's not talk about sad things, I will explain the main operating modes.

1. SS, DC load, set the current to 20 Amperes (actually a maximum of 20.1 Amperes) and if the power does not exceed 150 watts, then the load goes into operating mode. If there is an excess, then it beeps and turns off.

2. CV, the same, but we set the limit voltage. When switching to this mode, a maximum of 151 Volts is displayed, which is quite logical, since it is usually reduced rather than raised.

3. CW, fairly common mode, constant power. We set the power in Watts and the load will support this power taken from the source.

4. CR, a very rare mode for cheap devices, but quite common for industrial ones. Here you can set the resistance of the "virtual resistor" which will be the load. those. The load current will directly depend on the source voltage. Unfortunately this mode  very rough and allows you to choose only with a resolution of 1 ohm.

very rough and allows you to choose only with a resolution of 1 ohm.

It also turned out that the load starts very gently and sometimes it is even annoying. For example, when setting the current to 3 Amperes, the current first rises sharply to about 2.3-2.3 A, and then very smoothly reaches the set value. The total installation time is about 30 seconds.

Another problem that I encountered is that the current load was not calibrated. But "there was no happiness, but misfortune helped." The fact is that the voltage calibration was excellent. But I was always confused by the two buttons to the right of the settings buttons. when clicking on them, it gave out some incomprehensible numbers like 4556 and 65432, obviously some two values. At first I thought that this could include imitation of interference or ripples, the letter Mu was confusing. But at one “wonderful” moment, I realized that the load also began to terribly lie in terms of voltage.

and then I remembered that before that I had poked these buttons and tried to select something with the buttons for setting the value. Well, then it's a matter of technology.

And so, about the calibration. To the right of the value setting buttons there is another pair, the top one is voltage, the bottom one is current.

I'll show you how to calibrate using current as an example.

Connect the ammeter in series with the load.

1. Select the SS mode, set the current, for example, 4.5 Amperes (the more, the better).

2. Poke the lower right button (near the -0.01 button), it will display a certain constant on the screen, it will have great importance, for example 52435 or 65432). using the parameter setting buttons, we achieve that the real current is equal to the set one.

3. We turn on the SS mode again, set a small current, for example 0.5-1 Ampere.

4. Press the same calibration button twice, it will display a constant with a smaller value, for example 3452 or 4321), using the same setting buttons, we achieve that the real current value corresponds to the set one.

5. Repeat until you get bored :) After each time, the value of a larger and smaller current will more and more correspond to the real one, or rather, the real one will more and more correspond to the set one.

With voltage, it’s about the same, but there are two ways, right and wrong:

1. Incorrect, we apply a stabilized voltage and by changing the constants we achieve that the load indicator shows exactly. This method is very fast, but due to the large resolution of the display, it is less accurate.

2. Correct. We supply a current-limited voltage to the input, for example, a power supply unit connected through a light bulb, but a power supply unit with current limitation is better.

We connect a voltmeter to the load terminals.

We transfer the load to CV mode, apply a certain voltage to the input, for example, 20-60 Volts (the more, the better) and set, for example, 5 Volts less than the input. Now the input voltage should be equal to the set one, since it is set by the electronic load.

We press the upper right calibration button (to the right of +0.01), we get into the calibration mode and use the parameters setting buttons to adjust the mode so that our external voltmeter shows what is set.

After that, we go back to CV mode, set for example 5 Volts (2-5), and repeat everything with the second constant as in the current calibration example.

Then I think everything is clear, by successive approximation we achieve an accurate setting of both the upper and lower values.

I didn’t take much measurements specifically for the review, but here is at least one informative photo left.

On the left is an example of work before calibration, it can be seen that the current was clearly overestimated, I raised it with a step of 1 Ampere, i.e. 0-1-2-3-4.

In addition to the incorrect current setting, the entire installation process took a long time, approximately 1 minute 40 seconds.

On the right is an example after calibration, I raised it to 5 Amps, 0-1-2-3-4-5, the current was set exactly and it took about one minute.

In addition to the actual basic parameters, you can measure (calculate) such quantities as mAh and Wh, for this there are three windows below that display the corresponding measurements. The clock runs while the load is on, regardless of the set operating mode, I don’t know how to reset all these values, since the unit itself remembers them. I tried not only to reload the software, but also to launch a second copy of the program from another folder, therefore, to reset it, it is necessary to distort the power supply of the load itself, which is inconvenient.

But the Chinese would not be Chinese if they had not screwed up here too.

Remembering how the USB tester worked, I decided to conduct a similar experiment here, set the current to 4 Amperes, and started taking screenshots every 6 minutes, respectively, there should be values of 400 mAh, 4 Wh / 800 mAh, 8 Wh, etc.

But it turned out that the mAh readings were underestimated by exactly 10 times, however, I paid attention to this even when I was experimenting before, but I just decided to double-check.

Well, how is it?

I even remembered a fragment from the book False Mirrors.

He has a small box in his hand. We crowd around, trying to see what it is.

“Warlock-9300,” Shurka replies. Finally, it turned out the way I planned...

The box is a tiny elevator car. The most common, brown, with sliding doors, with a piece of cable at the top.

That's just a height of the elevator ten centimeters.

- The most convenient form, - says Maniac. - "Nine-thousander" was also supposed to work like that, but it did not materialize ...

- Sasha ... Sashenka, my dear, - Padla says hoarsely. “Are you sure you didn’t mess up with the size?” BUT?

- I somehow didn’t think about the size, - Maniac says self-critically, and I understand that Padla is waiting for another stage of punishment for the joke.

- Apparently, somewhere with a comma was mistaken ...

Above I wrote that about one moment I had to ask for help from those for whom Chinese is native. At the bottom right of the working window of the program, the recording of the work log is turned on, as a result, a csv file with such incomprehensible values is formed in the folder with the program.

In general, a lot of means have been provided for working with the load, and partly for this reason there will be no further continuation in the form of the final assembly of the device, since I feel that everything is still ahead.

For example, there is a hypothetical possibility to build graphs -

As far as I understand, the graphs are based on data from another program, I downloaded it and it even tries to work, though it displays nonsense, so the screenshot is from the developer.

But an even bigger reason for the temporary pause in the assembly was that in the process of searching for information, I came across a module that can measure, display and control the operation of the device.

But all this is implemented somewhat strangely, the module has its own current and voltage measurement circuits, on the left you can see the wires that go to the current-measuring resistor (and a very correct one, with four pins), but the module is also connected to the 485 interface.

In addition to the basic features, it is stated that such an addition allows -

Optional bluetooth control.

Setting load shedding thresholds, such as minimum voltage or current, as well as limiting operation by time.

Mode memory.

Voltage drop compensation on wires

Current up to 50 Amperes

coulometer

18 bit ADC.

Choice of language - Chinese, English.

There is a truth and a minus, even on Tao this module costs about 28 bucks: (But it is quite possible that I will fork out.

But the idea to switch to such control was also caused by software glitches.

1. From time to time, spontaneous values jump on the screen, for the benefit of a short time and do not interfere in any way

2. Management. Comrades, this is a cap. I understand that the software version is a test one, but so .....

Even in simple current/voltage selection mode, etc. changing each parameter takes about 3 seconds.

For example, you need to set 1.2 Amperes, it will look like this -

press 1,

3 seconds pause,

press 0.1

3 seconds pause

press 0.1

3 seconds pause.

Now imagine how long it takes to set, for example, a current of 5.55 Amperes ....

But to be honest, I still do not lose hope that the software will be “finished”, and besides, I can say that there are no special comments on the load itself (i.e., on the hardware), in fact, they work by themselves not bad, and besides, they have a quite reasonable price for both functionality and workmanship.

Actually, that's why I have a question, maybe one of the programmers who also wants such a device can help in terms of the program. Perhaps there is an option to fasten an arduino with a normal screen, buttons and an encoder. In this case, I can deal with the "iron" part in terms of redrawing the circuit for repetition, and together we can make a pretty good device.

For a heavy load, I’m still slowly looking for a good ammeter with a voltmeter, as well as a multi-turn resistor and a case + PSU. But maybe I'll think about transferring it to digital control. In any case, at least one more review with the application is planned.

This is probably all I have. Ordered a load through an intermediary

I'll tell you about a useful device for radio amateurs - about a current electronic load with the ability to measure battery capacity. Why is this device needed?

Everyone has come across a situation where you need to find out the parameters of some kind of power source, for example, a laboratory PSU, an LED driver, or a charger. After all, practice shows that manufacturers do not always indicate the correct parameters. Of course, there is the easiest option - load it with a resistor calculated according to Ohm's law and measure the current with a multimeter. But for each case, you need to make your own calculations and it is not always possible to find a powerful resistor of the required rating, they are quite expensive. It is more expedient to use an electronic or active load that allows you to load any PSU or battery, and regulate the load current with a conventional potentiometer.

And by including a multifunctional digital wattmeter in the circuit that shows the capacity, this load stand can discharge the battery and show its real power. By the way, unlike IMAX 6, our system can discharge batteries with a current of up to 40A. This is useful for car batteries.

The circuit is based on a dual operational amplifier (op-amp) LM358, although only 1 element is involved.

The current sensor is a powerful resistor R12, preferably 40W, although I set it to 20W. You can connect several resistors in parallel to obtain the desired power so that the final resistance is 0.1 ohm. R10 and R11 (0.22 Ohm / 10W) are current leveling elements for power switches. I actually have 2 x 0.47 Ohm / 5W in parallel for each transistor.

The OU controls two composite KT827 transistors installed on separate radiators. Transistors are optimal for this circuit, although they are quite expensive.

Principle of operation.

When the device under test is connected, a voltage drop forms on a powerful current resistor R12, the voltage at the inputs of the op-amp changes accordingly, and therefore at its output. As a result, the signal supplied to the transistors depends on the voltage drop across the shunt. The current flowing through the transistors will change.

Using a potentiometer, we change the voltage at the non-inverting input of the op-amp and, as described above, the current through the transistors also changes. These transistors allow you to work with currents up to 40A, but require good cooling, because. they work in a linear fashion. Therefore, in addition to massive radiators, I installed a fan with speed control, which can be turned on with a separate button. The speed controller circuit is assembled on a small board.

Theoretically, the maximum input voltage can be up to 100V - the transistors will withstand, but the Chinese wattmeter is only rated up to 60V.

Button S1 changes the sensitivity of the OS, i.e. switches to low currents for accurate measurement of low power sources under test.

Important features of this scheme:

- the presence of feedback for both transistors,

- the ability to change the sensitivity of the OS.

- coarse and fine current adjustment (R5 and R6).

The transformer in the circuit feeds only the op amp and the indicator block, any one with a current of 400mA and a voltage of 15-20V is suitable, anyway, the voltage is then stabilized to 12V by a linear stabilizer 7812. There is no need to put it on a radiator.

Dream interpretation of many animals Why do many animals dream

Dream interpretation of many animals Why do many animals dream What to give a girl for christening

What to give a girl for christening How long does carnival last

How long does carnival last Solar eclipse in February Aspects of a solar eclipse

Solar eclipse in February Aspects of a solar eclipse Holy week before Easter, what can you eat every day?

Holy week before Easter, what can you eat every day? February predictions for Capricorn

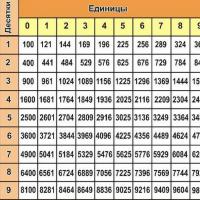

February predictions for Capricorn Tasks for logarithms with a solution

Tasks for logarithms with a solution