Device for laying bricks for jointing. Brick laying tools - working tools. Tools fall into three categories

What are and how to make a device for laying bricks yourself

Brick is one of the most common building materials. Its high performance characteristics allow it to be used in a wide variety of areas, including the construction of fences and the construction of a foundation for a fence.

Despite the seemingly fairly simple work, there are certain technologies for laying bricks. Their choice depends on the purpose of construction and the quality of materials. In order for the bricklaying process to be easier and technically correct, various devices are used.

Types of devices and their use

The following tools are commonly used for masonry:

Trowel (trowel)

The most common and necessary tool. It is a smooth steel blade. It performs several functions: grouting, leveling concrete mortar, removing excess mortar.

plumb line

This tool belongs to the category of measuring tools. It is used to measure and check the angles that are formed during the masonry process. The angles must strictly correspond to the calculations.

Cord

Designed for marking the height of masonry in preparation for work, as well as for checking the correctness of the work performed.

bucket shovel

Although this tool is widely used for mixing concrete, it is also used in masonry. With its help, the concrete mixture is applied to the brick. Especially necessary when working with a large amount of solution.

Level

Also applies to measuring instruments. It consists of a robust housing, inside of which there are containers filled with non-freezing liquid. In addition, inside there are balls of air. It is they who allow you to accurately determine how smoothly the masonry is being carried out, both in a horizontal and vertical position.

When setting the level on the masonry, if the work is done correctly, the balls are strictly in the middle of the fixture. Otherwise, they show the level of inclination in one direction or another.

Stitching

The main tool for bricklaying, especially if the brick is used as a decorative element. With its help, seams are processed. They not only align, but also acquire the desired shape or pattern. The patches come in a variety of shapes and sizes.

rule

A tool for monitoring work. It is an absolutely smooth rail, with which you can measure and check the surface, determine how evenly the laying is going on. Especially widely used to check the external masonry.

Pickhammer

In case of laying errors or to achieve the required shape, this tool is used. It allows you to chip off unnecessary parts and give them the desired appearance.

ordering

It is attached to the first row of masonry and allows you to accurately measure the location of bricks, their rows relative to each other. Often used to create a variety of patterns and patterns on the outside of brickwork. In addition, the order is widely used for marking future window or door openings, design features of a building or structure being erected. It can also be used to secure the cord and level the masonry.

These are the basic masonry tools. With the development of production technologies, they are increasingly improved and automated to facilitate the work of the builder. However, you can make such a device yourself.

How to make a similar tool with your own hands

In order to make a device yourself, you need to decide for what purposes it is intended:

- Cord attachment. Ordering is not always in the arsenal of the first improvised tools, and fixing the cord is necessary. There is an option for fastening with nails, but for this it is necessary to wait for the solution to dry completely. This is not very convenient.

In order to solve the problem, you can make a fairly simple tool yourself. A device in the shape of the letter "T" is cut out of a metal sheet. A cord is attached to it. Then the edges of the device are bent strictly according to the shape of the brickwork. Thus, even without the use of complex devices, the cord is securely attached to the masonry and does not disturb it. - Work at height. Often there are situations that require work with bricks at a height. Construction companies use cranes for this. For work at home or in the garden, structures such as scaffolding can be useful. Such a device is made quite simply. Near the wall or fence, for which it is necessary to lay at a height, 2 goats of the same height are installed. Wooden boards are superimposed on them. The main thing in the construction of such devices is to ensure their maximum stability.

- Brick laying at the same height. In the absence of a cord or level at hand, you can use the following simple device. M-shaped parts are cut out of a steel sheet. Then a hole is drilled in the middle of each piece. Then it is bent at an angle until the correct corners are obtained, an elastic band is inserted into the hole. One corner is attached to the outside of the first brick in the row, the other on the outside of the last brick in the row. The elastic is stretched, and a kind of level is obtained. It can be used both to check the already finished masonry, and as a guide when doing work.

- Solution dosing. Very often there is a need for an accurate dosage of the solution, it is needed in cases of seam thickness calculated up to a millimeter. The wizard won't help here. But there is a device that you can do yourself. For this, a sheet of iron or steel is taken of exactly the thickness that is necessary for the seams. An oblong hole is cut out in it, which corresponds to the width of the brick. It's pretty easy to use. It is simply superimposed on the brickwork, with the help of a bucket-shovel and a trowel, the mortar is applied, leveled, and the excess is removed. The result is an absolutely flat surface and the same thickness of the solution throughout the masonry.

- Filling joints with concrete. It is not always possible to accurately and quickly calculate the amount of mortar and fill the seam completely. For the qualitative performance of such work, another device is intended. It can also be made from sheet metal. A rectangular sheet is cut or taken, holes are cut in it, which are the same size as the brick. The device leans against the bricks, the seam is rubbed exactly over their area. Using this device, as well as using the previous one, you can control the thickness of even side seams in hard-to-reach places.

Thus, there are a large number of tools that are made specifically for correct and fast masonry. In the absence of any of the main devices, it can be successfully replaced with a do-it-yourself device.

Video of the quick masonry tool

In the following video you can see the use of one of these devices:

When constructing brick structures, masons use hand tools and a variety of devices that allow:

- improve accuracy when laying masonry, maintain the evenness of the seams and the general plane of the wall surface;

- make work easier;

- improve work productivity.

Hand tool

The main tool of a bricklayer, used directly in the laying of masonry:

- Trowel (trowel)- a device in the form of a triangular metal flat spatula attached to a wooden or plastic handle. Required:

- application and leveling of masonry mortar;

- removal of excess plastic mass;

- leveling the brick by tamping with the back of the handle;

- filling and grouting joints between adjacent blocks.

- Pickhammer, - the difference from the classical instrument is in a different form of metal mutual strikers. On the one hand, it is a pointed part resembling a chisel or a chisel, on the other, a striker in the form of a rectangular bar. The sharp end is used to break off small parts from the brick, while the blunt end is used to level the surface or split the block into two pieces.

- stitching,- applied at the final stage of work. It is necessary to create a continuous seam between adjacent rows and give a decorative look.

Another tool group belongs to the marking and measuring group:

- plumb line, - used to control the verticality of external and internal walls;

- mooring line, - with its help, the horizontality of the masonry rows is monitored;

- water level, - is necessary to determine the level of the axes of various corners of the building and check the horizontalness of the seams around the entire perimeter of the building;

- building level, - used for current control of vertical and horizontal surfaces;

- square, - this tool checks the squareness of the corners; one of the rulers must be at least 500 mm long (the size of two bricks);

- aluminum rail 2–3 meters long, used for general measurement of the horizon or vertical; can be equipped with water eyes-controllers.

This whole set of tools was used and is used directly in the construction of brick structures. With sufficient experience, such a special set is quite enough for a professional bricklayer when working on a garage, one-, two- or three-story houses, or any outbuildings.

The construction of a building, which is subject to increased requirements for the state of the front surface, will require the use of special devices that increase the accuracy of work. They are also suitable for beginners and inexperienced craftsmen.

fixtures

The control of the horizontality of the seams, the vertical of the wall surface and corners is carried out by means of orders . This device is a metal corner or a wooden lath with marked marking lines. The divisions determine the vertical size of the block along with the thickness of the seam. At these points, a mooring cord is attached, along which the horizontality of the seam is monitored.

The order is mounted on the finished wall - when performing at least 5-6 rows and setting the solution. Prior to this, a regular bricklayer's tool and a device for performing even masonry are used.

Do-it-yourself ordering

The easiest way is to make a tool from wooden slats, but the strength will not be enough. Therefore, it is advisable to use such a device when building a garage, outbuildings or a small garden house.

Using a metal corner with verified edges and a shelf of 40–50 mm, you can get a more serious tool. The length of the rail is 1.5–2 meters. The marking is applied based on the height of the block (from 65 mm) and the thickness of the seam (10-15 mm). Holes Ø 4–8 mm are drilled under the mooring line, at the locations of the control points.

In the lower part, symmetrically, side stops are attached, through which fixation is carried out with the side walls of the building. The distance between the lower and upper plates must be at least 40–50 cm. The fixture is set using a building level and a plumb line.

Cleansing of internal cavities

New chimneys or ventilation ducts are freed from the influx of excess mortar with mops. This tool is a square plate with a size of 14 cm, attached to a steel handle 1–2 meters long. In addition to the cleaning function, with a rubber plate, the joints are completely filled and the surface is smoothed with a solution.

Performing level laying

The horizontality and verticality of the seam, and, accordingly, the accuracy of the entire brick building structure, in addition to the skill of the performer of the work, depend on the correct application of the masonry mortar.

Excess or lack of the latter leads to curvature of the walls, decrease in strength, violation of sound and heat insulation. In addition, the moisture resistance of the seams is violated.

To improve accuracy, it is used solution dispenser. It is a rectangular tray having the width of the wall being made. In the center is a through hole through which the solution is applied.

The length of the fixture is selected for the size of one or three bricks at once. The device is designed in such a way that when installed on a wall, between a row of bricks and the upper cut of the product, free space is formed - this is the thickness of the applied mortar.

Together with a horizontal design, a device for end application of the mixture is used. Thus, a constant thickness of the seam is ensured, the solution is dosed and saved.

Application

The dispenser is installed on the finished row of masonry. Thanks to the bottom and side stops, the product ensures, provided that the previous layer is made exactly, the horizontality of the mixture and its uniform thickness. Filling is carried out by means of a shovel, bucket or trowel. The latter, among other things, is used to level the solution and remove its excess.

The principle of using a face dispenser is similar to a horizontal device. The only difference is that due to the small amount of mortar, all operations are performed by a manual trowel.

Do-it-yourself dispenser

A device for even masonry can be made on your own. The material used is wood, plastic or metal. The difference between them is the service life and the way the elements are attached to each other.

The geometric parameters of the future device depend on the type of blocks used - brick, gas or foam concrete, etc. For each type of product, the thickness of the seam and, accordingly, the amount of the mixture will be different.

The width is selected according to the size of the future wall and fixed with side stops. The height of the lower stops is determined by the thickness of the seam. The simplest design is a plywood product with a thickness of 16–24 mm.

A wooden box is knocked together from it in accordance with the selected parameters. As the lower limiters and side stops, you can use wooden blocks or scraps from the same plywood. Suitable steel corner or furniture corners.

The cost of factory products

With large volumes of work, it is advisable to consider the possibility of purchasing a finished product. It is most often implemented as a set. For example, "Set of Bricks" consists of:

- template "Brick", - used for laying the mixture on a horizontal row (bed);

- template "Brick", - used for a single block with a size of 65 mm;

- template "Brick", - for one and a half bricks with a size of 88 mm;

- corner "Bricklayer", - is mounted on the outer corners of the building; in addition to controlling the angular parameters, it is used to fix the mooring line;

- mason's trowel;

- video material with lessons on the use of the device and the basic basics of masonry.

The main elements of the dispenser are made of high-strength plastic. The average market price is 1500-1900 rubles per set.

Tip 1. In the manufacture of devices for even masonry, it is advisable to lay a joint thickness of 10 mm, which is most in demand for single and one and a half bricks.

Tip 2. To prolong the life of a dispenser made of wood or plastic, several layers of highly wear-resistant varnish, such as parquet, can be periodically applied to the most worn areas.

Tip 3. All, without exception, tools, at the end of work, must be cleaned of the remnants of the mixture and rinsed thoroughly, otherwise they will quickly fail.

Tip 4. The time or finances spent on the manufacture or purchase of the necessary devices will more than pay off with the quality of the masonry, the speed of work and the savings in the masonry mixture.

The bricklaying process is not easy and responsible: both the functional and aesthetic properties of the final structure depend on the quality of the work. Masters with many years of experience can boast of the ability to quickly and easily measure the seams, install stone blocks evenly, without special tools. Ordinary inhabitants, erecting, for example, a fence near the house, often use their own strength. To help them, there are a number of tools and fixtures for laying bricks that can facilitate the process of erecting elements and structures.

Devices for work

Ceramic or silicate brick is a classic building element. Nowadays, they lay out either some kind of functional layer of the structure, or they perform a lining, since a wall made only from it is a troublesome, labor-intensive business and requires a large thickness in order to keep heat in the room. However, whatever the element being arranged, the following bricklaying tool is required to create it:

- Trowel (popularly - trowel). It is a spatula for throwing and leveling the solution.

- The bucket is used for large volumes of masonry, when you need to lay a lot of mixture.

- Jointing - a tool for decorating finished seams on the outside of the wall. May have different sizes and patterns.

- A pick (hammer) is needed if something needs to be corrected: to level the position of the brick or to chip off the unnecessary.

- Ordering is a professional tool that greatly facilitates the work: it allows you to accurately measure the evenness of the masonry, the position of the bricks relative to each other, form an ornament, mark the opening, pull the cord.

Control intermediaries

The basic set helps to directly lay the bricks on top of each other and decorate the wall. To make the masonry even, you can not do without control tools and fixtures:

- The bubble level is indispensable for horizontal alignment of rows.

- The plumb bob plays the role of controlling the evenness of the vertical plane and the angles of the tool.

- The rule is a flat wide rail for leveling and controlling rows of bricks.

- The cord is pulled to orient the rows, their height and evenness.

- A square is needed when laying wall intersections.

In the work of the master use the set "Mason". A device for laying bricks in it can be both ordinary and unfamiliar to the townsfolk, but greatly simplifies the work. The set can be purchased from specialized stores. Experienced masons have a personal kit, which includes all the items necessary for a particular master.

Non-standard inventions

In addition to the basic set, there is a special tool for laying bricks, designed to facilitate the work of both an experienced craftsman and a layman. With it, you can align the rows, adjust the thickness of the seam when laying the mortar. Each device for laying bricks is a certain simple design with parameters suitable for performing a given operation (height, width, thickness of the working part).

Ready custom tool

An interesting fixture for quick bricklaying has the form of a tray without a bottom with longitudinal stops at the base.

The width of the device is adjustable, which allows it to be used for different types of dressing. It is designed for uniform laying of the mortar along the entire length and width of the masonry. This tool was invented by the American company Bricky, and serial production of original kits was also launched there. Then cheaper analogues appeared in many countries of the world. Device material - plastic. Unfortunately, the sand, which is part of the masonry mortar, can wear out the surface of the tray, which entails the need for its periodic replacement. But the craftsmen came up with a way out of this situation: the scratched surface is covered with various compositions (enamels, varnishes), which allow extending the life of the tool.

Vertical seams between bricks or blocks also need to be carefully worked out, but it is not so easy to lay the mortar evenly and in the right amount. To do this, there is a similar device of the same production. It limits the area of application of the composition and the thickness of the future seam.

How to apply

The brick laying tool is very easy to use:

- Adjust the width of the device to the desired one.

- Install it in the direction of work flow.

- Fill the form with masonry mortar at the level of the rails.

- Remove excess with a trowel.

- Move the fixture to the desired distance and repeat the operation.

You should not lay a lot of mortar at once: you need to have time to lay the bricks before the mixture seizes. It is very convenient to move the tray: the stops at the base fix its position relative to the plane of the wall, so it does not have to be constantly corrected.

Since the masonry tool is subject to active wear, you can make a similar tool from scrap materials. To do this, take laminated plywood 10 mm thick or a corner profile, make 2 identical pieces for the sides and 1 for transverse fixation of the width you need. Fasten the parts together and use the finished tool according to the same principle. For convenience, fixing edges from metal corners can be attached to the base of the rails.

What is the price

In different configurations, you can buy a device for laying bricks: the price of the original set is about 3400 rubles.

What does it include:

- Tray for horizontal seams.

- 2 vertical strips for brick and block masonry.

- Trowel.

- A set of fasteners.

- CD with detailed instructions.

Similar sets cost differently, depending on the configuration: a set of horizontal and 2 vertical fixtures can be bought for 600 rubles. (Kovrov). Separate parts are sold on various resources: a tray can be bought for about 1000 rubles.

homemade device

Not everyone can afford to buy a kit that can make work easier. Yes, and this is useless if you want to independently arrange a small stone structure or build a house. It is much easier, cheaper and faster to make a device for laying bricks with your own hands. The craftsmen came up with such a tool: 2 slats are hammered perpendicular to each other - the main one corresponds to the thickness of the future seam, the auxiliary one is attached to the middle or edge of the main plane. Thus, you can make 1 or 2 fixtures that are installed on one or two sides of the masonry.

The brick laying rail is convenient to use: it is used for both horizontal and bonded jointing. The principle of operation is similar to the use of the American model: they are installed along the masonry, the mortar is laid, the excess is removed and the blocks or bricks are installed.

How many centuries the construction industry has existed, the same number of its representatives invent and improve the construction tool.

The main tool for laying bricks is a trowel, a comfortable handle and the correct angle of which allow you to comfortably manage it.

Of course, not a single construction site is complete without such a profession as a bricklayer. And because the tool for laying bricks occupies a special place among other tools. So special that at some point in history it even went beyond just a construction tool.

But here we will not consider cultural and historical symbols, but the purpose and characteristics of some traditional bricklaying devices, which should help future masons in their work.

Brief classification of masonry tools

If we take into account all the tools for stone work that exist today (even mechanized devices have appeared in recent years), then they can be divided into two large groups: working tools (which directly perform the operations of building walls from brick or cinder block) and control and measuring fixtures.

- trowel for stone work (trowel);

- mason's hammer (pick);

- mortar blade;

- stitching;

- mop.

The group of measuring instruments includes such products as:

- plumb lines;

- building levels (flexible and bubble);

- specialized square of a bricklayer;

- orders (intermediate and angular);

- folding meter, measuring tape;

- intermediate pendulum;

- rule;

- control template for inter-row openings.

It is also possible to single out into a separate subgroup devices endowed with an auxiliary function, and additional devices that ensure the safety and convenience of a person during work.

Back to index

Working tools for laying bricks

This group includes tools used for the construction of walls and facing facades made of bricks. The presence of these tools on the construction site is essential for efficient work.

The most famous and almost universal masonry fixture is the well-known trowel (trowel).

The main tool of a bricklayer and stove-maker is a triangular (sometimes in the form of a drop) spatula with a curved handle. The approximate length of a standard trowel blade is 18-19 cm.

The purpose of the trowel-trowel is to apply cement mortar to a brick wall under construction, level it on masonry, fill the seams formed between the brick rows, and also remove excess mortar residue from the seams.

Its handle is made either from wood, or from plastic, or from a rubberized material. In any case, when choosing this irreplaceable item, you should pay attention to the fact that its handle is well covered by the hand and does not slip out at the slightest movement.

Tools used when laying brick ovens: a - pickaxe hammer, b - trowel, c - jointing for convex joints, d - jointing for concave joints, e - mortar shovel.

The second important tool is a pickaxe (sometimes called a combination hammer). A standard hammer is made approximately 30 cm long.

It has quite a lot of functions due to the fact that on the one hand the specified object has a shock (hammer) part, and on the other hand it is equipped with a pointed device for splitting. Thus, they can tap the laid brick so that it takes the desired position, chop and hew the stone. This makes it indispensable, especially in cases where inconvenient and hard-to-reach places are being laid.

The solution vane is designed to supply and spread fresh mortar over a relatively large area to be treated. It makes it possible to quickly and efficiently spread the mortar along the wall under construction. In addition, it is easy to stir the ingredients of the cement slurry in the box or tray.

A bricklayer's jointing is a tool that is used to decorate the seams formed during masonry. For this reason, the narrow trowel part of the jointing has a triangular or semi-oval section to form concave or convex internal seams. It is she who performs the operation, without which it is very difficult to imagine.

Mop will be of more interest to stove-makers. It got its name from the process of the same name, the essence of which is to remove the mounting solution when it is squeezed out of the seams inside the ventilation shafts or chimneys under construction. The mop is a square rubber plate mounted on a metal handle.

Back to index

Lines, mooring cords and other control devices

A well-chosen control and measuring tool is of great importance for the quality of construction. Suffice it to say that the loss of control over the process of laying bricks can most likely lead to the collapse of the walls of the building, which is ultimately fraught with disaster. Therefore, the work of a bricklayer on a construction site without such devices, despite their, at first glance, secondary importance, is simply unthinkable.

The simplest of them and the most traditional is the plumb line. It consists of a cone-shaped metal case, which is suspended on a twisted cord through an aluminum bar. From time immemorial, they check the accuracy of the installation of vertical elements: walls, masonry corners, pillars, window and door openings.

At the same time, all plumb lines are divided into lighter and heavier ones. Their use in certain cases directly depends on the height of the structure: the higher the structure being checked, the greater should be the mass of the plumb line. The explanation here is very simple: a light plumb line hung on a long cord, being somewhat attracted to the wall of the building, will distort the real picture of the degree of verticality.

Thus, the position of the wall within the height of one floor is controlled by a plumb line of 200-400 g, and along a height of several floors - by a plumb line weighing 600-1000 g.

At the same time, the control of both verticality and horizontality of brick laying is carried out by such a device as ordering. This is a kind of complex beacon, assembled from dissimilar structural elements (pipes, rails, corners), with the help of which a worker can quickly and accurately, without using the “by eye” principle, lay bricks.

For this purpose, a special scale is applied along the height of the order, the division of which is equal to the thickness of the brick row (77 mm for a single one and 100 mm for a thickened one). Also, in order, the lower and upper boundaries of the openings of windows and doors, ceilings and other structural elements of the building are marked in advance.

Orders are set using a plumb line before the installation of the walls. They are placed in the corners of the building and where the walls are adjacent to each other. For accuracy, these control instruments are installed every 10-12 m. Between the marks of the brick rows that are marked on the orders, a mooring cord is fixed, along which the brick is laid.

Another device for checking the vertical and horizontal positions of a brick wall or ceiling is the well-known building level. Most often, levels in the form of an aluminum profile are used for stone work, having three length options: 300, 500 and 700 mm.

The position of the brick wall vertically and horizontally is determined by the orientation of air bubbles inside two sealed glass ampoules partially filled with an antifreeze liquid. The presence of the bubble strictly in the middle of the ampoule means that the structure to which the level is applied is in a strictly vertical or horizontal position. The deviation of the bubble to the right or to the left indicates a deviation from the vertical or horizontal.

As a rule, this large, even lath made of planed wood or a special aluminum profile is used to smooth out various irregularities in the masonry from its front side. Carrying it along a freshly laid wall, a bricklayer can easily notice a defect in his work and correct it in a timely manner. The length of a standard tool ranges from 1000 mm to 3000 mm.

The erection of the walls of almost any building is associated with the installation of brickwork. Of course, if you are starting to build a house, and you do not have certain experience in performing construction work, then you can turn to a specialist bricklayer for help. But when building an outbuilding, you can make brickwork with your own hands using some tools. These simple devices will help to significantly speed up the process of building a brick wall, and get a fairly high-quality result.

Using accessories on the device different designs of bricks:

- Helps to align the seams between the rows and the entire plane of the structure.

- Facilitates the working conditions of the bricklayer.

- Increases the productivity of brick laying.

Auxiliary tools for masonry

When carrying out work on the construction of the wall of the building, the bricklayer uses a certain set of tools and devices.

Hand tool

Most often with brickwork walls, hand tools are used, without a set of a bricklayer it is impossible to perform this type of work. Masonry tools:

There is another group of tools, which is actively used in the construction of brickwork, which can be called measuring.

Measuring tools include:

Super do-it-yourself brick laying tools

Using all these tools, even with a not very rich experience of a bricklayer, you can build small buildings out of brick. But if the task is set, to build a building to which increased requirements will be imposed on the state of the facing surface, it is sometimes very difficult to do without the use of special super-devices that improve the quality and accuracy of work.

ordering

Through this device, the verticality of the wall surface and the corners of the building is monitored, and the horizontality of the brickwork seams is also checked. Ordering constructively consists of a wooden lath or a metal corner, on which marking lines are applied. The markup division value determines the vertical size of the block or brick and the thickness of the mortar layer. The mooring cord is attached exactly at these points and allows you to control the horizontalness of the seam. The ordering is installed on a part of the wall after laying 5–6 rows, and the solution has completely solidified.

Through this device, the verticality of the wall surface and the corners of the building is monitored, and the horizontality of the brickwork seams is also checked. Ordering constructively consists of a wooden lath or a metal corner, on which marking lines are applied. The markup division value determines the vertical size of the block or brick and the thickness of the mortar layer. The mooring cord is attached exactly at these points and allows you to control the horizontalness of the seam. The ordering is installed on a part of the wall after laying 5–6 rows, and the solution has completely solidified.

Do-it-yourself ordering

Make such a device it is possible from wooden slats, but such a device will not be strong enough for laying large buildings. Therefore, such a tool is often made from a metal corner with a shelf of 40–50 mm and verified edges. The length of the order rail is 1.5–2 meters. Marking is done depending on the thickness of the seam (10-15 mm) and the vertical height of the brick or block. Holes with a diameter of 4–8 mm, for attaching a mooring line, are drilled at control points. Side stops, for fixing to the walls of the building, are arranged at the bottom of the fixture. The device is installed on the wall using a plumb line and level.

Fast brick laying tool

The accuracy of a brick structure directly depends not only on the skill and experience of the bricklayer, but also on the correct and even application of the mortar on the masonry. Such a mortar dispenser template is a rectangular structure, which is set in width in accordance with the thickness of the building wall. A through hole is made in the center of this template for loading the solution.

The accuracy of a brick structure directly depends not only on the skill and experience of the bricklayer, but also on the correct and even application of the mortar on the masonry. Such a mortar dispenser template is a rectangular structure, which is set in width in accordance with the thickness of the building wall. A through hole is made in the center of this template for loading the solution.

Such a dispenser is installed on the previous row of bricks and filled with mortar using a bucket, shovel or trowel. The trowel is also used to level the mortar layer and remove excess solution.

It is easy to make a super device for laying bricks with your own hands from wood, plastic or metal. The geometric dimensions of this device depend on the size used for laying the material (brick, block). In accordance with the thickness of the future wall, the working width of the template is selected, which is fixed on the sides with limiters. The thickness of the mortar joint is determined by the height of the stops from below.

The simplest, but short-lived, the design of the template is made of plywood. Wooden blocks can be used as side stops and limiters from below.

- To increase the service life of a wooden or plastic template, it is necessary to cover the most worn parts of the template with several layers of parquet varnish.

- The thickness of the seam is set to 10 mm, which is ideal when building a wall with a thickness of one or one and a half bricks.

- To protect the entire tool from premature wear, it must be periodically cleaned of the solution.

February predictions for Capricorn

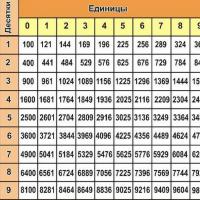

February predictions for Capricorn Tasks for logarithms with a solution

Tasks for logarithms with a solution What is the name of Zhenya. Family and marriage. Eugenia - Aries

What is the name of Zhenya. Family and marriage. Eugenia - Aries On which finger which ring is worn Mythology of the XXI century

On which finger which ring is worn Mythology of the XXI century Belgian griffon - a small brave guard

Belgian griffon - a small brave guard How to Overcome Stage Fright: The Science of Public Speaking

How to Overcome Stage Fright: The Science of Public Speaking Slavic wedding rings - myth or reality?

Slavic wedding rings - myth or reality?