How to build a bath from a bar with your own hands?

In terms of its operational and aesthetic characteristics, built on a suburban area is a worthy alternative to traditional log buildings, which are not inferior in almost all respects, and above all, in terms of environmental friendliness and heat-conducting qualities.

In addition, even a novice builder will be able to build it much faster and easier, due to the fact that for this purpose a material that has undergone special processing is used, the weight of which is much less, compared even with a rounded log.

Many-sided timber: how not to make a mistake with the choice of material for the bath

For many owners of summer cottages and other suburban real estate, there is no alternative to wood as a material for construction, but here is a way to determine which bath is better from a bar or a log- everyone finds his own.

And often in such a confrontation, a beam wins, which is a product made of solid wood and having a rectangular or square section with dimensions from 100 to 400 mm.

Types of timber and their main characteristics

Depending on the processing method, the timber can be:

- unplaned ( or sawn);

- planed;

- profiled;

- glued.

For the construction of a bath, you can use any of these materials, but most often you have to find out which timber is better for a bath - planed or profiled.

Glued laminated timber, due to the presence of chemical compounds that, under the influence of high temperatures, can be a source of harmful or even toxic fumes, it is not recommended to use.

The project of a two-story bath from glued beams, video:

It is quite suitable for the construction of a bath, but it is often subject to deformation processes - it can be led or twisted, and in addition, a log house made of such material shrinks significantly and is often uneven.

It should also be noted that it needs exterior and interior decoration, since its appearance is rather unpresentable and practically nullifies the economic benefit from its low price.

Planed timber- the material differs from the unplaned one in that it undergoes special processing, due to which it acquires a smooth polished surface of the 1st class of purity and is practically not subject to cracking.

Construction of houses and baths from timber This type is quite popular due to the fact that it is possible to choose the material according to the level of humidity, which affects the overall construction time of the facility, since it is possible to significantly reduce the shrinkage time.

Although, of course, the cost of chamber-drying timber will be somewhat higher than that of a similar material with natural moisture, but in each case, based on economic feasibility, the appropriate material should be selected.

In case it is being building a bath from a bar with your own hands, then it is quite reasonable to opt for a profiled type of material. Its installation is much simpler and easier for a beginner, thanks to the presence of a special "comb", which provides not only a snug fit of the log crowns to each other, but also more accurate.

The presence of a special profile does not allow moisture to enter the interventional space and allows you to keep the insulation in a normal state, which naturally affects the thermal conductivity of the walls, which, given the functional purpose of the object, is a very important factor.

Profiled timber, as well as planed, has machined edges, and the main difference between them is the presence of a special locking system in the form of a comb at the first. The material can be either with natural moisture content from 20 to 26%, or dry, if it has passed the stage of chamber drying - within 12–16%.

What do you think: what material is better to build a bath?

Sometimes profiled timber is called planed and this is a small mistake, since in fact it is one type of material that differs only in the presence or absence of a locking connection.

Construction of wooden baths from a bar

Before you build a bath from a bar with your own hands, you should find out what kind of wood is the best for this. And, despite the fact that the most common timber is made from coniferous species, deciduous types of wood are preferred for this object, primarily aspen, alder and linden, which, among other things, also has special healing properties.

But since the cost of a beam made of linden is somewhat higher than, for example, pine, such a compromise is sometimes used: the log cabin of the bath is built from coniferous wood, and lining made of linden or other deciduous wood is used to finish the steam room.

Moreover, due to the large amount of resins, coniferous material is less prone to decay, which means that a bathhouse built from it will last a long time.

Once determined, what kind of timber is better to build a bath, other criteria for choosing a material should be taken into account.

First you need to examine the beam for the presence of cracks on it, which can have a very negative impact on shrinkage processes or become a gateway for moisture to get inside the wood, which, naturally, will lead to its gradual destruction.

It is imperative to conduct a visual inspection of the products in order to detect bluish spots on it, which indicate the initial stage of putrefactive processes, and traces of insect habitation or stay, as wormholes will tell.

In addition, you need to check the beam for defects, including twisting, which will affect the quality of the assembly of the log house and its performance in the future.

How to assemble a bath from a bar with your own hands? Stages of construction.

So, for the construction of a bath, the best option is to choose a planed beam, which has high aesthetic and operational characteristics, at a very affordable price.

But before you start construction, you should prepare a project and calculate the required amount of material. It should be borne in mind that it should not be purchased in parts, but immediately for the entire facility.

Therefore, when large baths are being built from timber, even several units of vehicles can be involved in transporting the material to the site, but having delivered the timber to the site, it is necessary to solve the issue of its storage.

It is not recommended to dump it in a heap, but it is necessary to first prepare a platform for it and install it from improvised materials: logs, beams, boards, a small podium in order to avoid contact with the ground.

In addition, spacers should be installed between the rows of timber, providing a gap of about 1.5–2 cm for ventilation.

The foundation for a house made of timber

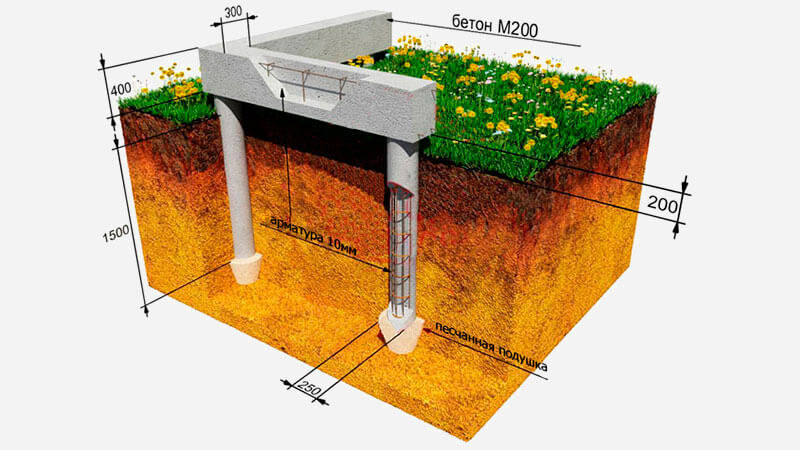

Bath from a bar- the structure is quite light, so it does not require a powerful foundation. And since there is no need for a basement, the best options for it would be to choose either a columnar type of foundation. But a monolithic-tape view, of a shallow type, is also quite acceptable.

Also, the choice of the basis for the bath is influenced by: the geological features of the site and the climatic features of the region. But if it is being built small log bath, then it is easiest to do it with your own hands, for which you should prepare a trench a little wider, approximately 10–20 cm, than the lower embedded trim and 50–60 cm deep, taking into account the fact that the freezing depth is no more than 40–50 cm.

But in the event that the soil freezes much deeper, then one should tend to the pile or columnar type. These two types of foundation can be done independently, as well as tape, without the involvement of special equipment, although, of course, it takes much longer to screw screw piles by hand, but two or three workers can do it.

An important element of these types of foundations is grillage device, which performs the function of a load distributor on all elements and links them into a single structure. It can be made in various ways, but in the case construction of a bath from a bar it can be a monolithic grillage made of concrete, as well as arranged in the form of a strapping of logs or timber, with a cross section of at least 300 × 300 mm.

When building bath from a bar with an attic, in which rest rooms, billiard rooms or sports facilities may be located, it is likely that a more massive and durable foundation will have to be arranged.

But no matter what type of base was chosen, before proceeding with the installation of the first crown, it should be properly waterproofed using special compounds, mastics and / or roofing material for this.

Installation of the first (mortgage) crown

As a rule, the bar for the first crown should have a larger section, so if, for example, the bar for a bath has a size of 150x150 mm, then a bar with a section of 200x200 mm should be purchased separately for the embedded crown.

Most often, products for the first crown are made from larch, wood that is practically not subject to decay, even in a humid environment, or oak, known for its high strength.

Additionally, it is recommended to coat the bar of the lower crown with an antiseptic. As a rule, the lower crown is not fixed, and its stability is guaranteed by the weight of the bath, since it is, even under reliable protection, quite vulnerable to moisture, after a while it may need to be replaced, which will be quite realistic.

After that, another important stage of work should be completed and logs should be installed, which will become the basis for creating a subfloor.

The project of a bath from a bar 6x6 with an attic, video:

How to make a bath from a bar with your own hands correctly?

You can make your task much easier and speed up the construction process, if you do not order a beam separately, but immediately purchase a complete set for the construction of a bath, according to a finished project.

In this case, it is only necessary to strictly follow the instructions and lay the timber in strict accordance with the plan, which details where and in what place, in which row of the log house this or that element should be installed.

Otherwise, you need to plan everything yourself, including marking and making elements of the required length, while taking into account that the standard length of a planed beam is 6 m, although products of a different size can be purchased.

Before starting work, you should make sure that the planed timber has undergone special treatment with antiseptics and fire retardants, but if this is not the case, you will have to perform this operation yourself.

- interventional insulation made of jute, tow or other material is laid on the first crown, observing the necessary overlap along the edges of about 7–10 cm, and in order to fix it, you can use a construction stapler or small nails;

- the beam of the second crown is laid and their fastening is carried out for which it is recommended to use wooden dowels or metal studs;

- for installing dowels or studs ( pins) holes need to be drilled in such a way that it passes completely through the beam of the upper row and enters at least a third into the lower one, while the step should be approximately 1.2–1.5 m;

- next stage - laying insulation on the second crown, installation of the third row of timber and so on to the very top;

- it should be noted that the last two crowns do not initially need to be fixed, since they will have to be removed to install ceilings, which are recommended to be mounted only after shrinkage of the log house.

Bath from a bar 4 by 4 with a terrace, video:

To ensure better thermal insulation, the manufacture of baths from a bar is recommended to be performed using a corner joint with a root spike according to the principle of the so-called warm corner, which will significantly reduce heat loss during operation.

Also very popular when working with planed timber and other types of connections, including " into the bowl", "in half a tree" and "in the paw".

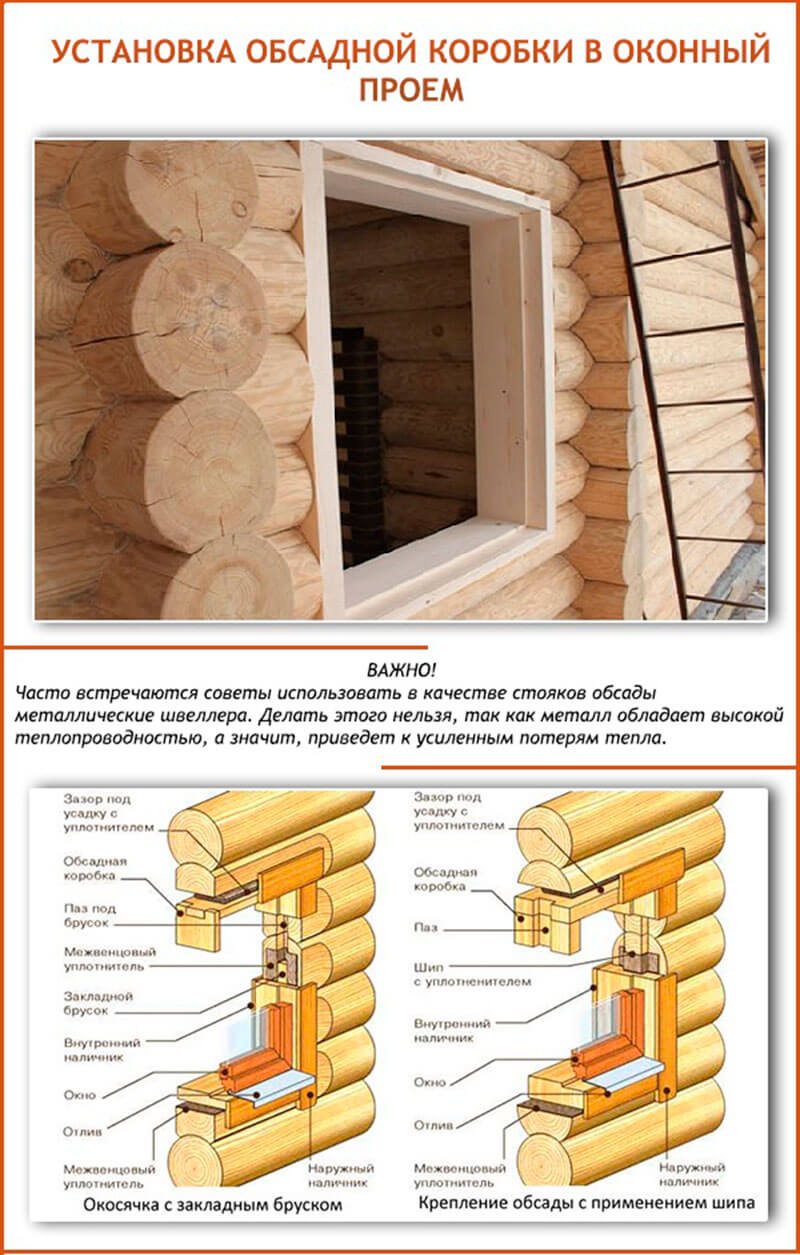

The device of window and door openings, as a rule, is carried out simultaneously with the assembly of the log house, although subsequent cutting is also allowed, after the structure has shrunk. And the direct installation of structures is carried out before the start of finishing work, when shrinkage processes will not lead to deformation of window frames and door frames.

In addition, it is recommended that before installing them, perform the so-called casing ( or pigtail), a special structure independent of the walls of the log house, which does not allow the window to deform even in the case of fairly serious shrinkage processes. This is especially true if material with natural moisture is used for construction.

Construction of internal partitions, for which a planed beam with a smaller section can be used, as a rule, is performed simultaneously with the assembly of the log house. This is necessary in order to cut them into the outer crowns, which will provide the necessary strength of the entire structure.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical