Masonry mortars for brick kilns

The strength, reliability and pleasant appearance of stoves and fireplaces largely depend on the quality of the masonry mortar with which they are laid out. If some component is not enough or too much, the seams will crack. As a result, the smoke from the stove will begin to pass into the room, and the cost of fuel will increase, since due to the excess air supply, it burns faster. Or you can not waste time calculating proportions, but buy a ready-made composition.

Masonry mixture for fireplaces and stoves consists of a binder, aggregate and water. If it has only one binding element, then it is considered simple, if there are two, then complex. The main characteristics are strength and ductility. At the same time, according to plasticity, they are divided into 3 types: skinny, normal, fatty. For laying fireplaces and stoves, the second option is the best option, since it does not crumble when dried. When heated, it expands almost exactly the same as a brick. Bold has excellent plasticity, but when it dries, it will crack.

Clay mortar and technology of its preparation

Clay is one of the best options for laying a brick oven. But you should not use it for chimneys and foundations, as it collapses due to high humidity. For manufacturing, you will need fine sand (up to 1 mm) and good quality clay. Sand must first be sifted through a sieve to remove debris and small stones. The thickness of the seam when laying the furnace with a clay mixture should not be more than 5 mm, otherwise it will crack due to high temperature. The consistency should be homogeneous, without lumps, similar in density to sour cream.

The maximum temperature that the clay mortar can withstand is + 1000 ° C. At the same time, its volume during heating changes in the same way as that of a brick. Therefore, the masonry remains intact and durable. Compared to others, the consumption of the clay mixture is greater. So, for laying hundreds of bricks, you need 2 buckets of clay and one and a half sand. Consumption can be reduced if the composition is passed through a sieve, and the seams are made thinner and smooth building materials are used without chips.

It is recommended to pre-soak the clay in two days, then it will become more plastic. To make the composition as thick as sour cream in consistency, the clay is passed through a sieve, just like sand. After kneading with the desired ratio of components, it is sifted again. Then it will turn out to be as homogeneous and of high quality as possible. It should spread easily and slide off the shovel. The optimal proportions of mortar for laying a brick oven are 1 part clay and 1 part sand. Water is taken 25% of the volume of the binder component. The proportions may vary depending on the fat content of the clay.

Guide: how to check the quality

To find out the quality of the clay and whether it is suitable for laying fireplaces and stoves, you should make several solutions with different proportions, or rather, 5 mixtures consisting of the following components:

- clay without any additives;

- the same ratio of clay and sand;

- clay and 10% fine sand, as well as 25 and 75% sand.

Each of the five compositions is thoroughly mixed in dry form, and then water is poured. It is added until the mixture becomes like a thick dough that sticks to the hands. To check for quality, the same amount of test is taken from each. The resulting portions are molded into balls with a diameter of not more than 5 cm. After that, they are left to dry in an unventilated place for a week and a half. A high-quality solution is one whose ball, when falling from a height of a meter, did not crumble into pieces.

But it can be used to check for quality and a faster way. The ball is placed between two boards slightly larger than itself. After that, the top board is pressed against it until cracks appear. If they appeared immediately, then it has a weak plasticity, which means that the ratio of the components is chosen incorrectly. Such a composition cannot be used for a brick oven. If cracks began to appear in the ball only after compression by 30%, then the proportions of the components were chosen correctly. It is considered the best option for laying fireplaces and stoves. If the cracks appeared only after the ball was flattened by half, then it has too high plasticity.

There is another quality control method. To do this, tows are made and wound on a stick 5 cm thick. If no cracks appear on it, this indicates high plasticity, the tow is cracked and torn - low plasticity. If rare cracks are visible, and it remains intact - a solution of good plasticity with the correct ratio of all components.

lime mixture

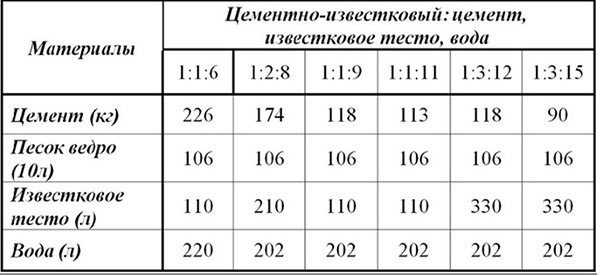

For the construction of the foundation of the furnace and the construction of a chimney above the roof, lime compositions are used. You will need water, sand and lime paste. Cement is added to increase strength, and gypsum is added to reduce setting time, but it is usually poured only for plastering.

The quality depends entirely on the lime test. Pour such an amount of water into powdered or lump lime so that it cannot boil. The process of preparing the dough lasts almost half a month. All this time it should be covered with a small amount of water. Ready lime should be stored for a month before being used to mix the solution.

Instructions for the manufacture of lime composition:

1. Dough and sand are passed through a sieve. If the dough is too thick, then water is added to it.

2. Sand is poured into lime and everything is thoroughly mixed until smooth.

3. The proportion of sand depends on the quality of lime and can be from 0.5 to 5 parts.

Medium ductility is considered optimal. This can be determined as follows: a couple of minutes after cooking, a wooden spatula is lowered into the composition. If, after pulling out, nothing remains on it, then the solution is not plastic enough. If the thickness of the dough is about 2 mm, then it is of medium plasticity, it should be used as an oven.

Mix with cement

The cement composition is the most durable. It is used for laying foundations in places with high humidity and for finishing pipes above the roof of a building. Thanks to cement, it sets quickly, but that is why it must be used within an hour. After this time, it begins to harden and strength decreases. It includes water, sand and cement, the proportions of the components depend on the brand of cement.

Guidelines for the preparation of cement mortar:

- sifted sand is poured into the container;

- cement passed through a sieve is poured on top of the sand;

- everything is thoroughly mixed until it becomes a solid color;

- water is added to the required density.

Overview of ready mixes and their cost

It is absolutely not necessary to spend time sifting bulk materials and dividing them into portions, since you can purchase finished products for laying the furnace and knead it according to the attached instructions.

1. Each solution has the highest possible use temperature (in other words, this characteristic is called heat resistance), it depends on the composition. For example, Ogneuporsnabservis withstands heating up to +850 °C, and refractory of the same manufacturer - +1300 °C. The first kiln mixture consists of red clay, sand and plasticizer, and the second one consists of refractory clay and quartz sand. For the furnace, it is better to use a refractory option, and for the exterior of the furnace, a simple one is enough.

2. Plitonit also produces compositions for the construction and decoration of stoves and fireplaces. But unlike the previous manufacturer, it produces powders in different shades, such as gray and red.

3. The solution from the Terracotta company is somewhat different, but, like that of Ogneuporsnabservis, it withstands high temperatures - up to +1300 ° C. It includes kaolin clay, fireclay and sand. But the time for which it must be used up is 3 times less than that of the previous mixtures - only 1 hour.

4. When choosing a composition, you need to pay attention to what kind of brick it can be used with. For example, Finnish Weber Vetonit ML Tuli should only be used for refractory brickwork.

When buying a dry composition at any cost, it should be noted that it must be kneaded with a mixer, and not manually.

Ready-made clay mortar can be stored for months, and lime mortar for several days. Containers with them must be kept closed and in a dark place. Water is used only clean, without algae or other debris. All components should always be sieved.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical