We make gates with our own hands: photos, videos and drawings

a large number of different materials are used: metal sheets, wood, forging products, etc. But with the development of building technologies, more modern materials began to appear that simplified the manufacture of barrier structures, and one of these products is corrugated board - galvanized steel sheet coated with polymer compounds.

Gates, in the manufacture of which corrugated board is used, have a low weight, high technical and operational characteristics, and most importantly, ease of manufacture and installation, which allow you to do all the work yourself. But first, I would like to consider the most popular types of fences and the features of a phased self-assembly of gates from a profiled sheet.

Gates from a profiled sheet - the pros and cons

The most popular gate model is considered metal hinged structure, shown in the photo, which opens on both sides. At the same time, painted corrugated board is used for sheathing the frame, which can be decorated with forging elements. The floors of the protective system have a lightweight construction with a gate located next to it. This type of gate has gained popularity in private sector homes.

Such popularity was achieved by a large operational resource of the product without the need for regular repairs, unlike wooden counterparts. Modern models of gates made of profiled sheet are often supplemented with an automatic opening system, which is very convenient. At the same time, the profiled sheet used for the manufacture of fences has a whole a number of the following benefits:

- relatively low cost of profiled sheet;

- a simple process of manufacturing and installing gates, both with a gate and without it;

- long service life and ease of maintenance;

- versatility of the material;

- attractive appearance of the painted corrugated board.

If we consider disadvantages of such material I would like to highlight the following issues:

- to open the swing gate structure, you need a large free space around the protective structure;

- due to the large area of the gate leaves, they are subject to an increased wind load, which must be taken into account depending on the region in which the barrier is installed.

But still, the advantages of the swing gate design with a wicket, shown in the photo, cross out the minor drawbacks of such a product. Moreover, the problems are not so critical and they can be eliminated in the process of doing the installation work with your own hands. And as it became known from practice, gates made of profiled sheet are the most reliable among such structures.

Design features of swing gates

Considering the drawing of a standard gate from a profiled sheet, one can understand that such a barrier is based square metal frame or thick-walled pipe with a diameter of 30 mm. At the same time, horizontally located metal veins are used to reinforce the wings. Thanks to this reinforcement, the geometry of the gate will be held.

Considering the drawing of a standard gate from a profiled sheet, one can understand that such a barrier is based square metal frame or thick-walled pipe with a diameter of 30 mm. At the same time, horizontally located metal veins are used to reinforce the wings. Thanks to this reinforcement, the geometry of the gate will be held.

Making a swing gate structure from corrugated board is quite possible on your own, even in the absence of skills in working with metal products. All that is needed is minimal knowledge of the use of welding, a drill, an electric grinder, a screwdriver and a construction tape measure.

sash fastening swing fence is carried out using self-tapping screws for metal or electric welding directly to the pole. Due to the relative lightness of the profiled sheet, two strong metal hinges of 20 mm in diameter are enough to hold the door floor. Metal pipes with a diameter of 60 to 100 mm are used as bearing supports.

Depending on the fence that surrounds the house building, the gate leaves can be fastened to brick supports. But for this, even at the stage of erecting the fence, it is necessary to provide for the installation of mortgages in the seams between the bricks, to which the hinged gate supports will be welded.

From practice, it became known that the optimal dimensions of the entrance gate used in private housing construction are width indicators in 3 m. Such parameters are quite enough to enter the yard, both a car and a truck. Therefore, even for the purpose of saving, it is not worth reducing the width of the wings by more than 20 cm. If we consider the height of the barrier, then according to the drawings, standard structures are made no higher than 2 meters from the ground.

As a locking mechanism for the gate, pins in the form resembling the letter “G” are used, which are located on the bottom of each leaf. Clamps are installed in the surface of the earth or other covering of the yard - metal tubes with an inner diameter slightly larger than the thickness of the locking mechanisms. At the same time, there are no strict requirements for the locking mechanism. As an addition to the stoppers, a horizontal valve is installed at the location of the transverse.

The use of corrugated board as a finish for the swing gate frame will allow the fencing structure to harmoniously fit into the overall styling of the fence. Usually professional sheets are attached to the frame of the gate leaves at a distance of 50-70 mm from the ground so that they do not scratch the surface during opening and closing.

Consumables and tools

Gates made of corrugated board, photos of which can be seen in the article, can have a variety of designs and be equipped with a gate. If desired, they can be decorated with forging elements and opened with a paintwork to match the fence. At the same time, it is desirable to think over how the finished structure will look like, and develop a drawing in which to indicate all the parameters of the gate. Then it will be easier to understand what tools and materials will be required for the manufacture of a barrier structure with your own hands:

Gates made of corrugated board, photos of which can be seen in the article, can have a variety of designs and be equipped with a gate. If desired, they can be decorated with forging elements and opened with a paintwork to match the fence. At the same time, it is desirable to think over how the finished structure will look like, and develop a drawing in which to indicate all the parameters of the gate. Then it will be easier to understand what tools and materials will be required for the manufacture of a barrier structure with your own hands:

- profiled sheets for sashes and pipes for supports;

- corners or pipes to create stiffeners;

- profiled pipe or metal square for the frame;

- primer and paintwork materials;

- closures or locking mechanism.

From the tools you need to prepare the following:

- kapron construction cord;

- welding machine;

- the hammer;

- electric drill and screwdriver;

- electric grinder;

- scissors for cutting metal.

In the process of planning the design of the gate for making your own hands, it deserves special attention dimensions and the presence or absence of a gate. Large shutters significantly increase the weight of the entire barrier structure and therefore the frame must be made of reinforced materials.

Installation of gate supports

If the land is already fenced with a fence made of metal support pillars and a gate, then the hinges for the sashes can be fixed by welding directly on them. In the case of the need to install individual supports, it is necessary to perform a series of simple steps.

- Metal supports are treated with a primer and opened with paint.

- In accordance with the width of the gate, two holes 1.5 m deep break out of the corrugated board.

- At the bottom of the pit, a pillow of gravel and sand is arranged.

- Prepared supports are installed in the pits and fixed with reinforcement.

- The supports are leveled on a plumb line and poured with concrete.

Installation of hinges is carried out only after the concrete has completely hardened.

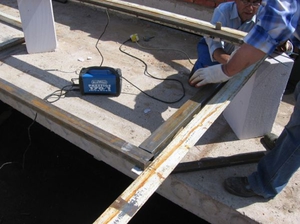

Do-it-yourself gate frame from profiled sheet

In order to correctly create a frame for a gate from a profiled sheet with a wicket, you need to familiarize yourself with the assembly drawings of the metal structure and follow a certain sequence do-it-yourself work.

If you still have questions about how to weld a swing gate structure from a profiled sheet, you can watch the video. Plus, there is a way to assemble without the use of a welding machine with fasteners.

How to sheathe a frame with corrugated board?

After the final drying of the painted frame, you can begin to sheath the frame with corrugated board. The profiled sheet is laid on the frame and carefully attached with self-tapping screws or rivets. At the same time, rivets have a more attractive appearance.

Self-tapping screws or rivets must be fastened only in the recesses of the corrugated board. For fastening 1 sq.m. material use at least 6 screws or rivets. This is primarily due to the fact that the gate leaves, in addition to their own weight, must withstand additional wind load. After the profiled sheets are fixed, the gates are hung on the hinges.

Earlier, we considered the scheme of standard swing gates. But given modern realities, constantly manually opening them is not very convenient. Therefore, this process can be automated. At the same time, you won’t have to come up with something new, since there are linear electric drives on sale.

Earlier, we considered the scheme of standard swing gates. But given modern realities, constantly manually opening them is not very convenient. Therefore, this process can be automated. At the same time, you won’t have to come up with something new, since there are linear electric drives on sale.

The set of automated equipment also control box included, electromagnetic locking mechanism and signal lamp. Swinging automatic gates made of corrugated board are connected to a typical AC outlet. In the photo you can see how all the elements complement the overall appearance of the structure.

Depending on which direction the doors will open, two options for installing an automatic structure can be distinguished: external and internal. But regardless of the opening method, the installation of automation is the same. If we consider the system control unit, then it may have left hand or right hand placement.

Due to the design features of the automated drive, it is necessary to provide a mounting gap from the gate leaves to the bearing support. If this has not been done in advance, then when opening the sashes internally, you need to carefully prepare and arrange places for their fastening.

Independent production of swing gates from a profiled sheet is an economical and reliable way to protect your backyard from unwanted guests. At the same time, the entire system can be automated, which will greatly improve the functionality and practicality of using the gate.

Some examples of finished gates

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical