How to make a brazier from metal: design options and manufacturing methods

Brazier is the main attribute of a country picnic and a comfortable summer vacation. You can buy this accessory today in any supermarket. Unfortunately, almost all factory structures are made of thin metal, which, after the first "barbecue season", begins to deform and burn through.

The system of assembly of the frying box is not always thought out by the creators, the connections of which, when used, turn out to be inconvenient and unreliable.

Knowing the problems of serial barbecues, home craftsmen prefer their own braziers. In addition to the impressive strength that home-made designs differ in, they allow the creators to fully show their talent and creative invention. It is for these reasons that we will consider in detail the topic of how to make a metal grill with your own hands convenient, durable and beautiful.

In addition to traditional designs, among homemade products you can find unique options. Each of them can be copied without any problems, decorating your summer cottage with an original and useful frying installation.

Design options for metal grills

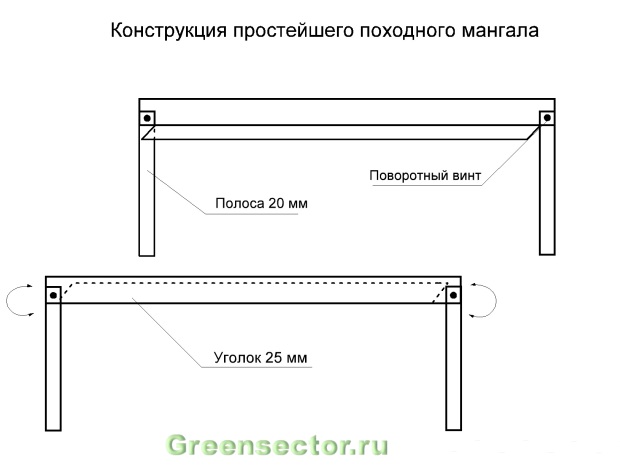

The simplest and easiest to make barbecue for camping conditions is two U-shaped metal racks stuck into the ground. They occupy a minimum of space in the backpack and are quickly brought to the “working position”. The only drawback of this system is its low height.

It will not work to put such a brazier at a level convenient for baking, because the fire here is bred right on the ground. Otherwise, this design captivates users with its practicality.

The classic metal brazier - a box with legs also has the right to camping life. Only for this it needs to be made folding in order to reduce the dimensions.

For this, window hinges are most often used, welding them to the bottom and long side walls. The end sides of such a brazier are inserted into the sides of the bottom and fastened from above to the side walls with the help of hooks.

A useful detail that you should pay attention to is the holes for adjusting the frying height. Thanks to them, you do not have to re-ignite the hearth to “turn up the heat”.

If you think that the fantasy of home-made people is limited to a banal frying box with holes, then we will easily convince you.

Childhood memories of pirate battles inspired the author with the idea of a barbecue-chest with treasures mounted on two scimitar swords. In addition to the usual frying of kebabs, such a box with a lid can be used as a mini-smoker. To do this, you will need to provide the structure with a small exhaust pipe.

In general, forging is a win-win decoration for any brazier. With its help, you can easily turn an ordinary iron brazier into a real work of "country art".

A useful detail of this design is the side shelf. On it you can lay out kebabs that have undergone a heat treatment process. Below you can make a grate for laying firewood.

Any home craftsman can make a forged brazier today. This does not require building a home forge and buying a blacksmith's hammer. It is enough to look into the construction supermarket and purchase forged decorative elements there. Fixing them to a metal box and legs is a simple matter.

A steel brazier for a summer residence should be not only beautiful, but also mobile. Therefore, we advise you to pay attention to the mobile version of such a frying hearth.

It can be easily moved to any place in the suburban area, hiding from sudden rain or the scorching rays of the sun. Equipping the brazier with a handy skewer, you can try your hand at the art of roasting upland game.

Of course, you will not take such a frying structure with you into the forest. However, it will look at the summer cottage no worse than the stationary one.

And here is a copy with a roof that protects the owner from the vagaries of changeable weather. The rotary holder for the cauldron, which expands the possibilities of this hearth, deserves special attention.

Do not rush to part with your grandmother's inheritance and hand over the foot-operated sewing machine for scrap. Better see how great her cast-iron bed looks like as a support platform for the barbecue.

The smoke from the brazier disturbs the creative imagination of craftsmen. Why not make an original brazier-steam locomotive, they think, sitting down at the drawing?

The main part of this brazier is an old gas cylinder. Having welded wheels, a pipe and a driver’s platform to it, you will pleasantly surprise your friends and neighbors. By the way, the pipe in this case is not a simple decoration, but a channel for the exit of smoke. Such a hearth with a smokehouse can be successfully used for roasting meat and cooking other homemade delicacies.

The military theme, covered in smoke and fire, often finds its expression in original installations.

A car enthusiast who is friends with a grinder and welding will gladly make an original brazier out of the front of an old car. Fortunately, such work does not require much effort. A traditional frying box with a grill is placed in the engine compartment and the design is ready to go.

Some craftsmen manage to make such a brazier mobile, supplying it with a full-fledged suspension with springs.

Take a look around. You will see a lot of unnecessary metal items that can be used to make a barbecue.

An old steel barrel is an almost finished brazier. Yes, not simple, but elegant and functional. By cutting out part of the sidewall, you can make a swivel cover out of it. A frying grate is placed inside the container or two supporting corners are welded for installing skewers.

Rims. What could be better and easier for making a country barbecue? They have all the attributes of such a hearth: a round shape, holes for ventilation and thick metal that will not soon burn through the fire. The only improvement that needs to be made is the installation of a steel sheet with holes inside the disk.

The native slots on the disc are a little too big, so small coals will fall through them. From above, a steel holder for skewers can be adapted into the rim or simply a frying grate of a suitable diameter can be mounted on it.

Optimal dimensions and ease of use

Other people's ideas are good, but how to make such a brazier yourself, you ask? First you need to decide for how many people kebabs will be most often prepared. If only members of your family (3-4 people) are among the lucky ones, then the optimal dimensions are 40 cm long and 30 cm wide. The last size is the length of the skewer excluding the handle. It cannot be increased so that the steel rod with meat does not fall into the brazier.

If the brazier will serve a large company, then its length is calculated according to the scheme of 8-10 cm per 1 skewer. That is, for a company of 6 people, a frying box with a length of 50 to 60 cm is needed with a constant width of 30 cm. A more voluminous box should not be made so that there is no overspending of firewood.

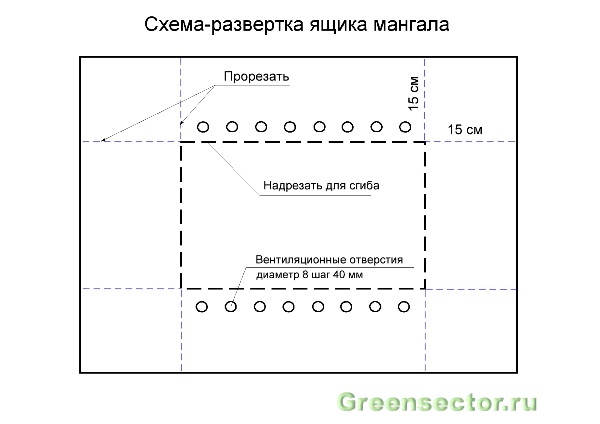

The optimal depth of the roaster is 15-20 cm. This is quite enough to ensure that the temperature during baking is high enough, but the meat does not burn.

Ergonomics is another factor to consider when sketching out a diagram of a future brazier. Its height from the ground should be such that you do not have to constantly bend over, turning the kebabs. Lower your arm, bend it slightly at the elbow and measure the distance from the ground to your fingertips. The resulting size is the optimal height of the barbecue with legs.

The thickness of the sheet for the brazier must also be chosen correctly. Experts say that 2 mm black or stainless steel will be optimal. A thinner sheet burns through quickly, and a thicker one is difficult to process and increases the weight of the structure.

An example of making a simple metal barbecue

The set of tools for this job is obvious:

- Roulette;

- Core (for stuffing holes before drilling);

- Bulgarian;

- Electric drill;

- Welding machine.

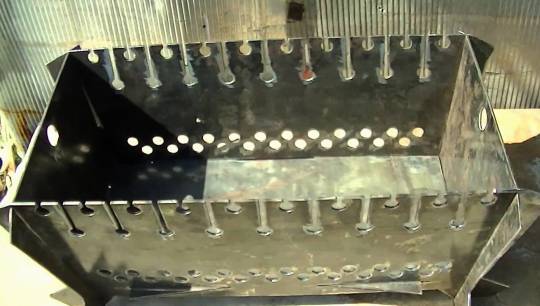

The first step, from which the manufacture of a homemade metal brazier begins, is cutting sheet steel. Having marked the dimensions of the bottom and side walls on it, we cut out all the blanks with a grinder. At the bottom of the long side walls, we need to make holes for air to enter. To do this, we fix a 6 or 8 mm drill in the drill chuck and make ventilation (the distance between the centers of the holes is 3-4 cm).

A more rational option is not to cut out all the parts separately, but to make cuts in the sheet with a grinder, so that later they can be bent into a three-dimensional structure.

Having bent the cut sheet into a volumetric box, we weld the joints of the walls. This can be done not with a continuous, but with a tack weld, so that the metal is less deformed. For better fixation of skewers on the upper ribs of long walls, shallow grooves can be cut.

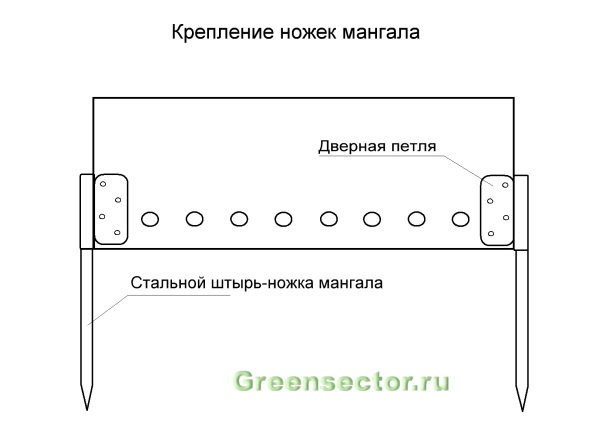

The next operation is welding the legs. It is better to make them removable so that the brazier can be transported in the car. To do this, some craftsmen use nuts, welding them to the bottom of the bottom. Then threaded rods are screwed into them. We'll take it easy and use the lower parts of the old door hinges. They have an eyelet for welding tacking and a hole deep enough to accept a steel pin-leg.

Our barbecue is ready for the first barbecue. All operations for its cutting and assembly will take no more than 2 hours.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical