Balcony extension: step by step instructions

Adding a balcony to a private home expands the living space and can make the architecture of the building more interesting and attractive. Balcony, a rather complex engineering structure, its extension requires compliance with standards that ensure the safety of the structure, compliance with fire safety requirements, etc. Any protruding architectural structures on beams or cantilever slabs are erected taking into account the rules of strength of materials.

When choosing a place for a balcony, compliance with the overall architectural composition and constructive feasibility are taken into account. The panorama opening from the balcony, shading or sunny illumination of the place is also important. In the process of planning the extension of the balcony to the house, the internal arrangement of the rooms and the convenience of accessing the balcony are taken into account. To add a balcony on the first floor, no special calculations are required. Brick support posts or a light strip foundation are equipped, on which the floor is laid and a fence is attached.

Regulatory requirements for balconies

When calculating the extension of a balcony on the second floor, many factors are taken into account: thickness, material and age of the walls, design loads, taking into account the weight of the structure itself, people present on the balcony, snow, etc. The dimensions of the balcony, materials and method of installing the frame depend on this.

- the calculated load on the slab over the entire plane is 200 kg / m2, the strip load is calculated taking into account a group of people standing along the parapet in a section 80 cm wide and is 400 kg / m2;

- the height of the balcony railing is at least 105 cm with a load on the railing handrails of 30 kg/m2, and a vertical load on the railing of 100 kg/m2;

- the angle of inclination of the balcony slab from the main wall to the edge is 2 °, to drain rainwater (approximately 2 cm per 100 cm of the site).

In addition to the above parameters, a 100% margin of safety is added to the calculated figures. Given the presence of a few more specific nuances, it is easier to entrust the design of an extension to a balcony to a competent specialist.

Balcony frame structures for private houses

The balcony consists of three main elements: the base, the protective fence and the canopy. According to the type of fastening of the base, balconies are divided into two types. Console-slab and console-beam.

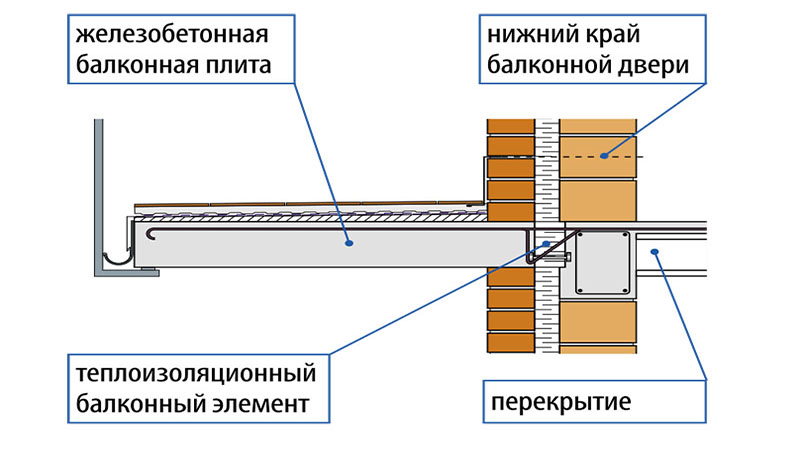

Balcony on a cantilevered slab

In the process of building a box at home, a reinforced concrete slab is laid at least 40 cm into the load-bearing wall. The following rows of building material securely fix the balcony slab. Such structures are used in buildings with thick and heavy walls. The width of the balcony area should not exceed 1 meter.

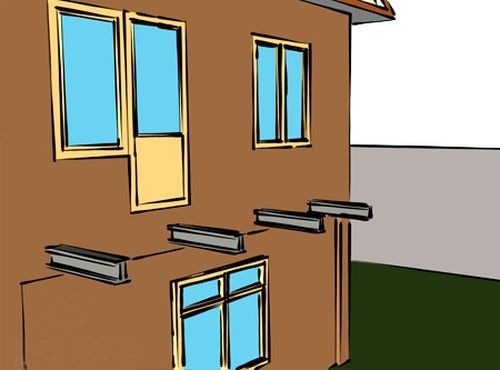

Balcony on cantilevered beams

Reinforced concrete or steel beams are laid into the wall during the construction of the house box. Sometimes holes are made in an already erected wall and beams are inserted into them to a depth of at least 40 cm. In this case, the balcony platform is additionally reinforced with brackets or support posts. The width of the site is allowed from 1.2 m to 1.5 m. Support posts under the balcony allow you to increase the width of the site by 2 - 2.5 meters.

- Reinforced concrete slabs for the base of the balcony are heavy and are installed at the time of construction. To add a balcony to the house, it is more reasonable to use the cantilever-beam method with a metal channel inserted into the wall and a wooden floor.

- Balcony railings are made of wood or metal. Various original versions of wooden railings or metal gratings can be purchased at the store or ordered from the workshop. In any case, the fence must be strong, securely fastened and of sufficient height. The canopy performs the utilitarian functions of protection from wind, sun and precipitation. A metal frame is made for it and covered with roofing material. But, if you approach the process creatively, the canopy will decorate the balcony.

The device frame for the balcony in the house

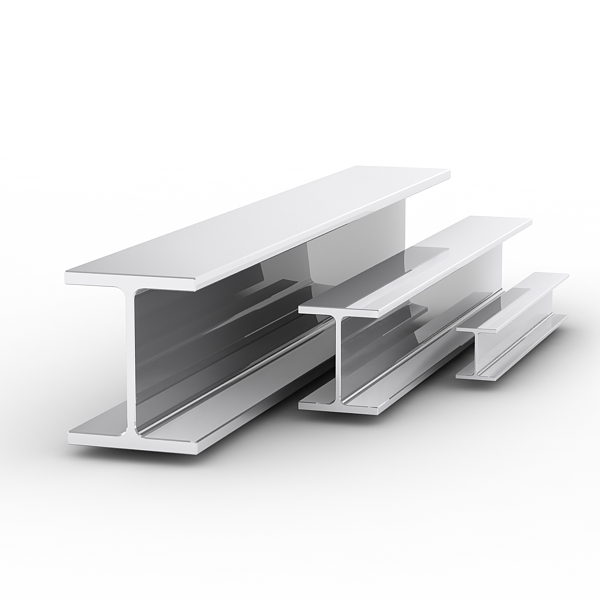

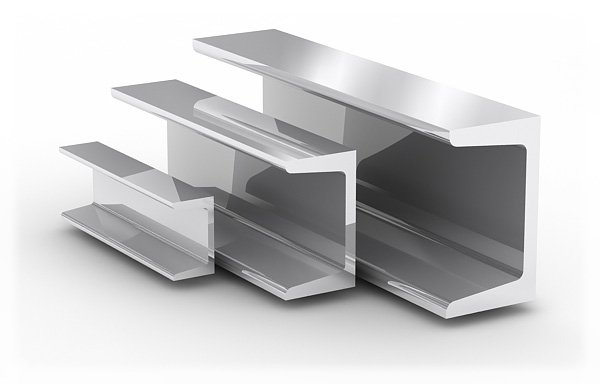

To install the base of the balcony, a channel or an I-beam is used. The channel has a U-shaped profile, and the I-beam resembles a railway rail. For a balcony platform 1.5x2 meters, you will need 4 such metal beams 2 meters long. Channel in section 50x150x50 or I-beam 150x50x150 with a wall thickness of at least 5 mm, provided that a wooden floor is laid.

- In the wall, 4 holes are drilled at the same level to a depth of 50 cm with a span of 50 cm. Beams are inserted into the holes, if it is a channel, then with the wide side up, aligned with the levels, packed and concreted. Under the beams, a metal corner 70x70 is attached to the anchors to the wall of the house and is attached to the beams by welding. This will prevent individual beams from sagging in the wall of the house. The same strapping is done at the ends of the balcony beams. Three strips of metal are welded across the beams for the bundle, along the entire balcony area.

- For the reliability of the structure, struts are mounted under the extreme beams of the frame. They are welded separately from a corner in the form of a right triangle. The free space of the triangle is filled for beauty with an openwork ornament made of a metal rod or square. With the release of a balcony beam of 1.5 meters, the side adjacent to the wall and the side of the brace welded to the beam are equal to one meter.

Support posts are mounted from metal pipes with a diameter of at least 2 inches. The upper end of the support is brought under the cut of the extreme beams and fixed by welding. The lower part of the support post, treated with anti-corrosion mastic, is immersed in a pre-dug hole to a depth of 0.5 meters. The free space around the support is compacted and poured with concrete.

Arrangement of the floor, fencing and canopy of the balcony

- The floor for the balcony is made of dry planed boards 30-40 mm thick. The boards are laid from the wall to the edge of the balcony. The end sides of the boards are bolted to the outer beams, the intermediate fastening can be done with self-tapping screws. A minimum gap of 1-2 mm is left between the boards. Without a gap in wet weather, boards may swell and the floor may swell. The floor is covered with an antiseptic and painted.

- To protect the balcony at the corner extreme points, two metal racks are welded. A metal inch pipe with a height of at least 105 cm is fine. A U-shaped railing profile is bent from a metal corner or pipe. For the calculated balcony, its dimensions will be 1.5x2x1.5 meters. At the corner points, the railing is welded to the posts, and the end ends are securely fixed in the wall. Metal mortgages are made in the wall, to which the ends of the railing are welded.

- The facade and side openings of the balcony railing are closed with decorative metal bars, wooden balusters, plastic panels, etc.

- For a canopy in the workshop, a frame is ordered. The roof of the canopy can be made of galvanized iron, macrolon, shingles or other roofing material. The roof of the canopy is fastened with bolts and self-tapping screws. A canopy is installed by fastening to the wall with 4 anchors (φ16, L = 250mm, R cm = 30 kg / cm 2) is enough.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical