Chimney brick for a fireplace

Properly drawn up scheme and design for the chimney play a very important role. With incorrect calculations of the height of the pipe, the furnace structures will begin to smoke, then everything around will be covered with a layer of soot and soot. Any stove or fireplace for heating requires the disposal of air that is saturated with combustion products.

The chimney must have good draft, it must also be protected from moisture and precipitation.

In order to avoid problems in your heating system, you need to create the right brick chimney for the fireplace. This is a guarantee of comfort and safety.

Fuel costs, clean air in the room, fire safety and the ratio of lost and produced heat depend on the correct design and construction of the chimney. When creating a channel for the removal of all combustion products, all building codes that are provided for when installing fireplaces must be taken into account.

The main characteristic of the chimney is the material from which it is made. Recently, furnace chimneys made of stainless steel with a small addition of molybdenum have become popular. But to create stoves and fireplaces in which flue gases are removed without increased acidity, brick is also successfully used.

Choice of size and shape

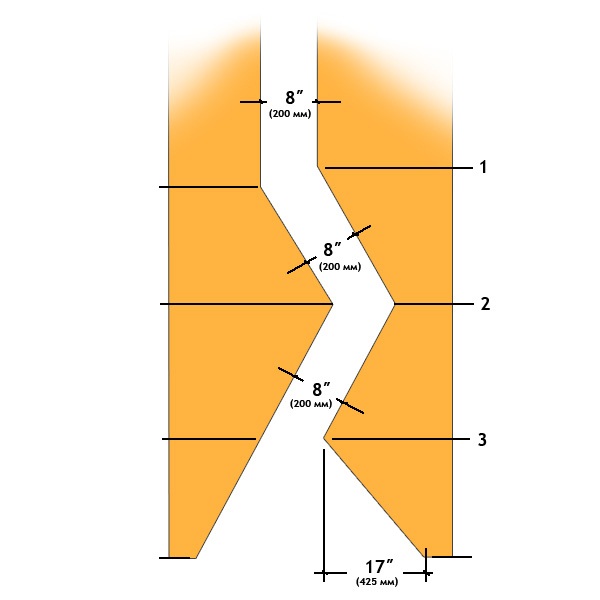

The cylindrical shape is considered optimal for the chimney. The more obstacles the smoke has on its way, which are created because of the corners, the more difficult it will be for it to pass and the more soot will be deposited on the walls. The dimensions of the chimney are determined by the height and diameter of the structure. The diameter should be calculated based on how powerful the equipment will be, what obstacles are in the way of smoke, how many of them, what is the width of the chimney inlet. The height is calculated taking into account building codes, the height of the building, the type of roof and the dimensions of neighboring buildings.

When drawing up a project, it is necessary to take into account the requirements for all horizontal sections of a brick chimney for a fireplace. Their length should not exceed 1 m, because warm air tends to move not horizontally, but vertically. If this requirement is not met, then the draft will be poor, and soot will be deposited very heavily in this area.

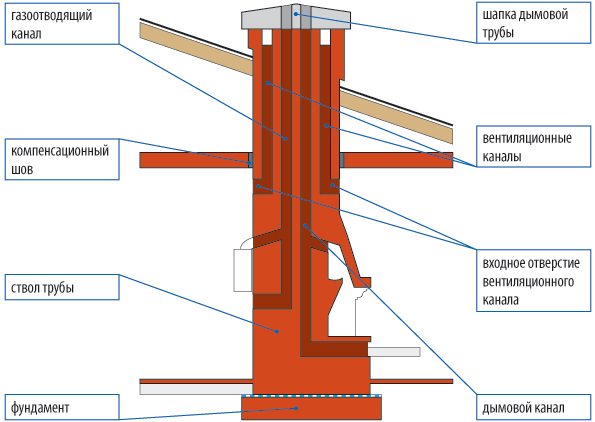

Design features of the chimney

Connecting a boiler or fireplace insert to a brick chimney is often prevented by problems with mismatched diameters. In these cases, a reduction adapter must be used. In this case, the area in which the chimney will be connected to the equipment is treated with a special sealant. The subsequent assembly of the chimney from the pipes is carried out in the direction of the condensate flow (with expansion upwards). This prevents condensate from escaping to the outer walls of the pipe.

Brick chimney should be assembled in accordance with the draft. Each fireplace requires its own masonry, which is prescribed in layers. It is recommended during construction to minimize the roughness on the walls inside and monitor the tightness of the building.

If the house already has an old brick chimney that can be used for a gas boiler, then you should first make a sleeve. To do this, an acid-resistant steel pipe must be installed in the old chimney, while leaving a technical gap between the masonry and the new pipe. When creating chimneys, tees are often used. In their design, it is necessary to take into account all the corners of the outlet and provide inspection doors.

Properly made insulation for the chimney ensures its safety and the safety of the whole house. With the help of insulation, the heating of the pipe is accelerated and the formation of condensate is reduced. Insulation protects the structure when passing a brick pipe near combustible materials. If the chimney is laid through ceilings, then all fire regulations must be observed, which depend on the temperature of the pipe and the ceiling material.

It would be best if the surfaces of the ceiling and walls, which are located near the chimney channel, are finished with exclusively non-combustible materials. Otherwise, they will have to be covered with metal sheets that have a layer of non-combustible material.

The part of the chimney pipe facing the street is protected from the wind and additionally fixed. Deflectors, wind vanes and nets provide protection from debris and precipitation. If the presence of a cap is the norm for a stove or fireplace, then its absence for gas equipment is a violation of the entire security system.

When laying the smoke channel, it is necessary to maintain the appropriate angles of the chimney, this will increase the draft and protect against water ingress.

Mistakes made during the construction of the chimney are fraught with very serious consequences. Therefore, it is very important to comply with all technical requirements and building codes. The consequences of improper design can be very different: from expensive rework to the outbreak of fire or poisoning by combustion products.

When building a brick chimney, it is recommended not to use materials that are not intended for this purpose (for example, aluminum or asbestos). During operation, changing the diameter of the chimney without the help of a specialist will significantly reduce the efficiency of the system. The load on the base of the chimney should in no case exceed a value that can lead to the appearance of destructive processes in the house.

It is possible to combine several installations into one network for chimney only after engineering calculations by a specialist in this profile.

List of the most dangerous mistakes

These errors include:

- Insufficient thermal insulation of the chimney, which leads to ignition and charring of adjacent materials.

- The use of unifying protection of two or more channels by one fungus. As a result, the ventilation system collapses and smoke enters the house.

- Unauthorized repair and modification without special preliminary calculations.

The device of the correct and technically safe is a rather difficult task. Each case is unique and has its own nuances. Therefore, it is necessary to consult with specialists at least when drafting a chimney for a fireplace.

Design requirements

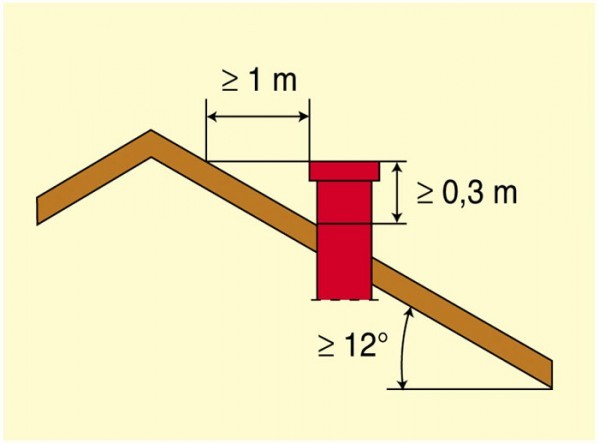

The height of the chimney depends on its distance from the ridge.

- It is impossible to create artificial exhaust ventilation in the room, which will not be compensated by an appropriate supply ventilation.

- Do not remove smoke into ventilation ducts if ventilation grilles are installed on them.

- Fireplaces should be placed near internal partitions and walls made of non-combustible materials. The smoke channels themselves should be located in the outer walls of non-combustible material. If necessary, they must be insulated from the outside in order to avoid the appearance of condensate from the exhaust gases. If there are no walls in which smoke channels can be placed, then root or mounted chimneys are used to remove smoke.

- For each fireplace, a separate channel or a separate chimney should be provided. It is allowed to connect two fireplaces to one pipe, which are located on the same floor. When connecting two pipes, it is necessary to provide for cuts 12 cm thick and at least 1 m high from the lower pipe connection.

- If the fireplace will be used for large-scale heating, then a radiator pipe (a special device made of plates that increases the heat transfer area) can be connected. At the same time, the intensity of combustion can be regulated by controlling the air exchange. You can use a damper (gate) as an alternative.

- Smoke in fireplaces should be removed in the simplest way. Therefore, it would be ideal to create a vertical chimney with a height of more than 6-7 m or to build a more complex structure that has bends with an angle of at least 45 °. When using a knee, a tee is installed to facilitate access for subsequent cleanings.

- In addition to the shape, the appropriate degree of thermal insulation and the location of the chimney are important. Smoke warms the chimney, which means that it is necessary to protect all ceilings and walls from fire. If a multi-layer chimney passes near wood or plastic, then they must be insulated with basalt-based materials. The place where the chimney passes must be protected from the cold. The chimney is protected by a weather vane or fungus installed at the end.

Tools and materials necessary for creating and arranging a brick chimney for a fireplace: cement mortar and a container for it, brick, a set of chimney pipes with all the necessary elements, lead sheet or sticky aluminum tapes, jointing, trowel, measuring tools (tape measure, building level , square), mop, hammer, ladders, shovel for supplying mortar.

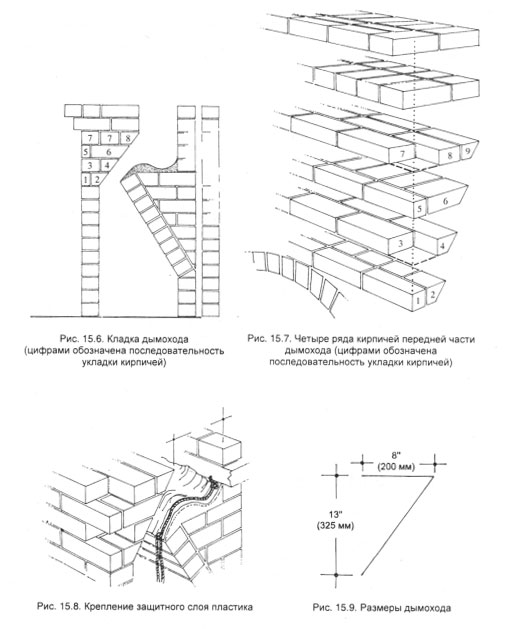

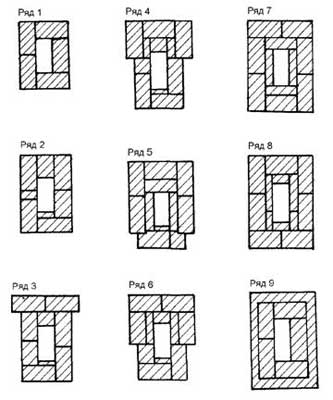

Chimney ordering

Independent creation of a chimney for a fireplace requires great care in execution. The solution must be checked by hand in order to avoid the penetration of debris and small pebbles. Each row of bricks being erected must be checked against the order on the drawings attached to the project. To prevent temperature fluctuations and destruction when brickwork is overheated, the frame for the fireplace should not come into contact with all external walls.

For fireplaces, a tube is most often used, which continues the exhaust outlet of the fireplace. The laying of the inside of the chimney must be done on a clay-sand mortar. First of all, you should lay out the base of the pipe - at least 3-4 rows of bricks. The internal section of the channel through which the smoke will pass must correspond to the power of the fireplace.

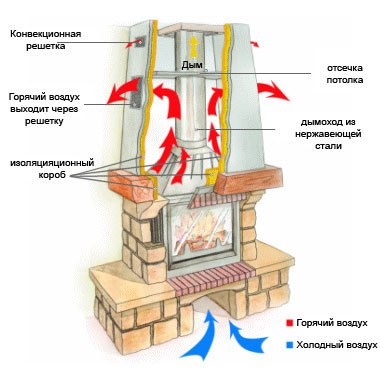

The principle of operation of a properly designed chimney.

For the entire length of the ceiling, fire protection should be made - fluff. The expansion of the pipe should be achieved by shifting the brick a quarter of the width towards the outer edge. It should be ensured that the base of the extension coincides with the surface of the ceiling in the house. The fluff must have a thickness of at least 50 cm. If it is smaller, then it is necessary to lay the expansion with sheet asbestos or other non-combustible materials around the entire perimeter.

After the ceiling is completed, the main riser is laid out between the roof sheathing and the floor in the attic. Its dimensions should be the same as that of the neck at the base.

A further scheme for laying the chimney for should provide for another extension of the pipe from the side of the street - an otter. It serves to protect against the penetration of atmospheric precipitation through the gaps between the roofing material and the pipe into the attic.

Metal pipes for a chimney have a number of advantages, they are durable, not subject to corrosion and strong enough.

Do not forget that bricklaying work on the outside of the house must be carried out with the addition of water and cement to the solution.

The chimney should be installed strictly vertically, its inner surface should be perfectly flat and not have ledges. If a withdrawal is being arranged, then it is impossible for it to go to the side by more than 1 m. When laying a pipe, it is necessary to take into account the absence of obstacles along its entire path. The chimney from two fireplaces can be led into one channel when they are located on the same floor. To do this, make a cut in a channel the size of half a brick with a height of at least 75 mm.

The height of the chimney for the fireplace must be much higher than that of the stove, since more air is consumed during the combustion process in the fireplace. To prevent heat loss, the walls of the chimney must be made of sufficient thickness. The thickness of the outer cold wall should be laid out in brick, and in the middle of the room, laying can be done in half a brick. If the room has wooden walls and it is necessary to lay a chimney through them, then the passage should be carried out only through a metal or asbestos-cement sheet.

The walls of the fireplace inside must be made at an angle, so the heat will go into the room.

You should know that the best shape for the section of the chimney will be round. Rectangular and square shapes will be worse, as soot will accumulate at right angles, which will impede the movement of gases. The most optimal sections for chimneys are 1/10, 1/15 or 1/12 of the size of the internal furnace hole. When installing chimneys, it is best to use ceramic or asbestos-cement pipes.

Ready-made chimney pipe kits are available for sale. They include collar plates for cladding, building blocks, protection for the top of the pipe and other necessary elements. The installation of such pipes begins with the installation of the first block at the very top of the structure. The cement mortar should be applied to the place where the pipes will be connected to the smoke box. The grooves of this block must face straight up. Inside you need to insert the first block of the lining (it is necessary to place the expanded part on top).

Brick cladding is fastened by means of anchor metal ties that are inserted between all external blocks of the pipe. Brickwork is brought to the top of the pipe blocks. After that, a layer of solution is placed on the edge of the last block and a cuff is inserted into the inner tube by pressing into the solution. Mortar is applied to it and bricks are laid. Then you should cover everything with a protective plate on the solution. The intersection of the pipes with the roof has a gap through which a melted or rain pipe can penetrate into the room. To avoid these unpleasant consequences, the gap must be sealed with a solution or a metal sheathing must be made.

Lead sheets or sticky aluminum tapes are used to create metal sheathing. Lead sheathing contains not only lead strips, but also an apron located on each side of the pipe (in this case, a collar structure is formed). One edge of the collar is sealed into the seams of the brickwork, while the other is left to lie on the surface of the roof. The thickness of the wall of the smoke head is made no less than a brick, but if the walls of the pipe are insulated with asbestos-cement slabs and plastered, then it is possible to lay out half a brick thick.

You can use prefabricated pipe heads. The installation of a multi-tiered deflector will make it possible to avoid draft tipping at the mouth of the pipe. A ridge canopy should be installed above the head, which will be freely blown by the wind. Metal caps and edging made of roofing steel will help to avoid destruction under the action of precipitation of the end part of the head. In order to provide traction, wind protection nozzles must be installed on the pipe heads. The head of the chimney must be removed above the zone where the wind backwater action takes place. At the end, spark arresters are installed on the pipe heads, which have the form of a cap and a wire mesh on the sides (the mesh size should be no more than 3 mm).

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical