Consumption of tile adhesive per 1m2: calculator

Tile adhesive is used for laying ceramic and porcelain tiles, allowing you to finish the room with the utmost simplicity. It is presented on the market in a wide range, differs in brand, main components, type of material with which it can be used, setting time and other characteristics. Depending on the type of product, its average consumption will also differ, which is also important to know in order to calculate the optimal purchase volume. Now the task remains - to determine the numbers that will help to purchase the required volume of the adhesive mixture. A special calculator will help you calculate the consumption of tile adhesive per 1m2, and you can also do this by other methods. Consider all possible options.

| Side size of a square tile (when using rectangular tiles, the calculation is based on the area) | Notched trowel recommendations (recommended trowel tooth size) | Adhesive layer after tile pressing – 1 (trowel angle 45°), mm | Adhesive layer after tile pressing – 2 (trowel angle 60°), mm |

| Up to 5 - 7 cm | 3 mm | 1,1 | 1,3 |

| Up to 10 cm | 4 mm | 1,4 | 1,7 |

| 10 to 20 cm | 6 mm | 2,1 | 2,6 |

| 20 to 30 cm | 8 mm | 2,8 | 3,5 |

| 30 to 50 cm | 10 mm | 3,5 | 4,3 |

| Over 50 cm | 12 mm | 4,2 | 5,2 |

Features of automatic counting

To calculate the volume of material quickly and accurately, you can use a special calculator. It is easy to find on any specialized site on the Internet. To determine the average consumption of tile adhesive per 1 m2 of tiles, you will need to set the following criteria in the empty fields of the form:

- the size of one element of ceramic tiles;

- type of facing material: tile or porcelain stoneware;

- work option: internal or external;

- base: wall, floor;

- basis: cement, concrete, plaster, metal, self-leveling floor, etc.;

- features of operational loads;

- composition characteristics;

- total surface area.

You will receive the result in a few seconds after starting the process. Your attention will be presented to the consumption of glue for tiles per 1m2 and for the performance of all work in general. There are several resources you can use to get accurate confidence in the correctness of the data you have, by comparing the calculated rates. The advantage of this method lies in its efficiency.

How to calculate yourself

A calculator is a handy thing, but if you doubt the correctness of the data provided, do the calculations yourself. To do this, first of all, you need to determine the thickness of the adhesive layer. It varies depending on the size of the tile itself:

- small tiles, mosaic - 2-3 mm;

- the average size of the elements is 3-5 mm;

- large tiles - 6-9 mm.

If we are talking about porcelain stoneware, the layer thickness will increase to 17-20 mm, because the material has a lot of weight, it must be securely fixed.

Important! It is not necessary to exceed the optimal layer thickness, otherwise it will dry for a long time. You should adhere to the standard indicators.

It is necessary to take into account in the calculations, and what are the features of the surface itself. For example, if we are talking about finishing the floor with standard ceramic tiles, the thickness of the pillow will depend on the presence of irregularities on the base:

- flat surface - 4 mm;

- floor with minor defects - 7-9 mm;

- base with noticeable level differences - up to 20 mm.

Attention! In case of significant irregularities, the highest point should be taken as the level. So all the cavities will be filled with a special composition. If the base has large recesses, you must first make a leveling screed.

Now we proceed to determine the optimal consumption of tile adhesive per 1m2. Initially, you need to study the packaging of the product, finding here the standard recommendations from the manufacturer. They are specified taking into account a layer thickness of 1 mm, as well as a flat surface. Now determine the height of the adhesive pad for your case, multiply it by the baseline taken from the package. You have received the average consumption rate of tile adhesive per 1m2. Multiply this figure by the number of squares to be finished. Be careful! Add another 10% to the existing figure to eliminate the possibility of shortages due to petty costs and unforeseen circumstances.

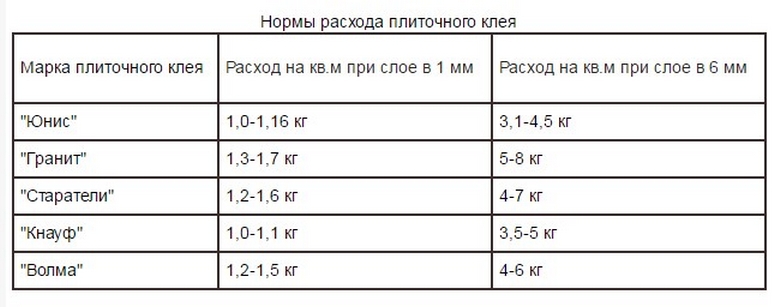

Differences by brand

It was mentioned above that the consumption rates of the mixture depend not only on the type of finishing material and base, but also on the manufacturer, the composition of the product. Consider this too. For example, Eunice Granite tile adhesive has a consumption per 1m2 of 3.5 kg. The numbers will be relevant if a 6x6 mm comb is used. The optimal layer thickness is 3-5 mm, the maximum is 10 mm. The consumption of Eunice Plus tile adhesive per 1m2 will remain within the same limits.

Often in finishing work, the Eunice 2000 product is used. It is used in exterior and interior decoration. The composition is able to hold tiles on the surface, creating a load of up to 80 kg per m 2. The thickness of the pillow is 3-15 mm. The average consumption when using a 6x6 mm spatula is 3.5 kg. If we talk about the Ceresit product, it is consumed in the amount of 1.7-4.5 kg per m2, depending on the type of surface and the type of finishing material. As for another, no less popular product - EK 3000, it will require approximately 2.8 kg per square meter if the mixture is laid with a 6x6 mm spatula.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical