Construction of a sauna stove: principles of operation that need to be understood

If you intend to install a large stove in the house, then this is one situation - here we “squeeze out” everything that is possible and to the fullest extent: a brick stove on a solid foundation and a seriously thought-out and insulated chimney. When it comes to a stove in a bathhouse, the situation here is much simpler and more varied.

Let us at least take into account that the market offers many already developed options for every taste. And the best choice would be to choose a ready-made, proven model. However, you will have to do the maintenance yourself, so it will be necessary to know the structure of the furnace.

Selection principle: the simpler the better

First, let's decide on the types of stoves that may come into your field of vision.

There are quite a few types, often in options for:

- Firstly, a brick wood-burning stove - for baths we are interested here in its simpler and less massive version, which is built in housing; build such a stove yourself;

- Secondly, a metal wood-burning stove; Many industrial versions of such furnaces have been developed, but you can try to make them yourself, knowing the design and technology of welding;

- Thirdly, electric heaters are a very popular option for saunas, which are already selected from the available offers on the market;

- Fourth, a furnace in which the heat source is gas; Such stoves are attractive due to their cheap source of energy, but require professional knowledge in the field of handling gas appliances.

Whatever the furnaces are - no matter what material they are made of and no matter what energy source they use, the principles of operation and design of all are very similar. Let's look at the device using the example of a metal heater.

Basic option

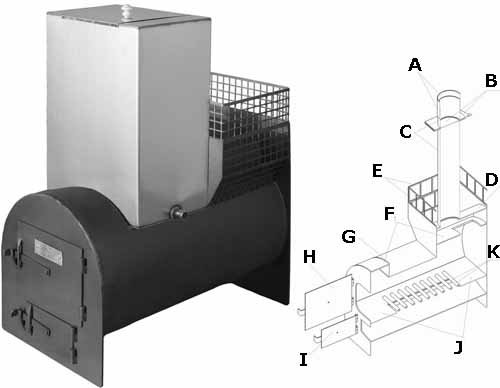

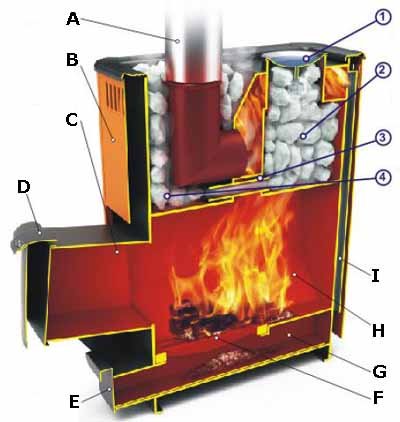

A good basic version of the heater is the example shown in Figure "B".

Its constituent elements are:

- A – clamp placed on the top of the pipe;

- B – gate, as a means of protection against reverse draft;

- C – pipe;

- D – vault;

- E – heater – the location of the stones to create the main heat in the bathhouse;

- F – body;

- G – location of the water tank, if hot water is also needed;

- H – firebox door;

- I – ash door;

- J – grate platform;

- K – grate.

Helpful advice!

There are many options for making metal heaters based on a regular pipe with a diameter of 15-20 cm.

But this work requires good knowledge in the field of welding and selection of metal, which during the operation of the furnace will often have to deal with moisture and ash.

Therefore, the advice here is this: if you are not confident in your abilities, it is better to turn to ready-made options that have already been developed and are commercially available.

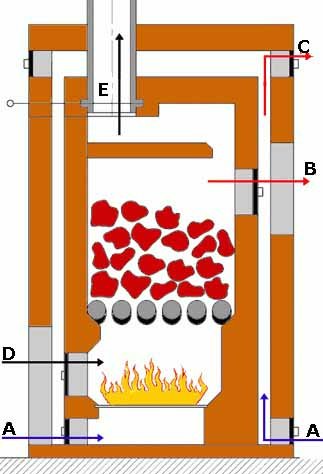

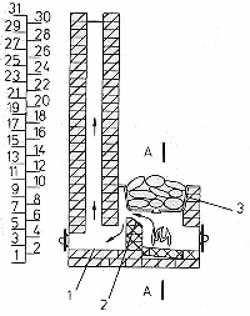

Air flow diagram

A very important component of calculating and analyzing the design of a furnace is understanding and creating a diagram of internal air flows.

Such a scheme could look like this:

- A – cold air intake;

- B – steam output;

- C – hot air outlet, secondary channel;

- D – burning wood;

- E – smoke output.

Diagram “E” shows a simpler oven design, and hence a simpler air flow diagram, although the idea remains the same - there are two air channels, the main and the additional:

- cold air inlet (1);

- warm air flow (2);

- hot air flow (4);

- steam exit through a separate channel (5).

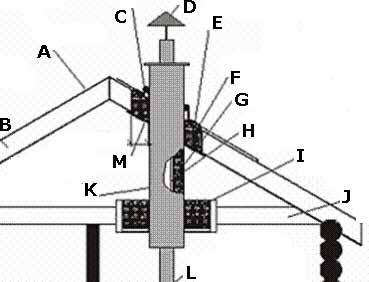

Chimney diagram

Organization of successful operation of the furnace is unthinkable without taking care of good draft, and therefore without reliable.

Figure “H” shows the chimney design in detail:

- A – roof and

- B – rafters, as structural elements of the roof;

- C – high-temperature sealant – pay attention to the need for reliable design of the joint between the furnace structure and the roof elements;

- D – rain cover;

- E – galvanized metal sheet;

- F – thermal insulation;

- G – thermal insulation, expanded clay is often used here;

- H – chimney;

- I – thermal insulation;

- J – steam room ceiling;

- K – protective pipe of the main furnace pipe;

- L – chimney;

- M – cement bonded particle board or any other temperature-resistant sealing material.

Other options and calculations

Diagram “C” shows another version of a metal heater, on which the air flow channels are clearly visible.

Please note that there are already two heaters here - the second is used to produce dry steam:

- A – chimney from a pipe;

- B – outer casing – behind it is an internal hot air channel;

- C – fuel supply channel to the furnace;

- D – combustion door, this double design allows the door to heat up less and cool faster;

- E – ash drawer, note the design feature of this furnace – the drawer is retractable, which will greatly facilitate the maintenance of the furnace in the future;

- F – cast iron grate;

- G – ash pan;

- H – firebox made of heat-resistant stainless steel;

- I – channel for the entrance of the secondary air flow.

The diagram also shows:

- 1 – water dispenser, it will determine the amount of steam you need – some models, primarily electric and gas, use an economizer for sauna stoves, which provides the most economical energy consumption depending on the temperature and humidity in the room;

- 2 – closed-type primary heater;

- 3 – pipe;

- 4 – additional heater for producing dry steam.

Calculations

If we talk about the quantitative design characteristics of the furnace, then it is necessary to keep in mind the following points:

- the solution to the question of how to calculate a stove for a bathhouse largely depends on the type of bathhouse itself and the size of its room;

- if the bathhouse is Russian, then the stove should provide a temperature of 50-60 degrees, which is not high at all, but the humidity is more than 60-70%, which is very significant;

- for a Finnish sauna, these parameters are exactly the opposite - the temperature is high - over 100 degrees, but the humidity is quite low - no more than 20%; the whole idea is based on the axiom - the lower the humidity, the easier it is to tolerate high temperatures;

- it is considered unacceptable when the humidity drops below 10%; in this case, it is strongly recommended to forcibly humidify the air;

- The choice of stove is made according to the volume of the bathhouse room, based on two parameters:

- there must be at least 12 cubic meters per person;

- the power of the stove should be calculated relative to the volume with a coefficient of 1.2 (minimum, in some cases 1.5) to take into account heat loss - thus, if the volume of the bath is 20 cubic meters, it is necessary to choose a stove for a volume of 24-30 cubic meters;

- when solving the problem of how to calculate the power of a stove for a bath, the main criterion is also the volume of the room: they proceed from the ratio - 1 kW of power must correspond to 1 cubic meter of volume;

- when it comes to independently organizing a bathhouse, the best option is to choose an electric furnace, which eliminates the need to create a chimney, and this is a very significant and responsible amount of work; the calculation and selection of an electric furnace is based on area - for 1 sq.m there should still be the same 1 kW;

As the main calculation method, which does not affect special knowledge in the field of heat engineering and mathematics, the following can be accepted:

- initial data:

- let the volume of the room be 3 x 4 x 2.5 meters - 30 cubic meters;

- heating to 60 degrees requires 50 kcal/hour per 1 cubic meter of volume;

- 1 sq.m of oven area produces 300 kcal per hour;

- thus we get:

- to heat our room per hour it will take 30 * 50 = 1500 kcal/hour;

- hence, the surface area of the oven must be at least 5 sq.m.

In the above algorithm, only the cost of heating 1 cubic meter to the required temperature requires discussion, which largely depends on specific natural conditions and differs significantly in Murmansk, Kostroma or Sochi.

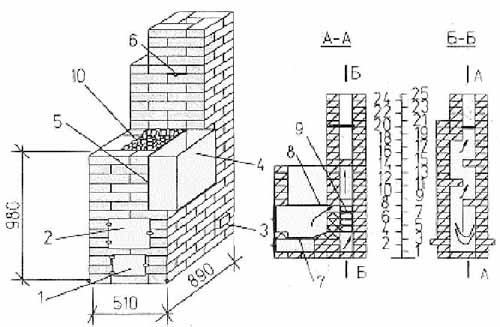

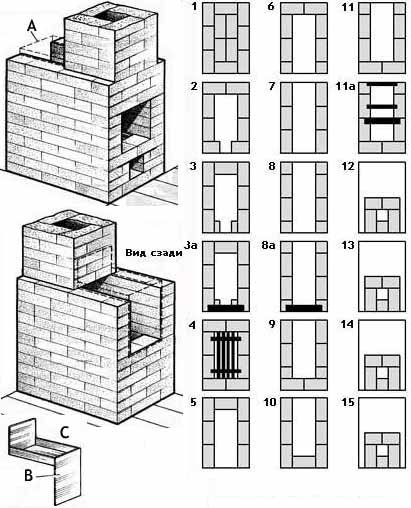

Brick kilns

The whole idea of the calculation is based on the assumption that you are going to build the stove yourself. This means it will be brick. All other types of stoves, in principle, exclude any calculations on your part - you simply make a choice from what is available, based on the volume of your bath.

We offer two options for brick heaters.

Their construction principles are the same, taking into account the following nuances:

- it will be necessary to create orders - layer-by-layer laying out of bricks, which significantly simplifies the entire construction process;

- must be accompanied by soil examination and, in any case, strengthening of the foundation;

- in diagram “F”, pay attention - the doors of the blower and firebox are located on different sides;

- in diagram “G” the warm air channel (section BB) has the appearance of a zigzag, this is of fundamental importance.

The construction of a brick bathhouse sooner or later raises the question of how to line the stove in the bathhouse. The lining of the stove in the bathhouse is usually done at will and over time, when there is confidence in the correctness of all calculations and the normal operation of the stove.

But what you need to keep in mind right away is the solution for the sauna stove.

Its preparation has some features:

- the solution must be created on a clay basis and can be of three types:

- clay;

- limestone, and

- cement;

- clay should have the following composition:

- sand – 4 units of measure;

- fireclay clay – 1;

- ordinary clay – also 1;

- For comparison, here is the composition of the lime mortar:

- sand – 2.5;

- lime – 1;

- cement grade M-400 – 0.5;

- composition of cement mortar:

- sand – 3-4;

- cement grade M-400 – 1.

Helpful advice!

Strengthening the foundation of the furnace does not allow even the slightest mistakes.

We strongly advise you to strengthen the foundation with a well-compacted sand and gravel mixture, place the stove itself on a reinforced concrete slab with an area one third larger than the area of the stove base, and under no circumstances drain the foundation.

conclusions

Creating a sauna stove is certainly a responsible process. If you don’t want the extra hassle, opt for reliable, ready-made metal options or an electric oven. But no matter which option you choose, be sure to have a good understanding of the basics of all the processes occurring inside, which the additional video in this article can help you with.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows in the apartment fog up?

Why do the windows in the apartment fog up? Construction and diagrams of brick stoves

Construction and diagrams of brick stoves How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill tiles in the bathroom

How to drill tiles in the bathroom Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical?

Which electric heater is economical?