How to lay linoleum with your own hands - everything from choosing materials to sealing seams

According to the majority, linoleum is quite a decent floor covering, but in appearance it still loses to laminate and parquet. However, today you can choose linoleum of very good quality, with a beautiful pattern and interesting texture. In addition, this coating has a huge number of advantages: affordable price, high wear resistance, ease of maintenance. But the most important thing is the simple laying of linoleum, which will avoid the involvement of specialists and save money. Do-it-yourself linoleum laying requires certain knowledge in the preparation of the base and the flooring technology itself. Therefore, first you need to read the step-by-step instructions.

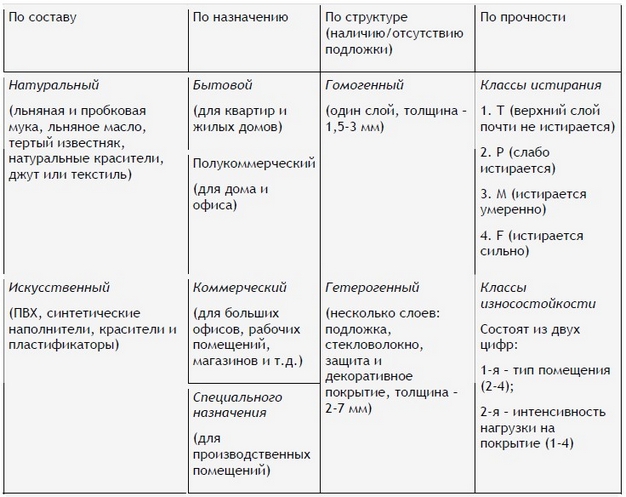

The table will allow you to easily understand all types and classifications of linoleum

The table will allow you to easily understand all types and classifications of linoleum

In order not to get lost in all the variety of linoleum, you need to decide on its principle. The main criterion is the patency of the room. In an apartment, office and school, the floor is subjected to completely different loads. Therefore, there are several:

- Domestic,

- And semi-commercial.

The household coating has a thin protective layer, the total thickness of the material is up to 3.5 mm, it is usually used in apartments. Its benefit is very relative, since the price of the material is lower and the laying of this type of linoleum is cheaper than that of commercial and semi-commercial, but it will last much less.

For a floor with a high level of use, commercial linoleum is suitable. Its thickness is 3 mm or more, and the protective layer is not less than 0.6 mm. Commonly used in schools, offices, shops, hospitals, etc.

Semi-commercial coating is used in rooms with an average degree of load. These may be small offices or hospital rooms. This coating combines elasticity and good wear resistance. The thickness of the protective layer is about 0.4-0.5 mm. Very often it is used in special areas of the apartment, where the load on the floor is very high, for example, in the kitchen, in the hallway or in the nursery.

A special place in the market is occupied by natural linoleum -. It consists of linseed oil, limestone, pine resin, wood flour and only natural dyes. Happens both with a basis, and without it. It has a number of valuable qualities:

- Environmental friendliness;

- Durability;

- Presentable appearance;

- Ease of care;

- The ability not to accumulate an electrostatic charge;

- Fire resistance.

Do not neglect the tips when choosing:

- It is necessary to carefully measure the floor in the room. To buy the optimal amount of material, it is better to take measurements for a greater length and width with a margin of 10 cm. But if there is a pattern on the coating that needs to be adjusted, then the margin should be even greater. The wider the linoleum, the fewer seams there will be.

- You can really check the quality only in a warm room. Pay attention to weight and density. Heavy linoleum is not pressed through and does not tear.

- Be sure to study the instructions for use of a particular type of coating. After all, when the question arises of how to lay linoleum, you need to know exactly which adhesive is suitable and which is not. For example, for a material with a fleecy inner surface, PVA or Bustilat M is used. And for a smooth wrong side, special latex-based mastics are used.

- If the linoleum is on a roll, then it must be unfolded and the surface carefully inspected for defects. There should be no bumps, no dents, much less peeling of the top film. You should definitely not buy such material in the hope that it will smooth out over time.

- Linoleum should be rolled upside down. If this is not possible, it is better to wrap the roll with protective material, paper or film.

Substrate preparation for laying

The smoother the surface of the base for laying, the less linoleum will wear off during operation. Therefore, you need to take into account all the nuances of how to lay linoleum. If it is thin, then laying will require more care, and preparing the surface for flooring more time.

To begin with, the skirting boards are removed. If you plan to use them in the future, then you should do it carefully so as not to damage the elements. After that, the surface is processed depending on its type.

One of the options for arranging the subfloor before laying linoleum

One of the options for arranging the subfloor before laying linoleum If there is a base for linoleum, then its alignment is mandatory for subsequent work. There are several ways before laying linoleum:

- - using a planer or grinder;

- By laying an additional layer of fiberboard, chipboard, plywood, etc.;

- Usage .

For use other methods of alignment:

- Covering the base with plywood on logs;

- Pouring concrete screed. After such alignment, do-it-yourself laying of the coating is carried out without much difficulty;

- With the help of a self-leveling floor.

If there is a carpet on the floor, then it must be removed, the surface must be thoroughly cleaned of dust and lint, and uneven places should be treated with a special solution.

Before laying on a concrete base, all defects - cracks, chips and cracks - must be eliminated.

Before laying on a concrete base, all defects - cracks, chips and cracks - must be eliminated. The ceramic tile base can be left. If some tiles are cracked or fallen off, then they need to be replaced. And then fill the surface with a leveling mixture.

New linoleum can also be laid without removing the old one, if it does not have cracks and holes. Before laying a new coating, the surface of the base is degreased.

For those who know how to properly lay linoleum, the main rule is invariably: an absolutely dry surface of the base, regardless of what it is made of. Otherwise, mold or fungus may form.

In addition to the base, it is necessary to prepare a laying tool:

- A sharp knife with a short blade;

- Pencil;

- Scissors;

- Roulette;

- Ruler.

The minimum set of tools for self-styling

The minimum set of tools for self-styling The covering should be laid at a temperature between 15 and 25 °C. Therefore, if it was bought in the winter, then before deploying it, you should wait until it warms up. After all, the cold material becomes very brittle and inelastic. In expanded form, it should also lie down for at least a day, since it is better to lay linoleum after it has smoothed out a little.

Laying technology

After the final preparation of the base, laying can begin. To understand how to lay linoleum correctly, you need to decide on the direction of laying the coating. For example, to enhance the effect of a marble pattern, linoleum strips are laid perpendicular to the window so that the coating looks monolithic.

To cut the material, you must use scissors with a replaceable blade, and in order for the edges to be absolutely even, you will need a wall marker. It is also necessary to follow a number of rules:

- The material must be cut in small cuts;

- For internal corners, the direction of the cut is from top to bottom;

- Leave a small distance between the wall and the edge of the covering.

For more information about pruning, see the video:

- Dry;

- Glue.

Free laying without glue is suitable for rooms with an area of \u200b\u200bno more than 20 m2. For reliability, you can make sure using double-sided tape. The following tools are also required:

- Ruler,

- Devices for measuring and welding seams.

The second method is suitable for large rooms or for floors with a high degree of exploitation. In this case, a solvent-free dispersion adhesive is used. Before laying the linoleum, glue is applied with a special spatula with teeth evenly over the entire surface of the material, and then over the base. Further, linoleum flooring is accompanied by smoothing with a blunt object towards the corners. Then the corners are adjusted, the air that got in during the linoleum flooring was released.

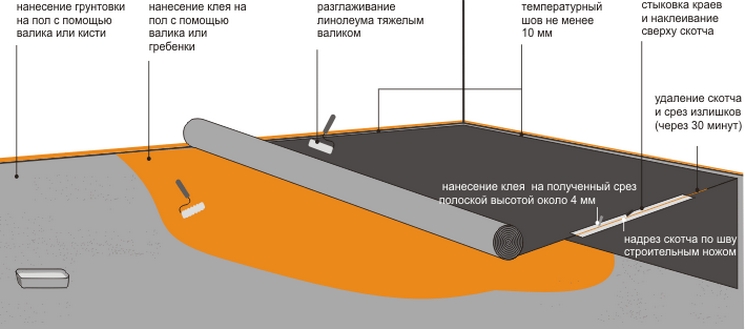

The technology of laying linoleum on glue on a concrete base

The technology of laying linoleum on glue on a concrete base An important point of laying is the sealing of seams. Previously, nails or adhesive tape were often used in the apartment. Now cold welding is used, which gives the material an aesthetic appearance and facilitates linoleum flooring. Most often used for semi-commercial and domestic linoleum.

Linoleum flooring using cold welding is carried out with glue, which can be of two types. This is a very important point, since it is impossible to properly lay linoleum without taking into account such nuances. If the material has been lying for some time and the seams have parted a little in different directions, then it is necessary to use thick glue, as if filling the space between the stripes. If the coating has just been laid, and the seam is butt-to-butt, then you need glue that will melt the edges. Watch the video that clearly shows how to do it:

For commercial linoleum, hot welding is used, which uses a cord. In this case, it is better to use the services of a specialist, since laying linoleum using hot welding is dangerous without special equipment. And if you want to lay linoleum with your own hands, then the best choice is cold welding.

Outcome

Having considered the laying process, we can conclude that laying linoleum with your own hands is not so difficult. However, it is worth attaching importance to observing the laying technology so that the coating brings comfort and warmth to the house.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical