How to eliminate the creak of the laminate without disassembling the coating

Laminate creaks what to do indiscriminately and how to eliminate different sounds when walking on a laminate. After laying the flooring, an unpleasant problem may arise - the laminate may creak. This may occur due to the fact that certain installation requirements were violated during installation. If such a situation arose, then you have to figure out why the laminate creaks. It is best to eliminate the cause without parsing the floor, because the locks can be disposable and after parsing it will be necessary to buy new material.

When a laminate creaks, what to do is of interest to many, but not everyone thinks about the causes of such problems. And there are many of them, such reasons include:

- Violation of the rules for preparing the foundation.

- Poor condition of subfloor.

- Poor quality laminate.

- Violation of floor laying rules.

- Poor choice of substrate or its complete absence.

If you do not follow all the rules for laying the foundation, then the appearance of various shortcomings is quite an expected phenomenon. Some of these problems can be fixed without parsing, but sometimes a partial parsing or a complete one is required. When parsing, there is a high probability of damage to the locks, as a result of which you will have to purchase additional material, and this will lead to an increase in the cost of the laminate floor. In order not to puzzle over the question of laminate creaking what to do indiscriminately, it is necessary to strictly follow all the laying rules.

Laminate creaking due to poor base preparation

Sometimes, laminate creaking can be the result of the original (rough) floor being in poor condition. If the coating was laid on a wooden floor, then it is necessary to check its condition before starting work. To do this, check for cracks and rotten boards. If the base is in an unsatisfactory condition, then alteration is necessary.

Before starting work, wooden floors need to be rallied. Rotten boards, even partially damaged, must be replaced. In the process, it is necessary to do alignment.

A concrete screed can have 2 problems:

- Roughness - in this case, alignment must be done.

- The old foundation may be crumbling. Most often, this option occurs if low-quality concrete is taken.

If the base is old and has begun to collapse, then it is better to replace it. But such work is very laborious and financially costly. Plywood at least 6 mm thick will help correct the situation. It is placed on the floor and fixed. Then the laminate is laid. With the help of plywood, you can also level the wooden base.

Installation of plywood for laying laminate

If the shortcomings of the finished laminate base appeared due to a poor subfloor, then the entire structure will have to be disassembled. There will be no other way.

Eliminate squeaking of laminate with uneven ground

If you clearly and correctly follow all the conditions for preparing the base for the laminate, then the likelihood of flaws is reduced significantly. All depending on the type of floor you need to level the floors. Irregularities have a negative effect on the locks of the boards. If the laminate creaks when walking, then the likelihood of an uneven floor increases. This problem needs to be fixed.

The most effective method would be to drill a small hole in the board. Next, the medical syringe is filled with PVA glue and this glue is injected into the hole. Filling is best done at a not very high speed until the glue comes out of the hole. If glue gets on the edges of the hole, then it must be removed. Then you need to leave the filling place for 3-4 hours. At this time, it is better not to walk on the floor so that the glue can grab.

Once the glue has set, you need to close the hole. For this, sealants or mastics, putties or self-adhesive films are used. Sealants and mastics can have colored bases, and therefore you can choose the composition that matches the color of the laminate as much as possible. To create the maximum effect of an intact board, you need to remove the excess composition with a cloth, and process the hole with fine sandpaper, then polish it with a cloth. For reliability, you can cover the board with a layer of colorless varnish.

Eliminate creaking by drilling laminate

Laminate squeaking when laying laminate on rubbish

When the owners of the house begin to be interested in what to do if the laminate creaks, it is important to remember how the premises were cleaned before laying work.

After preparing the base, debris often remains, and if large debris is removed, then such attention is not paid to dust and small motes. And this step is in vain. If there is sand under the laminate, then creaking is quite possible. Therefore, before laying, you need to thoroughly vacuum the rough base and all the cracks. If the gaps are large, then they must be treated with filling compounds.

If it is determined that the laminate is crunching due to debris, then you can either dismantle the entire coating or vacuum the laminate at the points of contact with the wall. To do this, remove the plinth, and the coating can be slightly lifted in order to have a gap. Insert a vacuum cleaner hose into this gap and try to remove debris.

It happens that the sounds from the coating pass over the entire surface area. In this case, it is likely that the laminate was laid without observing the temperature gap. Such a gap must be left between the edge boards and the coating, since the laminate has the property of linear expansion. If the gap is small, then under the action of the expansion, the locks begin to creak.

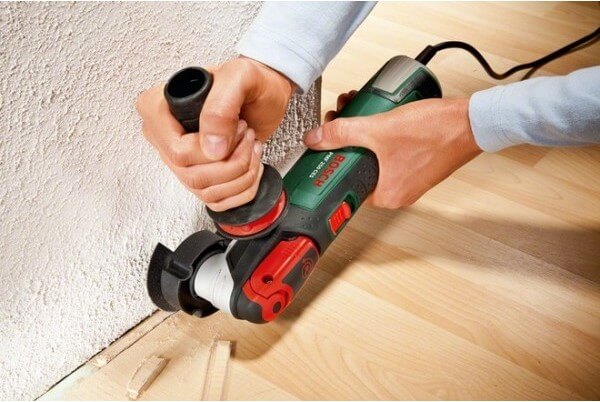

Correcting such a defect does not take much time and effort. To do this, you need to remove the plinth, and increase the size of the gap with the help of a grinder. The cover does not need to be removed.

Laminate creaking in the absence of a temperature gap

Laminate creaks due to the substrate

Such a moment can also be. This is due to the fact that the wrong substrate was selected. Laminate is a floating floor system and requires an underlay. This element provides some softness to the coating and hides small irregularities in the subfloor. Choose a substrate depending on the material of manufacture and thickness. If the coating creaks, then, most likely, the matter is in the wrong choice of substrate thickness.

When choosing a thickness, it is important to remember that the larger this parameter, the greater the gap between the floor and the board. A large gap can give a creak. Therefore, the substrate must be chosen of normal thickness.

The optimal thickness is 3-7 mm. the maximum parameter can be up to 10 mm. If the laminate creaks, what to do without disassembling the coating will be interesting in this case. But here everything is deplorable for the owners. In this case, it is necessary to dismantle the coating and replace the substrate with a thinner one. There are no other options for resolving the issue.

Laminate locks creak

A very common cause of an unpleasant sound is the discrepancy or loose connection of the locks. In the event of a discrepancy, a gap is formed, which can sometimes touch another board, resulting in a sound. With a loose connection of the lock, the same thing happens.

In this case, the situation can be corrected without parsing the surface. To solve the problem, an adhesive composition is used, which is applied to the locks, and the boards are trying to move towards each other. The surface is left for some time for the glue to harden.

Sometimes, instead of glue, it makes sense to use mounting foam. It sets much better and faster, and also holds the panels noticeably better. A big plus of the foam is that it is enough to apply it to the edges of the boards, due to the expansion it will itself reach the desired, opposite edge.

However, when working with foam, care should be taken:

- The joints must be cleaned from dust.

- Glue construction tape or masking tape along the edge of the board. This is done so that the foam does not stain the surface of the boards.

- Foam is poured into the joint.

- After some time, the excess frozen foam is removed.

The joint surface can be painted over so that the processing is not noticeable. Either a sealant or mastic of a suitable color is used.

Gluing laminate locks

When choosing a laminate, it is important to remember that a low-quality coating can also emit a creak, so you need to choose a quality material. In many cases, it is impossible to do without dismantling the coating, therefore, in such a case, you need to pay attention to what kind of locks the boards are equipped with.

On sale there is a laminate that can be dismantled up to several times. Of course, these coating options are more expensive, but it's better than buying new material all over again.

In this material, 2 main questions on the topic of creaks are revealed: laminate creaks, what to do indiscriminately and why laminate creaks. Now you know what causes may be behind the creaking of the panels and how to eliminate them without disassembling the floor.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical