Warm water and electric floor in a wooden house

It depends on many factors, and first of all, on its type. The underfloor heating system in the house creates the most comfortable temperature and humidity conditions in the premises. The air in the rooms is heated by convective processes. Cold layers have a higher density and are located near the floor, where heat is transferred from the surface with a higher temperature.

As it warms up, the air begins to rise upwards, contributing to the spread of heat and increasing the temperature in the room. The same physical principle underlies most heating devices, the difference is only in their location and operating temperature. Batteries or convectors have a relatively small heat exchanger surface, which must be hot enough to heat the air intensively.

A rapid increase in temperature leads to an increase in the speed of flows, in which dust and even small debris are involved. In the case of a warm floor, the heat transfer surface is the largest and is equal to the useful area of the room. This circumstance allows the use of lower operating temperatures from 27°C to 55°C. At the same time, the flow rate is lower, and the distribution of layers of warm and cold air is most comfortable for a person.

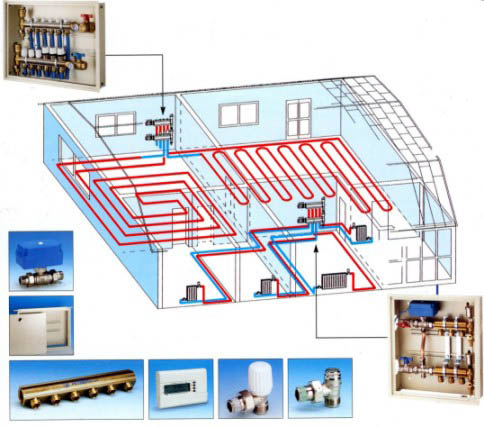

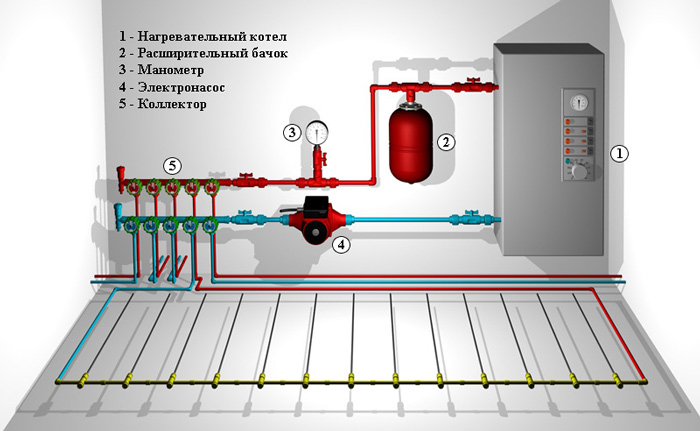

Underfloor heating scheme

Underfloor heating scheme Underfloor heating in a private house is the most efficient and safest heating system for the health of residents. In rooms equipped with heating devices of this type, there is no such thing as drafts. Statistics show that people living in houses with underfloor heating are less likely to get respiratory diseases. Popular wisdom is confirmed: keep your feet warm and your head cold.

Classification of heating systems

For heating individual residential buildings, autonomous equipment is usually used. Classification of warm floors can be carried out according to different criteria:

- By type of heat carrier: water, air and electric;

- By type of boiler used for heating: gas, solid fuel, diesel or electric;

- According to the principle of operation: convective or infrared type.

Each of these options has certain advantages and disadvantages. The type of heating system is determined even at the stage of preparation for design - at. The choice is made taking into account many factors, the decisive of which is the presence or absence of. At the moment, this type of fuel in our country is the most affordable and cost-effective.

The warm floor in a wooden house has some features associated primarily with the design of the building and the specifics of the material. When designing autonomous heating systems for individual housing, specialists are guided by the requirements of SNiP 41-01-2003, GOST 1759.087, GOST 10618-80 and GOST 1147-80. Wood has a relatively low thermal conductivity.

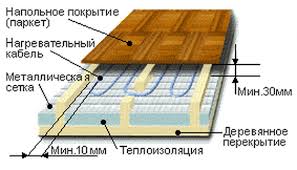

Installation of a warm floor in a wooden house

Installation of a warm floor in a wooden house Due to this property, the distribution of temperatures over the surface of a floor made from this material is extremely uneven. In those places where the heating element is laid, it is hot, but not nearby. This phenomenon is compensated in several ways:

- the use of so-called film infrared heating elements;

- using heat-distributing plates or other similar elements.

In our country, they are becoming more widespread, and, consequently, interest in new individual heating systems is also increasing.

One of the most efficient underfloor heating systems for a wooden house

One of the most efficient underfloor heating systems for a wooden house Underfloor heating device with liquid coolant

Country houses, for the most part, have a centralized gas supply. Thermal engineering equipment is represented by a boiler, as a rule, double-acting for. As a heat carrier, water is usually used, which has undergone special training, or without it. In underfloor heating systems in houses that are not intended for year-round use, it is better to use antifreeze. In this case, there is no need to drain the water from the pipes.

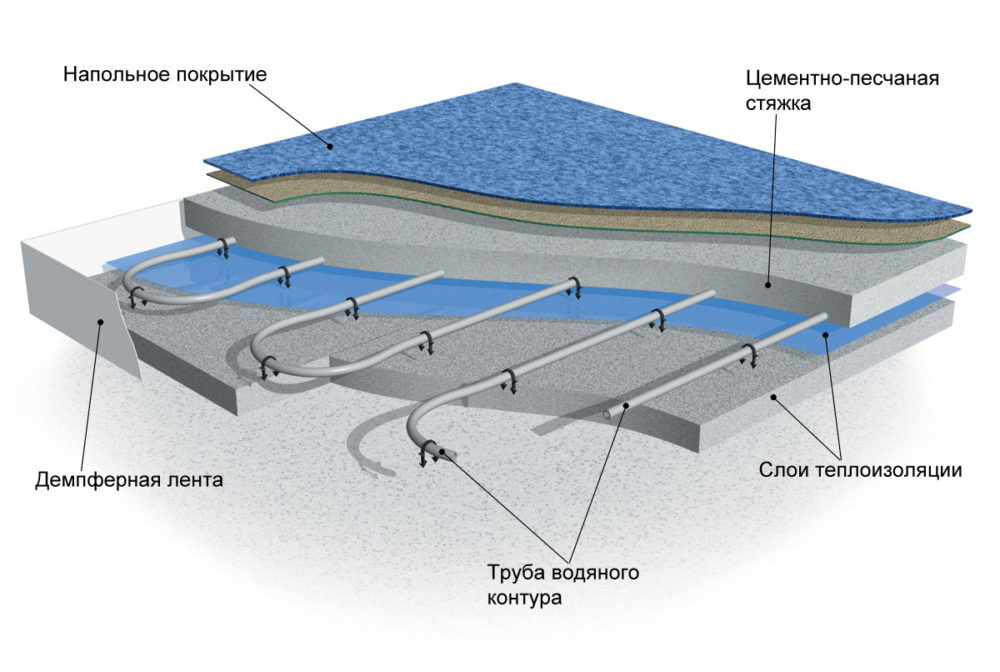

Scheme of the device of a warm water floor

Scheme of the device of a warm water floor Heating systems with a liquid heat carrier are of two types: closed or open circuit. The main difference is in the design of the expansion tank; in the first version, it directly communicates with the atmosphere. An increase in the volume of liquid due to heating is easily compensated by a simple increase in its level in the tank. A closed circuit system requires a specially designed dilator.

Read also

How to choose the right foundation for your home

The water heated floor of the house has the following device:

- gas or electric boiler:

- expansion tank;

- circulation pump;

- Mayevsky's crane;

- safety valve;

- distribution node;

- hidden and open pipelines.

Installation scheme and installation of all necessary equipment for a warm water floor

Installation scheme and installation of all necessary equipment for a warm water floor The heat carrier is heated to the set temperature in the boiler, this parameter is constantly monitored there. Warm water from it enters the main collector, through which it enters a special unit. This device is responsible for the uniform distribution of the coolant throughout all underfloor heating piping systems in each room. Thus, it is possible to achieve the same temperature in all rooms.

Preparing for the installation of a water-heated floor on your own

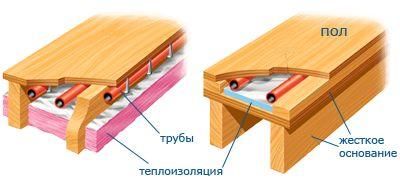

It is most convenient to carry out work on the installation of heating systems at the construction stage before the start of finishing operations. The most time-consuming part of the process is the installation of pipelines to ensure the circulation of the coolant. Usually in private houses, wooden floors laid on beams (logs).

During the assembly process, logs are laid, which are the supporting power elements. To increase the efficiency of the heating system, it is necessary to perform thermal insulation work. It is better to use mineral wool as a heater; basalt fiber mats have also proven themselves especially well. It is not recommended to use foam, which is often damaged by mice.

For laying the insulation, a boardwalk is arranged between the logs on the bars, hemmed in their lower part. Under the mats, it is imperative to lay a vapor barrier membrane. The use of such material makes it possible to avoid the penetration and accumulation of moisture in the thermal insulation and wood of building structures.

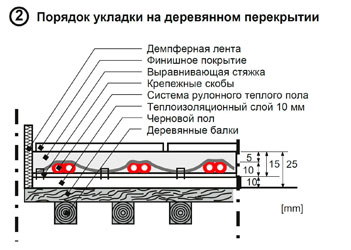

Step-by-step diagram and process of laying a warm floor on a wooden floor

Step-by-step diagram and process of laying a warm floor on a wooden floor Laying the subfloor is an operation to prepare the base for the heating system. The efficiency of the equipment as a whole and the cost of maintaining the house will largely depend on the quality of its execution. These preparatory operations can be started immediately after the installation of the roof, windows and entrance doors. The work does not require high qualifications and special tools, which means that it can be done by hand.

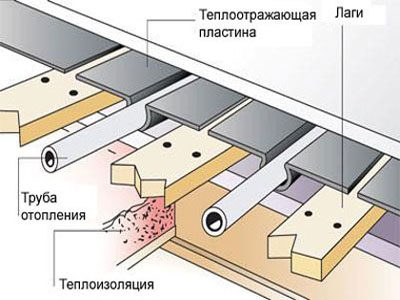

Installation of underfloor heating pipelines

The construction industry offers a wide range of accessories for heating systems. Underfloor heating pipelines can be made of different materials, but copper or metal-plastic is mainly used. Metal pipe has a higher cost and is difficult to use. These shortcomings are more than offset by the reliability and durability of the material.

How the installation of underfloor heating pipelines was completely done with your own hands is shown in the video below. This will give you a visual representation of the process. It is important to correctly place the tubes over the entire surface of the floor. Typically, the circuit diagram is a zigzag with a pitch of no more than 150-200 mm, the points of the inlet and outlet collectors are usually placed side by side. Pipes are laid in heat-distributing plates.

These devices have a relatively low price and are made of galvanized sheet metal with a thickness of 0.45 to 0.65 mm. The plate has a groove of the appropriate depth for laying the tube with the coolant. It is most convenient to place the long parts of the contour parallel to the lags, this approach will minimize the number of cuts in the beams. When making roundings, care and accuracy must be exercised.

If the minimum permissible radius of curvature is not respected, cracks and leaks may occur. After laying the pipelines of the underfloor heating system, work is carried out on laying the main flooring. Usually, a 50 mm thick calibrated board is used for these purposes, but recently composite materials have increasingly taken its place. Chipboard or QSB boards are attached to the joists with self-tapping screws. When performing this operation, be careful not to damage the tubes.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical