Chimney sandwich pipe: design features and installation recommendations

A beautiful, reliable and durable chimney is the dream of any homeowner.

The most effective way to get what you want is to purchase a sandwich chimney: its pipe is made of special steel that can withstand attacks from the most aggressive substances for a very long time.

In the article, we will consider how to properly install a chimney from a sandwich pipe.

Manufacturers offer sets of parts from which you can assemble an absolutely safe cylindrical chimney of any trajectory with convenient access for maintenance.

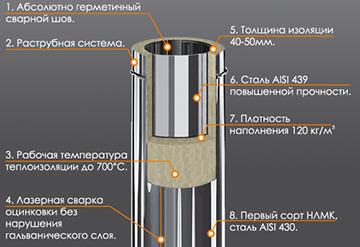

Each part consists of 3 layers, for which the product received the name "sandwich".

The inner layer is made of heat-resistant acid-resistant alloy steel.

The middle layer is stone wool insulation (usually basalt). It does not contain phenol-formaldehyde binders, therefore, when exposed to high temperatures, it does not emit harmful volatile substances.

Thanks to effective thermal insulation, very little condensate is formed in the sandwich chimney and good draft is always maintained.

The outer layer is a protective and decorative casing. It is usually made of steel - galvanized or stainless steel, but chimneys with an aluminum or copper sheath can also be found on sale.

What specific parts are included? First of all, the details of the chimney itself:

What specific parts are included? First of all, the details of the chimney itself:

- pipes;

- bends with different angles of rotation;

- tees with removable cups for collecting condensate;

- pipes with inspection hatches;

- head elements: caps, deflectors, spark arresters, etc.

The kit also includes special parts called cuts. They are installed in places where the chimney crosses ceilings, walls and roofs.

To fix the chimney to the wall, brackets are supplied, and for fastening the parts together, clamps and high-temperature sealant are supplied.

Each part is narrowed on one side, so that it fits snugly into the next one. This connection method (called a bell-shaped connection), coupled with crimp clamps and sealant, makes the smoke duct absolutely airtight.

Specifications of sandwich pipe for chimney

Each product is characterized by the following parameters:

- inner diameter;

- thickness of the heat-insulating layer (usually from 25 to 100 mm);

- steel grade used for the manufacture of the internal (working) part;

- and its wall thickness: from 0.5 to 1 mm.

In addition, various modifications of "sandwich" chimneys may differ in the way the parts are finally fastened to each other. The connection can be bayonet or flanged.

Three-layer pipe

When purchasing a set for a sandwich chimney, first of all, you need to choose the right diameter. Usually they are guided by the following rule: the cross section of the working part of the chimney should not be less than the cross section of the flue pipe of the furnace or boiler.

The requirements of SNiP on heating, ventilation and air conditioning should also be taken into account, in which the cross-sectional area of the chimney is tied to the power of the heat generator:

- up to 3.5 kW: at least 196 sq. cm;

- from 3.5 to 5.2 kW: at least 280 sq. cm;

- from 5.2 to 7 kW: not less than 378 sq. cm.

The thickness of the heat insulator depends on the temperature of the exhaust gases.

The thickness of the heat insulator depends on the temperature of the exhaust gases.

Be guided by the following dependency:

- 250 degrees (gas boilers of low and medium power): 30 mm;

- 400 degrees (powerful gas and liquid fuel appliances): 50 mm;

- 850 degrees (solid fuel appliances, especially coal): 100 mm.

It is important to clarify not only the thickness of the insulation, but also the temperature range at which it can be operated. For example, only special varieties of basalt wool can withstand a temperature of 850 degrees.

The steel grade of the working pipe should be selected in accordance with the type of heat generator. For a low-power wall-mounted gas model or a water heater column, even ordinary galvanization is suitable. Floor-standing gas boilers and low-power solid fuel boilers should be connected to a chimney made of AISI 439 steel with the addition of titanium, and powerful solid fuel appliances to AISI 316I and AISI 321 steel products.

For coal stoves and long-burning wood stoves (with partial gas generation), chimneys are made of AISI 310S steel.

In this case, the wall thickness of the inner pipe should also be taken into account: the higher the temperature of the flue gases (most of all it is in coal-fired furnaces) and the more aggressive the condensate is (long-burning furnaces with partial pyrolysis), the thicker the pipe should be.

Not always the inner pipe of the chimney is welded. In some modifications, a seam seam is used. Such products are quite suitable for gas equipment.

Finished steel chimney

It is better to purchase chimneys from well-known manufacturers and preferably in large, trustworthy stores. These products are easy to manufacture, so many try to fake them.

In fakes, low-quality steel and cheap insulation are used, which, when exposed to high temperatures, fumes (gives off harmful fumes). Sometimes they can be recognized by a too thin shell that does not hold its shape well.

Sandwich pipes have a large number of advantages - they are easy to install, and besides, they are durable. How to install - this article is devoted to this.

Sandwich pipes have a large number of advantages - they are easy to install, and besides, they are durable. How to install - this article is devoted to this.

How to choose polypropylene pipes for heating, read.

Typically, water pipes are laid below the freezing level of the soil and then they are protected from freezing. But this method of laying is not always possible, then the pipes have to be additionally insulated. At this link, we will consider how to choose a heater for pipes in the ground.

Three basic rules for installing sandwich pipes

When installing a sandwich pipe yourself, consider the following:

- Directly to the boiler you need to connect a simple pipe, not a "sandwich". Otherwise, sintering of basalt wool will occur, followed by its transformation into stone. This will damage the chimney.

- Between the surface of the chimney and building structures made of non-combustible materials there must be a distance of at least 250 mm. The pipe must be separated from combustible materials by 450 mm. The distance between the pipe and wooden rafters or lathing can be reduced to 130 mm, provided that the wood is wrapped with non-combustible heat-insulating material, such as mineralite.

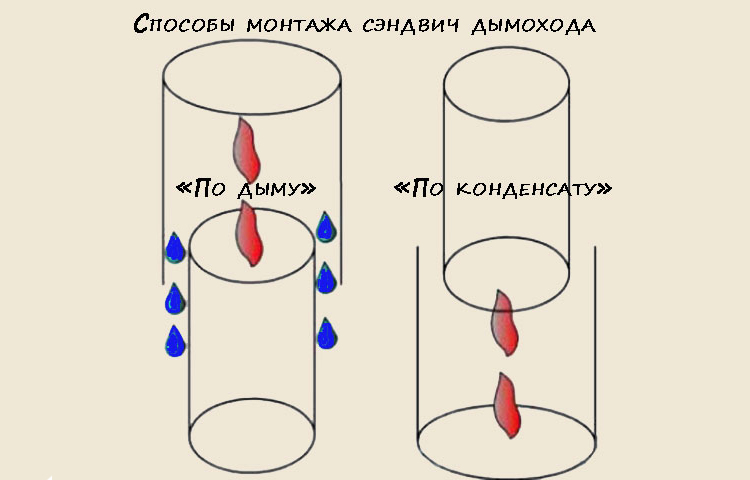

- It is better to collect vertical sections “by condensate” (the upper pipe is inserted into the lower one), since this method of connection is guaranteed to protect against leakage of condensate into the insulation. At the same time, it is better to place this part of the chimney outside, since when connecting “through condensate”, smoke leaks are possible.

Ways to install a sandwich chimney

Horizontal sections should be connected “by smoke” (the previous pipe enters the next one). They can be fearlessly placed indoors, since with such a connection, smoke does not leak outside the chimney.

Preparation for installation work

First of all, you need to develop and draw a chimney diagram. There are two ways:

- Lead a horizontal section directly from the boiler through the outer wall, so that the vertical part of the chimney is located on the street. This option is simpler: a hole in the wall will need to be made only once and the chimney can be assembled "by condensate" at an amateur level - smoke leakage on the street is not terrible. But with this solution, the draft will be worse, and condensate will form in large quantities.

- Place the chimney inside the building, passing it through the floors and the roof.

This solution provides the best traction and a minimum of condensate, but it is more complex:

- You will have to cross building structures several times, including the roof, which is especially difficult.

- A dilemma arises: on the one hand, the vertical section should be collected “by condensate” so that there is no risk of it seeping into the insulation; on the other hand, it would be desirable to assemble the chimney located inside the house “by smoke”, since with this method the smoke is guaranteed not to enter the room. In any case, high precision assembly will be required so that all connections are absolutely tight.

Chimney installation

In order not to have to empty the condensate trap often, purchase a sandwich chimney with a drain cock in a tee. After connecting it with a hose to some container, it is enough to turn the valve to discharge the accumulated condensate.

The chimney should be designed in such a way that the joints between the individual parts are always visually accessible, that is, they cannot be placed in places where they pass through walls or ceilings.

At the stage of preparation, the walls made of combustible materials (mainly wood), along which the chimney will be laid, should be covered with a steel sheet lined with mineral wool board.

Do-it-yourself installation of a chimney from sandwich pipes: procedure

Consider how to assemble a chimney from a sandwich pipe with your own hands.

Having attached an ordinary pipe (without insulation) to the boiler, we begin to build up a sandwich chimney.

Before connecting two parts, their inner pipes need to be pushed out of the thermal insulation by 100 - 150 mm - it will be more convenient to work this way. Inside, the wider part (bell) is coated with a heat-resistant sealant.

Having connected the parts, the socket must be compressed with a clamp, after which the thermal insulation with the casing moves to its original place.

After installing the tee with a condensate trap, a support bracket is attached to the wall under it. It will support the weight of the entire vertical section of the chimney.

Holes in the wall or ceiling are as follows:

- The edges of the hole are insulated with mineral wool.

- Next, a cutting is installed that has the form of a sleeve.

- The chimney pipe is brought into cutting strictly in the center. It must be fixed in such a way that it remains possible to freely elongate when heated.

- On both sides, the hole is sheathed with a steel sheet on a lining of mineral wool cardboard.

Roof cutting is used to pass through the roof. Its execution will depend on the angle of inclination of the roof - this must be taken into account when ordering a chimney. An apron is put on the pipe, the edges of which on the higher side are brought under the roofing, and on the lower side they are laid on top of it. The places where the apron fits the roofing material and the pipe are coated with sealant.

You will also need to install a snow retainer section. As the name suggests, this element prevents damage to the chimney when snow melts.

If the house has a gas boiler, then there must be a chimney. - the best solution compared to conventional systems. Consider what is the advantage of a coaxial chimney.

If the house has a gas boiler, then there must be a chimney. - the best solution compared to conventional systems. Consider what is the advantage of a coaxial chimney.

The requirements for installing a gas boiler in a private house are set out.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical