How to make a metal stove for a bath

There are a lot of metal stoves for a bath on sale, but good ones cost a lot of money. If you have sufficient experience in welding metal, you can make the furnace yourself, according to your size. About how to make a stove for a bath from metal (sheet), drawings and photos - further.

There is a significant difference between the modes of soaring in a bath and a sauna. In the sauna, the air temperature is very high - from 85C and much higher. At such a temperature, the humidity simply cannot be high - you will immediately get burned, and crumble in five minutes. And it is really small, about 5-15%. In the Russian steam room, the temperature is kept within 55-65°C, occasionally rising to 70°C. At such temperatures, the humidity "catch up" more - 50-60%.

To meet these different challenges, different approaches to building a furnace are required. The sauna requires the largest area of contact between the body of the furnace and the surrounding air and the acceleration of the passage of air flows along the walls. Everything is subordinated to the task of heating the air in the steam room as soon as possible. There is a heater, but it is small, open, usually located above the firebox. The stones in it warm up to a maximum of 200-250 ° C, since they give off a lot of heat to the surrounding air. You can get a little steam from such a heater. But in the sauna you don’t need much - one / two ladles will give 15% humidity. Just can't take it anymore.

In the Russian steam room, the task is different - not to overheat the room and achieve a large amount of steam. Moreover, the steam must be of a certain condition - it must consist of very small droplets. It is also called "dry" and it has a high temperature - about 130-150 ° C. Under this condition, after soaring in the body, lightness and a surge of strength are felt. Such steam is obtained only from hot stones, the temperature of which is at least 500 ° C. To reach it, the stones are “packed” inside the furnace - a box is placed in it - a closed heater.

As you can see, there are solid design differences. They must be kept in mind.

Homemade stoves for the Russian bath

What else should be kept in mind when designing a stove for the Russian steam room mode? The fact that having heated metal walls to keep the temperature within the required 60-65 ° C is unrealistic. Be sure to recycle. At the same time, hard IR radiation comes from the walls of the furnace and it is difficult to be nearby. The problem is solved in two ways:

Another thing to talk about is seams. In home-made metal furnaces (in factory ones, in principle, too), burnout often begins precisely from the seams. In production, this problem is circumvented with the help of bent structures. In the upper part, they try to avoid seams altogether. When making a do-it-yourself sauna stove, you are unlikely to be able to bend a sheet of metal 6-10 mm thick, so there is only one thing left - to make the seams as high quality as possible.

Kamenka: what size and where

The required number of stones depends on the volume of the steam room (provided that it is normal). Different sources have different recommendations with more or less - from 20 to 40 kg per 1 m 3. In principle, the more stones, the easier it is to get the required amount of steam, but on condition that the stove has enough power to heat them.

The problem is that stones of different breeds have different densities, and, consequently, the same mass occupies a different volume. In principle, for an average steam room with a volume of 12-14 m 3, the dimensions of the heater are approximately the following: 30 * 40 * 30 mm. The parameters can be slightly changed, made wider / narrower / higher - look at the design of the furnace.

The ratio of the volume of the furnace to the volume of the heater is a complex heat engineering calculation, which not even every heat engineer is able to master. It is much easier to use ready-made drawings or experimentally determined proportions. As a minimum, the volume of the firebox "free" from the heater should not be less. Better if even more by about 30-50%.

A little about where in the firebox it is best to place a box for stones. Everyone has long come to the conclusion that the highest temperature is in the upper part and at the back wall. This is where it makes sense to place the container. Firstly, part of the thermal load from the roof of the furnace will be removed, and secondly, the stones will heat up well.

Do not forget about the maintenance of the heater and that water must somehow get there. The service hatch must be positioned in such a way that you can easily reach the farthest edge with your hand. And the water supply deep into the heater must be organized so as not to get burned. Usually, a tube or a system of tubes is inserted, which diverge over the entire plane of the stone container. From the side of the room, this tube ends with a funnel. The pipe is lined with stones. When water is supplied to it, it is distributed over the surface of the heater / stones and evaporates.

Drawings of homemade metal sauna stoves

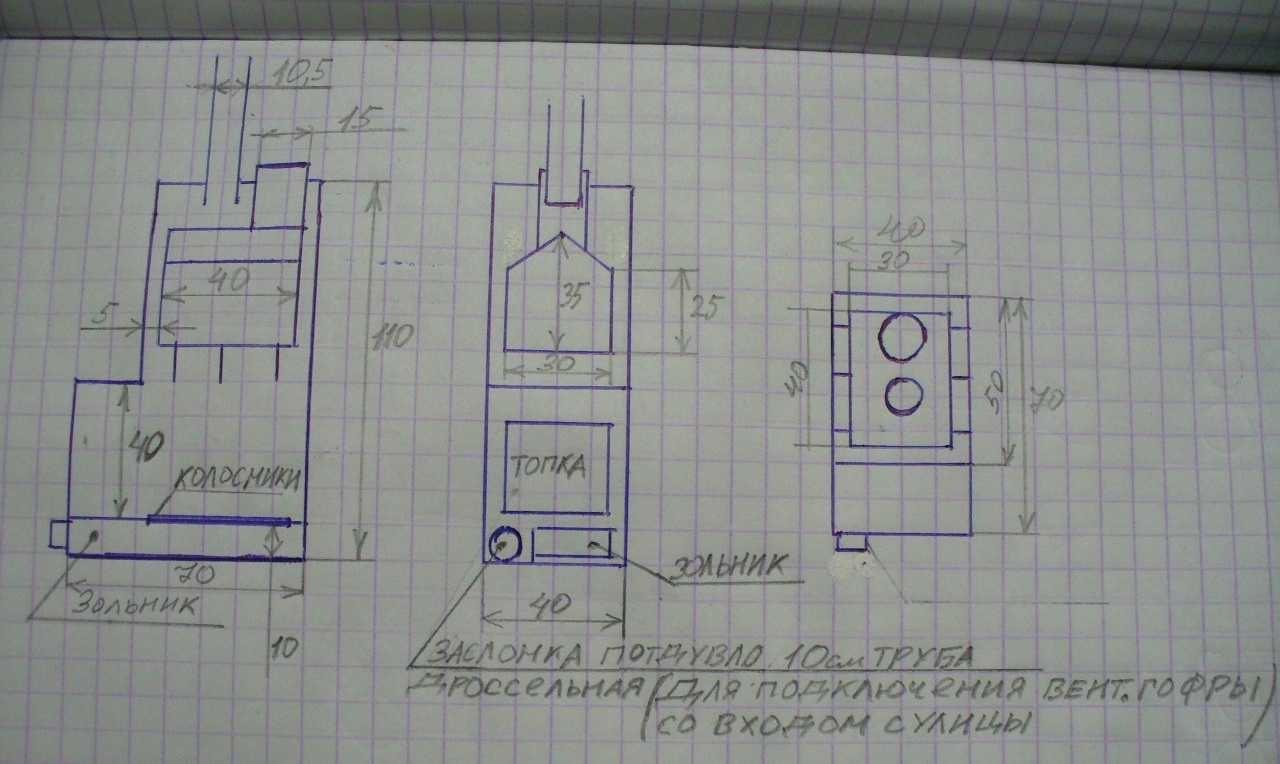

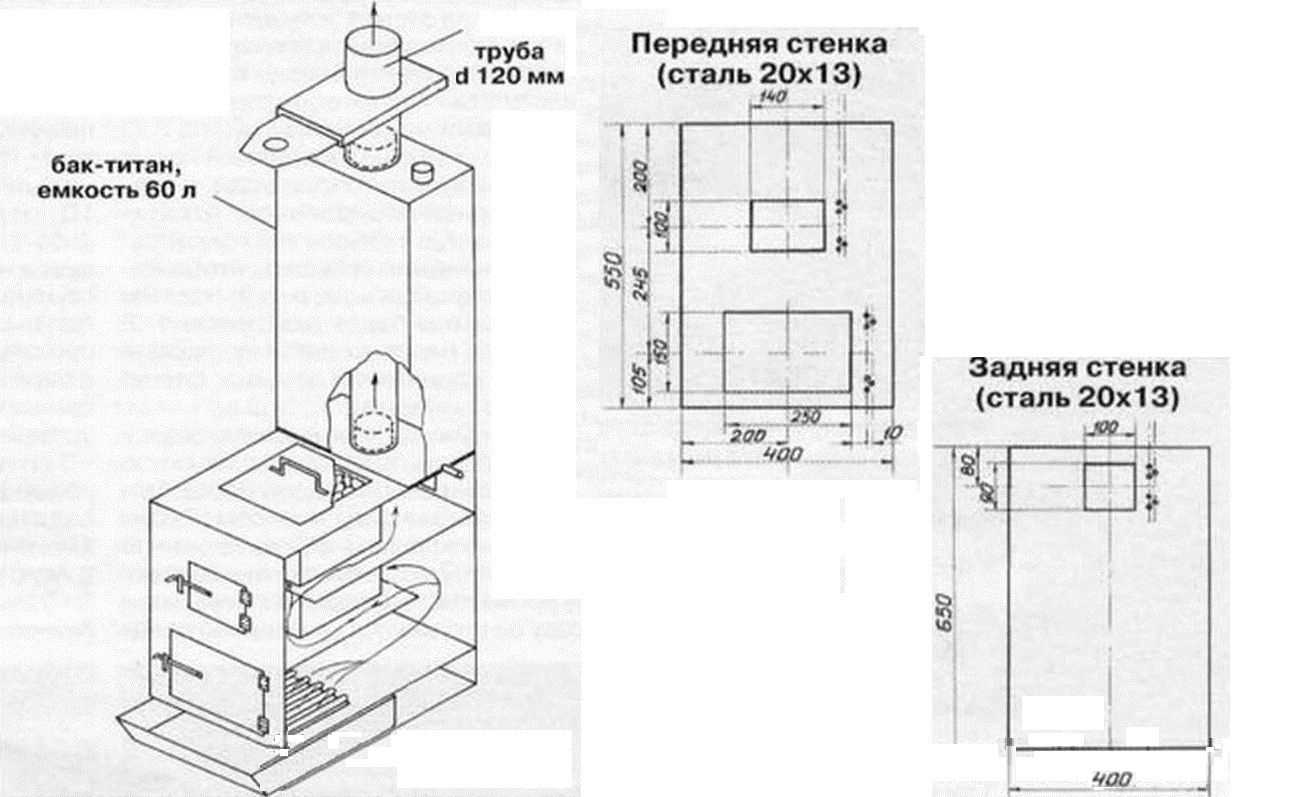

This stove is designed for a steam room 2 * 3 * 2.3 m. It was cooked from sheet metal 3 mm thick.

To activate combustion, an additional air duct is connected, laid from the street. Other solutions include stiffeners (corners) welded to the sides of the firebox in the upper part of the firebox so that the metal does not bend when heated.

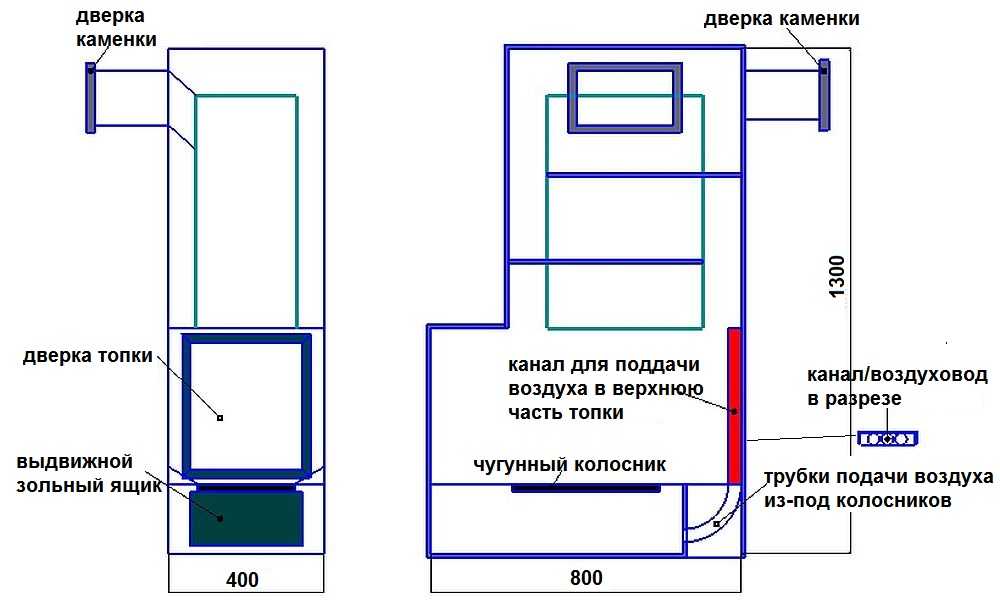

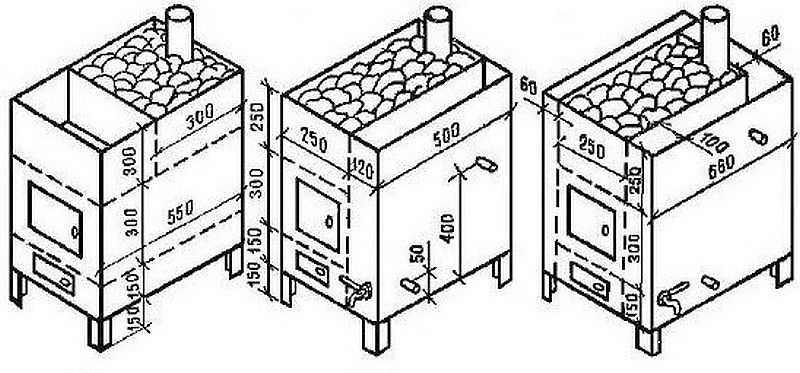

The following scheme of a metal stove for a bath is made with air supply to the top of the firebox. These are the so-called furnaces with afterburning gases. A metal plate is welded on the back wall. In the gap between this plate and the rear wall of the furnace, air is supplied from under the grates with the help of air ducts. This simple, it seems, the device solves two problems at once. Firstly, it cools the back wall, reducing the likelihood of it burning through. Secondly, the air is supplied to the upper part heated. Flue gases heated to high temperatures are concentrated there, most of which are combustible (up to 80%). When these gases mix with heated air, combustible substances ignite, the temperature in the upper part of the furnace becomes even higher, the stones are heated to higher temperatures. At the same time (when using dry firewood), much less fuel is required. Many long-burning stoves are built on this principle, but it has recently been used in sauna stoves.

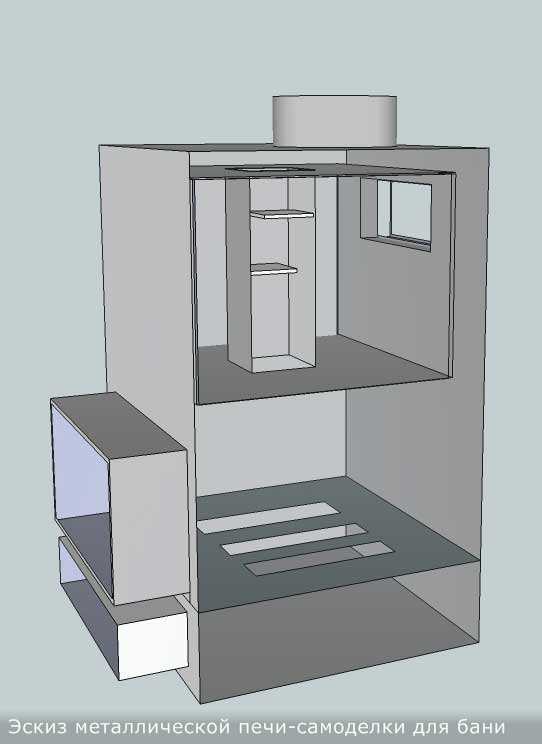

Approximately the same model, but without afterburning, is made in a different format. Here the dimensions are not indicated, but it is easier to understand the proportions and arrangement of various elements.

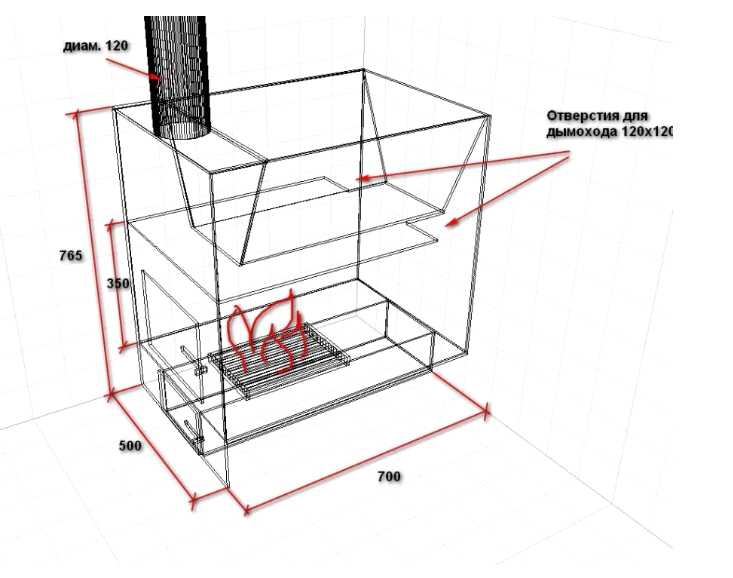

Volumetric model of a home-made stove-heater made of metal

In this case, the volume of the furnace is about 130% of the volume of the heater. Normal ratio. The chimney is shifted back, which is not always good - difficulties may arise when installing the chimney - it can rest against the ceiling beam - you will have to bend the chimney, which is undesirable. So think about the location of the pipe.

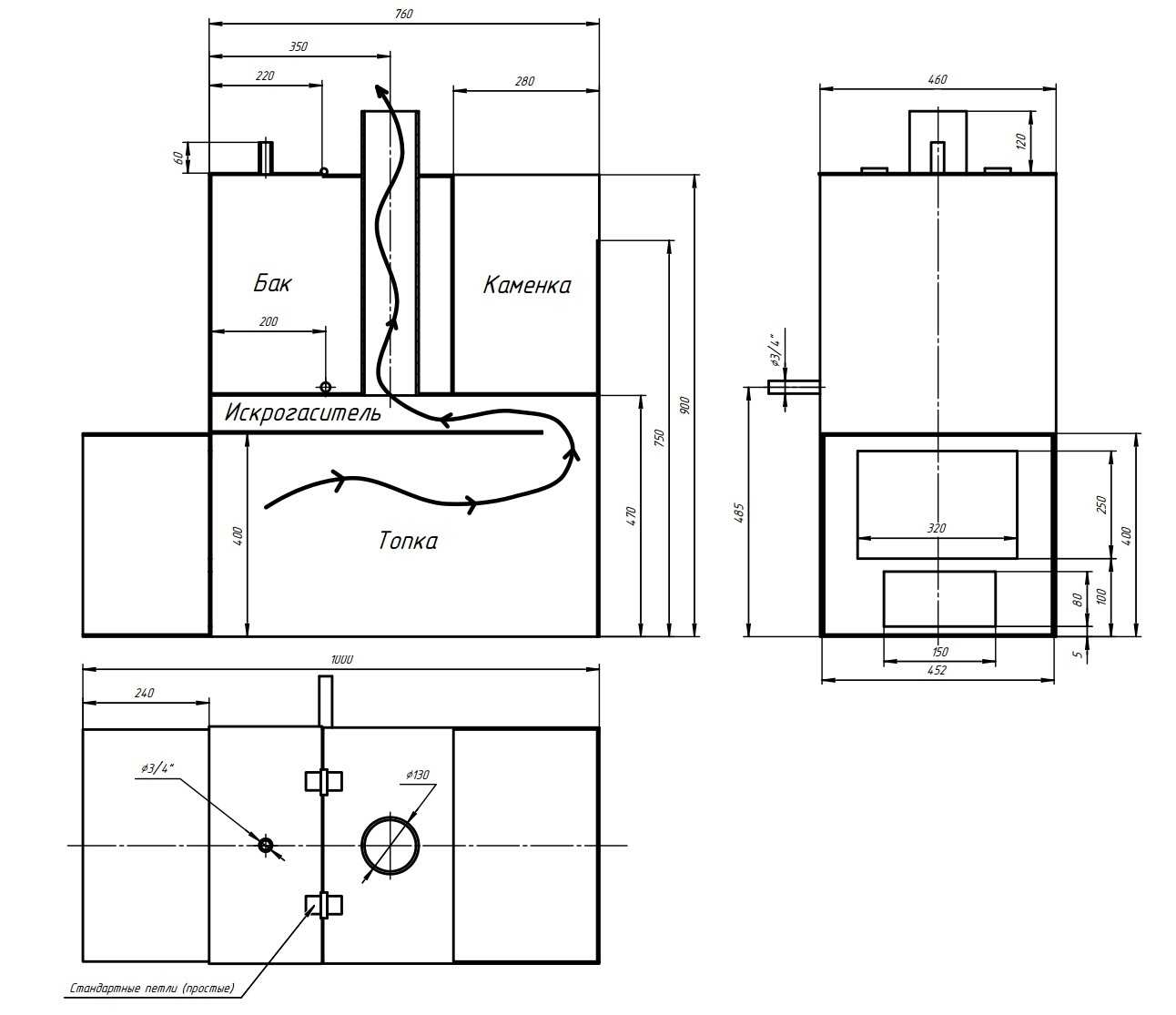

Even among bath lovers, there are constant disputes: a tank for heating water in a steam room is good or bad ... Some regulate the humidity by opening / closing the tank lid. This option suits them. Others say that this steam is “heavy”, and they take the tank to the washing compartment, and heat the water in it by building a heat exchanger into the furnace and connecting it to the tank with pipes. The next scheme is a furnace in a metal bath with a water tank.

The design is competent - with the help of a “spark arrester”, the path of flue gases is longer, it stays in the furnace longer, it heats the walls better. If you do not want a tank, you can put stones in its place.

An interesting option with a tank, which is located at the back of the oven. The chimney is moved back, and passes through the tank. The height of the tank is large, the heat removal will be effective - the temperature of the chimney at the exit from the tank will not be large for sure.

Interestingly arranged stone. It is not very large, but for small and medium steam rooms its volume is enough. It closes with a lid, which, on the one hand, is not very convenient: closing the lid after water has been supplied to the stones will be problematic. On the other hand, it is convenient to maintain.

![]()

How to make a sauna stove

As already mentioned, the main task of this type of heating devices is to quickly “catch up” with the required temperature and be able to maintain it. There is a simple solution - put a fan that will blow over the walls of the furnace, accelerating heating.

Approximately the same function is performed by the casing-convector. This is the casing around the furnace body. A gap of 1.5-2 cm remains between it and the wall of the furnace. Air is sucked into this gap from below. It passes along the walls, heats up, at the same time cooling the walls. Then it rises up, spreading heat throughout the steam room.

If the furnace body is made of thick metal, then the casing can also be made of thin. It rarely heats up to high temperatures, and burnout does not threaten it. If in the sauna stove the heater is located at the top, above the firebox, as in the photo, then holes can be made in the body to ventilate the heater. Then part of the air that rises along the walls will enter the heater, blow over the stones and heat up even more. Such a heater is called ventilated. It is good for dry air saunas.

Drawings and diagrams

The design of sauna stoves is simpler. You need a firebox of a normal size, in which large logs are placed. In the upper part, above the upper part of the firebox, the sides of the heater are welded, the volume of which is usually 20-25 liters. Variations can be in width / height / depth, but there are no special tricks.

Installing a tank for heating water in the steam room of a sauna is not the best idea. You won't be able to control the humidity, and it's easy to get burned at high temperatures. However, several options for installing tanks in the photo above.

Another type of heater is inside the firebox. If desired, you can make a lid on it and such an oven can be used in two modes - with an open lid for dry steaming, with an open one - to get more steam.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical