How to assemble and make a solar collector with your own hands

Using free solar energy for heating and hot water at home is quite tempting. This can be done with the help of a solar installation, the main element of which is a solar collector. But one of the limiting factors in the use of solar plants is their relatively high cost. But you can make them yourself. Therefore, in this article we will talk about the principle of their work, types, as well as how to assemble and make a solar collector with your own hands for heating a house and providing it with hot water from various improvised materials.

Solar collectors are heat exchangers that capture the energy of the sun and convert it, depending on their type, into the thermal energy of the liquid or air circulating in them. The liquid or air heated in the collector is used for hot water supply or home heating directly or through additional heat exchangers, for example, through indirect heating boilers. The main task of any such collector is to "catch" as much solar energy as possible and transfer it to the coolant circulating in it with the least loss.

Types of solar collectors

By the type of coolant circulating and heated in them, solar collectors can be:

- liquid;

- Air.

According to the design features and type of heat exchange surface, they can be:

- in the form of a container;

- Pipe;

- flat;

- Vacuum.

liquid solar collectors, as their name suggests, are filled with a liquid that circulates and heats up in them. It can be ordinary water or non-freezing liquid (antifreeze). In the first case, heated water can be supplied directly to the hot water supply system, to a storage tank or to an indirect heating boiler, and in the second case, only to the boiler. Such collectors can be used both for providing the house with hot water and for heating it. It all depends on the power of the solar plant.

Air solar collectors are mainly used for home heating. Cold air from the room is supplied to such a collector, heated there and fed back into the room using natural or forced circulation.

Most of these types of solar collectors can be made by yourself. Having shown your imagination, you can use various improvised materials for their manufacture: plastic or metal containers, pipes, hoses, used radiators and even beer cans. Below, we will look at several designs of solar collectors that you can make yourself using these and other improvised materials.

Solar collector made of metal or plastic container

The simplest solar collector can be made by hand from a metal or plastic container with a volume of 50-100 liters. This is the so-called summer shower, which is quite common in rural areas and cottages.

The best metal version of such a collector would be a stainless steel container painted black on the outside. True, the cost of such a new capacity is quite high. Therefore, you can use used containers. For example, weld a tank from two stainless containers from old washing machines. You can also use ferrous metal containers, galvanized or painted with waterproof paint. Plastic containers are good because they are lightweight and do not corrode, but they are short-lived, as plastic does not tolerate ultraviolet radiation.

The barrel is installed on the south side of the roof of the house or directly above the outdoor shower. If the barrel is not hermetic, then the supply of cold and the intake of heated is carried out from below. The pressure of warm water at the point of intake will be determined by the installation height and the water level in the barrel. It is filled with cold water, which is heated for some time, and then used.

If the barrel is airtight, then cold water is supplied from below, and warm water is taken from above. Such a container is connected to a cold water supply system (pumping station) and when heated water is taken into the barrel, cold water enters from the system, displacing the warm water to the upper part.

The advantage of such a solar collector is its simplicity. It is easy to do it yourself. If the barrel is cylindrical, then it is well lit by the sun's rays throughout the day.

The disadvantages of this design:

- It can only be used in the warm season;

- ineffective in windy weather and when the sun is covered by clouds;

- Large inertia - relatively long-term heating of water;

- Water heated during the day cools down at night.

How to make and assemble a solar collector from metal pipes

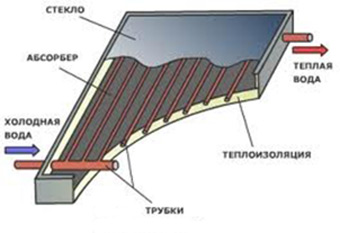

A simple and effective solar collector can be made by hand from thin-walled metal tubes: steel, copper or aluminum. It is a tubular heat exchanger (radiator), which is placed in a heat-insulated box made of boards, plywood or chipboard.

The best material for the manufacture of a solar collector radiator is certainly copper. It has excellent heat transfer and is not subject to corrosion. But this material is quite expensive. Aluminum tubes, although cheaper than copper tubes, can be difficult to weld.

The cheapest and easiest way to make a heat exchanger is from steel pipes. They can be welded using a conventional welding machine. For the manufacture of such a radiator, steel pipes with a diameter of ½ - 1 ″ can be used. At the same time, pipes of a larger diameter and with a greater wall thickness are used to supply cold and discharge heated water, and for the heat exchanger itself, pipes of a smaller diameter and with a smaller wall thickness are used.

Scheme of a solar collector radiator from pipes

The dimensions of the solar collector radiator, and therefore the length of the pipes, depend on the required power. But if you make it too big and bulky, then it may be difficult to assemble and install it. Therefore, it is best if its dimensions are within: width - 0.8-1 m, and height 1.5-1.6 m. The power of such a collector will be in the range of 1.2-1.4 kW. If you need to increase the power of the solar plant, then you can make several of these collectors and connect them together.

In this case, for the manufacture of a solar collector radiator, we need two thick-walled pipes with a diameter of ¾ - 1 ", 0.8-1 m long and 12-18 thin-walled tubes with a diameter of ½ - ¾" and a length of 1.5-1.6 m.

In thick-walled pipes that will serve to supply and drain water, holes are drilled for thin-walled pipes of smaller diameter in increments of 3-4.5 cm. One end of such a pipe is muffled, and a thread is welded or cut into it to the other.

The pipes are welded into one radiator design and painted with black matte paint.

Now you need to make a heat-insulated box for the radiator. To do this, you can use moisture-resistant plywood, chipboard, OSB or edged boards. But waterproof plywood (FSF) would be best.

The dimensions of the box are calculated taking into account the dimensions of the radiator, the insulation layer and the gaps between them. The height of the sides of the box should take into account the thickness of the insulation, the pipes themselves, as well as their distance from the bottom and the glass or polycarbonate covering the box (10-12 mm). In the upper end of the sides, a selection (groove) is made for glass or polycarbonate. Holes are made in one of the side boards for water inlet and outlet pipes. The elements of the box in one design are connected using self-tapping screws.

As a heater, you can take expanded polystyrene, ordinary (polystyrene) or extruded, as well as mineral wool with a density of at least 25. A layer of insulation (at least 5 cm) is mounted on the inside on the bottom and on the sides of the box. A sheet of galvanized metal or a layer of thick foil is laid on top of it, which are also painted matte black.

The radiator is fixed in the box with the help of clamps or clips, the presence of which must be provided at the stage of manufacturing the box. The location and dimensions of the clamps depend on the design of the radiator and the size of the pipes.

From above the box is covered with glass or polycarbonate. The cover is placed in the grooves (sample) and securely fastened. All joints are sealed.

The solar collector is ready. It must be installed on the south side of the house with a slope of 35-45 ⁰ to the horizon. On its basis, it is possible to manufacture a solar plant, which includes a heat-insulated warm water storage tank with a capacity of 100-200 liters or an indirect heating boiler.

Installing a prefabricated solar collector

Collector made of plastic or metal-plastic pipes

A do-it-yourself solar collector can also be made using plastic HDPE or PP pipes. Although the heat transfer of plastic is 13-15% less than that of metal, it is much cheaper than copper and does not corrode like black steel.

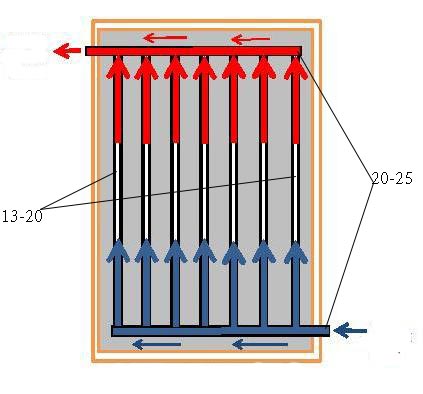

To make a simple do-it-yourself solar collector, HDPE pipes with a diameter of 13-20 mm can be laid in a box in the form of a spiral, fixed with clamps and painted black.

Variant of a solar collector made of plastic HDPE pipes

Polypropylene pipes bend poorly, but they are easy to connect by soldering using special fittings. Underwater pipes (horizontal collectors) can be made from PP pipes with a diameter of 25 mm, and the heat exchanger itself from pipes with a diameter of 20 mm. We paint the finished radiator of the solar collector black and mount it in a box, which is made in the same way as in the version with metal pipes.

You can also make a radiator for a solar collector from metal-plastic pipes. At the same time, they can be connected using fittings, in the same way as PP pipes, or laid in zigzags ("snake") or in the form of a spiral. The second option is easier. But it must be remembered that the bending radius of metal-plastic pipes should not be less than 7 pipe diameters.

Variant of a solar collector made of metal-plastic pipes

Solar collector from refrigerator radiator

If you have a radiator from an old refrigerator, then you can also use it to make a solar collector with your own hands. To do this, it is necessary to thoroughly rinse it to clean it of remnants of freon. During flushing, you should also check its tightness - for leaks. If they are, these places must be sealed with cold welding or soldered.

Radiator from an old fridge

The radiator itself must be painted with black matte paint.

It is also necessary to provide a way to connect the inlet and outlet pipes to the solar storage tank or other elements, depending on its type. To do this, for example, you can solder threads of the required size at the ends of the tubes or stretch rubber hoses, securing them with clamps.

The thus prepared solar collector radiator is fastened with clamps in a heat-insulated box, made according to its dimensions. The box itself can be made in the same way as in the previous cases.

Air solar collectors for home heating

In addition to the solar collectors described above, in which the liquid is heated using solar energy, you can make your own structures in which the air is heated. Such a solar collector can be used for additional heating of the house. Cold air from the room is fed into its heat exchanger, heated there and fed back into the room.

The heat exchanger for such a solar plant can be made of sheet metal, thin-walled metal pipes, and even cans of beer or other drinks. We will consider the designs of such collectors in another article of this section.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical