What chimneys are best for a bath? How to make a chimney for a bath through the ceiling? Installation of chimneys for a bath

Previously, sauna stoves did not provide for a chimney. Then the ancestors of modern people washed in black. Today there is no more need to inhale and there is no soot - all this is true, because modern baths are created according to new design laws. Basically, people build steam rooms on their own. You should also build a stove and build a chimney for a bath. But we must remember that this is a very responsible matter that requires a serious approach. You can accidentally make one small mistake, and the steam room will not work as intended. Therefore, it is very important to work slowly and very carefully.

Types of smoke exhaust structures

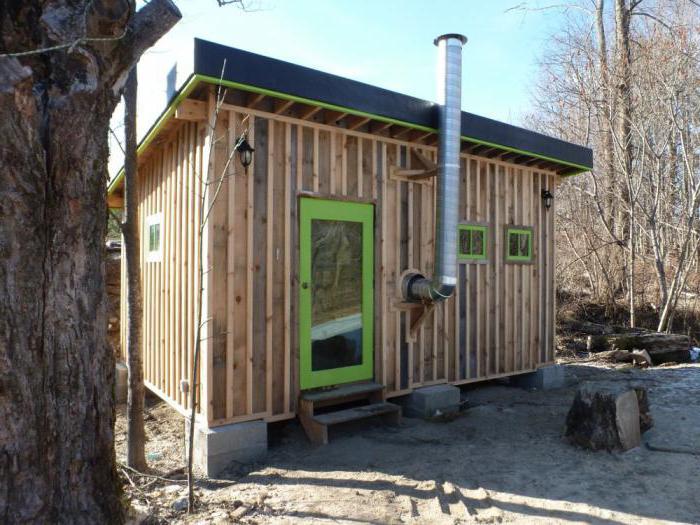

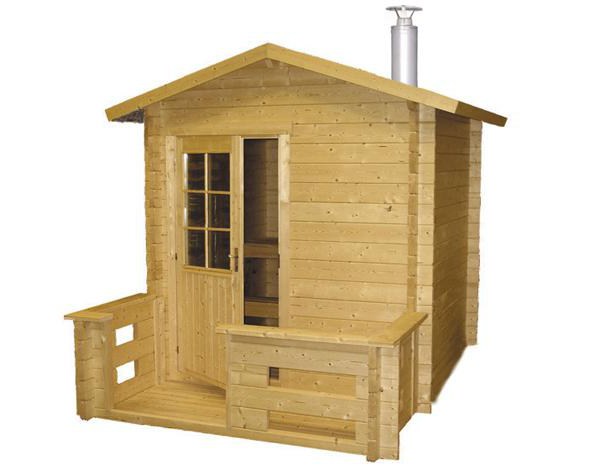

The chimney for a steam room can be external or internal. In our country, you can often find it is the internal options. Among their advantages is the absence of violation of the architectural style, as well as saving heat in the room. All heat remains inside the steam room. Internal systems are good because they have better traction. They are also easier to care for. Even the internal structure does not need insulation.

External systems are more like American traditional chimneys. They were previously used by the Americans on their ranches. They differ in quite an interesting appearance. If you decide to build an external solution, then there is no need to make a hole in the roof and ceiling, which definitely has advantages. The wall for the chimney inside must be at least 12 cm thick, and for the outer wall, the thickness must be from 38 cm.

Popular schemes for arranging bath chimneys

How is the smoke outlet structure arranged? Any element is a structure of pipes, flanges, fasteners. The main requirement for this building is the ability to operate at high temperatures without any changes in the properties and emissions of combustion products.

So that the chimney for the bath does not lose large amounts of heat, it is located as close as possible to the inner wall.  In this case, you will get the most effective traction. And if there are reasons why this configuration is not possible, then a thicker wall is created.

In this case, you will get the most effective traction. And if there are reasons why this configuration is not possible, then a thicker wall is created.  Thickness parameters depend on temperature. For example, if the temperature is lower than 20 °, then it is necessary to make thick walls, from 38 cm. If there are severe Russian frosts in the region, then the thickness should be about 58-65 cm.

Thickness parameters depend on temperature. For example, if the temperature is lower than 20 °, then it is necessary to make thick walls, from 38 cm. If there are severe Russian frosts in the region, then the thickness should be about 58-65 cm.

When there is more than one stove in the steam room or bath, then each of them must be equipped with its own chimney. Otherwise, the thrust will lose strength. Smoke extraction experts recommend the following. In cases where it is not possible to build several systems for furnaces, it is necessary to equip a cutting system at a height of about 75 cm. It is also important to consider that the inner surface of the future chimney is as smooth as possible. If there are any roughness inside, then soot will accumulate on the walls. This may increase the risk of fire.

The simplest chimney

This element will be based on a stainless steel pipe. And besides it, you need to prepare one elbow with a diameter of 20x120 cm made of galvanized steel, two elbows of 16x120 cm, three of stainless steel of 16x10 cm. You will also need a tee with a diameter of 16 cm and a plug to it. You also need a fungus that is suitable in size. The diameter of the chimney for the bath specifically in this case will be 16 cm.

Prepared pipes should be connected to each other using self-tapping screws.  It is necessary to make a hole in the ceiling slab, the diameter of which will be 16 cm. Next, it is necessary to remove the soft roof and thermal insulation from the roof surface 15 cm from the hole made.

It is necessary to make a hole in the ceiling slab, the diameter of which will be 16 cm. Next, it is necessary to remove the soft roof and thermal insulation from the roof surface 15 cm from the hole made.

The section of the pipe that will be outside is wrapped with basalt wool. The layer should be approximately 16 cm. You should also additionally wrap the cotton wool with an asbestos cord. Then a pipe with a diameter of 20 cm is connected, which is fixed and carefully smeared with bituminous mastic. An asbestos cord is laid in the gap between the two pipes. This is necessary to protect from rain.

This is how you can independently design and install stainless chimneys for a bath. This is a very affordable solution.

Features for different types of ovens

Modern equipment for baths is equipped with brick smoke exhaust systems.  Pipes made of ordinary or stainless steel are also used. Each material has advantages and disadvantages, and there are also certain nuances in the installation.

Pipes made of ordinary or stainless steel are also used. Each material has advantages and disadvantages, and there are also certain nuances in the installation.

for saunas for stoves metal

After the installation of the furnace is completed, you can immediately begin to equip the chimney. The first step is to attach several expansion supports to the pipe. Well, if these are pipes made of asbestos or "Sandwich". The latter can withstand significantly higher temperatures, unlike other analogues. However, you should not allow direct flame exposure to such a pipe. That is why a steel pipe is first mounted, and then, after the first bend, there is a sandwich or an asbestos-cement structure.

Now it remains only to organize the protection of the upper part from the rain. A stub might work for this. From below, another pipe is mounted on the pipe, which will then facilitate the process of draining condensate and cleaning.

If the oven is brick

This chimney for a bath is easy to build with your own hands. When a row of masonry blocks the stove, the construction of the chimney system begins.

So, on the 21st row of brickwork, it is necessary to form two channels. Then they will be merged. Further - on the right, the space above the core should be blocked. The gap between the core and the masonry will be 2-3 cm. Any voids are filled with mineral wool insulation. With 22 rows of masonry, the opening will already be closed, and after that you can start laying and shifting the channels to the middle. So that this overlap does not crack in the future, it is advisable to lay another row of masonry above the core of the furnace.

For those who managed to build a brick oven, making a chimney will not be difficult. The main thing is that there are no cracks. Also, the norm for the cross section of the pipe should not be exceeded. Otherwise, the gases will quickly cool.

How to make a chimney for a bath through the ceiling

Often modern baths are built from pine. This wood sometimes overheats. The process of smoke passage must be created with the utmost care. The wall must be protected by any non-combustible materials. You can slash steel sheets, mineral wool or brickwork is also suitable.

Another effective way of protection is a special ceiling-passage unit.  To do this, cut holes in the ceiling where this very box will be installed. After this operation, a pipe is pulled through the knot. It, in turn, must be insulated on each side.

To do this, cut holes in the ceiling where this very box will be installed. After this operation, a pipe is pulled through the knot. It, in turn, must be insulated on each side.

At the next stage, the pipe is erected above the roof. Its height must be at least 1.5 m. When it passes through the roof covering, it is necessary to apply a sealing cover. With this operation, it is possible to hermetically connect the chimney pipes.

In order to get good traction and a long service life, you need to clean the pipe from accumulated soot and debris once every six months. And then the bath will please its owner for a very long time.

Bath pipes

The chimney plays a very important role in creating a comfortable microclimate. The choice of pipe material for it is also important. The pipe is not only a chimney system, but safety in case of fire, as well as health. Let's find out which chimneys are best for a bath.

The pipe in the steam room can be made from a variety of materials. However, it is best to use stainless steel for this. This material has a lot of important characteristics, such as resistance to high temperatures, light weight, ease of use, good traction, resistance to aggressive environments. The best chimney for a bath is made of stainless steel.

Asbestos cement pipes are not very desirable. They do not comply with fire safety standards.  When exposed to high temperatures, a product made of this material may collapse and a fire will occur, which is very dangerous in a steam room where the walls are made of wood. This is a rather dubious economy.

When exposed to high temperatures, a product made of this material may collapse and a fire will occur, which is very dangerous in a steam room where the walls are made of wood. This is a rather dubious economy.

Ceramics is reliability and durability. Such chimneys are able to withstand high temperatures up to 600 degrees. But for the bath, these pipes are also poorly suited. It's all due to the weight. They are definitely not suitable for wooden structures.

Sandwich

This is the modern version. Chimneys for a wood-burning bath are assembled from it.  This product consists of two pipes. Non-combustible insulation is provided between them. Modern materials are used as it, such as basalt or ceramic wool, vermiculite. The smaller pipe acts as a chimney. The big one is the outer casing. Its task is to keep the insulation dry. The casing can be made of galvanized or stainless steel.

This product consists of two pipes. Non-combustible insulation is provided between them. Modern materials are used as it, such as basalt or ceramic wool, vermiculite. The smaller pipe acts as a chimney. The big one is the outer casing. Its task is to keep the insulation dry. The casing can be made of galvanized or stainless steel.

These are the types and everyone can make such a design with their own hands.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical