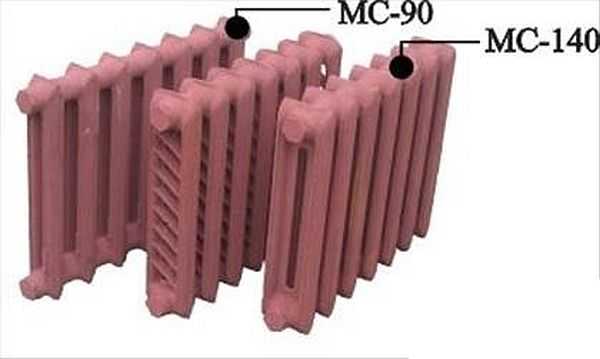

MS-140 - a cast-iron classic of the "Soviet" times

Cast iron heating radiators MS 140 can be called an undying classic. Despite the abundance of different models of heating appliances from the same cast iron, this one - still an "accordion" from Soviet times - is still in demand. It is produced in most countries that were previously part of the USSR. They are precisely produced in Russia, Ukraine and Belarus. It is possible that production has been established in other countries, but why transport goods to distant lands if there are factories nearby.

Characteristics and features

The secret of their popularity is simple: in our country, such a coolant in centralized heating networks that even dissolves or erases metals. In addition to a huge amount of dissolved chemical elements, it contains sand, rust particles that have fallen off pipes and radiators, “tears” from welding, bolts forgotten during repairs, and a lot of other things that got inside. The only alloy that does not care about all this is cast iron. Stainless steel also copes well with this, but one can only guess how much such a battery will cost.

MS-140 - an undying classic

And another secret of the popularity of the MS-140 is its low price. For different manufacturers, it has significant differences, but the approximate cost of one section is about $ 5 (retail).

Advantages and disadvantages of cast iron radiators

It is clear that a product that has been on the market for many decades has some unique properties. The advantages of cast iron batteries include:

Some properties under some circumstances are a plus, under others - a minus:

- Large thermal inertia. While the MS-140 section warms up, an hour or more can pass. And all this time the room is not heated. But on the other hand, it is good if the heating is turned off, or an ordinary solid fuel boiler is used in the system: the heat accumulated by the walls and water maintains the temperature in the room for a long time.

- Large cross-section of channels and collectors. On the one hand, even a bad and dirty coolant will not be able to clog them even in a few years. Therefore, cleaning and washing can be carried out periodically. But due to the large cross section, more than a liter of coolant “fits” in one section. And it needs to be “driven” through the system and heated, and these are extra costs for equipment (a more powerful pump and boiler) and fuel.

"Pure" disadvantages are also present:

Application area

As you can see, there are more than serious advantages, but there are also disadvantages. If we summarize everything, we can determine the area of \u200b\u200bits use:

- Networks with a very low quality of the coolant (Ph above 9) and a large number of abrasive particles (without mud collectors and filters).

- In individual heating when using solid fuel boilers without automation.

- In networks with natural circulation.

Manufacturers, models, specifications

MS-140 is produced by the following factories:

- Nizhny Tagil Boiler and Radiator Plant (Russia);

- Minsk Plant of Heating Equipment (Belarus);

- Lugansk Foundry and Mechanical Plant (Ukraine);

- JSC "Santekhlit" Bryansk region (Russia);

- Descartes LLC Novosibirsk (Russia).

The products have some features and differences, there are models with a center distance of 300 mm and 500 mm, as well as a lower depth option MS-90.

Nizhny Tagil Boiler and Radiator Plant

The plant's products are certified according to ISO 9001:2008 in the Russian Register certification, there is a certificate from the GOST R System and IQNet.

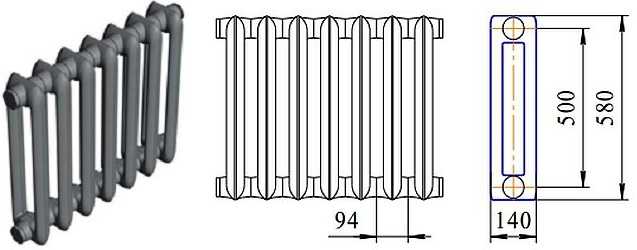

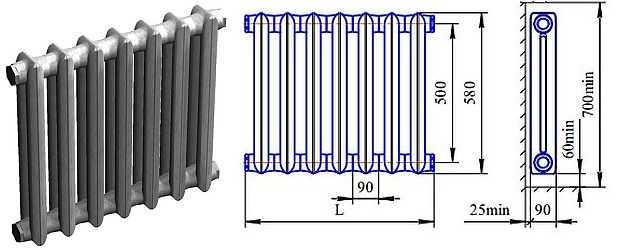

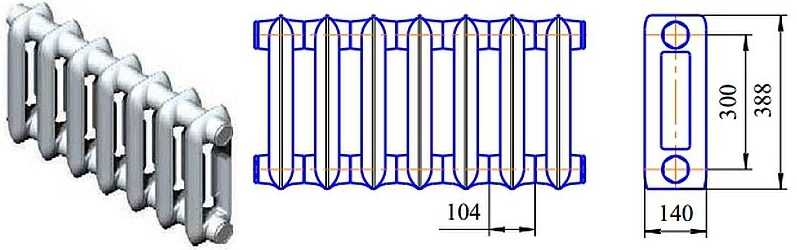

Heat carrier temperature up to +130 o C, operating pressure up to 12 bar, other technical characteristics are given in the table.

| Model name | center distance | Dimensions | Heat output of the section | Section volume | Section weight | ||

| width | depth | height | |||||

| MS-140-M2-500 | 500 mm | 94 mm | 140 mm | 580 mm | 160 W | 1.45 l | 6.65 kg |

| MS-140M-300 | 300 mm | 104 mm | 140 mm | 388 mm | 117 W | 1.11 l | 5.4 kg |

| MS-90 | 500 mm | 90 mm | 90 mm | 580 mm | 130 W | 1.15 l | 5.475 kg |

Minsk Plant of Heating Equipment

The enterprise produces cast-iron radiators MS-140 only with a center distance of 500 mm, but there is also a modified three-channel BZ-140-300, and it is also possible to install them on legs, and not hang them on the wall.

Heat transfer surface of one section MS-140M - 0.208 m 2, BZ-140-300 - 0.171 m 2.

There are many interesting models in the assortment of this plant: there are with a bas-relief, with a flat frontal surface (a new model, similar to aluminum), of different heights, widths and depths. There are plenty to choose from. In general, Belarusian cast-iron radiators are of high quality.

JSC "Santekhlit" Bryansk region

The operating pressure of heating devices from Bryansk is different for different models: for MS-140 - 9 Bar, for MS-100 and MS-85 - 12 Bar, the temperature of the working medium is +130 o C, the heating area of one section is MS-140M-500-0.9 - 0.244 m 2, material - gray cast iron SCh-10.

| Model name | Mezhos. dist. | Dimensions | Heat output of the section | Section volume | Section weight | ||

| width | depth | height | |||||

| MS-140M-500-0.9 | 500 mm | 93 mm | 140 mm | 588 mm | 160 W | 1.45 l | 7.1 kg |

| MS-140-300-0.9 | 300 mm | 93 mm | 140 mm | 388 mm | 120 W | 1.11 l | 6.1 kg |

| MS-110-500-1.2 | 500 mm | 82 mm | 110 mm | 588 mm | 125 W | 0.85 l | 5.6 kg |

| MS-110-300-1.2 | 300 mm | 82 mm | 100 mm | 381.4 mm | 79 W | 0.63 l | 4.45 kg |

| MS-85-500 | 500 mm | 76 mm | 85 mm | 581.4 mm | 115 W | 1.0 l | 4.45 kg |

OOO Dekart Novosibirsk

Novosibirsk cast-iron radiators have a working pressure of 9 bar, connection 1 ¼, temperature of the transported medium +130 o C.

Lugansk Foundry and Mechanical Plant

The operating pressure of these heaters is 12 Bar, the standard temperature is +130 o C, the connection diameter is ¾”.

In the assortment of the Luhansk plant there is a radiator with a flat front panel RD - 100 500 - 1.2, its technical characteristics are given in the table.

Calculation of the number of sections

Determining the exact number of sections in a heating battery is a long process. It is necessary to take into account the region, the material of the walls, what windows-doors cost, how many windows are in the room, what is their area, whether the room is warm or cold, etc. If you need an accurate calculation method, see here, and you can roughly calculate based on the area of the room. It is believed that on average, 100 W of heat is required to heat 1 m 2 of an area. Knowing the area of \u200b\u200byour room, determine how much heat will be needed: multiply the area by 100 watts. Then divide by the heat output of the selected radiator model.

For example, in a room of 12m 2 we will install MS-140M-500-0.9 of the Bryansk plant. The thermal power of the section is 160 W. Payment:

- Total heat needed 12m 2 * 100 W = 1200 W

- How many sections are needed 1200 W / 160 W = 7.5 pcs. We round (always up - it’s better to let it be warmer) and we get 8 pcs.

Results

Despite the fact that the radiators have the same name: MS-140, their technical characteristics are different. The fact is that they are produced in different countries, and meet their industry standards. But for the end user, this is good: you can choose the option that suits you best. And the difference is pretty big in some respects.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical