Purpose of the elevator unit of the heating system

Any building connected to a centralized heating network (or boiler room) has an elevator unit. The main function of this device is to lower the temperature of the coolant while increasing the volume of pumped water in the house system.

The purpose of the node

Elevator units are installed when superheated water is supplied to a residential building from a CHP or boiler house, the temperature of which can exceed 140 ºC. It is unacceptable to supply boiling water to apartments, as it is fraught with burns and destruction of cast-iron radiators. These devices do not tolerate sudden temperature changes. As it turned out, polypropylene pipes, which are so popular today, also do not like high temperatures. Although they are not destroyed by the pressure of hot water in the system, their service life is significantly reduced.

Superheated water supplied from the combined heat and power plant first enters the elevator unit, where it mixes with chilled water from the return pipe of a residential building and is again supplied to the apartments.

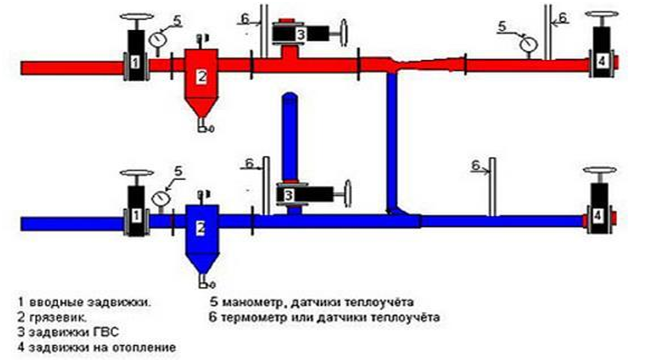

Principle of operation and node diagram

Hot water entering the residential building has a temperature corresponding to the temperature schedule of the combined heat and power plant. After overcoming the valves and mud filters, the superheated water enters the steel body, and then through the nozzle into the mixing chamber. The pressure difference pushes the stream of water into the expanded part of the housing, while it is connected to the cooled coolant from the heating system of the building.

![]()

The superheated coolant, having a reduced pressure, at a high speed rushes through the nozzle into the mixing chamber, creating a vacuum. As a result, the effect of injection (suction) of the coolant from the return pipeline arises in the chamber behind the jet. The result of mixing is water that has the design temperature, which flows into the apartments.

The elevator diagram gives a detailed idea of the functionality of this apparatus.

Advantages of water jet elevators

A feature of the elevator is the simultaneous performance of two tasks: to work as a mixer and as a circulation pump. It is noteworthy that the elevator unit operates without the consumption of electricity, since the principle of operation of the installation is based on the use of differential pressure at the inlet.

The use of water-jet devices has its advantages:

- uncomplicated design;

- low cost;

- reliability;

- no need for electricity.

With the help of the latest models of elevators equipped with automation, you can significantly save heat. This is achieved by regulating the temperature of the coolant in the zone of its outlet. To achieve this goal, you can lower the temperature in apartments at night or during the day, when most people are at work, study, etc.

The economical elevator unit differs from the conventional version by the presence of an adjustable nozzle. These parts can have different designs and levels of adjustment. The mixing ratio of a device with an adjustable nozzle varies from 2 to 6. As practice has shown, this is quite enough for the heating system of a residential building.

The cost of equipment with automatic adjustment is much higher than the price of conventional elevators. But they are more economical, functional and efficient.

Possible problems and malfunctions

Despite the durability of the devices, sometimes the elevator heating unit malfunctions. Hot water and high pressure quickly find weak points and provoke breakdowns.

This inevitably happens when individual assemblies are of improper quality, the calculation of the nozzle diameter is incorrect, and also due to the formation of blockages.

Noise

The heating elevator can generate noise when operating. If this is observed, it means that cracks or scuffs have formed in the outlet of the nozzle during operation.

The reason for the appearance of irregularities lies in the distortion of the nozzle caused by the supply of a coolant under high pressure. This happens if the excess head is not throttled by the flow regulator.

Temperature mismatch

The high-quality operation of the elevator can also be questioned when the temperature at the inlet and outlet differs too much from the temperature schedule. This is most likely due to the oversized nozzle diameter.

Incorrect water flow

A defective throttle will result in a change in water flow from the design value.

Such a violation can be easily identified by the change in temperature in the incoming and outgoing piping systems. The problem is solved by repairing the flow regulator (throttle).

Defective structural elements

If the scheme for connecting the heating system to the external heating main has an independent form, then the reason for the poor-quality operation of the elevator unit can be caused by faulty pumps, water heating units, shut-off and safety valves, all kinds of leaks in pipelines and equipment, malfunctioning regulators.

The main reasons that negatively affect the circuit and the principle of operation of pumps include the destruction of elastic couplings in the connections of the pump and electric motor shafts, wear of ball bearings and destruction of seats for them, the formation of fistulas and cracks on the body, aging of oil seals. Most of the listed faults can be fixed by repair.

The problem of fistulas and cracks in the case is solved by replacing it.

Unsatisfactory operation of water heaters is observed when the tightness of the pipes is broken, their destruction occurs or the tube bundle sticks together. The solution to the problem is to replace the pipes.

Blockages

Blockages are one of the common causes of poor heat supply. Their formation is associated with the ingress of dirt into the system when the dirt filters are faulty. Increase the problem and build up of corrosion products inside the pipes.

The level of clogging of the filters can be determined by the readings of the pressure gauges installed in front of the filter and after it. A significant pressure drop will confirm or disprove the assumption about the degree of debris. To clean the filters, it is enough to drain the dirt through the drain devices located in the lower part of the housing.

Any malfunctions of pipelines and heating equipment must be eliminated immediately.

Minor remarks that do not affect the operation of the heating system are mandatory registered in special documentation, they are included in the plan for current or major repairs. Repair and elimination of faults takes place in the summer before the start of the next heating season.

Masonry mortars for brick oven

Masonry mortars for brick oven Why do the windows fog up in the apartment?

Why do the windows fog up in the apartment? Construction and diagrams of brick ovens

Construction and diagrams of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical