Why do I need a make-up valve in the heating system

Over time, the amount of fluid in heating systems gradually decreases. Even if there were no accidents and no selection is carried out, the number still decreases due to the following reasons:

- When removing air congestion, when Mayevsky's taps are opened;

- When excess pressure is released, when its permissible level is exceeded and a special regulator is activated;

- When cleaning filters and other preventive work;

- Increase in the internal volume of pipelines due to their thermal deformation (increase in size when heated);

- Wall thinning due to corrosion.

Most of the factors lead to negligible water consumption. But their summation over a long time will create a result that can affect the performance of the heating. In open circuits, water deficiency is compensated by a large volume of the expansion tank, and replenishment is made every few years by adding it manually. Closed systems are very sensitive to the loss of even a small volume of fluid. For its timely replenishment, a special unit is used, which has a valve for feeding the heating system.

In addition to timely replenishment of coolant losses, a special adjustment unit performs other functions:

- Filling and draining the heating system;

- Preparation of water for heating;

- Flushing the heating system;

- Does not allow the coolant to enter the water supply network.

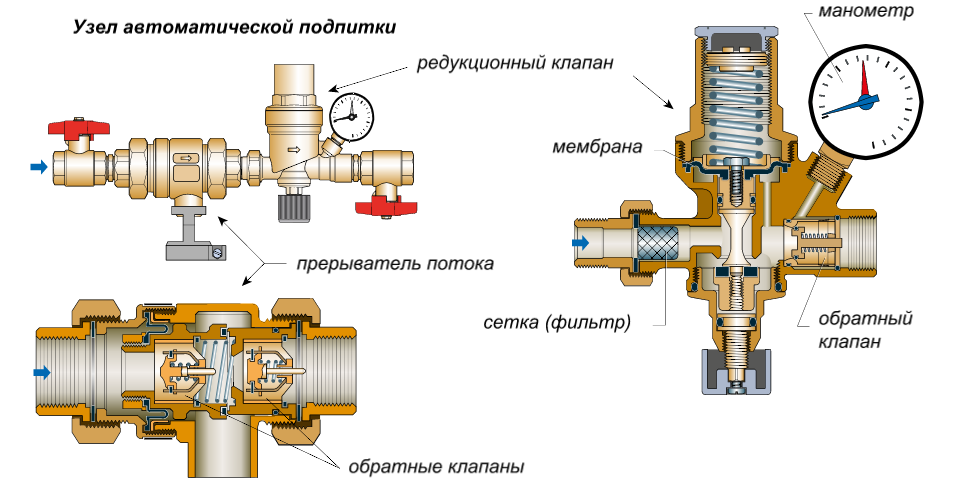

The automatic pressure control unit (automatic unit) can be:

The automatic pressure control unit (automatic unit) can be:

- Simple when it includes a pressure reducing valve and a set of valves;

- Difficult when a make-up pump is additionally included in the automatic unit.

The ideal place where the automatic make-up unit can be installed is the place that has the least pressure and is located as low as possible. The best installation point is in front of the circulation pump.

The adjustment of the node operation can be either manual or automatic.

Manual adjustment involves periodic human intervention in its work. To do this, focusing on the readings of the pressure gauge, independently open and close the fluid supply valve.

With automatic - the coolant is supplied without any outside intervention. The automatic unit independently controls the pressure of the liquid in the system and delivers it there through the pressure reducing valve.

Advice! The unit for automatic feeding of the heating system can be additionally equipped with a filter to remove impurities. This will reduce the formation of scale.

pressure reducing valve

H2_2The pressure reducing valve can be:

- Mechanical, water supply through the gearbox is carried out by simply opening the shut-off valves;

- Have electrical contacts for automatic adjustment of the water pump.

An automatic pumping pump is necessary in cases where water cannot pass through the gearbox due to the low pressure of the water supply network. In this case, neither manual nor automatic adjustment will be able to compensate for fluid losses.

Important! The reducer, in addition to lowering the pressure, serves as a fuse against hydraulic shock.

The automatic pump will create the necessary pressure and pump water through the reducer into the space heating system. In addition, such a pump can be equipped with a storage tank, which will provide it with liquid even if there is no connection to the water supply. There are also submersible make-up pumps for use in wells and wells.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical