How not to lay laminate flooring. How to properly lay laminate flooring on a wooden or linoleum floor. Installation of panels using the locking method

In this article we will tell you in detail how to lay laminate flooring detailed photo instructions. Having seen the installation process with your own eyes, you will easily complete this work.

Preparing the foundation

So let's start, first of all, check how level the base is (if the base is not level, then voids will form under the laminate, and when you press on it, it will sag and creak, and eventually break).

If you have an old wooden floor or just poured concrete, then the first thing you need to do is make sure that its surface is even. To do this, we use a regular building level. Allowable differences (holes) are 1-3 mm. at a length of 2 meters.

It is easy to fix a wooden floor by making a dry screed - 1 cement 3 sand, mix (WITHOUT WATER), pour a thin layer onto the wooden floor and level it with the rule.

We glue USB plywood on top and twist it.

Or compact it with a special tamper for semi-dry screed (for this, when preparing the solution, you will need to add 10-20% water and mix it in a concrete mixer to obtain a wet cement-sand mortar.

If you just have a poured concrete floor, then you need to set up the beacons and make a finishing screed.

Underlay for laminate

We lay a substrate on the finished base (usually foamed polyethylene or balsa wood is used). After laying, we glue them together with tape so that when installing the laminate, the backing does not move apart.

Let's start laying laminate flooring

On top of the prepared base, the first row of panels should be laid (starting from the corner). We take a piece of laminate and cut it into 5x5 centimeter squares; they will serve as spacers, since you can’t put laminate against the wall.

How to properly connect laminate flooring video:

The panels are joined end to end, and the gap in relation to the wall should be controlled.

Be sure to remember that laminate flooring should be laid on top of a wooden floor at an angle of 90° to the boards!

When laying the next row, it is necessary to ensure that the end seams between the panels in the second row and the end seams in the first row do not match, so that the laminate locks do not break during operation.

To perform the steps described above, you can use a fragment of the panel left over from trimming the first row. If its length is more than 20 cm, then use it to start a new row.

However, if you want to make the most accurate and aesthetic offset, you will have to trim the new panel by approximately one-third of the board (this principle is called “offset by a third of the board”).

The second row is assembled in the same way as the first.

When joining rows, it may be necessary to knock out the locks using a hammer and a special safety bar (any wooden block or a piece of laminate, insert the lamella into the lock and tamp it down).

When the second row is completed, you should, by analogy, assemble the entire covering, while simultaneously monitoring the correct installation and observing the gaps from the laminate panels to the walls (5-10mm).

The last row of panels will most likely have to be sawn into lengths of the laminate panel, the photo shows how to mark the last row of laminate panels, lay the laminate on the penultimate ripple and mark as shown below.

Try to carry out these steps with care, however, you should not indulge in it too much. of great importance, since the cut line will be hidden by the baseboard.

After laying the floor covering, you should remove the wedges that separated the laminate from the wall and install the baseboards.

How to lay laminate flooring on a wooden floor video

A wooden floor under a laminate can be leveled using plywood. How this is done is shown in the video below.

That's all! If you use the information given in this material useful recommendations, then when asked “how to lay laminate flooring on a wooden floor?” you will feel confident and will not fall into a stupor.

Video: How to lay laminate flooring correctly: mistakes and basic rules

In addition, after you have read the above, you are quite capable of installing laminate flooring on a wooden floor on your own!

So, the choice in favor of a laminated floor has been made, the material in the required quantity has been purchased and delivered to the installation site.

All that remains is to invite a team of craftsmen and wait for the work to be completed. Is it really necessary to pay extra money for installation of the coating?

A good owner is quite capable of coping with such a task, of course, if he has certain basic skills and the proper level of accuracy and attentiveness.

The technology of laying laminate flooring cannot be rushed. To ensure that the installation of the coating itself does not cause difficulties, and that the resulting floor lasts a long time without losing its operational and decorative qualities, it is necessary to carry out thorough preparation for work.

Assessing the condition of the floor surface

Usually, even before deciding to purchase a laminate, the condition of the “subfloor” is assessed and appropriate repair and restoration work is carried out.

Usually, even before deciding to purchase a laminate, the condition of the “subfloor” is assessed and appropriate repair and restoration work is carried out.

By and large, a laminated floor can be laid on any surface subject to the main condition - it must be smooth, durable, and free from areas of dynamic deformation.

Otherwise, “weak” places will inevitably appear on the new coating, where surface integrity may be damaged, joints may diverge, and squeaks may appear.

Ideally, the floor should be strictly horizontal, with permissible differences of no more than 1-2 mm per linear meter.

- must not have significant cracks, gouges, peeling or crumbling areas. If it is impossible to correct existing defects, installation on an uneven floor cannot be carried out. You'll have to update the screed - or. You can start laying the laminate only after the coating has completely hardened, in accordance with the deadlines established by the concrete technology.

- If it is expected, its entire surface must be carefully checked. If areas of “playing” or creaking boards are identified, they must be repaired or replaced. Possible irregularities can be processed with a plane or sanding machine, and existing cavities can be filled with wood putty.

- You can lay laminate, provided that there are no holes or bumps, delamination of joints, through wear, or areas of destruction of the concrete base. This coating cannot be repaired; it will be easier to remove the linoleum and carefully prepare the base for the laminate.

If funds allow, the ideal option would be to cover the entire floor surface with 10-12 mm, having previously laid them underneath with plastic film for water vapor barrier. The process of laying laminate flooring will be significantly simplified, and the sound and thermal insulation qualities of the floor will increase significantly.

We prepare the necessary materials and tools

Good advice to all novice craftsmen - before laying the laminate, after it is delivered from the store, it is worth unpacking the panels and letting them rest for 2-3 days in the room where the flooring will be carried out.

Equalizing the temperature and humidity levels of the material and the room will facilitate the installation process and eliminate the risk of warping of the laid coating.

This time can be devoted to preparing the necessary tools and materials.

First of all, you need to have the required quantity available, regardless of the type of base.

The underlay not only has a good insulating effect - it has a shock-absorbing effect and prevents friction between the laminate board and the rigid base, which ensures the longevity of the floor covering.

The substrate can be polystyrene or polyurethane foam, with or without a foil heat-reflecting coating, produced in rolls or in the form of rectangular panels.

The substrate can be polystyrene or polyurethane foam, with or without a foil heat-reflecting coating, produced in rolls or in the form of rectangular panels.

More expensive, but very quality option – .

- The lining material is laid end-to-end, without overlaps, so to securely fix it to the floor you will need double-sided tape. You can also use regular adhesive tape to secure the rows of backing along the seams.

- It is worth immediately preparing a set of wooden wedges, 10-12 mm thick, for laying the laminate at the required distance from the walls of the room.

- You can cut laminated panels to the required size with a regular hacksaw or jigsaw.

- For high-quality joining of seams, you will need a hammer, preferably a rubber or wooden one (mallet). You can also use metal, but only through wooden spacers (bars).

- To install sections of the coating located near the walls, you need to have a small mount, or you can make a lever from a steel strip with a hook and a shoulder protruding upward, through which the force of the hammer can be transmitted.

In principle, the materials and tools for installation are ready. However, there are a few other things to consider before you get started.

How to avoid unwanted mistakes

It is best to precede the installation by drawing up a plan carefully drawn to scale - the required visibility and clarity will appear in further actions.

What is important to consider:

- When answering the question: how to lay laminate along or across, the following is important: the direction of the longitudinal joints should be parallel to the direction of the rays from the main source of natural light (windows) - in this case, the seams will be practically invisible.

- The laying direction is usually from the far left corner, straight. For the panels of the first row adjacent to the wall, the groove must be outward, and the tenon must be cut so that a smooth end is obtained. Longitudinal cutting of panels is best done using a circular or vertical hand-held power saw.

- On the plan, be sure to take into account that the last strip that completes the installation must have a width of at least 100 mm. If this does not work, you will have to reduce the width of the first row. The same should be taken into account if there are any internal corners in the room.

- The thickness of the laid coating should not interfere with the free opening of the doors. Sometimes you have to remove and trim the door leaf from below in advance.

- When planning, do not forget about the pipes passing through the thickness of the floor. To cut shaped grooves for them, you will definitely need a jigsaw.

After thinking through all the theoretical issues, you can proceed directly to installation.

Laminate installation process

Laminated floor panels are available in interlocking or adhesive versions. In turn, locks can be one of several systems - “Click”, “Lock”, “5G”.

How to lay laminate flooring correctly?

Each type of laminate has its own installation features.

Features of laying laminate flooring with the “Click” system

Currently, this is the most common locking system among laminate manufacturers and popular among craftsmen.

Currently, this is the most common locking system among laminate manufacturers and popular among craftsmen.

Its main difference from others is that it is possible to insert a figured tenon into a complex groove only at a certain angle - for different manufacturers - from 25 to 45 degrees.

When the two panels are rotated in one plane, the lock securely snaps into place.

Another convenience is that disassembling the covering is also not difficult; when you turn the panel, the lock will “open.”

- Work begins with the assembly of the first row of panels. It is laid along the wall and wedged on both sides with 10-12 mm dies. This gap is necessary to compensate for the thermal expansion of the laminate flooring. The assembly process is simple - insert the tenon at the desired angle, accurately aligning the edges, lower the panel down until it clicks into place.

- The second row is assembled by ensuring that the transverse seams are displaced by half the length of the panels (30-40 cm is allowed). The strip along its entire length is assembled completely, and only then is it connected to the first row. This will most likely require an assistant. After fixing the second row, it is also wedged from the walls from both ends with blocks.

- Then the work continues in the same order until the room is completely covered.

It is imperative to monitor the cleanliness of the grooves so that no sawdust or other debris remains there.

If the material fits well, you most likely won't even need a hammer.

Features of laying laminate flooring with the “Lock” system

This locking system is gradually falling out of use, although inexpensive laminate models can be produced with it.

This locking system is gradually falling out of use, although inexpensive laminate models can be produced with it.

The connection between the tenon and the groove occurs strictly in one plane, and the engagement occurs due to special protrusions and grooves.

The joint turns out to be much less durable, although disassembly, if necessary, is not easy - the tenon may be damaged.

- When assembling the first row, after connecting the end sides of the panels, to ensure that the tenon is completely inserted into the groove, tapping with a hammer is carried out through a wooden spacer. Wedging the row away from the wall is done in the same way as in the case of the “Click” system.

- The second row is assembled gradually, one panel at a time (also taking into account the displacement of the transverse seam by half the length of the board). The first panel is inserted into the groove of the first row, tapped with a hammer until it is completely connected, and then wedged away from the wall.

- The second panel is tapped on both the long and short sides for reliable fastening of the longitudinal and transverse lock. Further work continues in the same order.

- The most difficult thing is installing the last panel of the row adjacent to the wall. This will require either a pry bar or a curved lever.

Work is carried out in rows or “ladders”, to the end of the room. The last row is also carefully mounted with power transmitted through a lever.

It is very important to correctly measure the force of the hammer blow or the force on the lever so as not to damage the surface of the laminate or break the lock's tenons.

Features of laying adhesive laminate

Although such laminated panels are equipped with a tongue-and-groove system, they do not have a locking connection. Thus, the strength of the joint is ensured only by gluing.

Such floors are distinguished by good solidity and moisture resistance, but it will no longer be possible to dismantle or repair a separate section of the covering.

The installation process is more labor-intensive, and you will also need to purchase special glue. It is not recommended to use the usual PVA.

- The technology for laying laminate is generally similar to the “Lock” system - the sequence is the same. The difference is that each groove is generously coated with glue (in accordance with the instructions included with it). Excess glue that appears after the panels are joined is immediately removed with a clean, damp cloth.

- After laying the first three rows, be sure to take a break of at least 2 hours so that the glue has time to set. The same rule applies in the future, until the entire laminate is completely installed.

Master class on laying laminate flooring in video format

A video about how to properly lay laminate flooring, showing installation technology and preparatory work.

Let's finish the job

After the entire floor surface is covered with laminate, the spacer wedges at the walls are removed. The final stage will be the installation of skirting boards that will hide the expansion gaps.

It is important to remember that in no case are the skirting boards screwed to the laminated covering - only to the wall.

The transition to another covering at the junction of adjacent rooms can be covered with a decorative overlay or use.

In fact, installation work finished - you can move on to cleaning the room and decorating the interior of the room. As you can see, there is nothing overly complicated. The main thing is maximum attention, thoughtfulness of every action and the highest accuracy. Everything should work out!

Many people are interested in how to lay laminate flooring correctly. There are many installation methods, since each brand of laminated panels has its own characteristics and is intended for installation in certain conditions. For example, some boards are suitable for laying on a warm floor, while others are not, so the process will be different.

Laying laminate flooring with your own hands will not present any difficulties.

Each manufacturer stipulates the installation procedure in the price list and gives recommendations on the installation of their products. You just need to follow the instructions, and then laying laminate flooring with your own hands will not present any difficulties, and a properly installed floor will last for many years.

Transportation and storage of laminate

Although laminate from reliable manufacturers is manufactured using high-precision technologies with constant quality control at every stage, damage to the panels cannot be completely ruled out.

The laminate is manufactured using high-precision technologies with constant quality control at every stage

This can happen due to improper transportation of the floor covering and violation of storage conditions.

Hence the conclusion:

- Laminate flooring should be transported only in original packaging, checking its integrity before loading;

- You should not throw packages on the floor, so reduce the load on your arms and back as much as possible when carrying them and avoid sharp turns;

- you need to remove all obstacles from the path in advance;

- laminate should be stored in the same temperature conditions in which it will be installed;

- it is necessary to avoid direct sunlight, this is especially true if there are panoramic windows;

- Before installation, the panels should be unpacked, laid out evenly in the room at a distance of at least half a meter from the walls and left for 48 hours to acclimatize.

Necessary materials, tools and aids

To properly install a laminate floor in an apartment, you will need:

- folding meter, level, pencil, ruler, angle and spacers;

- a timber for tamping the laminate and a rubber hammer;

Tools required for laying laminate flooring

- fine-toothed hacksaw and knife, which can be replaced with a jigsaw or circular saw with a fine-toothed blade;

- skirting board of suitable design;

- plastic film if laminate is laid on a concrete floor;

- sound-absorbing underlay for laminate;

- clamp for installation and spacer wedges.

What you need to know when installing laminate flooring yourself

To understand how to correctly lay laminate flooring with your own hands, you need to familiarize yourself with the manufacturer’s requirements set out in the package insert and watch training videos.

Compliance with instructions - necessary condition, and in case of damage to the panels due to broken technology, the guarantee for free replacement of the material does not apply.

Scheme of laminate laying technology

Key points:

- initially check the quality of laminated boards and carry out acclimatization;

- use flooring strictly in specified areas;

- carefully prepare the base for the laminate, which should be dry, even, clean and smooth;

- lay soundproofing material on the base, and when laying it on concrete, first cover it with film, forming a waterproofing barrier;

- lay a substrate on top of the insulating layer;

- choose correct location panels relative to light and walls - along or across. In large rooms not cluttered with furniture, laminate is laid along the main light source, which will help hide the seams and achieve a natural palette of colors, and to visually expand the space, install the coating across the walls;

- panels are laid most often using the method brickwork, which reduces the load on them during operation;

- To prevent laminated boards from swelling, you need to leave a gap of 5–10 mm between the edge of the covering, walls and doorways;

- After installation, it is necessary to check the tightness of the joints, and during the installation process, use high-quality and suitable sealants.

Of considerable importance for the trouble-free and durable operation of a laminate floor is right choice grounds, which are necessarily indicated by manufacturers in the recommendations.

For example, it could be a concrete screed over a heated floor, old wood covering, asphalt, tiles, linoleum, chipboard. Carpets, foamed PVC flooring, and similar materials are not suitable as a base for laminate flooring and must therefore be dismantled.

- Otherwise:

- when walking, the seams may come apart; moisture accumulated under them will lead to the formation of mold and mildew on inner surface

laminate and its destruction.

Before laying laminate flooring on a wooden floor or other base, you need to prepare for the work process.

Diagonal laying visually expands the space

- The preparatory stage is:

- in sorting panels by texture, shade and decorative pattern;

in measuring the room to calculate the number of panels and determine whether it is necessary to narrow the width of the first row in case of curvature of the walls. Important!

Remember: to achieve the best result in terms of color perception, lay laminated boards using a mixture of different packages.

- Work order:

- The base is cleared of debris and leveled. The better the base is prepared, the easier it will be to install the panels and the more durable the laminate floor will be.

- Waterproofing is laid in the form of a PE film with an overlap of 15 cm and the joints are taped. It is recommended to run the film onto the wall a little and then cover it with a plinth. A backing is laid on top of the insulation, which will hide small irregularities and make the base smooth. Unlike waterproofing film

- The substrate should be laid joint-to-joint with the seams secured with tape.

- Start laying from the left corner of the room. The laminate is assembled with a lock towards itself, which will make it easier to snap the panels together. Having laid the first board, fix the distance from the edge of the panels to the walls along the entire perimeter with spacers or spacers.

- Lay the second board by inserting it at an angle of ≈ 45º into the lock of the previous one and smoothly lowering it.

- The longitudinal edges must form a straight line in order to lay the second row of panels in the longitudinal profile without seams.

- They reach the end of the first row, and then, if the walls are uneven, the last board is turned 180º and cut, keeping a distance from the wall of 5–10 mm, depending on the length of the panels.

- Laying the second and subsequent rows begins with a cut piece of the last panel of the previous row, if its length is not less than 40 and not more than 90 cm. This will reduce the consumption of materials and ensure that the seams are staggered.

- Continue laying the rows until the entire space is covered, and remove the spacers. Last panel mounted using a clamp.

- For pipes encountered along the way, grooves are made 10–20 mm larger than the diameter of the pipes, a part is cut out for fitting, glue is applied to it, inserted and fixed until completely dry, and then the grooves are lined with cuffs for heating elements.

- The baseboard is nailed down and the thresholds are installed.

There are some nuances when laying laminated boards diagonally. This technique is more complex, but it brings a unique zest to the interior and emphasizes the individuality of the environment.

To achieve the best result in terms of color perception, lay laminated boards using a mixture of different packages.

In addition, diagonal laying visually expands the space, which is very valuable for small apartments.

Specifics of diagonal laying

It’s not difficult to create an unusual, original laminate flooring; you just need to know how to correctly lay the laminate diagonally and what are the features of diagonal laying compared to classical technology. Required Tools and the preparatory process are no different from regular installation.

The conditions are the same - a clean and as smooth surface as possible, for which it is recommended to use special self-leveling mixtures. They are applied to a floor cleared of debris and leveled with a spatula.

Important: after leveling, the difference in height of the base should not exceed 2 mm per square meter.

After passing preparatory stage, begin diagonal installation of the laminate floor:

1. Choose the direction of laying the boards. The optimal angle is ≈ 35-45º.

2. Calculate the amount of laminate. Here lies the first feature, since diagonal calculation has a formula - to the area of the room you need to add the product of the width of the room x 1.42 x the width of one board. For example: the length of the room is 5 m, the width is 3 m, the length of the selected laminated board is 1 m, and its width is 0.1 m. Then:

- room area 5 x 3 = 15 m²;

- area of spare material 3 x 1.42 x 0.1 = 0.436 m²;

- substitute the values into the formula 15 + 0.436 = 15.436 m²;

- divide the result by the area of one board (0.1 x 1 = 0.1) and get the number of laminated boards, i.e. 15.436/0.1 = 154.36 ≈ 155 pieces + 10% margin ≈ 170 panels will be required for diagonal flooring.

3. Pull the rope diagonally to control the laying angle and prevent deviations.

4. After the leveling mixture has hardened, the surface is covered with cellophane, on top of which a substrate or cork sheets are laid with the joints sealed with tape.

5. To simplify the installation process, experts advise starting diagonal laying from the center of the room, since working with long panels is much more convenient than with small triangles.

6. Having laid several rows, check whether the angle of inclination is evenly maintained and click the boards using a rubber hammer for adjustment.

7. Spacers fix the gaps between the covering and the walls.

8. Equip pipe passages, if any, sealing them silicone sealant suitable shade.

9. Remove the spacers and install the plinth, preferably with ready-made internal channels for pulling cables.

The main differences between diagonal laying:

- the first panel of each new row is selected separately, rather than using sections of the last board of the previous row, as with the standard method;

- to cut the last panel in a row, proceed as follows: measure the distance to the wall, taking into account the expansion joint on one side and put a point on the board, then measure the distance on the opposite side and mark a new point, then connect the points and cut along the intended line with a jigsaw with the wrong side sides;

- The end sides of the panels are connected in the usual way, and the long sides in the following order: slightly raise the opposite edge of the board, insert a block into the lock and click it into place by pressing on the floor. The panel is rocked a little to seal the joint.

Remember these features, follow the recommendations of experts, and the question of how to properly lay laminate flooring will disappear by itself. Videos that will solve all the problems will help you visualize the installation process, and the time spent watching will be fully repaid with an elegant, beautifully laid laminate floor. Good luck with your renovation.

Laminate manufacturers emphasize in their advertising campaigns that the installation of this popular floor covering has become so simple that anyone can handle it. Who has no experience working with laminate at all. You need to read the instructions, watch the company’s advertising video, and as a result of your efforts, the room with the new floor will quickly be transformed, and the admiring family will extol your construction achievements. Despite the fact that before installing the flooring, your success in this field was not much different from the ability of one of the characters of the English writer Jerome K. Jerome Uncle Podger to hang pictures.

Indeed, the improvement of panel interlocking systems has greatly simplified the installation process. If laying laminate flooring with a Lock lock requires certain experience and skills, then the next generation of locks - Click - does not impose such requirements. And the market already sells laminate flooring with 5g and Megalock locks, and even with aluminum locks. Soon everything will be like in Russian fairy tales, when all you need to do is bring the packages into the room where the installation will take place, and hold the flooring without opening the boxes for a couple of days. To adapt to the temperature and humidity in the room. And then you open the packages, and the panels themselves are laid “at the behest of the pike.” However, the devil, as we know, is in the details.

Laying laminate

The work of installing the flooring has become much easier. The same cannot be said about preparing the base before laying. The base must be level, stable and dry. The difference in height is permissible within 2 mm per 2 m. In some cases, a waterproofing device is required before laying the substrate and the laminate itself.

Laying the substrate

Substrates differ in the material from which they are made, characteristics and cost:

Manufacturers claim that the substrate is able to level the base under the laminate. This is an exaggeration. The substrate must provide heat and sound insulation. The underlay can compensate for minimal unevenness in a leveled old wooden floor or plywood base, but no more.

Important! The substrate is laid end-to-end, the joints are fixed with tape. This way it will not move when laying the laminate.

Choosing a installation method

We determine the method of laying the covering: diagonally, perpendicular or parallel to the light (along or across the room). Diagonal installation is more often used in narrow spaces - this is one of the ways to visually expand them.

It is usually customary to lay the laminate perpendicular to the light source (the long side along the flow of light) - this is a window in the room. In daylight, the joints between the panels are less noticeable.

However, when laying the covering on a wooden floor, you must be sure to focus on the direction of the floorboards. On such a floor, the laminate is laid perpendicular to the floor boards to reduce possible deflection. If the old wooden floor is covered with plywood on top, the flooring should be laid in the traditional way - perpendicular to the window.

In small narrow rooms without natural light (corridors, hallways), laminate flooring is laid across in order to visually expand the room.

Laying laminate flooring with different types of locks

For installation work you will need:

First, plastic wedges are installed to maintain a 10 mm gap between the laminate and the wall. The first row is laid horizontally from the corner of the room in the direction from left to right. The ridge of the panels of the first row is directed towards the wall. The panels are connected at their ends. The last panel in the row is cut with a jigsaw or hacksaw and laid in a row. You can start the next row with the remaining piece of the panel (provided that its length is more than 300 mm). It is important that the seams in adjacent rows do not match.

Advice. To give panel offsets a more accurate appearance, a technique such as “offset by a third of the board” is used. One third is cut off from the new panel, after which it is laid.

The first and second rows are joined. When using panels with a Lock-lock, you will need to hammer them with a mallet (through a die) to fix the ridge in the groove of the adjacent panel.

Click system panels are laid at an angle of 45° until they click into place. This coating can be disassembled if necessary.

The panels of the last row will most likely need to be cut to size. Remember that the cutting line will be covered by the baseboard, so small unevenness in the cut area is not a problem. After laying the laminate on the wooden floor is completed, the wedges are removed and the baseboard is installed. First, see how much you need to trim the panels of the last row. The flooring will not look very good if the width of the panels of the first and last rows is very different. In this case, it is better to trim the panels of both the first and last rows.

In this two-part review, we will talk about how you can lay laminate flooring alone. The instructions for the laminate indicate the installation method, but it is almost always designed for two people, since the row in this case is 4–5 m long and will fall apart when installed by one person. We will show you a simple way that you can use to lay laminate flooring alone. In the second part of the review we will discuss some details this process.

Part 1

Here is our room of about 17 m², in which we will lay laminate. Laminate is ordinary, inexpensive, 33 classes, has standard sizes, its thickness is 8 mm. For installation you will need the following tools:

This set consists of a corner, a pencil, a tape measure, a stationery knife and a tool for sawing laminate - a jigsaw or saw. If you have neither one nor the other, you can use a hacksaw. The first thing to do in this case is to check the floor for large dips and bumps. The floor must be more or less level, otherwise the laminate in such places may shrink and the lock will come apart. After we have done this, we lay out the backing.

We do not line the entire substrate; we first roll out one row, lay the laminate down to the edge, then roll out the next row.

We lay it from left to right, that is, we lay out several boards, starting from the left side. Lay the first row and see what the rest turns out to be.

It is undesirable for the remainder to be less than 30 cm. If the last piece turns out to be too small, then trim the first one and make sure that nowhere you get such short pieces. The laminate board has two different sides. We lay the laminate with a wide lock towards itself:

Here's the other side of the board:

We begin to assemble the first row. To our left is the first board, lift the second one, connect it, make sure that the joint matches in width, then fasten it:

We do the same with the next board. This results in a series like this:

We retreat 8–10 mm:

Let's cut off this part, from which we will make several linings:

We carry out the markings. To do this, place the laminate sheet with the wide lock towards you, then turn it over, rest it against the wall and mark it about 8 mm smaller:

Take a square and make a mark:

We always mark and saw from the wrong side, since in this case, when filing with a jigsaw or circular saw, chips are obtained on the wrong side, and not on the front side. When the board is in place, the cut will be on the far side, to our right, and on the left we will connect the joint.

We sawed down this part and made linings from the scraps. We insert them at the joints:

Here we place the lining at the beginning and at the end. Then we join the end board.

Our laminate is smooth, it does not have a chamfer. If the laminate has chamfers - and they may even differ in color - then you need to lay it in accordance with the pattern, that is, shift the boards by half or by a third, as you like. In our case, the joints are not visible, so we can ignore this.

We begin to lay out the second row. The length of the wall turned out to be such that there was an offset of half the board. This happens rarely, more often you end up with scraps 40–50 cm long, and when such scrap remains, we start the next row with it. Here we started with a whole board, but since there is no cutting, we will start the second row with half a board.

Insert our cut:

Take the whole board and insert:

The joints look like this:

Raise the board and fasten the far edge:

Then fasten the left edge. That's it - the laminate is connected. Here is the transverse joint, here is the longitudinal one - nothing fell out anywhere:

This is what it looks like:

Then do the same on the other side.

There is such debris on the laminate, it must be removed:

We finish laying the second row. We insert the last piece in the same way:

We put a lining and raise the board slightly:

We have two rows of laminate flooring installed. Let's start laying the next row. We put the lining and place the following board:

Up close, this process looks like this:

We lift the board, insert it, and snap it into place.

One move and that’s it, the laminate is in place. Now we need to download it, here and at the beginning:

We continue installation.

Sometimes the laminate is slightly curved, and it is impossible to fasten it with your hands. After we inserted this edge, the laminate protrudes a little.

In this case, take a piece of laminate and insert it with a lock into this lock:

The cutting width should be 20 centimeters so as not to break the edge. We insert the cutting and give it with a hammer, after which it falls into place. First we do the edge, then the middle, and in this way the board must be pierced several times along its entire length.

All this can be done alone, and in this way rows of any length can be collected, even up to 6–8 meters. There is no need to insert them entirely.

Part 2

In the first part of this review, we started talking about how you can lay laminate flooring alone and managed to lay three rows of laminate flooring. In the second part we will continue our story. Here we will touch on some of the nuances of this process: we will tell you how to lay laminate in the corners doorway and under the radiator, what needs to be done in cases where the lock is tight, and we will also demonstrate the advantages of this technology to all those who doubt it.

Laying rows of laminate

So, we continue to lay the laminate flooring. Let's start laying the next row. In this case, the edge of the board is inserted, and there is a small gap in the middle:

To prevent this gap from appearing here, you need to shake the piece of laminate with your hand:

You don't need to put in a lot of effort. That's it, the laminate is fastened.

Place the next piece.

If the board is raised, you can sink it by shaking it with your hands:

The laminate is recessed, there are no cracks, the locks are fastened. If you find it difficult to hammer in pieces of laminate by hand, you can do this: place a piece of laminate and tap it with a rubber mallet.

In our case, this is not required - the laminate fits in easily.

We usually make the backing end-to-end and glue it with tape. In this case, there is no need to do this - the backing is branded, here you need to take out this film and cover the next row with it:

What to do with tight locks

What should you do if the lock is tight? Usually tight locks are found on thicker laminates with a thickness of 10–12 mm.

It is difficult to insert such a board by hand. To do this, we use a piece of laminate, the lock of which fits into this edge of the board:

The length of the piece must be at least 20 cm so as not to break the edge. This is how we insert and nail it down:

Laying laminate flooring in the corner of a doorway

I would like to draw your attention to the following point. Here is the doorway:

The instructions for laying the laminate indicate: make a gap 10 mm wide from the wall:

This means that in the corner we will also have a gap 10 mm wide:

But we never do this and we don’t advise you, because the door casing usually does not have a thickness of 10 mm, it can be 8 mm, it can be 6 mm, and if it is semicircular, then its edge generally has a thickness of 2 mm. If you make a gap of 10 mm, and you have cash standing, you will get a gap here:

We always round this corner on the laminate a little, because if you cut it at an angle, you will get a hole. We make a gap of 3, maximum 4 mm from the area where the cash will be located:

Reliability of this technology

Also here, nothing has been sawed or filed, this is laminate from the package:

Insert and click this part:

Then we disassemble and check the locks:

Nothing broke off anywhere.

What to do if the battery is interfering

Now we’ll tell you what to do in cases where the battery interferes. Here the laminate may not fasten:

In this case, you need to push the bar in a sideways motion, as shown in the following figure:

This must be done very carefully so as not to break the lock. This is how the bar slides in and snaps into place.

How to insert the last row

A nail puller can be used for this operation. It presses the laminate in cases where the lock is tight and the planks are difficult to join.

We lay the last plank like this:

In order not to spoil the wallpaper, you can put something under the nail puller. We push the bar into place.

This is what the finished room looks like:

Now, using this technology, you can lay laminate flooring alone. Good luck!

All rights to the video belong to: Roman Zaitsev

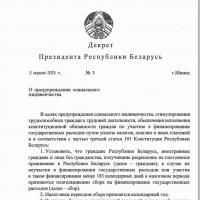

Teacher remuneration system

Teacher remuneration system Legal compass: what the payslip hides How income tax is calculated in Belarus

Legal compass: what the payslip hides How income tax is calculated in Belarus Archpriest Andrei Tkachev: biography, family

Archpriest Andrei Tkachev: biography, family Baked pike with potatoes Pike in the oven with potatoes and tomatoes

Baked pike with potatoes Pike in the oven with potatoes and tomatoes Wheat flour: varieties and types

Wheat flour: varieties and types Calorie, chemical composition and nutritional value

Calorie, chemical composition and nutritional value What does a laid table mean in a dream?

What does a laid table mean in a dream?