How to apply silicone in the bathroom. Updating silicone seams in the bathroom: tips and our own experience. How long does it take to dry after applying silicone sealant for the bathroom

Where is silicone used?

Surface preparation.

Care of silicone seams.

******************************************************

Different types of silicone and their features.

This article will focus on sanitary silicone sealants.

Silicones are divided into acidic and neutral. Acidic ones have a pronounced smell of vinegar. Neutrals have almost no smell.

In terms of performance, they almost do not differ.

The price categories of silicone sealants have a much greater difference. As usual, the more expensive, the better.

Sanitary sealants are available for wet areas. They contain bactericidal additives.

Personally, I prefer acid sealants.

Colors of silicones are issued the most various. About colorless, I note that there are matte and glossy. In certain cases, this matters.

For example - when sealing linen winding on water fittings - if you use a glossy sealant, it will always seem that water has come through. Which, of course, will be annoying.

Matte sealant will just be appropriate here.

Where is silicone used?

When repairing an apartment, silicone is used:

- when installing plumbing fixtures;

- for sealing gaps between the window and the window sill, as well as around the perimeter of the window;

- for sealing water fittings;

- for sealing air ducts.

The main mistakes that occur when working with silicone.

- Insufficient preparation of surfaces before silicone. Just cleaning the surfaces of dirt and dust is not enough. Be sure to degrease the surface with a degreaser, acetone, gasoline. Do not use white spirit, thinner 646, etc. - after their application, an oil film remains on the surface.

- When removing excess silicone, it becomes a pity for beginners to throw away these surpluses, and they try to somehow use them in further work. This is absolutely impossible to do. Often, you have to throw away more surplus than in the useful balance, but there's nothing you can do about it, you need to put up with it.

- The life of acid silicone is five minutes after application. During this time, you need to have time to remove the excess, otherwise a film will form that will prevent this from being done.

- The most common mistake is removing excess silicone “dry”. Be sure to spray the silicone with the solution described below before removing it. You can’t just sprinkle water - the result will be deplorable.

Tools and materials for working with silicone.

1. Painting knife:

This knife has one secret - a spare blade hidden in the handle.

With a knife, you can cut the old silicone, clean the seams, open a new silicone cartridge.

Chisel. It is used to clean the surface from coarse dirt.

Scraper for final cleaning of surfaces.

Stick for removing excess silicone.

Specialized scraper for removing excess silicone.

It has a built-in blade for cutting the neck of the cartridge.

Curly spatulas for removing excess silicone. The working edge must correspond to the intended width and shape of the seam.

Masking tape for surface protection.

Ice cream stick, sharpened to the desired radius.

cartridge gun

Brush for spraying soapy water.

Cutter for stripping seams from old silicone.

Toilet paper.

Spray.

Soap or neutral detergent. Suitable Fairy or App. Attention! Do not use alcohol detergents!

It is not necessary to have all these tools, it is enough to choose what is necessary for a specific task.

Surface preparation.

Surface preparation is reduced to cleaning and degreasing. Special attention: surfaces must be dry!

We clean with a chisel, scraper. Wipe with a rag with a degreaser. We are waiting for one minute - you can start silicone!

Silicone application technology.

Getting the tool ready.

We make soapy water by rubbing a piece of soap in water or adding it to water detergent. 1 tablespoon of detergent is sufficient per liter of water.

Actually, a liter is a lot. In most cases, 200 grams is enough.

We fill the sprayer. If it is not at hand, then you can use a brush or any brush.

We release the roll from the wrapper. We tear off several strips of two squares.

Cut off the end of the cartridge. We screw an extension spout onto it and make an oblique cut on it.

When silicone is applied, it is important to do it in one pass.

In this case, the width of the "sausage" of silicone should be greater than the width of the intended seam.

We obtain the desired width by cutting off the tip of the cartridge in the appropriate place.

We make the cut obliquely and we will apply the sealant, pressing the cut to the seam.

We insert the cartridge into the gun and do a test squeeze. Sometimes silicone has a colorless liquid at first, it needs to be removed.

All excess silicone is placed on a sheet toilet paper and wrapped in it so that it was impossible to get dirty later.

So, let's start applying silicone to the seam or into the corner.

The procedure for applying silicone.

For beginners, it is better to apply silicone at a time no more than 1m. Otherwise, you may not have time to withdraw the surplus.

When applying silicone, it must be taken into account that spraying with soapy water causes this solution to flow down.

Therefore, if you start the silicone of the vertical seam, then the lower horizontal seam will then have to be dried.

So it is better to start from the bottom tier, and then move up.

It is also useful to start from the corner at once in both directions. Let's say half a meter.

If a vertical seam goes up from the same angle, then masking tape must be glued to the vertical seam area in front of the silicone of the lower seams so as not to soak it when sprayed with soapy water.

So, silicone was applied to two sections half a meter from the corner. When applying, it is important to try to fill the gap in the corner as deep as possible.

This will keep the silicone in place.

To achieve this, you need to press the cartridge nose with a cut to the corner and, when extruding, make sure that there are no voids.

The silicone should lie in an approximately even layer, slightly larger than the width of the intended seam.

If somewhere there was a pass, then you can go back and add more silicone.

After the end of the application, we shoot the stock with a special button on the gun to stop the movement of the sealant.

The next step is to moisten the scraper with soapy water, which will remove the excess.

By the way, an ordinary teaspoon is well suited for this purpose.

If you do not let the silicone dry on it, then it will be quite suitable for further use.

When removing excess, you need to make sure that the silicone does not fall from the scraper (spoon).

At this point, gently tear off the scraper from the seam, spread the excess on a piece of toilet paper, wipe the scraper clean, moisten with a solution and continue to remove from the place where we finished.

If excess silicone remains on one of the surfaces (outside the resulting seam), then you should not worry about this - it can then be removed without problems - with a scraper with a blade.

Here it is important not to get carried away and not to climb onto the non-wetted area of the seam, because it is impossible to remove silicone “dry”! - The edges of the silicone will be smeared along the walls and it will be impossible to trim it!

So, the excess is removed, you can continue applying silicone.

We continue again in both directions in order. If there is a corner ahead again, then we start from the corner and approach our stopping place.

If there is a rounding along the way, for example, the edge at the sink, then silicone is applied as usual, and removed with a scraper in a perpendicular position - that is, gradually tilting it, following the radius of the rounding.

In some cases, you can correct the shape of the resulting seam with a finger dipped in soapy water.

With silicone adjoining the sink to the wall, it is important not to “fail” the seam so that there is no recess in which water could stagnate.

This can be achieved by removing the excess with an ice cream stick placed horizontally.

By the way, the faucet on the sink at this moment can greatly interfere, so you need to remove it in advance or use a short stick.

Having finished with the lower tier of horizontal seams, proceed to the vertical seams.

Removing excess silicone, cleaning surfaces.

Excess silicone remaining on the wall (floor) can be easily cleaned after drying with a scraper with a blade. The remains are wiped off with a cotton cloth.

If you happen to accidentally drop silicone on the front surface, then you can immediately wipe it off with a rag moistened with a degreaser, or you can wait until it dries and peel off without problems.

True, at the same time there is a risk of stepping on it and pulling it all over the apartment, so it is better to use the first option.

How to remove silicone from a joint and clean the surface.

Old silicone can be removed from the joint by cutting through it with a sharp knife, separating it from adjacent surfaces. Clean up the remains with the same knife or scraper with a blade.

If you have time, you can wet a rag with a special compound and put it on the seam for 24 hours, and then easily remove it.

Care of silicone seams.

The curing time of the joints varies depending on the thickness of the joint and the humidity in the room.

On average, after two hours it is already possible to pour water on the seam, and after a day - wash it.

If silicone was used to seal the tile joints of the plumbing hatch, then it takes from three to five days to wait for complete hardening.

Silicone does not require special care, it is enough to wash it with soapy water with non-abrasive sponges or a regular cloth.

If blackness began to appear on the silicone, this means indoors high humidity or in this place the silicone has a hole in which water stagnates.

The fight against blackness comes down to eliminating these causes.

Below is a video showing the silicone window sill.

4 comments

-

I tried to work with a cosmophen. The result did not suit me. You have photo video good example? And, maybe share the welding technology?

Agree with the previous statement. The only minus cosmofen can no longer be replaced as silicone, but at the same time it is not necessary. It does not turn yellow and does not turn black. Unfortunately there are no photos either. The principle of operation is approximately the same as with silicone.

During the repair work one way or another, it becomes necessary to use a sealant. But you need to know how to properly apply the sealant, otherwise the work will go down the drain. Typically, silicone sealants are used to fill gaps and cavities to seal and protect against various factors media, for gluing various surfaces between each other, for sealing seams and joints, for example, in shower cabins, wall joints, for sealing downpipes, for gluing loose stone tiles, for sealing window frames and boxes, etc.

Remember: silicone sealants should not be applied to damp surfaces.

Sealant technology.

Silicone sealants are applied at air temperatures above +5°C. (usual operating temperature range from -50 to + 180°C). High-temperature sealants retain their properties at a temperature of +250°C.

Sealants are purchased in cartridge-tubes and can be applied both manually and with a mounting gun.

Buy silicone sealant by color and purpose in the construction market.

Don't forget the silicone gun, as sealant is squeezed out by the mechanical piston of the gun. Also prepare a spatula for silicone. They are made of white rubber or plastic. They have the shape of a shoulder blade, a rectangle or another shape with rounded corners of different radii.

Prepare surface for applying sealant. If necessary, remove the old sealant, clean the surface of dirt, and then degrease with acetone, alcohol or a special degreaser. Let the surface dry - about 30 minutes.

To form a correct seam, it is necessary that the silicone interact with both sides of the seam. If there is an interaction with a third party - the base, then the silicone loses its elasticity and, when deformed or stretched, it simply mechanically breaks.

How to apply silicone sealant?

Cut the edge of the sealant spout at an angle of 45 ° and screw the nozzle in the form of a syringe onto the tube. Carefully direct the sealant nozzle into the joint and squeeze the sealant from the gun into the seam. We start from the far edge, we lead the gun towards us, we hold it at an angle, we try very hard to apply the sealant at a time and in an even layer.

Excess silicone should preferably be removed immediately with a plastic spatula with a rounded end. The spatula must be kept straight, in one position. Conduct in the same way as when applying to yourself. Do not tear off the surface, do it at a time.

The surface setting time is usually no more than 5-10 minutes. During this time, it is necessary to form a seam.

Drying time (i.e. complete hardening) of the sealant usually occurs after 5 days.

[ Click on photo

for increase ]

It's a pleasure to watch a professional tiler apply silicone sealant. With an economical movement in one pass, the seam is filled, it is just as easy to level it. Alas, attempts for the first time to independently apply and level the sealant on the joint intended for this, often end up with a sealant sloppily stuck not only into the seam, but also far beyond its borders, smeared with hands, clothes and tools.

Still would! The ease with which the finisher performs this work is due to considerable experience and knowledge of the rules for working with this material. Let's take a look at this technique.

Technologies

Which sealant to choose: silicone, acrylic or polyurethane?

Sealants are compositions based on polymers. Used to fill cracks, crevices, fill voids around doors, window boxes, water pipes, heating pipes

Professional Joint Sealants - Overview

Professional seam sealers are used to fill seams building structures and joints. These are mastics that harden when exposed to moisture from the air.

How to use expansion joint sealant

For sealing joints that are subject to deformation, polyurethane sealants of medium hardness and elasticity are used.

Joint sealing. Overview of technologies and materials

The key to successful joint sealing is the use of high-quality materials in compliance with all technological requirements

Sealant silicone Titanium (Tytan). Instructions for use

Titanium Silicone Sealant is a recognized global brand that has stood the test of time.

Before starting work, it is necessary to correctly fix the tube with sealant in the gun. Give Special attention cut off the silicone tip. Make a hole with a utility knife, cutting off the tip at an angle of 45 degrees and at such a distance that the diameter of the resulting hole matches the size of the seam to be sealed.

Before starting work, lightly press the trigger of the gun so that the first droplets of silicone appear in the hole, which will mean that it is fully ready for action. After that, we proceed to consider the question of how to properly apply silicone sealant. Clean the desired surface from dust and dirt and degrease it special means. This procedure can be done with gasoline or alcohol.

If the gluing procedure on this surface has been carried out more than once, then be sure to clean it of the remnants of the old silicone. This can be done with a simple spatula. If the surface is affected by a fungus or mold, be sure to disinfect it with a special agent and wipe it with alcohol. After applying the solvent, wipe the surface dry with a cloth.

Apply masking tape parallel to the seam to protect the rest of the surface from contamination with sealant. Between the glued tape, leave exactly the space on which the silicone will be applied. As a result, all excess sealant will be on the glued strips. How to apply silicone sealant evenly so that it lies on the seam in an even strip?

When processing a seam, keep the gun at the same distance from it at all times. Don't apply the layer too quickly as you will end up with discontinuous bands of silicone with bubbles inside. Also, do not hesitate to remove excess silicone. We give the seam an aesthetic look. This can be done with a spatula, removing excess silicone with it.

Another good way process the seam - a finger dipped in a soapy water solution. Be sure to wash your hands immediately afterwards to avoid any bits of silicone remaining on your skin. Keep an eye on the application of the seam so that the layer does not turn out to be too thick. In addition to wasteful material consumption, after application, you will have to tinker with alignment.

Carefully peel off the masking tape so as not to damage the elastic seam, and if necessary, rid the surface of unnecessary contaminants while the sealant is still in its raw form. Simply wipe dirty areas with a cloth dampened with soapy water. We are waiting for the sealant to dry completely in order to check the seam for water tightness and start using water.

One of milestones when carrying out repairs or assembling structures - the design of joints. It is on how well they are sealed that the duration of the operation of the premises, individual nodes and the preservation of their attractiveness depends. The modern building materials market allows you to choose the perfect sealant. Most often it is a silicone-based solution. But to get a really high-quality result, you need to not only buy the right material, but also know how to use the sealant correctly. You will learn about this from this article.

To understand why silicone sealant is most often used, it is enough just to get acquainted with its main advantages - these are:

Where can silicone sealant be used?

Another significant advantage of silicone is that the range of applications for such a sealant is really almost unlimited. It is used in various industries - from the assembly of equipment to mechanical engineering.

In construction, with the help of such material, a number of the following works can be carried out:

How to choose the right silicone sealant?

In order to appreciate all the advantages of your choice and complete all the planned work quickly and efficiently, when buying a silicone sealant, be sure to keep in mind that it differs in:

How to use silicone sealant?

The whole process of work consists of 3 simple steps:

Materials and tools for sealing joints

Silicone consumption

At the time of buying consumable, take into account the amount that you will need to complete the work of sealing the joints for 1 time. According to the standards, the consumption of silicone is about 300 ml per 17 linear meters with a thickness of the applied layer of 3-4 mm.

Application of sealant

Proper application of silicone will give a high-quality joint sealing result. Therefore, adhere to the following sequence of actions in the course of work:

Conclusion

As you have already seen, sealing the joints with a special silicone sealant is very simple. The main condition is to buy the right, high-quality material and follow the sequence of work. In this case, you do not have to spend a lot of time and effort at this stage of repairing your home.

Substances and their physical properties

Substances and their physical properties Classification, structure, nutrition and the role of bacteria in nature

Classification, structure, nutrition and the role of bacteria in nature Bacteria - the most ancient organisms on Earth Bacteria - the oldest group of living organisms

Bacteria - the most ancient organisms on Earth Bacteria - the oldest group of living organisms Epithets, metaphors, personifications, comparisons: definitions, examples

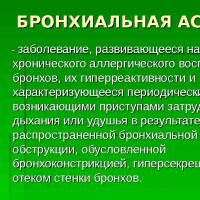

Epithets, metaphors, personifications, comparisons: definitions, examples Bronchial asthma Bronchial asthma

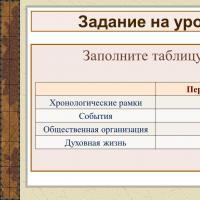

Bronchial asthma Bronchial asthma Roman Empire Ancient History

Roman Empire Ancient History Flexible removable dentures: design, features and benefits Varieties of soft dentures with photos

Flexible removable dentures: design, features and benefits Varieties of soft dentures with photos