Instructions on how to cover the roof with roofing material with your own hands

The abundance of modern roofing materials and various additional elements makes it easy to do roofing work yourself without resorting to the help of professionals whose services are quite expensive. In addition, the presence of the Internet and a large number of reference books greatly facilitates this process. Despite the development of new materials, traditional ones also continue to be used and, precisely for this reason, the question of how to cover the roof with roofing material with your own hands remains relevant to this day.

Main stages of work

Any construction required start with preparation necessary materials and drawing up a work plan. Otherwise, you can forget about a seemingly insignificant detail that will nullify all efforts. In addition, the plan allows the work to be carried out in stages, which significantly reduces errors and irregularities in the laying of material, which can lead to the need to start the whole process again.

The main stages of roofing:

- Carrying out the necessary calculations and purchase of material.

- Surface preparation roofs.

- Laying roofing felt

- Additional sealing roof areas with an increased risk of leakage.

It should be immediately clarified that for roofing work with roofing material, at least two people and a number of additional equipment, as well as tools, will be required:

![]()

- Qualitative knife, quite often they use several clerical or homemade shoe knives to get an even cut.

- Roulette, for measuring pieces of material.

- Burner, is needed to fuse the individual parts of the roofing material.

- Special ice rink, which will allow you to glue the joints of the roofing material after they are heated.

All these tools are sold at any hardware store, and the roller and burner can be rented without spending money on their purchase. Although, if finances allow you to better purchase this equipment, as it can be useful if you need to repair the roof of the house.

Selection and purchase of roofing material

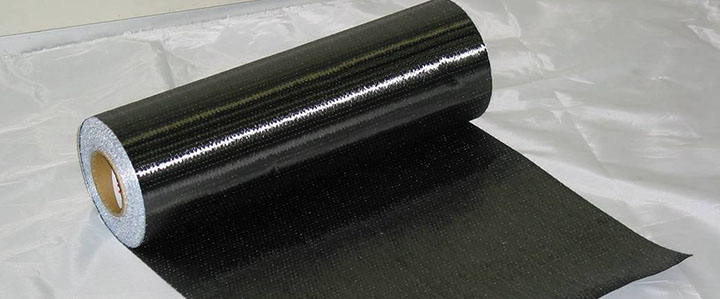

From the right choice of material not only the operational life of the roof as a whole depends, but also the ease of work in particular. A wide choice of roofing material is produced, which is marked with a special designation.

For installation on the roof roofing material with initial letters R.K. is required., which means "Roofing felt", the next letter shows the fraction of the upper layer. For the roof, material with coarse-grained dressing is usually used - RKK 350.

The numbers in the abbreviation indicate cardboard density, which was used as the basis for pouring bituminous masses. If the roof is covered in several layers, then RKK350 is used for internal work, and RKK400 for the outer layer, which has an additional layer of asbogal. This material provides maximum resistance to negative environmental factors, and also increases protection against mechanical and physical influences.

Another important point when choosing a material is its weight, this is especially true if the roof covering is changing and the lag and rafter system has already been built. The weight of the material must be selected so that the rafters can withstand it.. It should be borne in mind that in winter, in addition to the weight of the material itself, the weight of snow is also added, which increases in spring during thawing.

Preparation of rafters and roof covering

The next stage of construction in the question of how to cover the roof with roofing material with your own hands is the preparation of the rafter system and the foundation.

Rafter system for roofing material should be in increments of no more than 15 cm to ensure minimal sag in the flexible material. The ideal solution is considered cover the entire roof with sheet material type of plywood or chipboard, the cheapest option use fiberboard sheets, but they can warp under the influence of a variable temperature.

A continuous coating will minimize possible loads on the soft roofing felt not only in winter, but also in the event of heavy and sharp objects falling onto the roof, such as tree branches during gusty winds or large hail. Rigid bedding will give the roof a more aesthetic appearance, eliminating the deflection of the roofing material between the elements of the crate.

In some cases, the roofing material is not laid on a wooden roof, but on a concrete slope. As a rule, such work is carried out in case of restoration or replacement of the old coating with a new one. It is necessary to carefully clean the old cover material by removing it from the roof. If the material was resin-based, it is easier to heat it up, and individual fractions can simply be melted. When large cracks, holes and other defects are encountered in concrete, they must be carefully repaired before laying a new roofing.

Direct laying of roofing material

The material is laid in multiple layers, and the steeper the roof slope, the fewer layers are needed to ensure high-quality waterproofing. This is due to the fact that with a steep roof during rainfall, water does not linger on it, completely and quickly draining to the ground or into water intake channels. On average, for roofs with a slope of 450, two layers are enough, but for a roof with an angle of 15-200, at least 3-4 layers of material must be laid; when the angle decreases, it is recommended to use an additional waterproofing membrane.

For laying roofing material, three classical methods are used. How to lay, everyone decides for himself. However, regardless of the choice of laying method, it is done in such a way that there is roofing material lunge not less than 30 cm. These remnants are needed to tuck the roofing material under the edge of the slope and place it on the pediment.

The first method, which is the most common, provides for laying roofing material in strips along the roof slope. The first strip is laid with the release, on the pediment, from which the wind blows the main part of the year, then all subsequent strips are laid from 10-15 cm, overlapping each other.

Quite often, the roof has a fairly large area and one strip length is not enough to cover two slopes at once. In this case, segments are used so that each of them overlaps the ridge by 25-30 cm. After laying the main material on the roof ridge, an additional strip is applied along the entire length of the ridge, which will hang on each slope.

The second method is called laying across the slope, the people say herringbone. You need to start laying the strips from the edge of the slope, gradually shifting to the ridge. The overlap of individual strips should also be at least 10-15 centimeters. The roof ridge is closed with a single sheet in both directions at once.

Third way. It is used for multi-layer coating or in the case when sheets of roofing material have a non-standard cut. This method involves laying the first layer along the slope, and the next across. The parameters of the release of material towards the gables and the edge of the slope, as well as the overlap of the ridge, are performed, as in the first two methods.

When laying roofing material on a complete surface it must be impregnated with a special rubber-bitumen mastic, which will improve the adhesion of the roofing and the base. If several layers are laid, then they are laid with an offset, so that the joints of different layers do not fall on the same line.

Separate sheets of material are glued together as a result of heating the roofing material with mastic. In order to understand when the roofing material reaches the required temperature, a polyethylene film is applied to it during the production process, which begins to brighten, and then completely burns out during exposure to the flame from the burner.

As soon as the film starts to burn, the roofing material is ready for gluing. If you keep him under fire for too long, he may burn through, which will lead to damage to the entire segment. The heated material is carefully pressed against the surface of the entire roof with a hand roller or an old rag rolled into a roll so as not to get burned. Subsequent heated layers are laid only after the previous ones have cooled down.

When laying roofing material on a wooden roof, its individual sheets are fastened not by gluing, but with the help of planks that are hammered into the rafters and logs. Planks can be made in advance from metal or wood. Wooden slats are not durable, and after 5 years they can be deformed and cracked by water under the influence of external factors. This is what makes metal fasteners popular, especially if it is made of aluminum or galvanized iron, which is not afraid of corrosion.

Given the need to fasten the roofing material with rigid strips, it is necessary to adjust the sheets of material in advance so that the joints fall on a rigid structure that will allow you to install fasteners.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical