Roof overhangs

Roof installation will not be completed if the roof filing is not completed. This stage of construction works forms the final appearance of the building and ensures the protection of the facade and foundation from moisture, therefore, it must be carried out with great care.

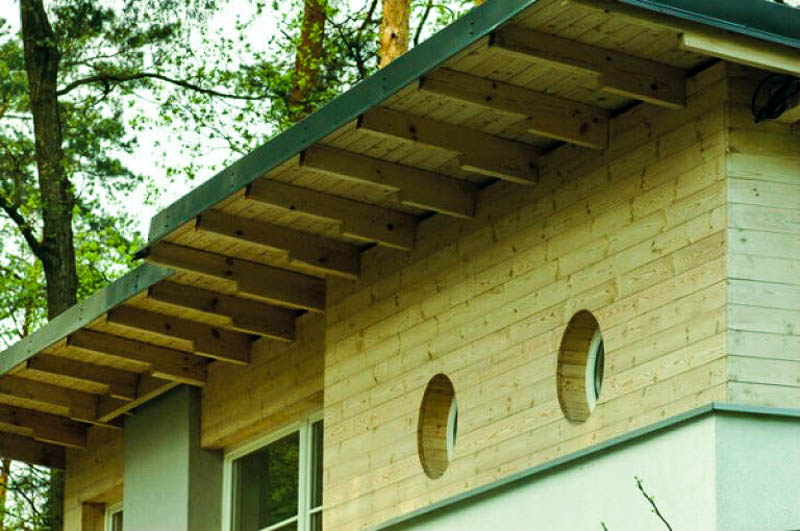

Any roof has certain design features, for example, overhangs that hang over the walls of a building or over a pediment. Accordingly, they are called cornice (side) or frontal (pediment).

The overhang, or as they used to say, the eaves, protrudes beyond the wall of the house and protects it and the foundation from excess moisture (so that rain or melt water rolling down the roof does not fall on the walls and does not wash away the foundation) and shade the facade from bright sunlight. As a rule, the width of the overhangs ranges from 40 to 100 cm. For a wooden house, overhangs are made from 55 cm wide and up to 120 cm, for a brick house - up to 55 cm.

The filing of a sloping roof allows you to make an overhang of a smaller width than that of a steep one, since in the first case the trajectory of precipitation from the roof will go far beyond the boundaries of the blind area and, of course, the walls.

Installation technologies for overhangs (cornices) may differ depending on the roof structure, the length of the slopes. The filing of a gable roof, for example, is easier to do than a four-slope one.

The most elementary way to make a roof overhang is to use rafter legs. They should protrude beyond the perimeter of the walls. The wider the overhang, the longer the rafter legs should be. But in this technology there is one small, but very significant nuance - the weight of the truss system increases and the load on the building envelope and, ultimately, on the foundation increases.

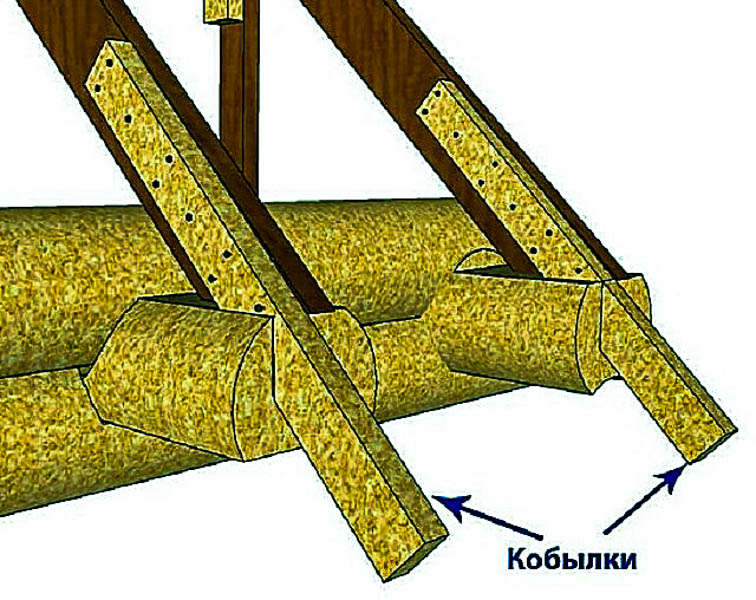

The second technique provides the possibility of creating a lightweight structure with a minimum consumption of materials. Since there is no load on the overhangs, it is possible to build up the rafter legs using “fillies” - pieces of edged board, which, of course, are much thinner than the rafters. Fillies allow you to mount cornice overhangs from lighter (which facilitates installation) and cheap building materials.

Filly is also used when the length of the roof slope exceeds the maximum standard length of lumber - 6 m.

The advantage of using fillies is that they can be used to create a new roof slope line (by changing the shape of the roof overhang), because they are fixed at the right angle. In addition, if you decorate the protruding part of the fillies with carvings, then the structure as a whole will become more elegant.

The advantage of using fillies is that they can be used to create a new roof slope line (by changing the shape of the roof overhang), because they are fixed at the right angle. In addition, if you decorate the protruding part of the fillies with carvings, then the structure as a whole will become more elegant.

The fillies are attached to the rafters. For more reliable fixation, roofing nails are used, which are hammered through (through the rafters and the overlay board) from opposite sides, do it in a checkerboard pattern at a distance of 15 cm, and their protruding parts (by 30-40 mm) are bent. Fillies are attached with a minimum of four nails to ensure a secure connection.

Not hemmed and hemmed

The overhang is a continuation of the roof and an integral part of it, so you need to choose the right type of overhang, taking into account the composition of the roofing cake and the climatic conditions of the area where the house is located. Roof overhangs can be: not hemmed and hemmed.

Sometimes the overhangs are not hemmed so that decorative supports (protruding parts of the rafters or filly) are visible, which are an element of the exterior. In this case, all work is carried out as carefully as possible so as not to spoil their aesthetic appeal. But it must be borne in mind that non-hemmed overhangs increase the windage, and a strong gust of wind can rip off the roofing material, especially in areas with high wind loads.

Not hemmed overhangs are left on gable, single-slope or hip (four-slope) roofs.

A variety of materials are used as roof lining.

A variety of materials are used as roof lining.

It is recommended to hem overhangs on any type of roof, regardless of the shape, angle of inclination or width of the eaves. After all, this allows not only to improve the decorative qualities of the structure, but also to protect it from the aggressive effects of the environment.

Ventilation is important!

Roof overhang filing should not impede the passage of air and hinder the natural ventilation of the space under the roof. This applies to both cold and insulated roofs with residential attics.

When filing cornice overhangs, it is not allowed to use mounting foam or any sealants so that condensation does not form and the roofing cake does not get wet.

Ventilation grilles installed in the roof lining, gaps between the hemmed overhang and the wall will provide natural ventilation and significantly extend the life of the roof itself. But only the side overhangs should be ventilated, and the front ones are sewn up tightly.

It should be noted that the filing of cornices is done not only in new houses, but also in old ones. Therefore, in such buildings, before sewing up the overhang, it is necessary to carefully examine the roof structure, and most importantly, all protruding elements. What does not hold well must be fixed, what is rotten must be removed (cut or sawed off, replaced with good wood) and only after all defects found have been eliminated, the surface must be treated with an antiseptic, and then proceed to filing.

It should be noted that the filing of cornices is done not only in new houses, but also in old ones. Therefore, in such buildings, before sewing up the overhang, it is necessary to carefully examine the roof structure, and most importantly, all protruding elements. What does not hold well must be fixed, what is rotten must be removed (cut or sawed off, replaced with good wood) and only after all defects found have been eliminated, the surface must be treated with an antiseptic, and then proceed to filing.

On the rafters and on the box

There are two main methods for filing roof overhangs: along the rafters and along the wooden box. Roof overhangs with a slight slope are usually hemmed along the rafters. The location of the mounted skin will also correspond to this angle of inclination.

Before starting to sheathe the overhang, it is necessary to align the protruding legs of the rafters (fillies), for which they pull the cord and saw off the excess parts parallel to the plane of the wall. And if some rafters turned out to be a little shorter, then these deviations are corrected with the help of scraps of boards, which are nailed to the rafter legs that stand out from the general row. Only after the line is completely aligned, the work associated with filing the overhangs begins.

wooden box

The construction of the box is a more troublesome method, entailing additional consumption of materials, but this filing technique is ideal for roofs with a large angle of inclination. The frame of the box is made from two scraps of a thick board (40 mm) or a bar.

The design of the box is simple: one piece of board (or bar) is placed close to the wall, its upper part is attached to the rafters, and the lower part is connected to the second board, one end of which is fixed on the lower part of the rafter leg. It turns out a triangle, the middle part of which is the rafter leg (the number of triangles corresponds to the number of installed rafters).

To give rigidity to the wooden box, it is additionally fixed with metal corners. After installing the box and the device of the crate, they begin to file the overhang with the material chosen for this purpose: edged board, wooden clapboard, siding, spotlights, profiled sheet.

To give rigidity to the wooden box, it is additionally fixed with metal corners. After installing the box and the device of the crate, they begin to file the overhang with the material chosen for this purpose: edged board, wooden clapboard, siding, spotlights, profiled sheet.

The filing of the front overhangs is slightly different from the installation of the side ones. For the device of the pediment cornice, the ridge board is made a little longer so that it extends beyond the perimeter of the pediment to the required distance, the crossbeams of the crate should protrude to their ends, the cornice board is attached to their ends, and then the lower part of the pediment overhang is hemmed.

Cornices can be hemmed after the installation of the truss system or after the installation of the roofing material has already been completed - there is no fundamental difference in the order of work. But, if external insulation of the building is planned, then the filing of the roof is carried out only after the insulation work has been carried out. And it doesn’t matter if you sheathe the overhang perpendicular to the facade or along it.

Sheathing board

A good option for sheathing is a board, 15-20 mm thick. Its width is chosen based on the width of the cornice and the desired decorative effect - in the range from 50 to 250 mm. It is desirable that the materials used do not have significant deviations in size, because otherwise the appearance of the structure being created will deteriorate.

Filing a wooden overhang does not create any particular difficulties during installation. The board allows you to provide natural ventilation of the roof, because no matter how hard you try, there will still be gaps between the wooden elements, in addition, when hemming the box, they usually leave small gaps between the boards (10-15 mm) and then you do not need to cut in the ventilation grill.

If the length of the boards is not enough, they are joined with an offset: in such a way that a through seam is not formed, and they are attached to the frame in several places to prevent deformation.

If the length of the boards is not enough, they are joined with an offset: in such a way that a through seam is not formed, and they are attached to the frame in several places to prevent deformation.

The filing at the corners of the four-pitched hip roofs is joined at an angle of 45 degrees.

The tree is not very resistant to aggressive environments and pests, because no one is immune from the appearance of woodworms, mold or even fungus in his wooden house. Therefore, beforehand (before use), wooden building materials must be treated with any antiseptic or fire-retardant composition. It is advisable to do this twice: before installation and after it.

clapboard

The filing of roof overhangs with clapboard is also used quite often. The main thing is to choose high-quality material - even, without bluish spots, not too damp and not overdried (natural moisture is what you need), not having a lot of knots.

Before use, the lining must be folded on the street and left for several days, so that it, so to speak, acclimatizes a little and does not warp after installation. This is if it was stored in a warehouse or in a barn. In the event that the material was shipped to you directly from the stack on the street, it is immediately ready for use.

The lining is laid tightly, leaving no gaps (as is done when installing boards), but at certain intervals small holes are cut out, which are covered with ventilation grilles.

The filing of any overhang is carried out with a clapboard treated with protective compounds.

Siding

Siding

PVC siding is most often hemmed with cornices when this material was used for cladding the facade of a house. The remaining trimmings are quite suitable for this case. Siding is laid and fixed perpendicular to the walls, and installation along the walls with long panels is not used, because they are thin and will sag even if they are fixed in several places.

Depending on the width of the eaves, the siding pieces are fixed at least in two places, and for reliability it is best to attach them at four points. To make the finish look neat, use corners at the joints, planks in the shape of the letter "P" to decorate the edges. Be sure to install ventilation grilles.

When filing roof overhangs with siding, you need to be very careful to prevent marriage in work.

By the way, overhangs are always hemmed along the crate, regardless of the material used.

Soffits

Soffits

Soffits are also used for filing overhangs - perforated panels that allow air to pass through and thereby protect the roof from the appearance of fungus. The panels are fastened together with lock-type joints.

By the way, spotlights are not only fully perforated, but also with perforation in the center and even solid - without perforation at all

They produce plastic, steel, aluminum and copper roofing spotlights. Plastic products are similar in appearance to vinyl siding, but they are thicker and wider. These spotlights are popular because they are inexpensive, durable, UV resistant and visually appealing. When installed, they form a seamless web.

Steel spotlights are much stronger than plastic ones, but also much heavier, but they are able to withstand even high mechanical loads. Often they come with roofing material.

The filing of overhangs with aluminum soffits is now increasingly being ordered - it's fashionable. Aluminum is lightweight, does not corrode and does not expand under high temperatures. That's just the color palette of spotlights from this material is not diverse and consists of only two colors: white and brown.

Copper spotlights are the most expensive, but also the most presentable and durable. They will last for many years without losing their decorative qualities.

So, by choosing spotlights from one or another material (depending on your financial capabilities), you can correct the look of your house and create an original architectural ensemble with interesting contrasting elements. And, of course, to reliably protect the building from rain, sun and wind.

So, by choosing spotlights from one or another material (depending on your financial capabilities), you can correct the look of your house and create an original architectural ensemble with interesting contrasting elements. And, of course, to reliably protect the building from rain, sun and wind.

Decking

The lining for overhangs should be chosen so that it not only copes with its functional purpose, but also looks good and is durable.

Despite the fact that corrugated board is primarily a roofing material, it has all these qualities, and its wide color palette allows you to choose the color of the lining to match the color of the roof, facade, or, conversely, use contrasting shades. Here it is possible to use even halftones - a tone darker or lighter. Sheathing with corrugated overhang is very convenient.

Decking is hemmed in the same way as all other materials. It is durable, easy to use, lightweight, decorative, but does not let air through, so you need to mount ventilation grilles at a certain distance or leave a gap along the wall of the building with a width of one wave.

Decking is hemmed in the same way as all other materials. It is durable, easy to use, lightweight, decorative, but does not let air through, so you need to mount ventilation grilles at a certain distance or leave a gap along the wall of the building with a width of one wave.

Frontal board

After the filing of the new overhangs is completed, the frontal board is nailed to the ends of the overhangs of the rafters. Since they are cut obliquely, their cuts are slightly larger than the diameter of the rafter legs. The width of the frontal board is chosen in such a way that the ends of the overhangs are completely covered. The thickness of the board can be from 20 to 30 mm, because it does not experience strong wind loads, so a thicker material is only an additional financial cost for which there is no justification.

On top of the frontal board, the material that was used for filing the overhangs (lining, siding, corrugated board ...) is mounted. The outer corner of the overhang is closed with a corner, metal or wooden, which comes with the siding (which is much less common, because it is less resistant to precipitation).

That's it - your roof filing is finished!

That's it - your roof filing is finished!

To give the structure a more attractive look, a corner is also installed at the junction of the filing and the walls of the house - it hides irregularities and attachment points with screws or nails.

We give a guarantee

Specialists of Moskomplekt LLC have been working in the construction industry for many years, so they have rich experience in solving any tasks assigned to them. Hemming any roof is not a problem for us! If you need to do some work, call the office, write an e-mail or leave a message on our website. Managers will promptly contact you, consult, suggest how to conclude an agreement with us. We work quickly, efficiently and always give a guarantee. Contact us, we will help you.

Price for services

Prices are for 1 p/m

Installation of the frame of eaves and gable overhangs - 220-320 rubles.

Filing with spotlights - 240-365 rubles.

Board filing - 400-510 rubles.

Painting wooden elements in 2 layers - 45-85 rubles.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical