The process of insulating the roof with your own hands in a private house

Did you notice that the roof was sagging? Are there signs of roof damage? Is the truss system rotting or rusting? All these are the consequences of neglecting the work on insulation. Realized the need? Now let's figure out what a private house is, and most importantly, how to prevent this from happening again.

For carrying out independent work on thermal insulation of the roof, fibrous or monolithic materials are most often used. The former include heaters based on natural organic and inorganic fibers, the latter are foamed (polystyrene) and extruded polystyrene foams.

When choosing, they are guided by the material of the truss system (overlapping) and the side from which the work is performed: from the outside of the house or from the interior. Let us analyze the characteristics of the main thermal insulators, which have a direct impact on the possibility of conducting insulation without the involvement of outside workers. We do not consider insulation with bulk insulators due to their insufficient heat-retaining capacity, increased labor intensity, and excessive load on ceilings, walls and foundations.

Main differences

For clarity, we present the difference between the two types of insulation materials in the table.

| Name | fibrous | Monolithic |

|---|---|---|

| Vapor permeability | high | Low |

| fire hazard | Low: Organic due to flame retardant treatment | High: ignite easily when exposed to open flame, spread flame over their surface, emit toxic substances unsuitable for breathing |

| Zero: for inorganic due to non-combustible starting material | The use of flame retardants in the production of foam plastic gives it the property of self-extinguishing when the source of ignition is removed. | |

| Biological stability | Low: for organic even when impregnating, high for mineral | Low: Styrofoam, High: Extruded Styrofoam |

| Compressive strength (pressure) | Minor: slightly higher at the slabs. Squeezing significantly reduces the heat-holding capacity | High: withstand significant static loads |

| Flexural stability | High: for roll materials, much lower for slabs | Low: if the calculated force is exceeded, they break |

| moisture absorption | High: for organic, low for mineral heaters (about 1% of the volume) | Low: Styrofoam 4%, Extruded Styrofoam 0.4% by volume |

| Chemical passivity | High: do not react with chemically active substances | Low: dissolve when exposed to acids, solvents, petroleum products |

- outside with a wooden truss system - fibrous thermal insulators;

- with metal, stone, concrete roof support - monolithic heaters.

The lack of usable space forces us to use every opportunity to create favorable conditions in all rooms, including the attic, turning it into a residential attic.

External work is possible when replacing the roofing, or when installing a new truss system to replace the old one, or at the stage of building a private house with your own hands.

To implement the plan, it is best to choose a dry period of time, since this process takes a lot of time.

With wooden base

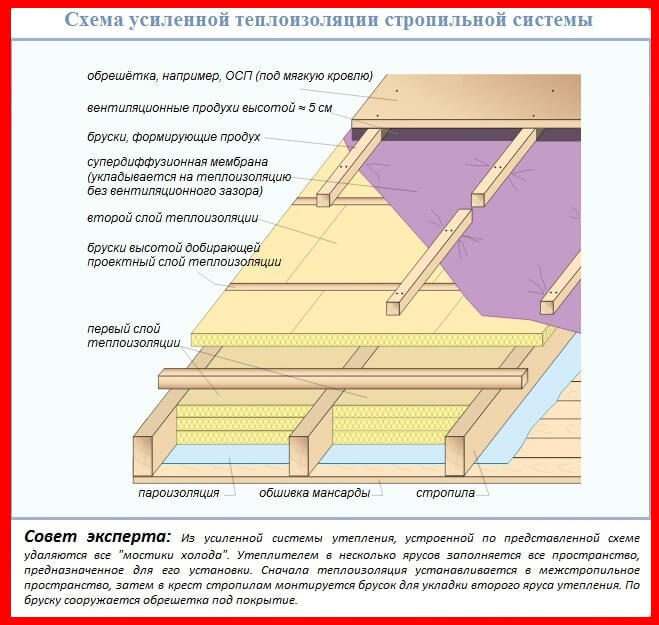

If a new roof support is being installed, then it is necessary to provide for a distance between the rafters 10-30 mm narrower than the width of the selected insulation material. This will make it possible to lay the heat insulator without additional fixing, to avoid cracks, excessive consumption of insulation.

After installing the rafters, before insulating the roof, a septic treatment of the materials used is carried out in order to prevent rotting and insect infestation.

From the inside, with the help of a construction stapler, a vapor barrier membrane is fixed, which prevents moisture from entering the insulation from heated rooms. Seams are sealed with double sided tape. During installation, the material is lightly stretched to avoid the formation of wrinkles. Laying of the strips is carried out from the bottom up with the top strip overlaid on the bottom. The amount of overlap is determined in accordance with the manufacturer's recommendations.

Insulation saturated with moisture by 20% reduces the heat-saving capacity by half, by 40% - heat saving is zero.

Close to the vapor barrier, a crate is installed for mounting the finish. The step and material of the crate is determined based on the finish used.

Then they move on to work on the roof from the outside. A heat insulator is laid between the rafters. In the case of using fibrous materials, consider the presence of a waterproofing covering material on the roof in case of rain.

A waterproofing film is laid on top of the rafters. Its fastening is carried out with a construction stapler. The film is laid with an overlap from the bottom up. The overlay of the strips is fixed with a double-sided reinforced tape.

The film should have a slight sag to prevent tearing at low temperatures.

The diffusion membrane is fixed with a counter rail using nails or screws. Across them, a crate is installed for mounting the roofing. When using a profiled sheet, it is recommended to use a batten spacing of 25 cm. In this case, the two lower boards are laid every 10 cm in order to be able to securely fasten the edge of the sheet and install the drainage system. Do-it-yourself insulation of such a roof in a private house ends with the installation of roofing material and additional elements. Installation of additional elements is carried out after finishing the pediment.

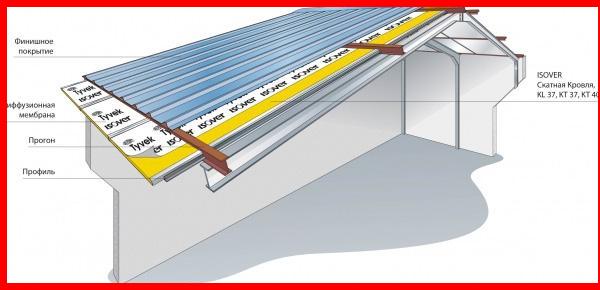

On metal girders

Roofing on a metal base requires insulation with polystyrene foam boards. This requirement is due to the possibility of condensation on the metal at low temperatures and the penetration of moisture into the volume of fibrous insulation. Waterproofing the truss system will lead to additional costs and may be broken during operation.

Before laying the insulation, the metal is protected from corrosion using varnishes, paints, primers. Expanded polystyrenes have zero vapor permeability and low water absorption. Protection from air saturated with moisture is necessary for metal rafters. For this purpose, steam and waterproofing is installed. The rest of the installation is carried out according to the above technology.

We warm from the inside

Such thermal insulation is carried out during insulation, creating a warm or cold attic after roofing with waterproofing. This allows you to protect the building from external atmospheric influences during a break in work due to lack of time or financial resources.

If, when installing the roofing material on a wooden crate, waterproofing was not installed, in this case there are 2 solutions:

Lay out the roofing material with the installation of a waterproofing membrane.

Roof insulation is carried out with polyurethane foam, inviting specialists.

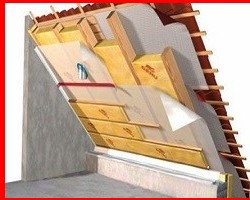

Warm attic

When using rolled materials, it is necessary to install fasteners to tension the supporting layer of wire or rope. Laying is carried out from the bottom up, carrying out the installation of support. Then we produce a vapor barrier of the insulation layer, not forgetting to seal the joint with adhesive tape. The installation of the crate for mounting the finish is carried out using nails or screws.

It is much more convenient to use rigid slabs of basalt or mineral fiber. In the presence of interrafter distances less than the width of the insulation, it is possible to install the heat insulator "in the thrust" without using a supporting layer.

Insulate the attic floor

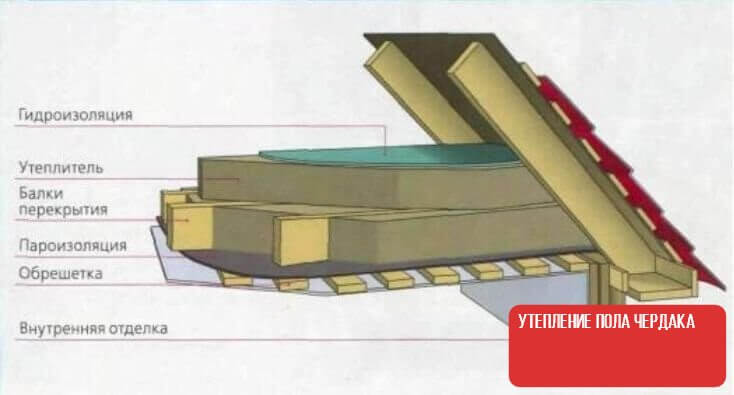

In the case of using the under-roof space as a cold room, it is necessary to insulate the attic floor in the house.

We work on wood

When installing an insulating layer on wooden logs, we install a vapor barrier layer on the side of the heated room. We fix the film with a stapler with a slight tension during the installation process. We stick double-sided tape at the junction and unwind the next strip. Carefully glue the strips together.

Do not forget to leave 20-30 cm at the edges for vapor barrier of the junction of the ceiling to the wall.

We install the crate for mounting the fine finish of the ceiling from the material and in increments in accordance with the selected finish.

From the side of the attic, we lay the heat insulator in two layers. The thickness of each is equal to half of the calculated. Laying is done in a checkerboard pattern to overlap the joints of the material. On top of the insulation on the logs we lay the subfloor.

We warm concrete

When insulating an interfloor ceiling made of concrete, it is advisable to use polystyrene foam plates. They will provide the same heat-saving ability with a smaller layer thickness, and will also allow, if necessary, to arrange a screed over the insulation. Diffusion membranes are not used in this case. The cracks formed during the laying of the foam are sealed with mounting foam or foam cuts.

If the metal cover

In the case of using metal structures as a ceiling, foam plastic can be used as a heat insulator. This will significantly reduce the cost of insulation. The most functional would be the use of sandwich panels, which, if desired, can be made independently. To do this, it is enough to hem a profile sheet from the side of the room. Lay polystyrene foam from the attic, corrugated board on top of it. The gaps are filled with mounting foam. If it is necessary to use the attic as a technical room, a cement-sand mixture screed with expanded clay is installed on the floor.

The screed device should be carried out after calculating the additional load on the interfloor ceiling.

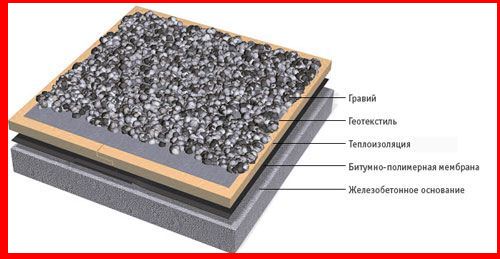

Insulating a flat roof

Reinforced concrete slabs are used as the basis for flat roofs. We begin to insulate with surface preparation. If the roof was covered with waterproofing material, it did an excellent job of protecting it from water, it is enough to clean it of debris and dirt. Otherwise, it is necessary to find the places of destruction (lag) of the layer and carry out repairs with a similar material.

The new roof is cleared of residual mortar and debris. Slots, if necessary, are cleared, sealed with mortar, mounting foam, bituminous sealant. Protrusions and depressions are aligned. With irregularities of more than 10 mm, the screed is laid.

Expanded polystyrene plates are laid in two layers so that the second layer overlaps the joints of the first. The insulation is fixed with dowels - umbrellas. The penetration of the dowel into the slab is at least 60 mm, into the insulation - 2 mm.

Before laying fiber boards, a vapor barrier layer is required.

The surface of the insulation layer is covered with bitumen, polymer, mastic waterproofing. The operated roof is additionally protected by a ballast layer.

To insulate your house, start with the roof, as the most loaded and critical part, through which the lion's share of heat loss occurs. Protect the hearth, live in warmth and pleasure.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical