Do-it-yourself rafters for a gable roof: design and installation

When planning the construction of low-rise residential, utility or commercial buildings, most designers choose a gable roof structure. This is due to the relatively simple installation technology, increased reliability of the design, effective removal of precipitation from the roof and unpretentiousness to operating conditions. However, to achieve all the benefits, you need to correctly design and install the rafters for a gable roof with your own hands.

Exterior of a house with a gable roof

Gable roofs are two inclined rectangular planes (slopes), which are supported by a rafter system. The side parts are made deaf or windows and sheathing are installed on them. The main parameters of such a roof are: the angle of inclination and the location of the ridge relative to the center line passing through the walls perpendicular to the slopes. That is, a gable structure does not have to have the same slope of the slopes or have a symmetrical appearance.

Many original designs use asymmetrical sloping designs to accommodate certain climate conditions or to improve façade design. It is worth noting that such solutions are very original, but in practice they are quite difficult to implement. This is due to the following reasons:

- The load on the walls and foundation increases at the place where the roof ridge is displaced. As a result, calculations can be significantly more complicated, especially when heavy roofing materials such as slate or ceramic tiles are used.

- It is required to produce separate structural elements for each slope, which can significantly increase the construction time.

- The roof at large angles of inclination of the slopes can be significantly affected by the pressure of wind flows. Therefore, it will be necessary to take into account the predominant direction of the winds in the calculations.

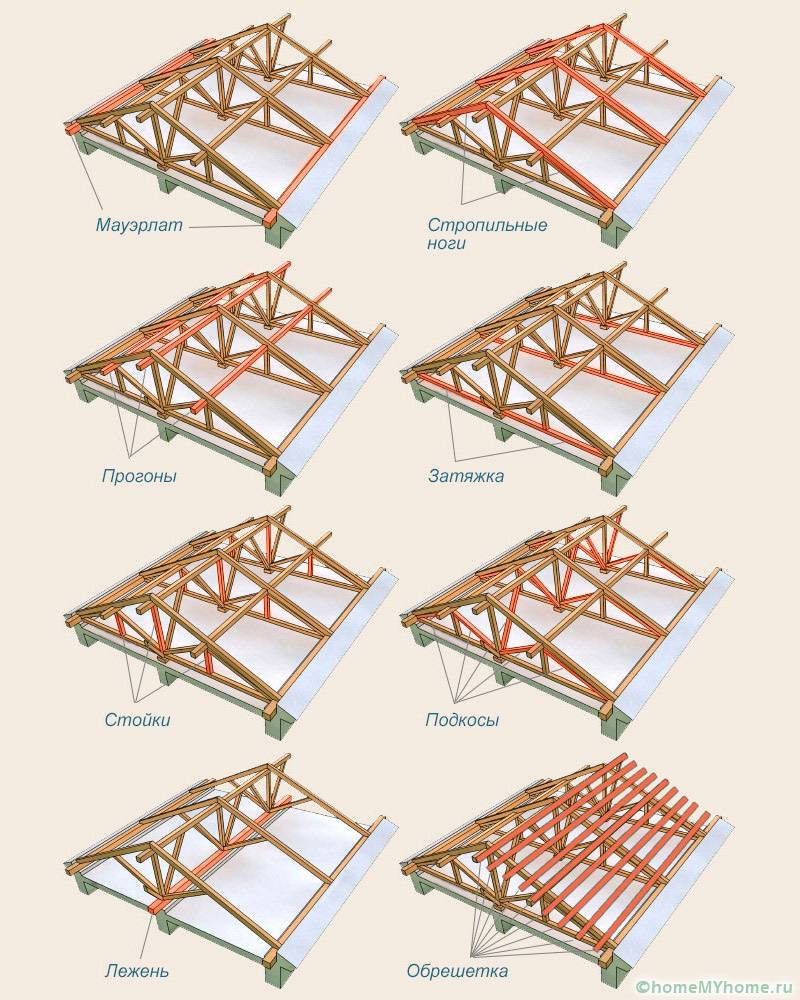

The main elements of the pitched roof system

Before you make rafters on a gable roof, you need to create a project, as well as study all the structural elements. You will need to design the following main nodes:

- Mauerlat. It ensures the transfer of the load of the roof structure to the load-bearing walls of the object, creating its uniform distribution. The beam is made from hardwoods such as larch, oak, ash. The minimum allowable cross section is 100x100 mm. It is allowed to use not only solid timber, but also glued, but with a section of 100x150 mm.

- rafters. The main structural element, which is designed to form a supporting frame, perceive the load of the roofing material through the crate and transfer the load to the Mauerlat. The distance between the rafters of a gable roof is from 0.6 to 1.2 m, depending on the weight of the roofing material and the amount of precipitation in a particular area.

- puff. A special design used to fix two inclined beams of slopes at a given angle of inclination, which is attached at a level just above the beams or slightly below the ridge. It is used in layered types of roofs.

- Rack. It is a vertically installed and firmly fixed element that performs the load-bearing functions of the roof. It is usually installed on the walls of the building to partially transfer the load of the roof. Gives additional rigidity to the structure.

- Run. There are two types: side and ridge. The side beam is a bar supported on racks and located parallel to the ridge beam. Helps prevent bending of the ramp under significant loads. The ridge run is installed along the line of junction of one slope to another and serves as a support for the ridge.

- Strut. Represents auxiliary supports for racks, which are located at an angle of 45 0 to the load-bearing beams of the ramps in order to increase the contact area with the racks and reduce the risk of ramp deformation.

- Sill. Serves as a fulcrum for the strut and strut.

- crate. It is used to fix the truss system in the transverse direction, transfer the load of the roofing material and its fastening, as well as ensure resistance to loads in the runs between the supporting beams.

Helpful information! Struts for the northern regions due to increased snow and ice loads on the roofs can be installed not only longitudinally, but also diagonally. Thus, a significant part of the load is perceived by the racks, and not by the walls of the building.

Types of gable frame systems

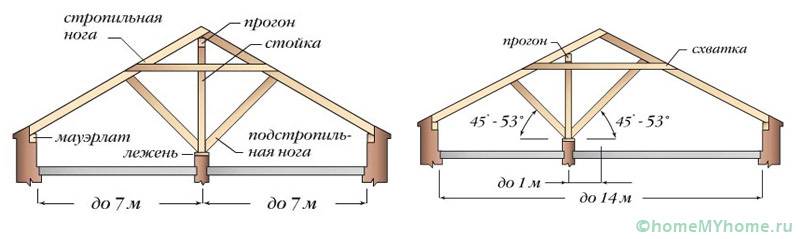

Do-it-yourself rafters for a gable roof can be hanging or layered. The hanging structure rests only on the side walls. Therefore, it is used only for installation on buildings with a distance between walls of no more than 12 m. To prevent collapse of the structure, auxiliary horizontal or vertical elements are used to increase the strength and reliability of the structure. The most successful elements are: strut, crossbar or puff. They can be fixed not only to the ridge beam, but also directly to the pitched beams themselves at certain angles.

Helpful information! If you plan to use the attic as a living space, then it is recommended to use puffs as supports, which will save maximum space.

For buildings with load-bearing internal walls, it is allowed to install layered pitched beams due to the possibility of installing additional supports. As a result, the limitation of the hanging system can be avoided and load-bearing beams can be installed even with a distance between walls of more than 10 m. The interval between the supports is selected for each structure individually, taking into account the purpose of the building and the use of the attic space.

Related article:

A separate publication provides a practical guide to the installation of the structure with useful tips and photos.

Preparatory work

Do-it-yourself rafters for a gable roof should be installed only after the preparatory work has been carried out. They consist in designing a pitched structure, creating a cost estimate, selecting the necessary materials and tools. However, the main part of the work, of course, is the competent calculation of all parameters.

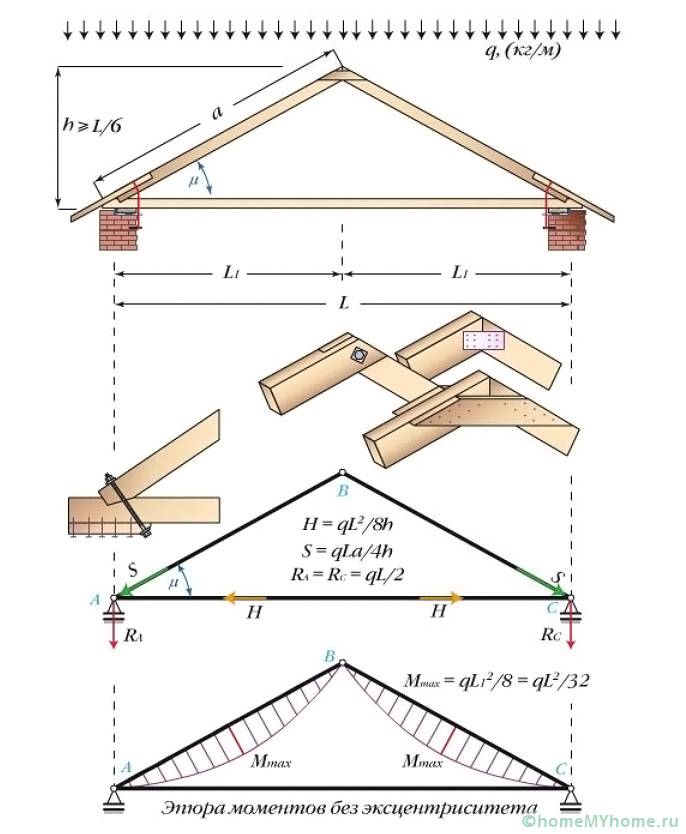

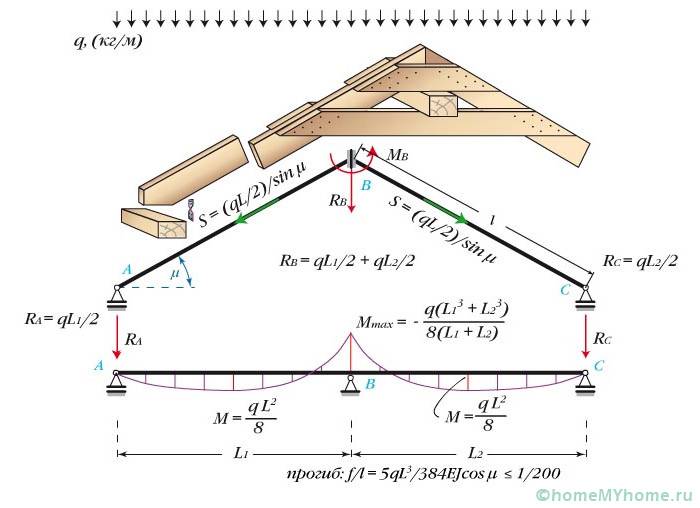

Do-it-yourself calculation of loads on rafters for a gable roof

When performing calculations, it is important to correctly calculate the load on the roof frame. There are three types of loads:

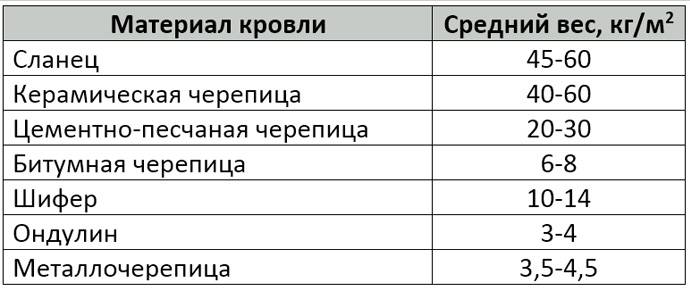

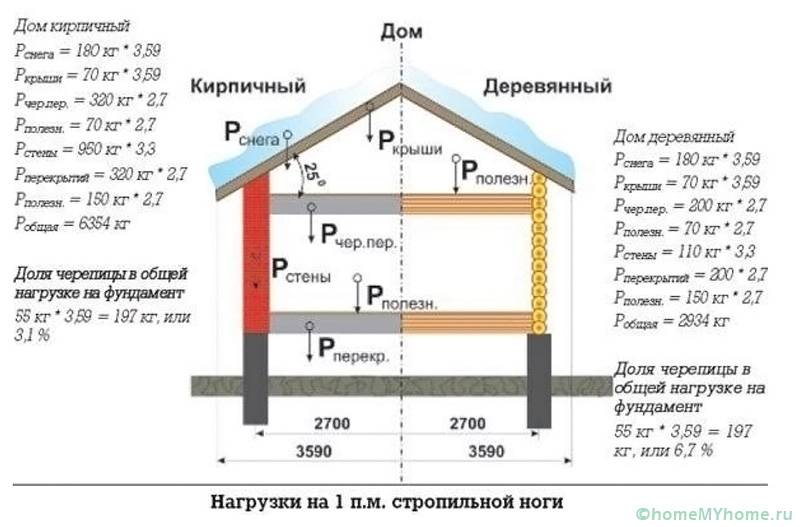

- Permanent. They include the weight of all materials used: insulation, lathing, insulating films, roofing material, additional elements, ebb and snow retention systems, trim, attic elements, etc. Approximate loads when using some roofing materials are shown in Table 1.

Table 1. The load on the rafters depending on the material of the roof

Attention! It is recommended that when designing a structure, a load of up to 50 kg falls on 1 m 2, otherwise the load on the walls will increase and a deep foundation will have to be laid.

- Variables. They are valid only under certain conditions, for example, during precipitation, repair or maintenance of the roof, wind loads, etc. When calculating, the maximum values \u200b\u200bof the desired values should be used.

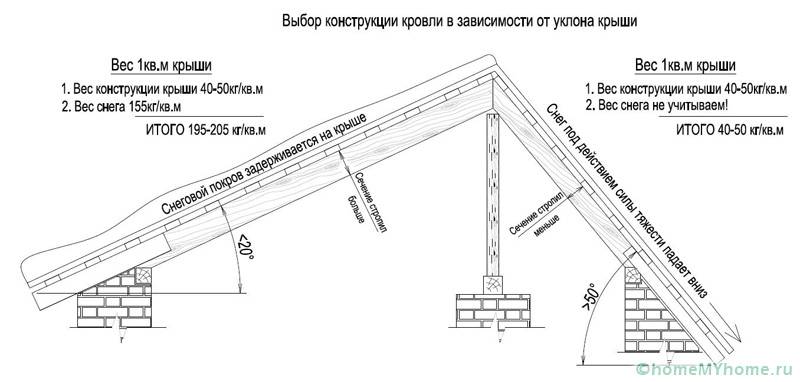

Calculation of typical variable roof loads depending on the angle of inclination

Helpful information! Do-it-yourself installation of rafters for a gable roof must take into account wind loads. To calculate them, one should take the indicators averaged over the region and multiply by the correction factor, which can be found in SP 2.01.13330.2011. Additionally, the location of the building should also be taken into account, for example, if the house is detached, then it experiences maximum loads.

According to SP 2.01.13330.2011, the snow load is defined as the total snow load multiplied by a correction factor that determines wind and aerodynamic pressures. The weight of snow per 1 m 2 can be from 80 to 320 kg.

Important! If the angle of inclination of the slopes is more than 60 0, then the snow load should not be taken into account.

- Special loads. Determined by seismic and/or storm natural phenomena. For the middle band, they can be neglected, making a margin of 10-15% for the overall strength.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical