What is the best way to sheathe wooden houses from the outside?

Completed, it is necessary to perform external work on the sheathing of the building. The facade of a wooden house cannot be left without protection, otherwise the material will simply lose its appearance or suffer from the destructive actions of rodents and insects. There are many options for exterior cladding. Each material has advantages and disadvantages, and when choosing it, as a rule, homeowners take into account strength, beauty and cost. In this article we will tell you how to sheathe a wooden house from the outside.

The main purpose of facing the building outside

Facing a wooden house is carried out to solve the following tasks:

- increase resistance to rodents, insects and fire;

- improve the appearance of the structure;

- protect the structure from heat loss;

- increases the sound insulation of the building.

The materials used for facing the building must meet certain requirements:

- the minimum level of moisture absorption and hygroscopicity, this prevents the process of wood decay;

- the material must pass air and remove excess steam inside the structure, these requirements directly affect the internal microclimate and the atmosphere of the house;

- the thermal conductivity of the material should be minimal, this will keep the heat inside the building and significantly reduce heating costs;

- the product must have high fire resistance, in the event of a fire, ignition will be minimized;

- have high resistance to chemical aggressive substances;

- be highly resistant to bacteria, insects, mold and mildew;

- the material must be environmentally friendly;

- soundproofing, i.e. products must contain noise.

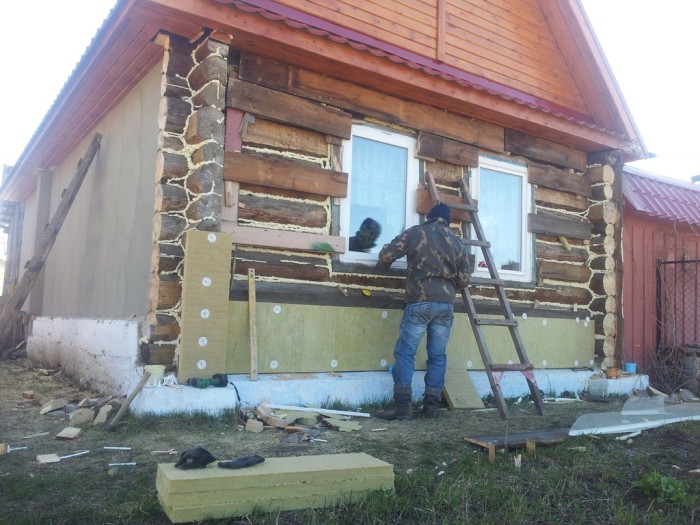

Features of building insulation

Insulation of houses is mandatory in the northern regions, but in the southern parts it will be enough to have the usual sheathing of the building, which will perform the function of insulation. Home insulation can be done using ordinary foam. Styrofoam is inexpensive and easy to use. It has low vapor permeability, so when laying it, it is necessary to think over the ventilation system. Lack of ventilation can lead to rotting and destruction of wood.

Mineral wool is one of the most common environmentally friendly heaters. Warming is carried out according to frame technology:

- fill the void between the bars;

- lay a vapor barrier layer (foil, roofing felt);

- fix the frame at a distance of 0.4 m along the wall;

- fill all voids with mineral wool;

- lay an additional layer of insulation, which performs the function of protection against moisture and wind;

- The final stage is the sheathing of the house.

Materials for sheathing wooden houses

Facing a wooden house can be done with the following materials:

- vinyl, ;

- fiber cement panel;

- porcelain tiles;

- wooden siding or block house;

- professional flooring, flat metal tiles and metal siding;

- wood.

Let us consider in more detail the characteristics of each material in order to decide how to sheathe the house from the outside cheaply and with high quality.

Vinyl siding

The characteristic of this product is suitable for almost any home and climatic conditions. Vinyl siding is highly resistant to damage and temperature. This material is relatively cheap, has a large number of colors, is easy to install and has a long service life.

- it is best to sheathe the dwelling with light-colored siding, because. dark colors may lose their color from exposure to sunlight;

- install the product only in the warm season, the air temperature should not be below 0, this is due to the fact that in warm weather the material bends perfectly and is easily cut out, and in winter there is a chance of getting a large amount of waste;

- use self-tapping screws as fasteners, which must not be completely tightened, because. at the moment of thermal expansion, the siding leads and it is able to break the panels out of the fasteners.

Basement siding is more durable than vinyl siding. If the house will be sheathed with this product, follow the above recommendations.

fiber cement panel

Fiber cement panels are the same siding, the only thing is that it is based on cement and synthetic fiber. In terms of performance, they are superior to vinyl. But of the shortcomings of these panels, it is worth noting the following:

- high cost, unlike vinyl, fiber cement costs 3 times more;

- fairly heavy panels;

However, fiber cement panels can be considered a unique material:

- it does not burn;

- does not melt;

- does not change color;

- impact resistant.

Important! If you finish the house with fiber cement, you need to make a suspension system, which in turn will create an additional load on the weight of the facade.

The photo shows a house sheathed with fiber cement panels.

Porcelain stoneware

Porcelain tiles will look good on the building. Unfortunately, this is the only advantage of this material. Of the shortcomings, it is worth noting:

- too much weight of the tile, which requires the use of metal hangers;

- porcelain stoneware is quite difficult to hang on a wooden structure;

- the cost of the product is very high.

Wooden siding and block house

If you are looking for cheaper options to sheathe your home, wood siding or a side house is the best option. These products will not only decorate the facade of the house, but also give a feeling of warmth and naturalness. The advantage of the material is:

- natural decorative look;

- ease of installation;

- high strength;

- optimal price.

Fasten wooden siding and block house to the crate, which can be attached to a log and timber wall. Of the shortcomings, it should be noted:

- the product is subject to decay processes;

- products react to weather conditions (wind, rain, snow, sun);

For information! You can extend the life of your siding with a special coating or impregnation treatment.

An example of cladding a wooden house with siding

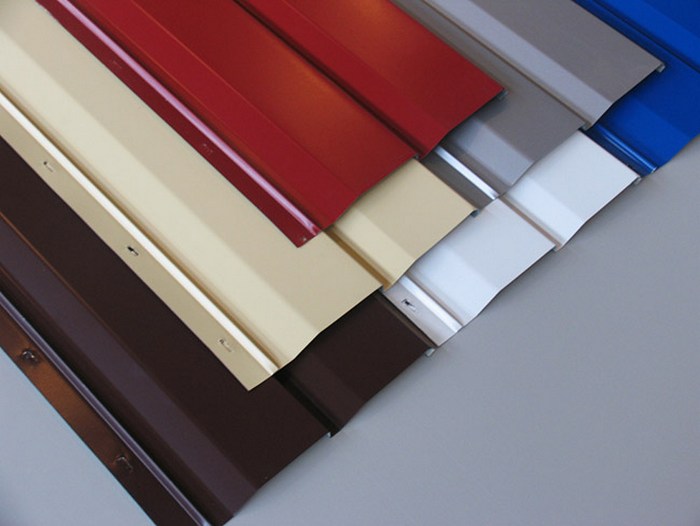

metal siding

Metal siding is corrugated board, only more decorative. This material fades much less in the sun, which makes it possible to use dark palettes for building cladding. Unlike vinyl siding, metal siding does not break during installation either in summer or winter, i.e. it can be laid at any time of the year. It is fastened with metal hangers and on a crate made of wooden beams.

How to trim a wooden house

If you have not decided what is the best way to sheathe a wooden house from the outside, study the reviews of the owners of private wooden houses. Most often, when facing wooden buildings, siding is used. Manufacturers offer a scheme that will allow you to understand how to sheathe a house and avoid mistakes:

- a layer of vapor barrier is laid on the wall;

- the first crate is mounted for the insulation of the building;

- insulation is laid in two layers;

- a second crate is mounted on top of the insulation;

- siding is installed.

Expanded polystyrene is used as a heater. The process of working with siding is quite simple, however, before decorating a house, three basic rules should be considered:

- do not overtighten the locks and fasteners, be sure to leave a gap of 1 mm;

- when laying boards, fix the hardware in the center of the mounting windows, and not at the edges;

- it is impossible to lay the elements of the skin closely into the extensions.

The thermal expansion of the panels is 12 mm along the length of the board, and the width is up to 1 mm. If these conditions are not met, the casing may break the fasteners or deform. The installation of the material is carried out as follows:

- drains, platbands of window and door openings are removed;

- we make a crate, we fix the extreme logs at the corners;

- with a level, we mark the installation of the starting profile, which must pass from the upper corner of the base at a level of at least 12 mm;

- fix the outer corners;

- install aquilon;

- set the start profile;

- we fix the board with the lock down into the grooves of the corners and press until a click is formed;

- we fix the board to the lags in the mounting edge;

- we lay the rest of the boards in the same way, fixing it to each board and fixing it to the lags;

- the last board is inserted into the penultimate one, while it is not necessary to fix it, for this the required height is noted, and the excess material is cut off;

- the last board is also laid without fixation;

- install the finishing profile, indent 6 mm up;

- we bend it, we start the edges of the board into the corners, and the cut edge into the finish;

- push up until it clicks and closes the lock.

Important! When sheathing windows and doors, they should be carefully sorted out and aligned to a perfectly rectangular shape.

The choice of material for sheathing a wooden house is quite large. In addition to quality characteristics and price, consider the vapor permeability of the product, this will protect the building from mold and dampness, and make your stay in the house as comfortable as possible.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical