How can you insulate a wooden house from the outside correctly using technology

The beam, due to its affordable cost, durability and strength, has become a popular material in the construction of houses. Natural wood creates a healthy indoor climate and has good vapor permeability. Low thermal conductivity is one of the advantages of timber, but insufficient wall thickness causes high heating costs.

Even with careful joining, gaps remain between the lumber, letting cold and draft into the room. You can change the situation by insulating a log house. The process of thermal insulation of a wooden building is distinguished by the availability of technology, so it is really possible to do it yourself.

Why is it preferable to place a heater outside?

External thermal insulation of a log house has its advantages:

- reduced heating costs;

- protection of hygroscopic wooden walls from moisture;

- the appearance of the facade changes according to the individual preferences of the owners;

- no reduction in interior space.

Criteria for the selection of thermal insulation material

When choosing a heater, you should pay attention to its characteristics: elasticity, resistance to burning and moisture, thermal conductivity, breathability. The thickness of the effective layer depends on the temperature in the region and the parameters of the beam. In a temperate climate, 50 mm of thermal insulation material is enough, and in winter frosts below -20 degrees, this figure doubles. The complexity of installation should also be taken into account, because the work is done by hand.

Ways of insulation, what to choose for walls made of timber

Exterior decoration of a log house is carried out in three ways:

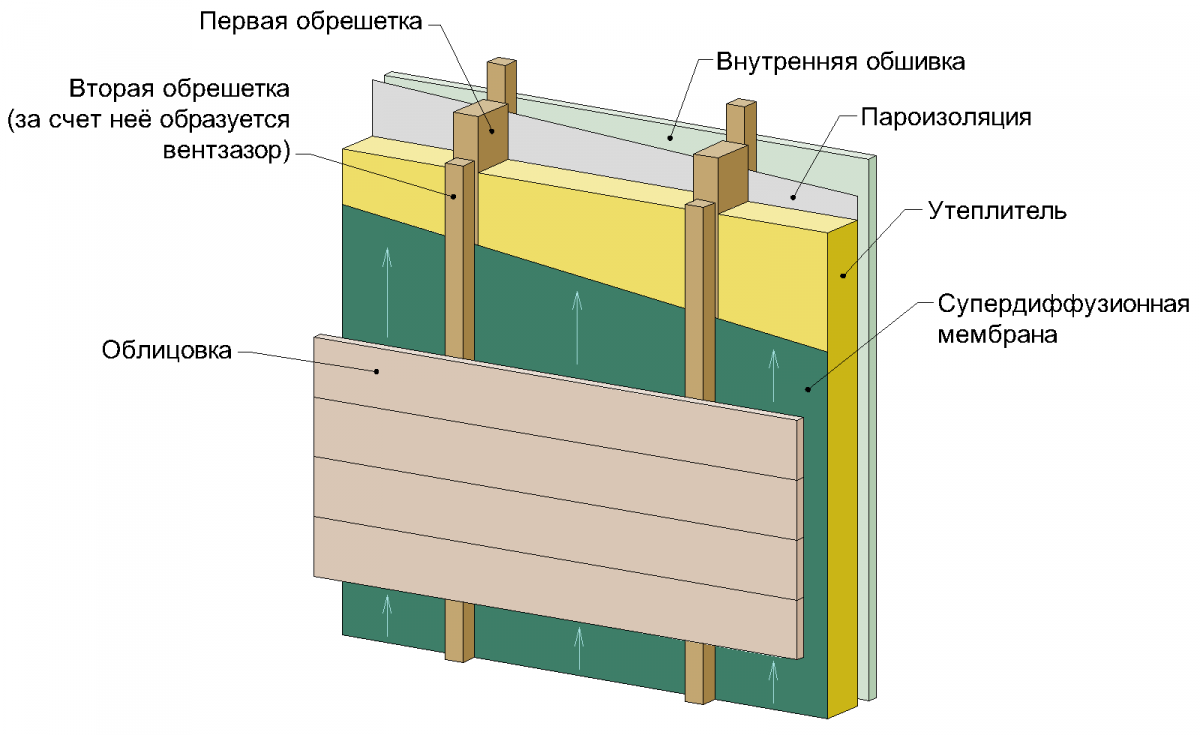

- Ventilated façade.

The hinged structure includes a wooden crate, insulation and external cladding made of clapboard, siding or porcelain stoneware. Do-it-yourself facade installation gives the walls additional heat and sound insulation and brings the dew point out. The design is easy to assemble and lasts up to 50 years.

- Sealed with polyurethane foam.

Polymer spraying creates a monolithic seamless surface and strengthens the walls of the timber. The work is carried out using a high pressure apparatus. He mixes the two components and delivers the composition through the gun to the surface to be insulated. Condensate does not collect under the polymer layer, it does not burn, does not rot, and reduces the noise level. After spraying polyurethane foam, finishing with facade material is required. The main disadvantage of this method of insulation is the high price.

- The use of foam boards.

The low cost of the material makes it the most affordable insulation. It is resistant to fluctuations in temperature and humidity, but has a significant drawback - it supports combustion. Fixing the foam on the walls is carried out with special glue. Before mounting the first row, a starting profile is nailed to limit the sliding of the material.

After analyzing the pros and cons of the ways in which a log house can be insulated from the outside, most owners settle on a ventilated facade.

![]()

Practical insulation for a wooden house

The best choice for warming the house will be mineral wool. It is made from slag, rocks or glass, so it does not support combustion. The material is easy to fit with your own hands, retains heat well and is affordable.

How to properly assemble a ventilated facade

The technology for the correct installation of a hinged facade includes several stages:

- fastening the crate;

- laying insulation;

- installation of a diffuse membrane;

- fixing the decorative coating.

Work begins with the application of an antiseptic layer to the beam, which protects against decay and moisture. A frame of wooden planks is stuffed onto the finished surface. The step of the vertical crate is 1.5 cm less than the width of the insulation. This will allow you to tightly lay the material, avoiding cracks and cold bridges.

The bars are attached to the wall with self-tapping screws, their vertical plane is set using a level with a plumb line. Mineral wool mats are inserted between the frame slats, pressed tightly and fixed with umbrella dowels. When a wooden house is located in a region with a low temperature, it will be correct to perform external thermal insulation in two layers.

To protect the insulation from moisture, a special perforated film is laid. It does not allow water to penetrate inside, and the moisture accumulated in the cotton is released to the outside. The membrane is overlapped and fastened with staples, its joints are glued with adhesive tape.

The ventilating layer of the facade is created by stuffing planks over the waterproofing. They provide a space between the insulation and the cladding in which air circulates. The second row of rails becomes the basis for the finishing facade coating. Slots for ventilation remain in the lower and upper parts of the structure. They are protected from precipitation by special visors.

Mineral wool is an excellent insulator, but it loses its qualities when wet, so it should be stored indoors. When working with the material, dust and fibers appear, which cause irritation. It is necessary to lay mineral wool slabs in goggles and gloves.

It does not take much time and money to insulate a log house from the outside. The result of high-quality work will be a comfortable room temperature at lower heating costs.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows fog up in the apartment

Why do the windows fog up in the apartment Construction and schemes of brick ovens

Construction and schemes of brick ovens How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill bathroom tiles

How to drill bathroom tiles Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical

Which electric heater is economical