How to connect a machine in a panel: assembly, installation, wiring

To understand how to connect a machine in a panel, you need to familiarize yourself with the minimum requirements for electrical safety and fire protection. Also, knowledge of the basics of electrical engineering will be needed to calculate the required load from electrical appliances. It is important to select the type of electrical appliance, its response rating and the number of safety devices.

Purpose of electrical protection

To understand how to connect a machine in a panel, we need to familiarize ourselves with its purpose and types. The electrical panel contains all the equipment for distributing power to household appliances. Here there are terminal blocks, an electricity meter, an RCD device, automatic devices, and relays.

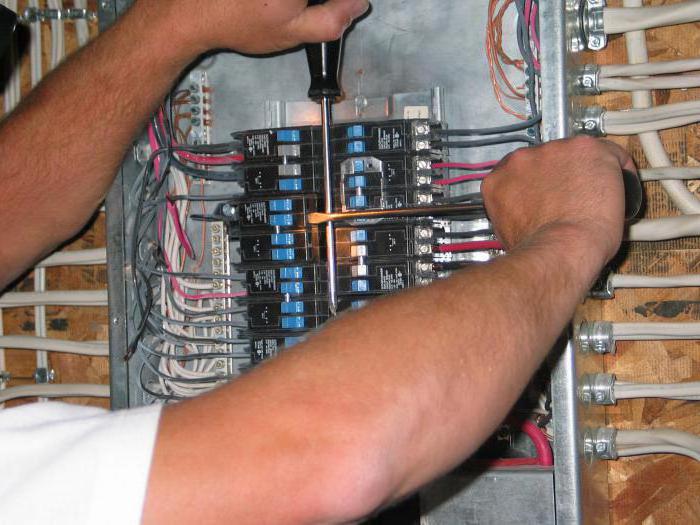

The equipment is held in place by a DIN rail made of conductive material and grounded at one point. They try to place the electrical panel at the entrance to the apartment or on the street side in a private house. The machine itself is a complex technical device. It is subject to certain requirements, depending on the purpose of the device.

A modern automatic meter protects wiring and equipment from short circuits and can even protect people from electric shock. It is prohibited to make homemade fasteners for the device in the panel in order to comply with safety rules when performing work on live devices. A specialist with the appropriate access group knows how to connect the machine in the panel. But if contacting a specialist is expensive and not profitable, then you can perform the replacement yourself.

It is also important to know how to connect the machine in the panel before purchasing and installing household appliances. So, for heaters, more powerful safety systems are chosen, and for low-power devices, you will need to add separate circuit breakers. For the latter, they install electronic ones. It is often advisable to install an RCD in order to provide a high degree of reliability of protective devices.

In most cases, electricians provide a standard connection diagram for live wires - from the top. However, often the meter box is installed by specialists who have nothing to do with electricity, and they supply the phases from the bottom of the machine. Therefore, before replacing failed devices, it is imperative to measure the voltage supply with a working voltmeter.

General information

The meter box in apartments contains a two-wire circuit for connecting electrical appliances. It is simple and contains a supply wire - “phase”, and a discharge wire - “neutral” or “zero”. Modern standards require the use of “grounding” to protect against short circuits. Devices such as a washing machine, refrigerator, electric oven must be connected using a three-wire circuit.

The general designation of the ground wire is yellow-green stripes. To connect the machine, it does not matter which terminal the phase wire is connected to. But it is recommended to connect it from above so that the next inexperienced specialist does not get caught in the current by grabbing the wire from the bottom of the machine out of habit. Before any work, it is required to turn off the input switch, but many electricians perform work under voltage.

Wiring and connection must be carried out by a specialist with appropriate education and approvals. Understanding the nuances of installing some machines is not easy, especially if the consumer decides to install a separate switch for each socket and light bulb. Some organizations can provide a ready-made electrical panel assembly. But in this case, it is necessary to provide for the possibility of installing additional machines in the future if you want to change the overall electrical circuit.

To install and connect the machine you will need:

- Tools: wire cutters, flat and Phillips screwdrivers, multimeter.

- A wire designed for the household appliance used must have a cross-section that is twice the load. Installation is carried out in an already installed panel, so the DIN rail is not taken into account.

- The machine must have standard fastenings. The wires are placed in a corrugated hose to protect them from mechanical damage.

The insulation is removed from the cable, the length of the stripped wire is selected to be no more than 10 mm, so that the exposed parts are out of reach for hands and do not touch metal parts. Grounding is recommended. In older houses it may be completely absent. But for your own safety you need to install it.

To connect the “ground” in the panel, a common open terminal block is used for each supply wire. The outlet conductor has one larger cross-section. “Neutral” is also recommended to be performed with one block, but of a closed type. It often contains potential that is dangerous to human life. starts by connecting the ground wire, then the neutral. Finally, a phase one is installed.

If there are several machines, jumpers are used, which begin to be installed from the input switch. A hose corrugated inside the shield is needed only for non-standard cable laying, when there is a risk of damage. Corrugation is not applied to short sections.

A replacement for jumpers is a common distribution plate, available for sale at any electrical store. To protect contacts from contact, a box for the machine made of plastic or other dielectric is used.

Device selection

The load on the machine should be less than the calculated one. 10, 16, 20 amperes are in demand. Higher ratings are usually used for boilers, house heaters, and ovens. For standard appliances, 10 amperes are suitable: PC, TV, iron or hair dryer. However, if several loads can be connected to one device, then the resulting value is obtained by adding all the ratings.

It is not recommended to use many devices, sockets, and lighting lamps on one machine. If one link fails, the socket can melt without turning off the fuse. So a 2-amp household appliance can start drawing 5 amps if there is a fault in the circuit board. A circuit breaker rated for 16 amps will not work. Even the insulation on the wires can melt.

Therefore, before choosing a machine, it is recommended to consult with an electrician on choosing the type of protective device. They differ in response speed, purpose of protection, connection, internal structure, number of phases. For installation in a panel, the phase wire is supplied from the side of the fixed contact; the marking is often already indicated on the body of the machine.

Switch types

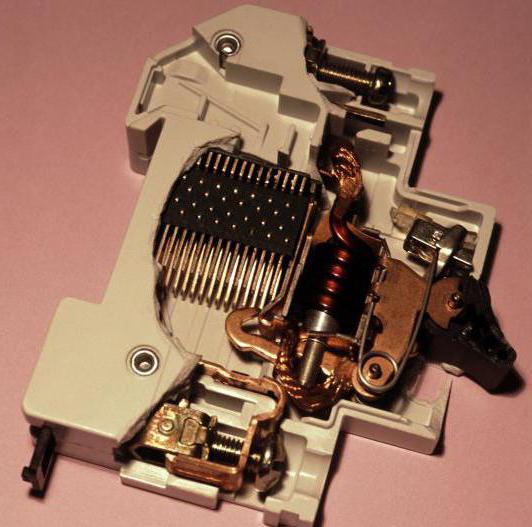

The design of a circuit breaker depends on its type: the response speed can be milliseconds for magnetic switches and several hours for circuit breakers with a bimetallic plate. The letter in the designation matters when choosing a protective device. For the house it is recommended to install types B, C.

Classes Z (for electronic devices), D (for electric motors and inductors), A (for long conductors) are rarely found in everyday life. Experienced electricians recommend combining machines with RCD devices (residual current devices) or using automatic circuit breakers. There are electromechanical and electronic protection. The second is less reliable and quickly fails; tracks and internal elements burn out under significant overloads.

When choosing the type of machine, it is recommended to take into account that the current rating through the wiring cross-section must exceed the possible overload and the maximum value of the switch. If the machine has a high response speed and sensitivity, then it will have a higher cost. However, it will not be reliable in all cases; erroneous responses to increased load are possible.

Such a problem can only be identified in each specific case when analyzing the type of household appliance and additional parallel loads connected simultaneously to the network.

Design features

The circuit breaker device is of the following types:

- Electronic principle of operation.

- Electromechanical.

- Electromagnetic.

For the home, budget options for automatic machines based on the electromagnetic operating principle are often chosen. The main working part is: It is advisable to choose a switch in proportion to the cost of the equipment. For ordinary functions, ordinary automatic machines are suitable, but if specific electrics are used, it is recommended not to skimp on protective equipment.

Fuses are used in production to this day in particularly critical components of the electrical circuit. The RCD primarily protects the human body from electric shock. From the basics of electrical engineering it is known that the current in a series circuit is the same. The operating principle of the device is based on comparing the current of the phase and neutral wires. The so-called one that occurs at the moment of a person’s defeat is revealed.

However, RCDs can often trip erroneously when operating large inductances or capacitances. The operation of the machine is not affected by the method of connecting the phase and neutral in a single-pole design. The overload is measured, the potential difference is not taken into account.

Common mistakes

Upon completion of the work, we received installation in which it was completed according to all the rules. But the machine still breaks for no apparent reason or the equipment in the house does not work. This result is possible if certain steps are performed incorrectly.

A simple and solvable problem is the lack of contact in the terminals of the machine. This is possible when the wire insulation is not sufficiently removed and the clamping jaws come into contact with the dielectric part. The bare end should protrude slightly beyond the boundaries of the machine, and they should be protected by a dielectric housing placed over the switch.

Let’s assume that the panel in the apartment has a non-standard connection diagram, and during installation the neutral of the devices could have been connected to the ground conductor. This type of malfunction occurs only for beginners, but it can lead to the failure of an expensive device: a TV, PC, charger or other type of equipment.

Burnout of the pads can occur when powerful devices are connected to the network, when the wire core on the machine is not stretched and has weak contact. A large load produces a spark, as a result the device heats up in this place, but does not knock out. Long-term operation in this mode leads to the fact that the plastic begins to melt until it ignites or short circuits to a grounded case.

A typical error occurs when the cross-section of the connected wires differs slightly. In this case, loose contact is possible, due to which a spark will occur. This will ultimately result in the result described above. To avoid fire, you need a non-flammable switchboard. Electrical installation is incorrect when connecting several sources of different power to one machine. The higher the difference between the most powerful device and the weakest, the less reliable contact is obtained in the sponges.

Ease of installation is achieved by forming the wires in the form of a Y-shaped arc at the connection point. This makes it easier to hold the conductor while tightening the terminal. Before making the connection, be sure to turn off the input switch, if possible.

To connect machines, you can use your own jumpers of the same cross-section. However, the best solution would be a common tire with standard fasteners. There are no problems when tightening single-core wires, but difficulties are possible when using multi-core conductors.

It will be necessary to terminate the conductors before tightening them into the terminal. For this, a special crimping device is used, which can be purchased at electrical stores. Standard sections are marked on its jaws; by selecting the appropriate part, the best contact is achieved after the crimping procedure. A smaller diameter will lead to partial breakage of the cable, and a larger one will not give the required result.

For crimping, special ferrules for a specific wire diameter can be used. There is a second method - soldering. It takes longer, but is less reliable and is used in low-power circuits. The junction is soft. At first, the terminals will be tightened to the maximum, but after some time they will loosen due to the fact that the solder begins to “float”. Poor contact can result in a fire.

What not to do?

Often, older buildings used aluminum wires, while new wiring diagrams have copper wires. Inexperienced electricians can twist two metals together, which over time can result in replacement of the wiring. This occurs due to a chemical reaction between two different substances: aluminum and copper.

An oxidation process occurs, the rate of which depends on the load in a given circuit. If such a connection is necessary, then installation can be done through insulated terminal blocks. However, after a long time the bolts will have to be tightened; they will weaken. Twists are not recommended for use in the shield. It’s better to sign each machine; after a few years, you may forget about the purpose of the device.

You can reduce the load on the machine by using energy-efficient household appliances and lighting lamps. This approach will allow you not to think about the possibility of insulation melting. The only risk remaining is a short circuit.

In case of malfunction

If the machine is knocked out, it is not recommended to turn it on immediately. First, you need to evaluate the possible cause of the malfunction: a recently hung shelf, a new appliance purchased, or the absence of previous events. Overload could occur due to burnout of part of the wire in monolithic structures. To find the problem area, there are instruments available to specialist electricians. This is relevant when the cost of opening the wall is much higher than the cost of diagnosing the electrical equipment of the house.

When the machine knocks out, it is recommended to use an ohmmeter and check if there is a short circuit to the ground or between the conductors: phase and neutral. Before doing this, turn off all household appliances. Connection to the circuit is carried out one device at a time, while measuring the current through the wire using electric clamps.

Exceeding the load of the machine's rating requires either replacing the switch itself or changing its connection location. During diagnostics, you can check the wire with your hands without a measuring device, by grasping the insulation while the consumers are operating. If it heats up, then an increased current flows in the circuit.

Masonry mortars for brick kilns

Masonry mortars for brick kilns Why do the windows in the apartment fog up?

Why do the windows in the apartment fog up? Construction and diagrams of brick stoves

Construction and diagrams of brick stoves How to lay paving slabs: tips and tricks

How to lay paving slabs: tips and tricks How to drill tiles in the bathroom

How to drill tiles in the bathroom Monolithic slab on coarse soil

Monolithic slab on coarse soil Which electric heater is economical?

Which electric heater is economical?