Magnesium rod for water heater. What is a magnesium anode in a water heater, how to replace it. Why do you need a magnesium anode in a water heater

Many owners of storage water heaters have no idea what a magnesium anode is for in a water heater and what functions it performs. The fact is that the boiler tank during operation requires regular cleaning of metal oxidation products and scale. You should know how to deal with these negative processes and ensure a long boiler life.

Since the steel from which the internal tank of the storage water heater is made is an alloy of iron and carbon, this factor is decisive for the life of the unit. Oxygen, which is part of the water, interacts with the material of the tank walls, causing the formation of corrosive deposits.

How is the inner surface of the boiler protected?

The inner surface of the tanks is protected by manufacturers, with the application of a glass-porcelain or glass-ceramic coating. But it is not able to serve even a third of the standard service life of a water heater. The coating is destroyed due to temperature fluctuations - microscopic cracks gradually form, their number and size increase. As a result, the material of the inner walls is completely deprived of surface protection.

The use of stainless alloys is not able to guarantee long-term operation, because food grade steel, which is regulated for production in this case, does not have the necessary stability. It is subject to corrosion, although it can last a little longer.

The main problems of water heaters made of stainless steel are associated with the need to use welding. When it is performed, heating the metal contributes to the burning out of additives that protect the material from corrosion, resulting in leaks precisely along the welds.

Functions of magnesium anode

magnesium anode just also is additional protection of an internal surface of a boiler against corrosion.

In addition to protecting the body, this unit allows you to extend the life of the heating element. Due to the formation of salt deposits, the heating element may soon fail. An anode made of magnesium cannot prevent such an impact, but due to its use, these deposits acquire a less dense structure, therefore, they are more easily removed when preventive work without causing damage to the protective coating of the heating element.

This element is a steel rod coated with magnesium alloy. The fastening of this element is carried out by means of a threaded connection. It is located next to the heating element.

The principle of operation of the magnesium anode

Imagine what would happen in the absence of such protection.

This situation causes the formation of the so-called galvanic pair. This phenomenon was discovered in the eighteenth century. Iron reacts with oxygen in the water. The surface layer of steel is destroyed, with the formation of oxide. Thus, it gradually collapses. This happens because the material of the walls of the water heater is characterized by a much lower electrochemical potential than the rest of the tank.

When installing a magnesium anode, it takes over all oxidative processes, because it has a much lower electrochemical potential than the case.

Almost all models of water heaters include this element in their design. Initially, the surface of this part has an even silver color. As a result of long-term operation, clear traces of corrosion deposits appear on it, but the integrity of the boiler walls is ensured.

The sacrificial anode is made from magnesium, because this metal has a weak electrochemical potential. In addition, the low cost of magnesium alloy does not lead to a significant increase in the cost of the finished product, so it is advisable to use this particular component. Using it as a consumable material is much more profitable than if there was corrosive wear of the walls of the water heater. Salts contained in water settle on the surface of the magnesium anode without adversely affecting other parts.

Anode replacement

Since the anode for the boiler is a consumable item, it needs to be replaced periodically. This procedure does not require significant time and special qualifications. This will require:

- Buy this part from a shop or service center.

- Remove the bottom cover of the tank.

- Remove the flange and the thermal sensor, which will then be accessible.

- Remove the heating element, slightly stirring. Deposits may prevent its dismantling. This procedure must be carried out carefully so as not to damage the assembly.

- Remove the spent sacrificial anode.

- If the replacement has not been made for a long time, instead of the whole product, only its core may be present. This is due to the complete destruction of the magnesium alloy layer.

- The heating element is cleaned and installed in place. If necessary, you can replace it.

- Install a new anode and assemble the water heater in reverse order.

Replacing the anode is not difficult. It is necessary to periodically clean the internal tank of the water heater from deposits formed and replace the magnesium anode in a timely manner. This will ensure long-term operation of the boiler.

The design of a storage water heater (boiler) of any type most of all resembles a conventional thermos device. Between the body and the inner tank of the boiler there is a layer of thermal insulation made of rigid polyurethane, the task of which is to minimize heat loss as much as possible. Entering the tank with a heating element (thermal electric heating element). The desired water temperature is reached by the built-in thermostat.

The internal tank, subject to constant temperature fluctuations and oxygen and heavy metal salts dissolved in water, is the most vulnerable part of this system. Therefore, a mandatory part of the design of the water heater is a magnesium anode, the purpose of which is protection of the inner tank from the harmful effects of corrosion.

If you need or Engels call our firm. We will produce it as quickly and efficiently as possible.

What is a magnesium anode

What is a magnesium anode

The anode is a thin round rod on which a layer of magnesium alloy 10-15 mm thick is applied. In the center of this rod is a threaded stud, with which it is attached next to the heating element. In some cases, the magnesium anode may be located on the top wall of the heating tank. Its diameter varies between 14-25 mm, length (without threaded stud) ranges from 140 to 660 mm.

Although boilers use titanium, zinc, and electrical anodes, magnesium remains the most popular option due to its affordability.

Magnesium anode: principle of operation

Now let's consider in more detail the question of why and why the anode in the water heater is so necessary and what is the basic principle of its operation.

The vast majority of boiler internal tanks are made from mild steel. Magnesium with valency II is a more active metal than iron with valency III, therefore it binds oxygen formed in water when it is heated, preventing oxygen corrosion of the tank and the metal shell of the heating element. This is the so-called tread protection. Hence the second name of the magnesium anode - the anode-protector.

An additional task of the anode is to prevent the formation of scale on the heating element. When water is heated, scale is formed as a result of precipitated salts of heavy metals. Due to the increased activity of magnesium, they react with it, and not with the iron from which the tank walls are made. Therefore, the formation of insoluble calcium carbonate salts is sharply reduced, and slightly soluble magnesium salts are converted into magnesium salt of carbonic acid. Scale, dense as a stone, becomes loose, separates from the walls of the tank and the heating element and settles in flakes to the bottom. Soft scale is easy to remove when cleaning the appliance.

Why do you need a magnesium anode in a water heater

The main tasks of the anode-protector are:

- providing passive protection of the tank against corrosion;

- prevention of scale formation on the heating element (heater);

- water softening.

During use, the anode gradually decomposes and dissolves until the complete destruction of the metal rod. When it decomposes chemical composition water does not change, so its use is absolutely harmless to health.

During use, the anode gradually decomposes and dissolves until the complete destruction of the metal rod. When it decomposes chemical composition water does not change, so its use is absolutely harmless to health.

Since it is a very important part of the design of any boiler, it is important to replace it in a timely manner. The replacement interval depends on the following factors:

- water quality (iron content and salts of heavy metals);

o intensity of use of the boiler itself.

Depending on these factors, the service life of the anode can be from 1 to 7 years, however, for better work water heater and prevent breakdowns, it is recommended to change it every year during the annual cleaning of the device.

When purchasing a new magnesium anode for a boiler to replace a worn one, you should pay attention to its quality. In the process of operation, a low-quality anode can give water a stable bad smell Therefore, it is better to purchase it from trusted manufacturers in company stores. You can check the quality by lowering the rod into a weak solution of food citric acid. The anode, made from cheap technical magnesium, will enter into a violent reaction with the acid, provoking an abundant release of hydrogen sulfide.

Water-heating household boilers - devices are utterly simple and outrageously defenseless. They are installed almost everywhere and make citizens independent of such a dubious structure as housing and communal services. Planned or emergency shutdown hot water now it does not bother, but only until the boiler is working properly. However, the constant temperature difference, and the composition of the water affect it, to put it mildly, not very beneficial. It is for this reason that almost all manufacturers install a magnesium anode in the boiler, which significantly increases the life of the device.

Stainless steel, from which boiler tanks are usually made for domestic purposes, is not of high quality. Otherwise, the price of the boiler would be exorbitant, and the manufacturer would hardly be able to sell it. In addition, this is not an all-metal vessel, but welded from several parts. And even if inside it will be covered with enamel and all welds are carefully processed, oxidation and accumulation of salts are still inevitable. Moreover, the temperature difference also plays a role, interacting not only with the inner walls of the boiler tank, but also with the internal structure of the metal.

Microcracks, and it will never be possible to completely avoid their appearance, impurities in water that can seep through a whole cascade of filters act destructively. And here the magnesium anode for the boiler shows its saving functions. The part is small, absolutely inexpensive, often included in the kit and completely irreplaceable.

It is the anode that sacrifices itself instead of the boiler. All salts and oxidizing elements first of all settle on it, and the tank itself remains relatively untouched, which significantly increases its service life.

How a magnesium anode works and why it needs to be changed

As already mentioned, a special magnesium-coated rod literally attracts all the salts contained in tap water. In addition, it reacts too actively with oxygen, leaving the latter no chance to take up the walls of the water heater. Because of this, the oxidation of the walls in the boiler does not disappear at all, but it slows down so much that if, in the absence of a magnesium anode, your boiler can leak after a year of intensive use, then this small element will increase this period by five, or even ten time, if you do not forget to change it.

Yes, the anode will break down. And how else, when he takes all the negative qualities of water on himself and interacts with all the harmful elements contained in it. After some time, a smooth steel bar will turn into something corroded by salts and, naturally, will lose its potential.

Few boiler manufacturers do not use a magnesium anode in their water heaters. In most cases, it is installed almost close to the heating elements, although by and large the location of the anode does not affect its functionality in any way. Everyone agrees with this. But why firms strongly recommend installing only appropriate anodes in their boilers is not entirely clear. The fact that they fit in size and thread and are much easier to replace is understandable. But recently, universal magnesium anodes have appeared, which are easily placed in any tanks, boilers and other heating devices. Their purpose does not change from this, and the timing of replacement does not depend on a specific manufacturer, but on the size of the anode itself.

Of course, you can’t stuff a pin one and a half meters long into a small boiler. But there are sectional anodes on the market, arranged in a row and adjustable. And also flexible, which are plastic pipe where magnesium balls fall asleep. This option generally does not require replacement for a long time, only replenishment with these same balls as they are oxidized.

In no case should you wait until the boiler starts to malfunction. This happens when the magnesium anode has not been able to cope with its duties for a long time. Therefore, you should hurry in advance and change the anode, long before the heating device fails.

- The first step is to turn off the power supply. This is done differently in different boilers. For some, it is enough to remove the plug from the outlet, with others you will have to tinker a bit, disconnecting the wires from the terminals.

- Then shut off the water supply. It is better to completely disconnect the pipes.

- Now you need to drain all the water from the boiler.

- Using a screwdriver, we dismantle the protective cover, opening access to the heating elements and temperature sensors.

- We remove the flange together with the sensors.

- Slightly loosened, we get a heating element. We do this carefully, trying not to damage the gaskets.

- We remove the old anode, from which only a small pin can remain. It depends on the period of operation and the quality of the water supplied to the boiler.

- In its place, we install a new one, bought in a store in accordance with the device passport.

Before you collect everything back, you should pay attention not only to the condition of the heating element, but also to clean the boiler itself from the inside. The boiler is washed with a strong pressure of water. But the heating element will have to be descaled with the help of folk tricks. It should be placed in a solution of citric acid for a day or two.

The assembly of the heating boiler is carried out in the reverse order, observing all precautions. In this case, you should carefully inspect all gaskets and, if necessary, replace them with new ones.

Turn on the boiler only after filling it with water, otherwise the heating elements may burn out.

Here is such a small and not at all complicated detail - this magnesium anode, without which the boiler will work much less qualitatively. Usually, the passport attached to the device indicates the recommended time for replacing the anode. But experienced experts advise doing it early. Then certainly rust, oxidation and salt deposition will be, if not completely neutralized, then minimized.

The purpose of this article is to help those who are faced with the repair of a water heater for the first time and do not know all the subtleties and details. We will talk about such an important component of almost any water heater as a magnesium anode. Next, we will tell you about the principle of its operation, the feasibility of installing it in a water heater, and how to understand when it is time to replace it.

Magnesium anode device

magnesium anode is a metal threaded rod, on which magnesium is deposited by mold casting (Latin Magnesium, element 12 in the periodic table of Mendeleev), mainly AZ63 alloy. Magnesium anodes differ in diameter, length and threaded stud, while there are a number of standard standard sizes, which are suitable for almost all types of water heaters that exist today.

Below we provide a list of standard, typical magnesium anodes. By clicking on the links you can see more detailed information about each item, photos and the current cost:

Working principle of magnesium anode

magnesium anode in the water heater serves to remove electrochemical corrosion and prevents the formation of heavy scale on the heating elements (heaters) in the process of heating water. The anode enters chemical reaction with water, softening it and absorbing the effects of hard water. Under the influence of these processes, it is destroyed, but due to this, the service life of the heating element increases, and most importantly, the welds of the inner tank of the water heater are protected from corrosion. Thanks to the anode, scale on the heating element is formed not solid, but loose (magnesium hydroxide is formed) and it will be easy to clean it during the next maintenance of the boiler.

The anode is an important part in the water heater, because if the heating element (heater) fails, it will not be difficult to replace it, but if the welds leak, the boiler will have to be taken to a landfill, it can no longer be repaired.

An excerpt from the instructions for the Ariston water heater:

"Magnesium anode is an integral integral part corrosion protection systems for water-containing containers. Necessary ANNUALLY check its condition. In case of severe wear, the anode must be replaced. The guarantee for the water-containing capacity with a worn magnesium anode (less than 30% residual volume) is void. It must be replaced at least once every 24 months. The magnesium anode is consumable, and is not replaceable under warranty."

An excerpt from the instructions for the Termex water heater:

Magnesium anode needs to be replaced at least once a year. If the water contains a large number of chemical impurities, the magnesium anode must be changed more often. The formation of scale on the heating element can lead to its failure, which is not a warranty case, and its replacement is not included in the manufacturer's and seller's warranty obligations.

Excerpt from the instructions for the water heater "Electrolux":

"Internal tanks are made of high quality medical stainless steel. As an additional protection of the internal tank against corrosion, the water heater is equipped with a magnesium anode. Annual Maintenance should include a mandatory check of the presence of scale on the heating element and the internal cavity of the water-containing container, as well as the condition of the magnesium anode. In the case of 30% or more wear of the magnesium anode, the anode must be replaced with a new one.

An excerpt from the instructions for the water heater "Polaris":

“When using a water heater with “hard” water with a large amount of mineral salts dissolved in it, the inner surface of the tank, as well as the surfaces of the heating element and the anode, become covered with deposits and scale over time. good quality water and long service water heater, replace the anode as it wears out, but at least once a year.

Thus, if you do not monitor the condition of the magnesium anode, you can be left without a manufacturer's warranty. Therefore, the anode is the most important part and we recommend installing it in the water heater.

Service life of magnesium anode

Most modern water heaters do not provide any warning system for the need to replace the anode. In order to check its condition, you must first dismantle the heating element from the tank, then unscrew the anode from the heating element, then inspect it appearance. As mentioned above, if the magnesium residue is less than 30%, it must be replaced. In the picture below you can see what the new anode looks like and the one that has already worked out its resource.

In order not to dismantle the water heater frequently to check the condition of the anode, we recommend that you write down or remember the service life of the first one and replace it after the same period of time. On average, the service life of the anode is 1-2 years, depending on the intensity of use of the water heater and the hardness of the water.

We hope that this information will answer all your questions about magnesium anode and it will be useful for you!

About the anode in the water heater, its properties and principle of operation, you need to know everything, because it affects the service life. If you do not change it, it has a bad effect on the duration of the boiler. What it is, what it is for and how to replace it, read below in our article.

The purpose of the magnesium anode

It protects the tank from corrosion and takes over all oxidation processes. Let's see how they function storage water heaters, details.

Tanks of boilers "Termex" or "Ariston" are made of stainless steel or covered with a protective layer of enamel. According to the statement, stainless steel does not give in to corrosion. But the following points should be taken into account:

- The body is made of food grade stainless steel. The material is not able to resist oxidation for more than six months. If the manufacturer used high quality steel for manufacturing, the cost of technology would be too high.

- The tank is not created in one piece. Basically, it consists of two parts that are connected by seams. Under the influence of high temperatures, the seams can be deformed, which leads to a loss of the properties of the stainless material.

What else do you need to know? Manufacturers try to prevent a reaction by coating the inner walls with protective agents. Over time, they also lose their effectiveness. When heated, water expands the metal, so the alloy is stretched, losing its properties.

After the formation of microcracks, oxygen oxidizes the metal, which leads to irreversible corrosion.

The metal case and the heating element create a galvanic couple. The case in this case acts as an anode. So that it does not deteriorate when exposed to water, the manufacturers installed an alloy next to the heating element, which includes magnesium. He takes on the role of the anode - as a result, all the oxygen goes to its oxidation, and the tank remains intact.

Over time, the alloy is destroyed, its particles settle to the bottom of the case, so a new one must be installed periodically.

Almost all Polaris, Gorenie, Electrolux brands include magnesium anodes in their models. How do they look? It is an alloy on a stick with a flat surface. During operation, corrosion begins to corrode their surface.

Why choose magnesium

Is it really impossible to make an element from other materials? In fact, the cost of magnesium is low, which allows not to increase the cost of the finished product. It also has a weak electrochemical potential. Magnesium attracts salt from the water to itself, preventing it from settling on other parts.

What is the life of the anode and how often should it be changed? Experts recommend replacing every year.

Signs when it's time to change a part:

- Noise is heard during operation.

- The water acquired an unpleasant odor, became cloudy.

- Prolonged heating.

- Frequent switching on and off of the boiler.

You can perform it at the same time as replacing the anode.

How to replace the magnesium anode with your own hands

Consider how to unscrew the details yourself:

- Disconnect the equipment from the network. Turn off the machine if there are contacts leading to it.

- Drain the water. The fastest way to do this is through the check valve. Shut off the water at the main valve, unscrew the water hoses and turn the check valve.

- In Gorenje models, the magnesium part is located on top. In order not to remove the boiler from the wall, simply pry off the top cover. If this is not possible due to proximity to the ceiling, the case will have to be removed.

- In other models, you need to remove the bottom cover. To do this, unscrew the fixing bolts and remove the latches.

- If the heating element is fixed on the flange, unscrew the nuts and screws, pull out the flange. Sometimes the heater must first be pushed in and then removed from the tank.

- The anode is unscrewed from the stand next to the heater.

How to select a new element? If you do not know how to replace the old one, take it to the store. The part must be selected according to the diameter of the thread. For example, in the Thermex Flat Plus model, the number is M4.

Install in reverse order.

How to extend the life of your water heater

Monitor the operation of the boiler in order to detect and fix the problem in time:

- Do you hear a hissing sound when drawing water? This means that the heater is covered with scale. Need to clean it up.

- It is advisable to install water filters. They reduce the concentration of impurities that subsequently settle on the parts.

- Occasionally look under the case cover to check the condition of the anode. If it is half worn out, it will need to be replaced soon.

- If you removed the old one, but did not have time to install the new element, do not start the technique. Buying a new element will cost less than buying a new boiler.

- Frequent use leads to rapid scale formation. Therefore, it is recommended to clean the tank once a year.

Decided on self-replacement? Be sure to unplug the heater and drain the water. Then start repairing. A video about replacing this part in the boiler will help you:

Social movements and their types

Social movements and their types Yamabushi-ninja teachers and their practices… Yamabushi and the secret of Shugendo numerology

Yamabushi-ninja teachers and their practices… Yamabushi and the secret of Shugendo numerology Secret rite on the Templar coin

Secret rite on the Templar coin How to cook beef heart salad, step by step recipe with photo

How to cook beef heart salad, step by step recipe with photo Carbohydrate-free diet - menu for the week: recipes for weight loss

Carbohydrate-free diet - menu for the week: recipes for weight loss Dynamic gymnastics for newborns

Dynamic gymnastics for newborns Exercises for the press at home

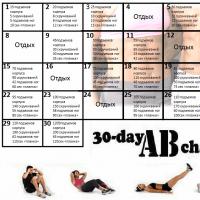

Exercises for the press at home