What diameter of the pipeline is best suited for creating heating for a private house. Diameters of pipes for heating a private house Cross-section of polypropylene pipes for heating a private house

When choosing pipes, consider a large number of their features. For example, in addition to taking into account the physico-chemical properties, it is necessary to take into account what their length and diameter will be. It turns out that the hydrodynamics of the entire heating system directly depends on the diameter. The most commonly used and used for private houses are pipes with a diameter of approximately 16-40 mm.

Scheme of the device of a polypropylene pipe.

Pipes of this size are able to withstand the pressure in the heating system, in addition, they are convenient to use in work, they will not create problems during the installation process. Using them, it is possible to ensure the wiring of the pipeline of a hidden nature.

What diameter of polypropylene pipes is used for heating

To correctly select the size, the internal diameter of the pipes is calculated using the following formula:

d = √(4-U-1000/πL),

where U is a value that is equal to the total water consumption in the house, which will fall on this water supply,

L - water flow rate, for pipes large diameter it is considered to be equal to 1.5-2 m / s, for a small one - 0.7-1.2 m / s.

Scheme of the heating system of the house.

Polypropylene materials for heating are used in a diameter of approximately 20-32 mm. For mounting a warm floor, plastic with a diameter of 16 mm is most often used. It is important at the beginning of work to assess all its complexity and select the necessary material. Given the various factors in the heating system, you need to correctly calculate the cross section of the pipe. Many things are important here: carrier temperature, flow velocity, pipeline length, pipe diameter and hot water pressure.

It is believed that only the correctly calculated size of the desired diameter polypropylene pipes for heating will help make the whole system reliable and efficient. In cases of an incorrectly selected size, some shortcomings in the operation of the system are possible. For example, if the diameter is larger than necessary, then the pressure in the heating system will become lower than necessary, which will lead to disturbances in the circulation of water in all apartments in big house. And only the repair work carried out, which involves the replacement of pipes with pipes of the correct size, will be able to establish the operation of the system.

How to choose the right pipe diameter

In cases where heating is carried out in a private house or cottage, the pipes must be selected taking into account the fact that the diameter will not change only when there is a direct connection to the central heating system. In the case of an autonomous pipe system, any size (different diameter and length) can be used, depending on the preferences of the owner of the house.

Related article: Do-it-yourself drywall slopes

When choosing the necessary blanks, it is necessary to take into account all the features, especially when it comes to a natural heating system, where the ratio of the cross section to the pump power will not be a primary feature. This fact is attributed to the advantages of this heating system.

Pipe installation scheme.

The disadvantage of such a system is the small radius of action and the high cost of the large-sized elements used in this case.

To ensure the efficiency of the system, it is necessary to maintain a certain level of pressure in it, allowing the water moving inside to overcome all obstacles in its path. Resistance (obstacles) can be in the form of friction of water against the walls, a tap or a tap and a heating device. The most interesting thing is that the resistance and speed at which water will flow depends on the length and diameter of the pipeline pipes. With a high water velocity, a small cross section and a long pipeline, the level of resistance in the path of water increases.

Which pipes are suitable for the heating system

Any heating system involves drawing up a project scheme. After that, it is necessary to prepare and select everything you need in advance (materials and tools for installation work): pipes, fittings and necessary tools. And only after that you can proceed with the installation of polypropylene pipes.

Elements are selected for a particular room, taking into account all its features and type of heating. It is important at the preparation stage to determine your strengths and understand what the work will be like. After all, installation is not always easy to do with your own hands, sometimes you have to turn to professionals for help.

For heating systems, it is possible to use polypropylene, metal and metal-plastic materials. All of these materials have their own advantages and disadvantages, which must be considered when selecting for your system. Polypropylene is considered the best material for heating system elements. In turn, metal ones are more overpriced, and also difficult to use, they are unstable to corrosion, which leads to a decrease in their service life. Metal-plastic materials are cheaper, easy to use, but their reliability and durability leaves much to be desired, so it is better not to consider this option for installing a heating system.

Scheme of heating from polypropylene reinforced pipes.

From this we can conclude that polypropylene is best suited for a heating system, as it serves good option for installation of pipes for water. It is important to know and be able to share different types polypropylene pipes, which are designed for hot or cold water. You need to use materials only for a certain type of work. For example, pipes for heating, where will go hot water, should not be used for pipelines with cold water, because temperature regime will be different and various violations and malfunctions in the system are possible.

Related article: Timber house: do-it-yourself construction, making dowels

For the installation of a warm floor or a heating system, you can safely choose polypropylene elements that have a large number of positive characteristics, among which the following points are worth noting:

- Reliability.

- Durability (exploited for 100 years).

- Corrosion resistant.

- No mineral deposits.

- High level of chemical resistance.

- Ease of mounting.

- Possibility of implementation repair work in case of malfunction or breakdown.

- Price availability.

The only, but the main drawback of this type of material is flammability and instability to high temperatures.

Required for heating systems right choice, which depends on the correct diameter.

The diameter of the pipes should not be very small, but not large either, so as not to affect the cost of the system and the water pressure in it.

Installation of a heating system using polypropylene pipes

Installation of the heating system involves the correct choice of the scheme of work. For example, the use of polypropylene pipes provides for several options for work:

Scheme of installation of hot water pipes.

- Gravity circulation of water in the system. In this case, there is no need to install a circulation pump, since the movement of water will be independent. This option is suitable for rooms where there are frequent chances of problems with power outages, which will lead to the impossibility of using the pump.

- Bottom spill system in heating. This system has a radial wiring, which involves the presence of a pump used to increase the water pressure, which requires a smaller diameter.

- It is possible to use one- and two-pipe systems with connection to the radiator using a side or bottom type of connection.

Installation of a heating system from polypropylene pipes

Installation of polypropylene elements can be easily done with your own hands, and it is not necessary to trust this process the work of the masters. During installation, welding (soldering) is used, in no case should threaded connections be used for pipes made of polypropylene.

Before welding, the workpieces are cut into segments of the desired length with the help of special scissors so that the edges are smooth, without burrs, and all this is done very quickly. The welding process is carried out using a special apparatus designed for this purpose. For welding, it is necessary to insert the pipe into the nozzle correct diameter(the diameter must match the nozzle) and heat to a temperature of 260 degrees. The heating time of the pipe depends on its diameter, for example, a 20 mm pipe will heat up for 5 seconds, but a pipe with a diameter of 50 mm will heat up for 18 seconds.

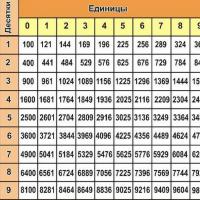

When designing and installing a heating system, the question always arises - what diameter of the pipeline to choose. The choice of the diameter, and hence the throughput of the pipes, is important, because it is necessary to ensure the coolant speed is within 0.4 - 0.6 meters per second, which is recommended by experts. In this case, the required amount of energy (the amount of coolant) must be supplied to the radiators. It is known that if the speed is less than 0.2 m/s, then there will be stagnation of air pockets. A speed greater than 0.7 m/s should not be done for reasons of energy saving, since the resistance to fluid movement becomes significant (it is directly proportional to the square of the speed), and besides, this is the lower limit for the occurrence of noise in pipelines of small diameters. Nowadays, polypropylene pipelines are increasingly being chosen for heating, which, although they have disadvantages in the form of the difficulty of ensuring the quality of the joints, and significant thermal expansion, they are extremely cheap and easy to install, and these are often decisive factors. What pipes to use for the heating system? Wall thickness data are given in the tables. For heating, polypropylene pipes are now used, which are reinforced with aluminum foil or fiberglass. Reinforcement prevents significant expansion of the material when heated. Many experts prefer pipes with internal fiberglass reinforcement. Such a pipeline has recently become the most widely used in private heating systems. Pipes are produced in standard diameters, from which you need to make a choice. Standard solutions have been developed for the selection of pipe diameters for heating a house, guided by which in 99% of cases it is possible to make the optimal correct choice of diameter without performing a hydraulic calculation. Standard outer diameters of polypropylene pipes are 16, 20, 25, 32, 40 mm. The inner diameter of PN25 pipes corresponding to these values is 10.6, 13.2, 16.6, 21.2, 26.6 mm, respectively. More detailed information about outer diameters, inner diameters and wall thickness of polypropylene pipes is given in the table. We need to ensure the supply of the required thermal power, which will directly depend on the amount of coolant supplied, but the fluid velocity must remain within the specified limits of 0.3 - 0.7 m / s Then there is such a correspondence of the connections (for polypropylene pipes, the outer diameter is indicated): Consider the choice of pipe diameter in more detail, based on pre-calculated tabular correspondences of energy, speed and diameter. Let us turn to the table of correspondence of speed to the amount of thermal power. The table shows the values \u200b\u200bof thermal power in W, and below them is the amount of coolant kg / min, when supplied with a temperature of 80 degrees C, return - 60 degrees C and room temperature 20 degrees C. The table shows that at a speed of 0.4 m / s, approximately the following amount of heat will be supplied through polypropylene pipes of the following outer diameter: And at a speed of 0.7 m / s, the values \u200b\u200bof the supplied power will already be about 70% more, which is not difficult to find out from the table. How much heat do we need? Let us consider in more detail, using an example, how much heat is usually supplied through pipes, and we will select the optimal diameters of pipelines. Our heating scheme is two-pipe. Hot coolant is supplied through one pipe, and the cooled coolant is discharged to the boiler through the other. Radiators are connected in parallel between the pipes. On each floor, the pipes branch into two wings with the same heat output, for the first floor - 7.5 kW each, for the second floor - 5 kW each. So, 25 kW comes from the boiler to the interfloor branching. Therefore, we need main pipes with an internal diameter of at least 26.6 mm so that the speed does not exceed 0.6 m / s. Fits 40mm polypropylene pipe. From the interfloor branching - along the first floor to the branching on the wings - 15 kW is supplied. Here, according to the table, for a speed of less than 0.6 m/s, a diameter of 21.2 mm is suitable, therefore, we use a pipe with an outer diameter of 32 mm. 7.5 kW goes to the wing of the 1st floor - an inner diameter of 16.6 mm is suitable, - polypropylene with an outer diameter of 25 mm. For each radiator, the power of which does not exceed 2 kW, it is possible to make a tap with a pipe with an outer diameter of 16 mm, but since this installation is not technologically advanced, pipes are not popular, more often a 20 mm pipe with an inner diameter of 13.2 mm is installed. Accordingly, we take a 32mm pipe to the second floor before branching, a 25mm pipe to the wing, and we also connect radiators on the second floor with a 20mm pipe. As you can see, it all comes down to a simple choice among the standard diameters of commercially available pipes. In small home systems, up to a dozen radiators, in dead-end distribution schemes, polypropylene pipes 25 mm - “on the wing”, 20 mm - “on the device” are mainly used. and 32 mm "on the line from the boiler." Pipe diameters can also be selected according to the conditions of hydraulic resistance for an atypically large length of pipelines, at which it is possible to go beyond the technical characteristics of the pumps. But this can be for production workshops, but in private construction it is practically never found. For a house up to 150 sq. m., according to the conditions of hydraulic resistance of the heating and radiator system, a pump of type 25 - 40 (pressure 0.4 atm) is always suitable, it can also be suitable up to 250 sq. m in some cases, and for houses up to 300 sq. m . - 25 - 60 (head up to 0.6 atm). The pipeline is designed for maximum power. But the system, if ever it will work in this mode, then not for a long time. When designing a heating pipeline, it is possible to take such parameters that at the maximum load, the coolant velocity would be 0.7 m/s. In practice, the speed of water in the heating pipes is set by a pump that has 3 rotor speeds. In addition, the power supplied is regulated by the temperature of the coolant and the duration of the system, and in each room it can be regulated by disconnecting the radiator from the system using a thermal head with a pressure valve. Thus, with the diameter of the pipeline, we ensure that the velocity is within 0.7 m at maximum power, but the system will generally work with a lower fluid velocity. From correctly calculated pipe diameter depends on heat and home heating costs. Adequately selected option will not require extra costs to heat the liquid and allow the coolant to pass through the system at a good speed. Pipe specifications include three types of diameters: Reference. The conditional passage is calculated to determine the capacity of the pipeline. When choosing the required section, the following parameters are taken into account: Attention! If the pipes have a smaller diameter, then this also leads to a loss of fluid velocity, since the resistance inside the system increases and the coolant does not pass. This fraught with loss of temperature and noise in operation batteries. First of all, calculate the power of the entire heating system. The calculation is made according to the formula: Qt=V*∆t*K/860 Wherein: For standard buildings, average values \u200b\u200bare used. The common starting point for determining the required cross section is the quadrature of the heated room - 10 sq. m. require 1 kW of heat, so the room is 30 sq. m. with a ceiling height of about three meters should get 3 kW. Having these data, calculate the diameter using the formula: D= √(354*(0.86*Q/∆t)/V), V— coolant velocity in the system (meters per second); Q- the required amount of heat for heating (kW); ∆t- the difference between the feeds (reverse and direct) (C); D- section (in millimeters). The size of the pipes depends on the type of heating system of a private house. The first and last pipes that are mounted with a heating boiler must match the diameter of its nozzle from 25 to 50 mm. Photo 1. Scheme of a heating system with natural circulation. The numbers indicate the components of the structure. It is advisable to choose the maximum allowable diameter, since in the future it will decrease to increase the pressure in the system (branching with an inch section is performed by a pipe in 3/4 inch, the next part is half inch). Reference. The first decrease is made after the first branch. At the end point, the minimum diameter corresponds to the recommended ( 12.7 or 19 mm). You will also be interested in: For systems with forced circulation it is permissible to take narrower pipes than for gravity, because the pressure in the system is provided by the pump. cross section depends on the connection scheme and on the wiring and varies in the system from less to more and vice versa or remains unchanged(with a single-pipe heating system). With beam spread section of the pipe leaving from a copper to a collector ― 19 mm, to the radiators, the branch goes with pipes in 12.7 mm. Batteries are used for space heating: Two popular types battery connections: Photo 2 Reference. The third type is not the most popular collector type, in which pipes go from one collector to each radiator. The method is good for heating, but expensive for the cost of equipment. In each type, the contour can go: Connection of radiators can be top, bottom, diagonal. The type of connection affects the diameter of the connected pipes and their number. For heating systems apply different kinds pipes. The most demanded type, manufactured from two types of steel: Metal pipes are made: The positive properties include: Of the shortcomings, we note only: Important! Regardless of which pipes the system is equipped with, it is recommended to mount the first links of the outlet and return from the heating boiler only metal parts. The most expensive, but also exceptional in quality. Produced from: Reference. For heating systems, pipes with markings must be selected EN 1057, indicating the treatment of copper with phosphorus, which further increases its resistance to water. According to the method of manufacture, pipes are divided into: In installation, they are connected by hard soldering. Among the advantages note: Photo 3. Copper pipes connected to heating radiators. Such structures serve for a very long time. The disadvantages include: Metal-polymer (metal-plastic) pipes - five layer construction: cross-linked (modified) polyethylene, adhesive layer, thin aluminum, glue and a protective layer of polyethylene inside. The tube is stitched with an overlap (ultrasound) or a butt joint (laser). Contours made of metal-propylene are used in: Photo 4. Metal-plastic pipes for heating systems. In the middle part of the products is a layer of aluminum. The use is due to the large number of advantages of this type: The disadvantages include: Pipes are used for heating installation in 16 and 20 millimeters. Be the first! Average score: 0 out of 5 . For cold water supply, polypropylene pipes with a homogeneous wall are used. Reinforced products are used for hot water supply systems and heating circuits, since the inclusion of an aluminum shell in the wall structure of a polypropylene pipe significantly increases the strength of the pipe material and reduces the amount of thermal expansion. When choosing components for a heating and water supply system, the decisive factors are the temperature of the liquid, its flow rate and pressure. Required area the section of the water supply is determined by the calculations made in accordance with the scope and operating conditions of the equipment. Based on the configuration of the pipe section (round ring), its geometric parameters are determined by the outer and inner diameters. The current classification of polypropylene pipes clearly defines typical dimensions each type of pipe products used for installation. To date, both domestic and foreign manufacturers produce components for pipelines in a standard version. Taking into account practical application standard engineering solutions have been developed to determine the optimal passage in products for home heating and other water communications. Based on the data in the table, it is possible to make the right choice of equipment and components for the heat main without resorting to hydraulic calculations. As a rule, one of the following outer diameter values is present in the marking: 16, 20.25, 32 and 40mm, which correspond to the inner diameters of PN25 polypropylene pipes: 10.6; 13.2; 16.6; 21.2; 26.6 mm. For ease of use, the correspondence of the diameters and wall thicknesses of polypropylene pipes used in heating and water supply systems are summarized in the table: Reasonable question. Why are external parameters applied to finished products, if the size of the internal passage of the pipeline is so important for functionality. The thing is that the outer diameter indicates the appropriate type of connection. The potential of using polypropylene pipes of various outer diameters at a coolant velocity in the pipeline of 0.7 m/s: The coolant supply rate and the amount of transferred thermal energy directly depend on the internal section of polypropylene pipelines. For clarity of this statement, the dependence of providing thermal energy on the intensity of the coolant supply and the values of the pipeline diameters is summarized in the table: Thermal power is indicated in W, the intensity of the coolant supply in kg / s. The calculated data are based on average temperatures: the supplied coolant at 80 0 C, the return at 60 0 C, the air in the room +20 0 C. . For example: at a flow rate of 0.4 m/s, the following amount of heat energy will be transferred in the pipeline: With an increase in the fluid flow rate to 0.7 m/s, the intensity of the coolant supply will immediately increase by 70-80%. Important! The practical purpose of the above table is to recommend, based on the value of the required amount of thermal energy, the required pipe diameter during the selection of pipe materials for a residential heating system. Let's look at an illustrative example: There is a typical house with a usable area of 250 m 2 . The building is sufficiently insulated and to create normal conditions residence needs heating at the rate of 1 kW per 10 square meters. m, that is, to create a comfortable temperature in the house, 25,000 watts of thermal energy (maximum) will be enough. On a note: the first floor always requires more heat - about 2/3 of the total amount consumed. Thus, out of 25 kW, heating the first floor will require 15 kW, the second - 10 kW. The house is equipped autonomous system heating on the basis of a double-circuit boiler. The radiators installed in the rooms are connected in parallel. The house has a wiring for two wings, with equal heat output. On the ground floor, the power for each wing is 7500 watts. For the second floor, both wings require 5000 watts each.What type of pipeline to choose

Polypropylene pipes are divided into several types, which have their own technical characteristics, and they are designed for different conditions. For heating, grades PN25 (PN30) are suitable, which withstand operating pressure at 2.5 atm at liquid temperatures up to 120 degrees. FROM.Questions of selecting the diameter of the heating pipeline

What diameters to connect

Correlation between pipe diameter, fluid velocity, and heat output

Selection of pipes by power

How much heat should the pipeline supply

There is a house with an area of 250 square meters, which is well insulated (as required by the SNiP standard), so it loses heat in winter time 1 kW from 10 sq. m. To heat the whole house, an energy supply of 25 kW (maximum power) is required. For the first floor - 15 kW. For the second floor - 10 kW.

Features of choosing other equipment

What pipe diameter is needed for heating a private house

Power calculation

Calculation principle

Determining the correct pipe size for heating systems

with natural circulation

With forced circulation

Types of radiators

Connection

Types of pipes for heating

metal

Copper

metal-plastic

Rated: 0 readers .What diameters are produced polypropylene pipe materials

Table with data on the diameters and wall thickness of polypropylene pipes used in everyday life series

Table with data on the diameters and wall thickness of polypropylene pipes used in everyday life series Influence of pipe diameter on the performance of the heating system

Selection table for polypropylene pipe material depending on the intensity of the coolant supply and the need for thermal energy

Selection table for polypropylene pipe material depending on the intensity of the coolant supply and the need for thermal energy  Two-storey house with a water heating system based on an autonomous boiler - in the context

Two-storey house with a water heating system based on an autonomous boiler - in the context

The boiler produces 25 kilowatts of thermal energy for heating the house. This means that for the heat main it is necessary to use polypropylene pipes and fittings with an inner diameter of 26.6 mm (at a feed rate of 0.6 m / s). given value corresponds to an outer diameter of the pipe 40 millimeters.

To supply the branches on the ground floor, 1500 watts of heat will be required. Using the data from the table, we get the following:

- at a flow rate of 0.6 m / s, the optimal diameter of the inner lumen of polypropylene pipes will be 21.2 mm - the identical external parameter corresponding to this value, according to the table, is 30 mm;

- for each wing, pipe material with an inner diameter of 16.6 mm is suitable, which corresponds to Ø 25 mm of the outer contour of the section of polypropylene pipes.

Now consider the procedure for connecting heaters.

Water heating radiators have an average power of 2 kilowatts, therefore, theoretically, pipes with a minimum outer diameter of 16 mm (PN16) are suitable for their insertion into the circuit. However, in practice it is recommended to use polypropylene products with an inner section of 13.2 mm and an outer diameter of 20 mm (PN20), since the use of PN16 polymer pipes is considered inappropriate due to low manufacturability.

The second floor is equipped with a 32 mm pipeline. Pipes and fittings Ø25 mm are used for each wing. With radiators, the picture is the same as on the ground floor - the batteries are connected using PN20 pipes.

Conclusion

Based on the above example, for each section of the pipeline in the heating system, you can select components required diameter- including the efficiency of the heating equipment will depend on this.

It should be remembered that the materials for the pipeline in the heating system are selected with the calculation of compliance with the maximum technical characteristics of an autonomous boiler, despite the fact that in most cases the unit will operate normally - in accordance with the specified operating parameters.

Choosing the diameter of a pipe for heating a house is a serious responsible task, and you need to approach it slowly; thoroughly weighed and calculated everything. In this article, we will consider systems with the so-called "forced circulation". In such a system, the movement of water occurs due to a special " circulation pump", which works non-stop.

The main task of heating pipes is to deliver heat to the heated elements (radiators) with minimal losses. From this we will build on when choosing the correct pipe diameter for heating a house. But to calculate everything correctly, you need to know:

- pipe length;

- heat loss in the building;

- element power;

- what will be the piping (natural, forced, one-pipe or two-pipe circulation).

The next item after you have all the above data in your hands, you will need to sketch out a general scheme: how, what and where it will be located, what heat load each heating element will carry. Then it will be possible to begin to calculate the desired section of the pipe diameter for heating the house.

You should also be careful when buying:

- metal-plastic and steel pipes are marked by the size of the inner diameter, there are no problems here;

- but polypropylene and copper - according to the outer diameter. Therefore, we need to either measure the inner diameter ourselves with a caliper, or subtract the wall thickness from the outer diameter of the pipe for heating the house.

Do not forget about this, because we need exactly the "inner diameter of the pipe for heating the house" in order to calculate everything correctly.

Choose the diameter for your heating

Do not count on the fact that you will immediately be able to choose the right pipe diameter for heating your home. The fact is that you can get the desired efficiency in different ways.

Now in more detail. What is the most important thing in a proper heating system? The most important thing is uniform heating and delivery of liquid to all heating elements(radiators). In our case, this process is constantly supported by a pump, due to which, for a specific time period, the liquid moves through the system. Therefore, we can choose from only two options:

- buy large-section pipes and, as a result, a low coolant supply rate;

- or a pipe of small section, naturally the pressure and velocity of the fluid will increase.

Logically, it's better to choose the second option. pipe diameters for home heating and here are the reasons why:

- with external pipe laying, they will be less noticeable;

- with internal laying (for example, in a wall or under a floor), the grooves in the concrete will be more accurate, and it is easier to hammer them;

- the smaller the diameter of the product, the cheaper it is, of course, which is also important;

- with a smaller pipe section, the total volume of the coolant also decreases, thanks to which we save fuel (electricity) and reduce the inertia of the entire system.

Yes and work with thin pipe much lighter and simpler than with a thick one.

The formula for calculating the diameter of a pipe for heating a house

For example, let's select a cross section for a copper pipe in direct proportion to how powerful the radiators are.

All pipes are manufactured in accordance with GOST. Consequently, all diameters are known in advance, as well as the amount of useful heat that they can pass through themselves, depending on the cross section and pressure. Therefore, it is not necessary to calculate each time what has long been calculated and recorded in special tables. All that is required is just to find a table with data that suits you and use it to select the diameter of the pipe for heating the house.

How were these tables created? Yes, very simple. Take this formula for calculating the diameter of the pipe, consider, and write down the result, and so on for all sections:

D= √(354*(0.86*Q/∆t)/V)Wherein:

V is the velocity of the liquid in the pipe (m/s);

Q- the required amount of heat for heating (kW);

∆t- difference between reverse and forward feed (C);

D– pipe diameter (mm).

It is known that in individual heating systems the coolant moves at a speed of 0.2-1.5 m/s. It is also known that the ideal speed should be in the range of 0.3-0.7 m/s. If the speed is greater than the optimal performance, then noise increases, and if it is less, then air jams may appear. For this, there are ready-made tables. In them we choose the speed that suits us.

There are tables for copper, polypropylene, metal and metal-plastic pipes. They have ready-made solutions for working in medium and high temperatures. For clarity, let's look at specific examples.

Diameter calculation for a two-pipe heating system

- total heat loss - 36 kW;

- loss on the 1st floor - 20 kW;

- loss on the 2nd - 16 kW;

- polypropylene pipes installed;

- system operation in 80/60 mode;

- temperature - 20 C.

Below is a table (a) based on the data of which, we will determine the required pipe diameter. In the table, cells with the best (optimal) fluid velocity are marked in green.

We count. Through the section of the pipe that connects the first fork and the boiler, the entire volume of liquid passes, and therefore all the heat, which is 38 kW. Let's determine which pipe to take here. We take our table, look for the corresponding line in it, then go through the green cells and look up. What do we see? And we see that with such parameters, two options are suitable for us: 50 and 40 mm. Naturally (this was written above), we choose a smaller pipe diameter for heating a house of 40 mm.

We have two wings on each floor. The circuit is also divided into two branches. We consider the first floor:

20 kW / 2 = 10 kW per wingSecond floor by analogy:

16 kW / 2 = 8 kW per wingAgain, we take our table and determine that in these areas we need a pipe with a cross section of 25 mm. It is also clearly seen from the table that we use this diameter until the load drops to 5 kW, then we will use pipes of 20 mm.

Important! From personal experience, I can say that it is better to switch to a pipe diameter of 20 mm when the heat load is not 5 kW, but 3 kW.

In such a simple way, we calculated all the diameters of the pipe for heating the house of the polypropylene pipes we need for a two-pipe heating system.

For the return water supply, you do not need to calculate anything, everything is much simpler there: you do all the wiring with pipes of the same diameter as for direct supply. As you can see, there is nothing complicated. All you need is a good, suitable for a specific case, table.

Some nuances of calculating the diameter for metal pipes

If you decide that you will use metal pipes for the heating system, then you need to consider that they lose heat. In small areas, it is almost not noticeable. But on extended systems, it can happen that the very last heating elements in the chain are cold or slightly warm. This is also a consequence of the wrong choice of pipe diameter. Fortunately, heat loss can be easily calculated:

q \u003d k * 3.14 * (tv-tp) q - heat loss per 1 meter (W / s); k - heat transfer coefficient (W * m / s); tw - hot water temperature (C); tp - temperature environment(FROM).Take a pipe with a diameter of 40 mm. Let's say the wall is 1.4 mm thick. Material - steel. Let's calculate:

q \u003d 0.272 * 3.15 * (80 - 22) \u003d 49 W / sHere is another proof of why you need to take the diameter of the pipe for heating a house with a smaller diameter. After all, it is clear that the thicker the pipe, the more heat we lose. And in this example, we got losses of almost 50 W per 1 meter of distance. And if the system is quite extended, then you can lose all the heat.

But don't get upset! Such accurate calculations needed only for multi-storey residential buildings. For individual heating systems, everything is simpler: the calculations are rounded up and this gives a certain margin.

Where to get tables?

Everything is simple here. Usually, all detailed tables with all the necessary data can be viewed (or downloaded for yourself) on the websites of pipe manufacturers. But it happens that there are still no tables. You can get out of this situation in the following way. If there are no tables for the outer diameter, then take it for the inner diameter and calculate from it. Yes, there will be inaccuracies, but, as experience shows, for forced circulation they are quite insignificant and acceptable.

After analyzing a huge number of already installed and perfectly working systems, experts noticed a certain pattern in the choice of pipe section. It is suitable mainly for small-sized autonomous systems.

In private houses, the pipes that come out of the boiler are most often one-half and three-quarters in size. Such a pipe diameter for heating a house is used up to the first fork, and at each next one, the cross section is reduced by exactly one step. But this method is applicable only for apartments and one-story houses, for high-rise buildings, alas, everything will have to be calculated very carefully.

Outcome

If we have private house or an apartment, autonomous heating for no more than 5-8 radiators and 2-3 forks, we can easily calculate everything ourselves. We will need to know how powerful each heating point is, the heat loss in the room and a good table for selecting the pipe diameter.

However, as it has already become clear, trust experienced specialists to calculate a complex multi-level system with numerous junctions and forks. Well, if you still decide to do everything yourself, then at least read articles such as ours and consult experts.

Dream interpretation of many animals Why do many animals dream

Dream interpretation of many animals Why do many animals dream What to give a girl for christening

What to give a girl for christening How long does carnival last

How long does carnival last Solar eclipse in February Aspects of a solar eclipse

Solar eclipse in February Aspects of a solar eclipse Holy week before Easter, what can you eat every day?

Holy week before Easter, what can you eat every day? February predictions for Capricorn

February predictions for Capricorn Tasks for logarithms with a solution

Tasks for logarithms with a solution