Supply and exhaust ventilation in the steam room. Ventilation in the bath: the right device on ready-made examples. Ventilation design in the dressing room

The presence of ventilation is a prerequisite for a comfortable presence in the bath. For the intake of fresh air and the output of the exhaust, ordinary ventilation is most often performed - they open the windows, doors, and vents. Such ventilation is called natural. Unfortunately, it is not always effective. For example, in large baths with a washing compartment (pool), forced ventilation is more effective in order to eliminate unpleasant odors, quickly dry surfaces and create an optimal microclimate.

The principle of operation of such a system

Any ventilation system consists of at least two holes. One of them is inlet, the other is exhaust. Fresh cold air, entering the steam room through the inlet, mixes with warm "local" air. The heat flow is distributed throughout the room. At the same time, the exhaust air is repelled to the exhaust opening and removed through it to the street or to other rooms of the bath.

If there are not enough natural reasons for the circulation of air currents, a forced ventilation system is arranged. Its essence is that fans are installed on one or both ventilation openings - supply or exhaust. They provide forced air movement. The supply fan draws in fresh air from the outside with its blades, and the exhaust fan, on the contrary, pushes the exhaust air out.

Often, gratings (slotted, louvered) or plugs are placed on the ventilation ducts, with the help of which they change the size of the hole and the intensity of air circulation.

If the supply opening is less open than the exhaust opening, then ventilation is enhanced. If the air flow speed reaches 0.3 m/s, there is a feeling of draft. This cannot be allowed. Ideally, the air movement should be smooth, slow, which means that the vents should open approximately the same.

Types of forced ventilation

There are the following types of forced ventilation (depending on the purpose of the fans):

- exhaust;

- supply;

- supply and exhaust.

Let's talk in more detail about each.

Exhaust ventilation

In the design of exhaust ventilation there is a fan-exhaust. It is installed on the exhaust hole ventilation system. There is also a supply hole in this type of system. Usually these are air ducts with ventilation grilles, windows with plugs, a gap under the door, etc. Exhaust ventilation reduces the air pressure in the steam room (creates a vacuum), which is compensated by the influx of fresh outside air.

Exhaust ventilation effectively removes harmful gases, unpleasant odors, excess moisture. This is especially true in showers, washing rooms, rooms with a pool, bathrooms of a bath.

The exhaust ventilation device is simple. Usually it includes a fan and a ventilation duct. Sometimes, when a powerful hood is used, the system is supplemented with a silencer.

Forced ventilation

Supply ventilation almost completely copies the exhaust system. But the fan is not installed to remove the used, but to supply fresh outdoor air.

When the supply system is operating, the pressure in the room increases, respectively, the exhaust air is drawn out through the exhaust ducts, doors, vents, gaps in the floor, ceiling, and walls.

Supply fans work to take in cool (and in winter - cold!) street air. To prevent this from reducing the temperature in the steam room, the ventilation system is equipped with special air heaters. Filters are used to purify the supply air.

Supply and exhaust ventilation

This is a combined system consisting of a forced air supply and a mechanical exhaust. In addition to fans, it can be equipped with recuperators, filters, silencers. It is possible to make the supply and exhaust ventilation fully mechanical by equipping it with an automatic control unit.

The design of supply and exhaust ventilation is the most complex. It is very important at the stage of its design to calculate the air exchange in the bath room. The amount of displaced air must be equal to the amount of supply air. This is ideal. But sometimes this balance is deliberately violated in order to create air flows of the desired direction. For example, if there is a bathroom in the bathhouse, then in order to prevent unpleasant odors from entering other rooms, it is artificially created underpressure. By installing a hood with high power. After that, the air from the room is more high pressure will independently go to the zone of low pressure. That is, go to the bathroom, and not to the steam room, showers, sinks.

Organization methods and ready-made schemes

Consider several ready-made schemes for performing forced ventilation.

Scheme #1. Exhaust ventilation

Behind the furnace, 0.3 m from the floor, a supply air vent is equipped. The exhaust fan is equipped on the opposite wall, a little higher - 0.4-0.5 m from the floor. Fresh air, getting into the steam room through the inlet, passes through the stove, warms up and rises to the ceiling. Gradually cooling down, it goes down and is drawn in by the exhaust fan. This forced ventilation scheme is quite popular due to the simplicity of the device and the rapid change in air flow.

Scheme #2. Forced ventilation

In a large steam room for a quick change of air, it is advisable to equip forced ventilation. For better circulation, air flows are directed not from the bottom up, as with natural ventilation, but from the top down. An inlet with a fan is equipped behind the furnace, 0.5 m above its level. The exhaust hole is placed in the lower part of the opposite wall, at a distance of 0.2-0.3 cm from the floor.

Supply ventilation according to this scheme works as follows. With the help of a fan, cold air is forced into the steam room through the inlet. Once in the range of the furnace, it quickly warms up and rises to the ceiling. Cooler streams are forced down and out through the exhaust port.

Scheme #3. Supply and exhaust ventilation

This scheme is intended for ventilation equipment in the bath steam room and shower room. A supply air vent with a fan is placed above the stove. The minimum distance from the heater is 50 cm. An exhaust hole (without a fan) is made on the adjacent wall next to the floor, away from the stove. In this case, the diameter of the exhaust duct should be 2 times larger than the diameter of the supply duct.

Another exhaust outlet with a fan is located in the shower room adjacent to the steam room, under the ceiling. Air enters the shower room from the steam room through a gap under the door.

Some mounting features

After choosing a ventilation scheme, it's time to move on to its installation. To do this, you will need the following devices and materials:

- Fan. Heat-resistant, moisture-resistant fans with the ability to control the speed are suitable for the bath. According to the installation method, they are channel or radial. Channel pipes are placed directly in the duct, and radial ones - at its outlet.

- Ventilation box. Can be solid - made of plastic or galvanized steel. Or flexible, made in the form of a corrugated pipe on a metal frame.

- Ventilation grates. Production material - according to your preference.

The ventilation system is mounted according to the following plan:

- According to the chosen scheme, holes are made in the walls (top and bottom). It is desirable that they be planned at the stage of building a bath.

- Ventilation boxes are installed in the holes.

- Mount (in a box or outside the hole) a fan - exhaust or supply.

- Connect the fan to the electricity network. The connection scheme will depend on the desired way to turn on the fan. The fan can be turned on in the following ways: simultaneously with lighting, by pressing a separate switch, through a motion sensor. Shutdown can also be done in different ways. For example, either when the light is turned off, or after a scheduled time (when using a timer).

- Ventilation grilles are placed on the ventilation openings.

Here is an example of a fan installation:

Competent installation of forced ventilation will help you organize active air exchange in the bath rooms. As a result, you will get rid of unpleasant odors in washing and bathrooms, provide " easy breath» in the steam room, protect yourself from defeat carbon monoxide.

The scheme of the steam room is such that it maintains a constant high temperature, and the air must be moist, saturated with water droplets. But indoors with such climatic conditions, mold will definitely breed, and combustion processes will be disrupted due to the lack of oxygen, not to mention the fact that people inside will have nothing to breathe. Therefore, it is necessary to design ventilation in the bath. We will talk about it in this article.

Do you need a ventilation system

When building a steam room, novice builders try to fit all the rails and lamellas as tightly as possible, thereby ensuring the absence of temperature losses. This is actually true, but if you do not leave natural openings or artificially created bends, then significant smoke is possible if the stove is powered by wood or coal. Any fuel leaves traces of burning. Carbon monoxide in high concentrations will lead to loss of consciousness and the possibility of death, especially if people in the room are steamed, with unstable pressure, dilated blood vessels.

Required for the following tasks:

- creating the necessary microclimate;

- airing and drying wood so that mold or fungus does not occur;

- the removal of carbon dioxide, there are people in the steam room, so a constant supply of fresh air is needed;

- facilitating the combustion process, for which oxygen is important;

- elimination of unpleasant odors;

- preservation of lamellas and shelves in their original form.

The principle of operation of the ventilation system in the bath

The entire ventilation network can be divided into natural, which is located in the walls, roof and foundation and is laid at the beginning of construction, and forced, which is activated only when using the steam room.

Both types work as follows: the exhaust oxygen is displaced and the space is filled with fresh air. The flow has two ends - inflow and outflow, respectively, you need at least two holes located according to the rule: supply hoods are lower than outflow ones.

Another nuance of the principle of operation - all the gas is taken from where it goes. That is, if the message occurs with the street, then everything should go there. Similarly - if in the next room, which is also possible. If the inlet and outlet are in different temperature conditions, then the flow will not form. However, it is recommended to do the inflow / outflow of air from the street, since even in the dressing room the air will be humid and insufficiently enriched with oxygen.

Proper ventilation in the bath in the steam room

When designing a building, you immediately need to calculate where the mines will go, what diameter they will be. And the holes themselves and the dampers on them are placed directly after facing with lamellas. There are 4 types:

- Finnish - 130mm inflow, 100mm exhaust.

- Swedish - 100mm inflow, 80mm exhaust.

- Russian - 100mm inflow, 100mm exhaust.

The most common solution, alas, is the lack of a ventilation system.

The size of the holes directly depends on what you want to end up with: a Russian steam room or a sauna.

Consider an example calculation. If the steam room is 3 m by 1.5 m with a height of 2.5 m, that is, approximately 10-11 m3, you need a 20 kW stove. In this case, it is better to use a natural type of air exchange - with an air inlet 10 cm from the floor at a distance of 30 cm from the stove, and a diagonal outlet - under the shelves at a height of 80 cm.

At the same time, it should be taken into account: from under the lining, the valve works only in the only closed position or in the open position. It should not be regulated, as it is made airtight, otherwise the steam will leave. Both outlets do not need to have the same radius, but if more efficient and faster circulation is needed, the first one can be made a little larger or two valves can be installed in different places. It is strictly forbidden to make it smaller than the supply device. This is against the safety rules.

It is imperative to make valves on the ventilation openings, which will hermetically adjoin the opening in the closed state - at the time of kindling and heating the steam room. In winter, these doors will be half closed, because the greater the temperature difference, the more air circulates. The hoods should be at the top, and the inflow should be at the bottom. This will allow oxygen to ventilate naturally. The most popular option today: 100 mm - supply, 80 mm - exhaust.

Types of ventilation

Some 5 years ago, no one spoke about the ventilation system in the bath, moreover, many argued that it was not needed in the bath. Enough presence of a window leaf. Times have changed, and now everyone is for ventilation in the bath. There is forced and natural. The chosen option depends on the area of the steam room, climatic conditions, as well as on the desire of the owner.

Natural

It works on the difference in temperature and atmospheric pressure differences inside and outside. This is a very effective and long used method. There is a nuance for arranging such circulation in the steam room. In the most heated room, due to the natural laws of physics, it is difficult to provide uniform heat. Usually the higher, the hotter, and the floors can remain quite cold. The task of the builder is to think over the system so that the draft does not blow on the legs, and unbearable heat does not accumulate on the ceiling. This can be achieved by dividing the flows into two or three extracts.

Forced

This is an electronic control that depends on temperature regime. You can turn the fresh air supply on and off as desired. Can be controlled with digital device- how many degrees should be maintained throughout the entire time of the procedure, as well as what humidity the system needs to be adjusted to.

Typically, such complexes are created for commercial purposes, therefore they are much more expensive than elements for natural outflow, and installation can only be carried out by specialists.

One of the main disadvantages of using electronic systems is the possibility of leaving the fan on, which can lead to ignition of the wiring and fire.

Combined

When buying an electrical device, pay attention that they have the maximum protection of all wires and electronics from moisture.

How to make ventilation in the bath through special products

These are gratings made in the walls at the floor level (20 cm from it) and the ceiling. In this case, it is necessary to achieve the maximum distance from each other, this can be achieved if they are mounted diagonally, for example, one is installed between the door and the stove, the second - on the opposite wall.

Elements for the device of the circulation system, as well as chimneys and tanks for the Russian steam room can be ordered from Ferrum distributors, which are represented throughout Russia. Wide choose and the quality of products will help you build a bath complex with your own hands with Ferrum products. can be viewed on the website.

Where to place the cold air inlet

It is located below. You can create it in the wall, but then it is necessary at the design stage to lay a pipe or shaft that will lead inside. In this case, it should be taken into account that fresh air will come from an adjacent room, and, therefore, it should not go out into the street, but into the same room. There is a minus - usually the shelves are installed opposite the entrance structure, and the circulation is felt by everyone present.

Another option involves the installation of air under the sun loungers. In many ways, this is the optimal location - it does not see through, does not spoil appearance. But just reaching out to it can be difficult to adjust the position of the damper. In such cases, during the bathing procedure, the upper outflow doors are moved, and then both are opened for ventilation.

And another common and winning option is to place the inflow behind the stove. This simultaneously promotes circulation and heating of coals. But there are a few "buts" - sometimes the stove is installed in the wall, then there is simply no way to organize a damper there. And one more thing - because of the intense heat, plastic doors will melt here and wooden doors can start to ignite, so only metal ones will do.

With the output outflow is easier, it can be mounted:

- in the ceiling, but then you have to make an additional box for output through the roof, because if the wet steam is in the attic, they will rot wooden rafters;

- in the wall - best option, is laid even at the time of the construction of the building.

How to make ventilation in a steam bath: hole sizes

The exact size of the airflow depends on humidity, temperature difference, minimum and maximum values. Experience suggests that the most optimal non-parameters are 10-15 cm, if desired, the outflow diameter can be increased, while flow systems cannot be larger.

In this case, it is necessary to install dampers. It is with their help that you will achieve the required radius when weather conditions change.

It is a common misconception that a person does not have enough oxygen to breathe if the supply is too small. This is not true. For an ordinary person, one cubic meter of air is enough for 1.5 hours.

Floor ventilation device

Why it's important: Wood flooring is affected by a number of factors, with moisture coming in from below, from the ground and foundation, and from above, from steam. Plus, condensation builds up. Such conditions are favorable for the onset of decay and for the spread of fungi and mold.

The most effective is the installation of vents under the floorboards. At the same time, there is no draft and the system can be used in the process of taking bath procedures. Another plus - ventilation occurs as if from the inside. That is, when aired, it dries top part floor covering, and when the hood is working - lower.

To make this as productive as possible, when draining the steam room, take it to the side so that moisture does not spread under the floorboards.

Ventilation of the foundation of the bath

If you already take care of this when laying the foundation, then you will not have rot and mold in the construction. Air vents with a diameter of 110 mm or more should be installed on all four sides. This will ensure acceptable circulation even if the bath complex is located in the middle of other buildings. It is best to lay these pipes opposite each other.

Ventilation of various auxiliary rooms

The rest of the rooms should also have their own circulation.

Attic

A gable window is not enough, as steam often enters this space and can negatively affect the rafters. It is optimal to arrange the inflow under the roof canopy, and the outflow - on the ridge. So the flows will pass from bottom to top on both sides.

Washing

For the organization of air exchange, forced ventilation is most often used, which directs the flows towards the vestibule.

Ground floor

Owners of private houses can use the basement for a bath. It's possible, but it comes at a cost. Now the integrity of the whole house depends on the safety and efficiency of the circulation system. Already at the design stage of the building, it is necessary to provide for the distance between the walls and the insulation, otherwise condensate from the temperature difference will accumulate on the surface.

It is required to create forced ventilation, since natural ventilation cannot be provided due to the impossibility of installation near the floor (after all, it is underground). We recommend entrusting this issue to professionals.

shower room

Taking into account the fact that in the rest of the rooms there is already an inflow and outflow of oxygen, it is enough to design air from the fans in the ceiling or at the top of the wall so that the unpleasant smells of dampness come out. You should also do if the bath complex has a toilet.

dressing room

Here, you should also take special care of the circulation of air flows, since due to the close proximity to the steam room, a strong temperature difference and condensation on the walls form in the room. Similarly, the intake-outflow option is suitable. You can also arrange windows that allow you to quickly ventilate.

How to arrange ventilation in the bath and steam room - calculation of the scheme

We have already said about the standard value: 1 cubic meter of space requires 24 cubic centimeters of bends. When choosing pipes, they often stop at pipeline pipes - they are inexpensive and effective, but we recommend assembling such a system from Ferrum stainless chimneys, they have a long service life and do not deteriorate from constant interaction with moisture. The standard diameter is 10 centimeters. So, the cross-sectional area is 78.5 cm2. One such box is enough for 3.27 m3 of room volume.

We calculate the number of cubic meters. Suppose that the steam room has dimensions of 2 by 2 m2, the ceilings are also 2 m high. We multiply everything, we get 8 m3. We divide this by 3.27=2.45. Round up to three. As a result, you need to organize 3 boxes with a diameter of 10 cm for the entire steam room.

Ventilation device

There are several solutions:

- The location of the window next to the stove or under it. At least 25-35 cm should remain above the floor. In this case, the flow moves down, then rises along the opposite wall.

- Both holes are on the same surface, which is not recommended, but occurs. Then, be sure to install a fan on the hood. This is true when the steam room has only one wall facing the street, and the rest are adjacent to residential areas.

- The cracks in the flooring, if you have a multi-layered leaky floor, can draw in air, pass it through the space under the covering, and then return it up again. This ensures good ventilation of the floorboards.

- If the inflow is located opposite the stove, then it will work only if the heating is on.

All these types are presented schematically in the picture:

In the article, we talked about how to properly ventilate the bath, showed diagrams and explained the structure of the steam room. Design your bath complex together with high-quality products from Ferrum. On the site you will find chimneys and accessories for arranging a bath. Bathe in pleasure with Ferrum.

Useful videos

Arranging a sauna is a very interesting process, but troublesome. It is necessary to take into account a good hundred little things, so that it is not only comfortable, but also safe for health. The latter also depends on air exchange - improperly equipped ventilation in the sauna can form a draft or, conversely, lead to too much heating of the room!

The steam room is a key place for ventilation

The most important room of any sauna or bath is, of course, the steam room. And in the steam room, the high temperature largely depends on ventilation, and not only it, but also the quality of rest. What is the use of hot air if it is stale and saturated with damp smells and sweat products?

In addition, we must not forget that any steam room is a place with high humidity, and therefore an increased danger for all elements (especially wooden ones) to become a breeding ground for mold and fungus. And what sauna can do without electrics now? Even with a minimum of electrical equipment, you need to conduct a banal light, make a switch - that's the risk of getting an electric shock when high humidity!

In order not to have to constantly think about high humidity, it is better to think about high-quality ventilation once. Thinking, of course, will not be enough - you also need to implement the plan correctly! Since school days, we all know that hot air has one pronounced feature - it always tends to rise up, pushing cold air down. Thanks to this, the natural circulation of air in the atmosphere on a global scale and in each room in particular is ensured. Applied to the steam room, thanks to this law of physics, we get the hottest places on the upper shelves and relatively cool on the lower ones.

According to generally accepted standards, the air in the steam room should be updated at least three times per hour., optimal recommendations - all seven times! Such air exchange can be ensured using conventional supply and exhaust ventilation - hot air, rising to the ceiling, exits through the exhaust vent, as a result of which a slight vacuum is created in the intake duct, and fresh air enters the room. Such a system is applicable to the toilet, but, unlike them, has its own characteristics.

But the task is complicated by the fact that the hottest steam, which is located at the top level of the steam room, should not immediately slip into the hood, otherwise you will be left in a cold sauna, which urgently needs to be heated. If this happens, it means that the hood is equipped incorrectly! Sometimes this is due to the impossibility of the correct arrangement of elements due to the architectural features of the building, in which case it is necessary to consider options for ventilation combined with a mechanical method.

Supply and exhaust ventilation in the sauna - arrangement scheme

To begin with, consider the classics - natural supply and exhaust ventilation. This type of drawing law is correct location inlet and outlet openings. The correct one is when the inlet is located near the stove or under it (if we are talking about the electric version), while the outlet is located on the opposite side. Also, cold fresh air will enter the steam room through a specially left 5-7 cm gap under the door.

The inlet openings must be located strictly below so that the cold air can have time to heat up before it enters the area where people stay.

For proper air circulation, one exhaust opening will not be enough. On the opposite side of the inflow, the first hood is located at a height of about a meter, the second is under the ceiling. Both openings must be connected by an exhaust duct, which leads either to the main ventilation system or to the chimney. If the air duct goes separately, then you need to remember that the higher the pipe rises above the roof level, the more thrust will be in the system - it is important not to overdo it!

So that you can regulate the intensity of air exchange, it is imperative to install shutters on the air outlets. How does such a system work? Let's imagine a standard steam room with a stove-heater at the far wall and a door at the near one. As expected, a gap was left under the door, and the hoods are located on opposite walls: near the stove and at the door.

Before heating the steam room, it must be properly ventilated so that there is fresh air in the room. The doors and outlets are then closed, leaving only the inlet valve open. The steam room will heat up quickly enough, since the hot air will soon have nowhere to go, which means that there will be no air discharge in the inlet.

When the sauna has warmed up, we still leave the upper channel closed, while opening the lower channel a little - thanks to this, air circulation in the steam room will begin, while the upper layers of the warmest air will not leave the room. Cold air will again begin to enter through the supply channel, but due to the proximity of the heater to the resting people, it will get already warmed up, gradually rising up and replacing the stagnant air.

Thanks to this air exchange, the room will have fresh and warm air. Vacationers may not even notice such a change, enjoying the process. Such a system provides economical handling of already heated air, which means you will save on coolant consumption. In addition, problems with mold and fungus will not affect you - thanks to this circulation, all elements will dry properly.

Combined system - when there are no other options

Structural features do not always give us the opportunity to provide ventilation strictly according to the above scheme. For example, a steam room has three adjacent walls with other rooms, and the inlet and outlet must be placed on the same wall. In this case, the correct location must be observed: the supply should be at a distance of 20 cm from the floor, while the outlet should be located at the same distance, only from the ceiling.

Cold air currents, entering the room, will pass through the stove, heat up and rise up, refreshing and warming the room. The disadvantage of this method is that the air circulation is too intense, which must be tightly regulated using valves on the holes.

There is also an option in which the inlet is not located below, under the stove, but above the heater. If the outlet channel is located at a higher level on the opposite wall, we will get a relatively normal movement of air masses. True, it may not be enough, therefore, in such cases, a fan is placed in the outlet to drive air. This will be combined ventilation.

Classic mistakes - what not to do

The most common mistake in the arrangement of supply and exhaust ventilation is the location of the ventilation openings at the same level. As a result, we get a draft below, and hot air at the upper levels will practically not take part in air exchange.

If you make only one hole for the air outlet under the ceiling, even with the correct placement of the inlet and outlet, the mixing of hot and cold air flows will be too fast - the steam room can cool down in a few minutes! Usually, the upper opening is used only in cases where you want to quickly reduce the temperature or completely ventilate the room.

Ventilation in the bath is not only comfort, but also an urgent need. It is needed both during and after bath procedures:

- In the process, it is important so that no one gets burned. The danger of carbon monoxide poisoning is always present - it is the result of incomplete combustion of fuel. Therefore, ventilation is necessary for the safety of people in the bath.

- Besides air that is inhaled and exhaled becomes "waste", and it must be removed, replacing it with a new one, with a greater proportion of oxygen.

- regulate the temperature, monitoring the condition of people, you can also use ventilation, especially when you need to do it urgently.

- Any stove runs on oxygen (combustion is oxidation), so it needs ventilation. And with a competent device, you can also get fuel economy.

- And, finally, drying after, on which the durability of the structure, especially its wooden parts, directly depends. Ventilation can be good prevention of fungus and decay.

At the same time, bath ventilation is quite complex and diverse in design. Of course, the issue can be reduced to financial investments, but in fact, you just need a good ventilation specialist who will find the best solution in each case. We will consider all the possibilities and features of the device.

The ventilation system in the bath: what can it be?

Ventilation systems in baths are divided at once according to several parameters:

- forced or natural;

- exhaust, supply or supply and exhaust;

- local or public.

Let us explain that the forced one differs from the natural one by the presence of fans that forcibly drive air in or out, the local one differs from the general exchange one in its local character, for example, the chimney above the stove is local ventilation, and the vents are part of the general exchange.

Let us explain that the forced one differs from the natural one by the presence of fans that forcibly drive air in or out, the local one differs from the general exchange one in its local character, for example, the chimney above the stove is local ventilation, and the vents are part of the general exchange.

As for the supply, exhaust and their combination, these are indications of which air is directed where: the exhaust drives the exhaust air out, the supply air drives fresh air in, and their combination creates a balanced air exchange inside the room.

This general terms for any ventilation, but our task is to consider a bathhouse that has its own specifics. We advise you to familiarize yourself with (8 types) along the way.

Useful video

Watch a short video, as one of the options for organizing ventilation in the bath:

Natural ventilation in the bath

It works on the principles of physics, which say that heating makes air lighter and causes it to rise. And an increase in the volume of cold air accelerates the movement of hot air. Knowing about this property, you can not install any devices at all, there are enough ventilation holes, the location of which will make some of them supply air, and others - exhaust.

And in the bath there is a stove, and this is a very favorable circumstance for the direction of air circulation. If the natural ventilation inlet is located near the floor next to the blower, then the stove itself will draw in fresh air, without any fan. Also, traction is improved by raising the finished floor just above the hole under the firebox.

The exhaust opening is usually made on the side that is opposite the wall with the supply opening, but this is not the only option.

Forced ventilation

If fans are placed in the same holes, then you can not be afraid of calmness or other weather conditions that adversely affect the air circulation in the bath.

In principle, there is no big difference between natural and forced ventilation in the circuit itself, it is only a matter of which holes the fans are in. Because you can not put them everywhere, reinforcing only the exhaust or only the inflow. But by creating a large difference between the inflow and outflow, we change the pressure in the room. This is easily detected by the way the door slams. The task is to create a balance between outflow and inflow, and the air during bath procedures should circulate slowly, without causing a draft. And when drying, a draft is only good.

IMPORTANT! The direction in which the fan drives the air depends on the location of its blades, so it is important to ensure that there is no exhaust fan in the supply opening and vice versa.

Bath ventilation device: principles of operation

Bath ventilation can be conditionally divided into permanently functioning (roofing, foundation, wall) and periodically functioning, during bathing procedures and stove operation. Both are parts of a single ventilation system, which is laid during construction.

The principle of operation of the ventilation system: displacement of exhaust air with fresh air. In the most primitive case, two holes are enough for this, but in practice, flow directions also matter, so the number of supply and exhaust holes can be increased, and they themselves are equipped with dampers, which are a means of controlling flows, their volumes and speed.

The principle of operation of the ventilation system: displacement of exhaust air with fresh air. In the most primitive case, two holes are enough for this, but in practice, flow directions also matter, so the number of supply and exhaust holes can be increased, and they themselves are equipped with dampers, which are a means of controlling flows, their volumes and speed.

Regardless of the location, the air inlets are always lower than the exhaust ones. Sometimes air flow is provided through the blinds at the bottom of the door to the steam room. But there is one rule: Where does the air come from, where should it go?. If we take from the premises, we need to return not to the street, but also to the premises. Otherwise it won't work.

The calculation of the area of ventilation windows is quite simple: we must proceed from the fact that each cubic meter of room volume needs a window with an area of 24 cm². Windows in no case are made directly opposite each other at the same height.

- When the bath warms up, the vents in the foundation close, the dampers in the steam room move.

- During soaring, the windows open slightly as needed.

- After completion of the procedures, the bath is ventilated entirely.

Also prepared to help you (10+ different schemes).

Bastu ventilation in the bath

Bastu-type ventilation, named after convection Swedish baths, is gaining more and more popularity in Russian baths. It is easy to make and highly effective.

The air flow under the furnace is carried out using a ventilation pipe from the street. In this case, a damper is required that would block it.

For air outflow, a box is mounted, which starts 20-30 cm from the floor and goes outside. The location of the box is diagonally from the furnace. The material is best stainless steel. The box must also overlap 100%.

So, it works as follows: if a certain volume enters the room, then the corresponding volume will be pushed out from there if there is an exit. A working furnace actively sucks in cold air from the supply air duct. Part of it is used in combustion (and leaves through the chimney), and part rises, heating up along the way from the stove. The excess volume in parallel begins to leave through the box, which takes air from the floor. Therefore, fresh heated air is in the breathing zone, and the exhaust is at the bottom and leaves.

Video

See how Bastu is explained and done in these videos:

Bastu ventilation is “turned on” and “turned off” by manipulating the valves. At the same time, the stove must work, because it is she who is the heat pump responsible for air circulation. If the stove goes out, the bastu ventilation in the bath will not work.

Bastu ventilation is ideally used in the sauna, where you need to change the air 6-8 times per hour. But in the Russian bath, the conditions are somewhat different, and although you can put the bass in it, there are restrictions on its use.

Bastu ventilation in a Russian bath

Russian banya is not too high temperature and plenty of steam. Under such conditions bastu ventilation in a Russian bath should not be “turned on” while soaring.

Russian banya is not too high temperature and plenty of steam. Under such conditions bastu ventilation in a Russian bath should not be “turned on” while soaring.

But you can safely start it at the very beginning, at the stage of warming up the steam room. In this case, the heating time will increase, but it will be uniform. If you leave the valves open, the bastu will dry out and overheat the steam room. You can try to "turn on" the bass at the last stage soaring - the air will be light, hot, you can breathe freely. Great ending to a run.

Bastu in the Russian bath useful for drying after procedures- she copes with this perfectly and there will be no smells, no mold with such drying.

Bath floor ventilation

The floor in the bath needs to be completely dried after the procedures. The first condition for this will be the organization of the correct flow, with a slope that will divert water into the sewer. Of course, there are several floor options.

For pouring (wet) floors, ventilation is especially important. Therefore, the gaps between the boards, reaching a width of up to 1 cm, are needed not only to drain water, but also to dry the boards. And the opening of the air in the foundation will help in this, which we will discuss below.

A dry floor does not imply gaps between the boards, because it is mounted from a tongue-and-groove board. So, the principle of its ventilation is somewhat different. It will be necessary to dry from above by means of salvo ventilation (this means opening all windows and doors) and the system that is provided in the bath, for example, forced supply and exhaust.

Useful video

Look at what dampness can lead to on a dry floor, even if it is covered with yacht varnish:

The ventilation riser in the washing room will be discussed below, but it also affects the ventilation of the floor.

And the floor is well blown during the operation of the furnace, if (as already mentioned), raise its level above the blower, and leave small gaps between the boards in the floor itself.

Bath foundation ventilation

Actually, everything starts with it, because it is mounted when laying the foundation. To do this, scraps of asbestos-cement pipes are taken, filled with sand and, in this form, are laid among the reinforcement, fastened with a knitting wire between the rods at a height of 5 to 12 cm above the ground. After stripping, the sand is removed.

There can be two such holes in total, laid on opposite sides of the base. However, in reality, it is necessary to take into account a number of various factors, on which both the number of holes and their diameter ultimately depend. By the way, the usual diameter is 11 cm.

Useful video

See what the lack of ventilation for floor and foundation ventilation can lead to:

Before designing ventilation, take into account:

- remoteness of the bath from the reservoir;

- location (on a hill or in a lowland);

- surrounded by other buildings on all sides;

- wind rose of this section;

- bath area.

It is clear that if the bath in the lowland or around solid buildings, more holes must be made, and even from all sides. You can also increase the diameter, but put a grille-blinds or damper.

CAREFULLY! Rodents can get into unprotected vents, so it is recommended to also tighten them with a metal mesh.

Holes provided with plugs are usually left closed during procedures, but they are opened to dry.

Ventilation of different rooms of the bath:

Due to differences in the temperature and humidity conditions of each of the bath rooms, ventilation in them is organized differently.

sinks

The washing compartment is the wettest, so it is recommended to equip it with a ventilation riser, which is located in the corner, under the floor. This is an asbestos-cement pipe, which is then brought to the roof and supplied with a deflector from above. Ventilation in the sink occurs due to the pressure difference between the room and the end of the pipe above the roof, the air tends to the outside, carrying excess moisture with it.

The reason why you have to bring it to the roof is simple: if moist air is immediately driven out into the street, then the wall where this hole will be located will quickly deteriorate from the outside.

steam rooms

attic

Attic ventilation is a special song. It is done at the stage of installation of the roof.

1- ceiling 2- spotlights 3- roof ridge

IMPORTANT! It is not true that for attic ventilation it is enough for a window on the pediment. These windows will not replace the supply and exhaust system in the roof.

Supply holes are made under the roof canopy (between the roof sheathing and the upper part of the wall, where the rafters rest on the Mauerplate), and exhaust holes are made on the ridge. There should also be openings on the gables, but they are small and very high.

It is also important to take into account the ratio between the area of supply and exhaust openings on one side and the total area of \u200b\u200bthe attic. It is optimal that the first be 1/500 of the second. The ratio between the area of supply and exhaust is not 50 to 50, exhaust should be 10-15% larger in area than supply.

This system is suitable for those baths in which the attic is cold. And there are also baths with attics. There, ventilation is also done at a time when the roof is still open from the attic.

For ventilation roof space(between the roofing material and the membrane) either natural or forced ventilation can be used. But for the functioning of both, aerators and spotlights are needed.

Aerators are installed either on the area of the roof slope, or on the ridge (these are the most effective). They serve for extraction. And the soffits are responsible for the flow of air. These are siding panels for sheathing roof overhangs, some of which must be perforated. The ratio of the area of the ventilation holes and the ventilated area is the same as mentioned above 1/500.

IMPORTANT! The efficiency of aerators will be higher if you install only ordinary or only ridge aerators.

Fans for the under-roof space are used as supply fans. Special attention placed on the wiring so that it does not cause a fire.

baths in the basement or basement of the house

Part of the owners country houses takes a basement or basement under the bath. Such an arrangement of a hot and humid room makes special demands on ventilation, on which the durability of the whole house now rests.

Note that the redevelopment of the former residential or utility premises includes the redevelopment of ventilation. In general, it is more expensive than the bath included in the project of a house under construction.

One way or another, you need do not forget about the ventilation gap between the walls and the insulation. This will protect against damage to the insulation by condensate. But the moisture in the air corridor must also go somewhere. Therefore, professionally made supply and exhaust ventilation is recommended for basement and basement baths, and it is better not natural, but forced. Both are accompanied by the installation of a basement deflector.

The location of the basement ventilation depends on the specifics of the project and will not be given here. It is also possible to install a special dehumidifier.

A good option would be to choose bastu ventilation - it's not so expensive, but very effective. The bastu device was mentioned above.

shower

If there is a shower cabin or an open shower in the bath, it is worth installing forced ventilation nearby, which will speed up the drying process.

If there is a shower cabin or an open shower in the bath, it is worth installing forced ventilation nearby, which will speed up the drying process.

If we assume that the air flow is provided by the existing supply openings located in the washing room and other rooms, then you can put the fan only on the exhaust opening, which is located near the shower. (You can do the same if there is a bathroom in the bath.)

dressing room

The dressing room suffers from condensation due to the temperature difference between it and the hot rooms of the bath. That's why ventilation in it is necessary in the same way as everywhere else in the bath. One air is located at the bottom, the other at the top. The lower one is responsible for the inflow of air, the upper - for its outflow. Installation of forced ventilation is not prohibited. In addition, you can ventilate the dressing room with the help of a door and (if any) a window.

In contact with

Room ventilation standards are prescribed in SNiP 41–01–2003, but they are not entirely applicable to baths. Why? Sanitary authorities regulate the frequency of air changes in the premises to ensure a favorable microclimate in terms of temperature and humidity. These indicators in the steam room cannot be called favorable for a long stay of a person, they are rather stressful. In addition, none of the premises considered in building codes and the rules, does not require the fastest possible drying and the fastest warm-up. Ventilation in the bath should maintain the microclimate in the premises under the given conditions with a significant increase in humidity and temperature, and at the same time completely exclude the appearance of drafts.

Another feature of the ventilation in the bath. Its functioning should be independent of external weather conditions, and the actual performance should enable rapid changes in humidity and temperature. Besides, technical capabilities ventilation should allow you to respond as quickly as possible to changes in the microclimate in the steam room, and for this they must have increased power compared to conventional ventilation systems.

Natural ventilation does not allow achieving such results, it is of low power and is highly dependent on weather conditions. In order to guarantee the required modes, forced ventilation is used - air is supplied / removed by special fans.

This is quite an interesting question. We have already mentioned that there are no state regulations for ventilating baths. This is due to the fact that the requirements for steam rooms are very individual, some want to steam in very humid and hot rooms, others prefer moderate values of humidity and air temperature. Such different microclimate values must be set in the same room using the same ventilation system. Since generally accepted standards do not exist (and cannot exist), then each user of the steam room should be able to “customize” them to fit their requirements. And forced ventilation of the bath will help to do this.

Practice shows that for a quick change in humidity and temperature indicators, six air exchanges per hour are sufficient. From these conditions, the technical characteristics of the fans should be selected. If, for example, the volume of a steam room is 2 m (width)×3 m (length)×2 m (height) = 12 m3, then the fan power should be 12×6=72 m3/h. The dimensions of the air inlet and outlet openings should be selected taking into account the dimensions of the fans. The designers have already provided for this parameter, the greater the fan power, the more installation space is required for it, the larger the inlet or outlet should be.

Prices for heat-resistant fans

heat resistant exhaust fans

How to choose a fan

All household fans are divided into two large groups:

Choose a fan at the place of optimal location and power, it is better to make a margin for performance - long-term operation electric motors with maximum load causes their accelerated failure.

It is highly desirable that the fan has several speeds of rotation or, possibly, smooth adjustment of the shaft speed. This will allow you to quickly achieve the optimal microclimate in the steam room. The switch or control panel must be accessible to people in the steam room.

Pay attention to the degree of protection of the case, a very important criterion. The air in the steam room is humid and hot, and these are the most unfavorable conditions for the operation of electric motors. According to European standards, the enclosure must have at least IP44 protection. It is advisable not to install a fan at the air outlet ( exhaust ventilation), with the same efficiency it will work at the inlet (supply ventilation). At the air outlet from the steam room, the operating conditions of the fans are the most difficult, there are high risks of breakdowns due to exceeding the critical values of the heating temperature of the insulation of the stator and rotor windings.

The fan grill must have louvers that direct the air flow down or disperse it in different directions. If the blinds can change their position - very well, it is always possible to change the direction of the air flow depending on the prevailing circumstances in the steam room.

Important. All work on connecting devices must be carried out with unquestioning observance of the PUE (Rules for the installation of electrical equipment). electrical wiring baths must have independent grounding.

Prices for centrifugal fans

Bahcivan radial fan

Where to locate the inlet / outlet of forced ventilation

The main condition is that the holes should be located only in those places that guarantee the effective operation of ventilation and exclude the appearance of drafts. Next, you can pay attention to architectural features rooms and design. You should not install fans "in beautiful places" if there will be no practical benefit from such an installation for creating a microclimate.

Exit holes. They are made at a distance of 10 ÷ 20 centimeters from the ceiling or in the ceiling. If the hole is under the ceiling, then the air is expelled through the duct in the wall to the street. In our opinion, this is the best option. If the hole is in the ceiling, then the air from the steam room enters under the roof. Advantage - the appearance of the facade walls of the bath is not disturbed. Disadvantage - high risk of waterlogging truss system baths, and this can cause very negative consequences. It is possible to remove moist hot air through the roof covering, but this is costly and increases the risk of leaks on the roof.

Entrance holes. There are three options.

- First. If there is a drain floor in the bath, then there is no need to make inlets, the air passes through the cracks of the floor covering.

- Second. It is allowed to make an inlet at the bottom of the steam room doors, holes are cut out in the canvas and a decorative grill is inserted.

- The third. The inlet is made in the wall of the bath at a height of about 10 centimeters from the floor. To avoid the appearance of unpleasant drafts, it is recommended to place them behind the stove, but you can choose any other place for yourself, the main thing is that cold air does not immediately fall on those taking bath procedures.

When choosing inlet/outlet openings, the power of the fans must also be taken into account. The more productivity they have, the farther they should be located from people.

And one more piece of advice. Ventilation copes with its tasks much more efficiently if the inlet and outlet are located diagonally across the room or on opposite walls. There is no universal description of the scheme for the movement of air flows in a steam room; there are too many individual room factors that change their movement.

You must ensure that the air moves as evenly as possible throughout the volume of the room. Thus, it will be possible to avoid the formation of “dead” zones unfavorable for washing, increase the uniformity of air heating, accelerate the heating of the room and improve the removal of exhaust air.

What types of forced ventilation baths

Unlike natural ventilation, forced ventilation can be of three types.

- Supply. Air is forced into the room, removal occurs naturally through the outlets. For a bath, this is the most acceptable option. The cost is available to all developers, quickly mounted, does not require large losses of time for periodic maintenance work.

- Exhaust. Forced air removal, natural intake through inlets. It is not recommended for a steam room due to the extremely difficult operating conditions of the fans. In terms of efficiency, it is not inferior to the supply one.

- Supply and exhaust. Both intake and removal of air is forced. It is used only in large buildings with many rooms for various purposes. Quite complex and expensive ventilation systems are installed only in exclusive baths.

Let us consider in more detail each type of forced ventilation of the bath.

Forced ventilation

The electric fan is installed in the inlet located near the floor. Air under pressure is injected into the steam room, due to the appearance of excess pressure, the exhaust air exits through the outlet. Inlet air is most often located near the floor; to reduce the risk of drafts, they are made behind the stove. Of course, when choosing a specific location for the hole, all the features of the steam room should be taken into account.

Important. The distance between the stove and the hole must completely exclude overheating of the electric fan and power cables. If design features do not allow you to safely place the fan behind the stove, then you should choose a different location - under the shelves, on the opposite side of the door, etc. The main condition is that cold air should not create inconvenience for those washing. Try not to place the fan in places where water may splash during washing.

Many builders quite deservedly consider the supply option of bath ventilation to be the most optimal solution. We fully agree with this opinion and recommend it to you for use. Another plus of this method of forced ventilation is versatility. Forced ventilation can be done not only in the steam room, but also in all other rooms of the bath.

Prices for a valve for supply ventilation

valve for forced ventilation

The fundamental difference is that the fan removes the exhaust air from the steam room, fresh air enters naturally. To increase efficiency, the exhaust duct should be placed under the ceiling. But the installation of an electric fan in these places is associated with great difficulties; for electric motors, operation in conditions of high humidity and temperature is extremely undesirable. If you decide to put the engine at the top, then carefully select the degree of protection of the case. Don't skimp on this one cash. It is much more profitable to immediately purchase an expensive, but reliable and well-protected fan, than to replace it several times later.

It is allowed to install an exhaust fan and much lower than the ceiling level. This position slightly improves the operating conditions of the engine, but significantly reduces the efficiency of ventilation. Make a decision yourself, consider your needs, opportunities, desires and features of the room.

Forced supply and exhaust ventilation

It has many options, forced removal and intake can be installed in each room, or in some there is a natural flow of air masses. For this, special holes are made or air passes freely through the existing slots. We have already mentioned that this type of forced ventilation in baths is very rarely installed.

Before starting work, you need to consider the location of the supply and exhaust ducts, determine the power and type of fans. It is necessary to purchase moisture and heat-resistant equipment, low noise, with the ability to adjust the speed of rotation of the blades. Modern increases the pressure of movement and the power of the air flow while reducing the number of revolutions. Due to this, noise is significantly reduced and the durability of the fan operation is increased.

Ventilation ducts can be made of galvanized sheet steel or plastic.

Plastics are preferable, in their own way physical characteristics fully meet the difficult operating conditions. Ventilation grilles must meet the parameters of the fans, the blinds must break the powerful air flow in different directions or direct it to the floor. If it is possible to independently adjust the position of the blinds - excellent, the possibilities of the ventilation system increase significantly, and the comfort of staying in the premises increases.

Prices for ventilation ducts

ventilation ducts

Prices for PVC ventilation ducts

PVC ventilation ducts

The installation algorithm for forced ventilation of the bath

Step 1. Choose one of the existing methods of forced ventilation, draw up a diagram of the location of the opening for supply / removal of air in the steam room. For example, here are some popular air hole patterns. Hand over the markings on the walls, once again carefully evaluate the correctness of the chosen solution. Purchase equipment, prepare tools for installation.

Step 2. Make holes for ventilation ducts. Keep in mind what to do in the finished log house through holes not so easy. The thickness of the beams can reach 150 mm, add to this dimension the thickness of the inner outer skin. The total length of the channel in the wall can be 30 centimeters or more, it is difficult to work with a chisel in a long and narrow channel. It is very good if you thought about installing ventilation even at the stage of bath construction, but this rarely happens.

How to make ventilation ducts

There are several ways to make channels, it all depends on what kind of experience you have and what geometry the hole should be in the end. Square holes are harder to make. First, you will have to drill holes of small diameter over the entire area of \u200b\u200bthe duct, and then chip the tree with a chisel. Such works may take half a day or more for only one channel. If the wall of the bath is thick, then it is better to make a hole in turn on both sides of the bath.

To drill round holes, you can use a wood cutter (metal crown). It is easier to work with it, the only drawback is the diameter limitation. On sale, you can rarely find a crown with a diameter of more than 120 mm. You should work slowly with a crown; after drilling the contour, you need to remove the wooden jumpers with a chisel. In order to reduce the load on the electric tool, the side planes of the crown should be lubricated with machine oil.

Step 3 If you are using an axial fan, then it is simply inserted into the channel. Keep in mind that the dimensions of the duct must be larger than the dimensions of the fan. Take a set of measures to prevent moisture from entering the crowns of the log house. To do this, use different kinds hydrobarriers, all "uncomfortable" and hard-to-reach cracks can be sealed mounting foam. Excess foam after cooling should be cut off with a sharp knife; it should not reduce the conditional diameter of the channel.

If, for technical or other reasons, it is necessary to use a radial fan for forced ventilation of the bath, then a special place must be prepared for its connection. Protect the installation site from atmospheric precipitation, bring pipelines of appropriate diameters and profiles to it.

Step 4 Connect the installed equipment to the mains. The wiring diagram depends on the type of equipment and specifications electric motor.

Photo - fan mount

Step 5 Install a fan switch. It must be in an easily accessible place. During electrical work, observe the safety regulations.

To increase the comfort of using the steam room, you can connect the fan to the temperature control unit. Electronics in automatic mode will turn on / off forced ventilation depending on the set temperature values. The second option for automating the ventilation system is used to ventilate the steam room after the bath. The fan in this case works from the timer.

How to check the performance of forced ventilation

We strongly advise you to check the efficiency of forced ventilation even before using the steam room. It is not difficult technically and does not take much time. If problems are found, you will have the time and opportunity to fix them. How to check ventilation?

Bring a smoldering firebrand to the inlet vent and see where and at what speed the air flow moves. Bring the smoking firebrand closer / further away from the hole, in this way achieve maximum visibility of smoke. Air must move through the steam room according to the optimal schemes provided. Pay attention to what obstacles change its direction, whether they can be removed and moved to another place in the steam room.

After you have verified the movement of air masses, make sure that the ventilation is working. Remove the smoldering firebrand from the steam room and find out the time during which the ventilation will completely remove the smoke from the room. In the steam room, his smell should not be felt. This time should not exceed three or four minutes. Conduct experiments on various fan modes, achieve the greatest efficiency of the system.

Don't try to over complicate forced ventilation, remember that what harder design, the greater the likelihood of breakdowns occurring somewhere. This rule applies not only to ventilation, but to absolutely all engineering and architectural structures.

It is advisable to provide ventilation holes even during the assembly of the log house. If it didn’t work out, then make holes before facing the outer and internal walls. And this does not work out - get ready for long physical labor. It will be especially difficult to work under the ceiling, cramped conditions do not allow you to take comfortable postures while working with the tool.

Properly equipped ventilation is the key to a comfortable stay in the steam room

Video - Types of forced ventilation

Video - Ventilation in the steam room

Dream interpretation of many animals Why do many animals dream

Dream interpretation of many animals Why do many animals dream What to give a girl for christening

What to give a girl for christening How long does carnival last

How long does carnival last Solar eclipse in February Aspects of a solar eclipse

Solar eclipse in February Aspects of a solar eclipse Holy week before Easter, what can you eat every day?

Holy week before Easter, what can you eat every day? February predictions for Capricorn

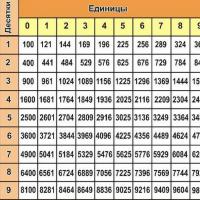

February predictions for Capricorn Tasks for logarithms with a solution

Tasks for logarithms with a solution