Polygonal masonry in modern construction. The concrete technology of polygonal masonry has been restored. Production of concrete blocks using antediluvian technology

Some building technologies of the ancient inhabitants of the planet still cause surprise, admiration and ongoing controversy of contemporaries. One of them is polygonal masonry, which is widespread in the ancient cities of South America. Despite the fact that official history attributes these objects to Indian civilizations, a number of researchers, not without reason, doubt this.

An example of polygonal masonry, Ollantaytambo, Peru

polygonal masonry- this is a special type of masonry, in which stone blocks do not have regular geometric shapes, but arbitrary and at the same time are ideally joined to each other. The stones adjoin each other very tightly, and even today, hundreds and thousands of years after the construction of these walls, it is impossible to insert even a razor blade between them.

The shape of the blocks, the safety of these walls and the quality of the joints are simply amazing.

The shape of the blocks, the safety of these walls and the quality of the joints are simply amazing. Examples of such buildings can be found in different parts of the world, but most of them are in Peru, in the ancient cities of the Incas. Despite the fact that the Andes is a territory of increased seismicity, the foundations of buildings and fortress walls, made using the technique of polygonal masonry, are perfectly preserved here. At the same time, no one particularly monitors their condition, does not protect them from atmospheric precipitation and does not carry out restoration, as is often done with respect to other outstanding architectural monuments. But their faces are still ideally adjacent to each other, and the strength of the masonry is beyond doubt. They can be seen in Ollantaytambo, Tiwanaku, Machu Picchu and, of course, Cusco.

Polygonal masonry in the historical part of Cusco is found at every step

Polygonal masonry in the historical part of Cusco is found at every step

Cusco was the capital of the mighty Inca empire, but even today there is a city in its place, which is very popular among tourists. Cusco is very peculiar, largely due to the numerous architectural monuments that have been preserved here since the time of the Incas. In this ancient city and its environs, there are many structures built using polygonal masonry, they are literally everywhere. In addition, in Cusco there are quite modern buildings that are built on ancient foundations, and it looks just amazing.

One of the streets in Cusco

One of the streets in Cusco According to the official version, the ancient Indians cut down multi-ton stone blocks in the rocks, and then transported them to the construction site. The blocks were of different sizes and arbitrary shapes, and already in place they were adjusted to each other so that there were tight joints between them. Well, over time, the ancient builders learned to cut stone blocks of the correct geometric shape, and the labor-intensive technology of polygonal masonry gradually lost its popularity.

Ollantaytambo, Peru

Ollantaytambo, Peru But this version has quite a few critics. Skeptics point out that next to high-quality polygonal masonry, one can often find coarser and less accurate masonry, which, in their opinion, was just built by the Incas. The Indians simply took advantage of the quality foundation that was made by the previous civilization. There are a lot of examples of such buildings, and there are even those where signs of at least three different building techniques are clearly visible.

Such buildings can be seen in the city of Cusco

Such buildings can be seen in the city of Cusco  The difference in wall laying technique is visible to the naked eye

The difference in wall laying technique is visible to the naked eye

Other researchers believe that it was possible to obtain such an unusual masonry using mortars, by analogy with concrete technology. That is, the ancient builders built these stones of arbitrary shape right on the spot, pouring the next rows of blocks as the walls were built.

Some researchers went even further and suggested that such structures could have been built during the existence of an ancient civilization unknown to science, which possessed unique technologies. Despite all efforts, no other traces of this outstanding civilization could be found, and the walls with polygonal masonry are in no hurry to part with their secrets.

As other examples of polygonal masonry, examples of buildings from times Ancient Greece or the Middle Ages, but many of them are inferior in quality and craftsmanship to Peruvian masterpieces, which indicates a fundamentally different origin of these technologies.

Delphi, an ancient Greek building. The polygonal masonry performed by the ancient Greeks is very different in quality from the buildings in the Andes, and grass has long been growing between the joints.

Delphi, an ancient Greek building. The polygonal masonry performed by the ancient Greeks is very different in quality from the buildings in the Andes, and grass has long been growing between the joints.

But the buildings with polygonal masonry, located on the mysterious Easter Island, are quite comparable with the fortresses and temples of the ancient inhabitants of Peru and Bolivia.

Example of polygonal masonry, Easter Island

Example of polygonal masonry, Easter Island Be that as it may, interest in these structures is only increasing, and the number of versions of their origin is multiplying with each new expedition. The official version of historians is clearly not enough to explain such a strange building style, so more and more incredible hypotheses continue to appear - from alien intelligence and giant people to civilizations of gods that possessed laser cutting technologies. Perhaps modern devices or latest methods analysis, which will finally give an answer to the question of how the ancient builders managed to build such high-quality walls from multi-ton blocks of absolutely incredible shape.

Before the main part of the text, let's take a look and enjoy the accuracy and beauty of the polygonal masonry that has come down to us through the centuries.

The most famous part is that attributed to the Incas.

Polygonal masonry in Egypt. Presumably by the ancient Egyptians. And this is older than the Incas.

Russia. Kronstadt.

Admire? Such masonry is widespread almost all over the globe - Mexico, Turkey, the Caucasus ... I have not put Roman aqueducts here as an example.

Let's now look at the definition of what is polygonal masonry.

The general definition of polygonal masonry sounds like

Polygonal masonry - masonry of the building wall, made of polygonal stones hewn to each other.

Here we can add that "completed often without a binder solution", if we are talking about the affairs of bygone days.

Polygonal mortar masonry is recognized as one of the subspecies of rubble masonry, namely dry masonry (if done without cementing mortar).

Dry masonry is a construction method in which buildings or their elements are constructed from stone without the use of a binding mortar. The stability of dry masonry is ensured by the presence of a load-bearing facade of interlocking stones carefully selected to each other. This is the most archaic of the masonry methods. Usually used to build walls, but entire buildings and bridges are known to have been constructed using this method.

Here is an example of entire buildings built in just the above way.

(Thanks to Vzor for the provided picture and description.)

Ancient builders figured out the best methods for laying stone without mortar or supports, from the base to the final pom-pom stone at the top of a sharp round roof. Buildings have been standing for several centuries, they cannot be destroyed by time. This is France, by the way.

In all these buildings, people are surprised by both the filigree precision of the stones and their size, especially when it comes to the buildings of Ancient Egypt and the Inca Empire. And, as a follow-up, the very possibility of mining and processing huge boulders and building structures from them.

What versions are given to us by various sources? Let's look at them, summarizing a little similar options.

1) Made by hand

Mining, processing, delivery and construction were carried out manually by people (respectively, the Incas, ancient Egyptians, Romans, etc.) using the tools, technologies and devices that existed then.

This method is criticized by all and sundry. The main criticism is based on the fact that it is impossible to manually extract such blocks, nor process them so smoothly, nor transport them, nor build a structure from them. It is simply impossible to do all this manually, especially with the technologies that existed at that time.

2) Made by reptilians, intelligent mushrooms, etc.

No matter how strange it looks, but if we take into account the criticism of paragraph No. 1, then only this option remains - Extraction, processing, delivery and construction were carried out by aliens from other worlds, because. there could not have been technologies on Earth that could have done this. So the aliens did it with the help of turbo-plasma cutters, anti-gravity engines, geo-concrete, etc. alien technology that is beyond our understanding. This theory also justifies the presence of strange drawings. aircraft, humanoids in spacesuits, etc., which are found from time to time among various peoples. Also, this version goes smoothly on those tracks in the quarries, on the stones, which seem strange.

3) Made by Atlantis

If you do not believe in aliens, and realize the impossibility of such operations manually, according to our knowledge of the ancients, then there is only one alternative left - our ancestors knew much more than we imagine about them. Accordingly, all this was done by the Atlanteans (someone says that they were giants, someone ignores the question of their size), which had disproportionately greater capabilities than even our civilization now. (Or not Atlanteans, but simply ancestors better developed than us.) They did it with the help of ultra-/infra-sound, stone softeners, magnetic fields and magma solidifying in them, geoplasticine and some technologies that deprived objects of weight. This version may be superimposed on giant skeleton finds, Atlantean legends, and the like. This theory also fits well with the marks on the quarries and on the cut stones, which seem strange.

4) Gift of the gods

When you do not believe in the possibilities of the ancients, or in intelligent mushrooms from Alpha Centauri, or in the Atlanteans, then only faith in Divine intervention remains. Divine technologies are divine for that, that we cannot understand them. Therefore, these technologies can explain everything. Even the construction of the Alexander Column. (He is also a god. He erected, changed the memory of people and added documents so that everything would fit in the accounting department.)

I propose to postpone the divine version. No, not to postpone for later, but completely. It is simply not interesting for consideration, because. it can explain anything without any effort. Boring.

Other versions that would not fit into those indicated above have not been found by me. If someone has something to offer, I'll be happy to consider and study.

Therefore, I propose now to proceed to the consideration of these remaining three versions in more detail. Let's start immediately with the second and third - i.e. the work was carried out by reptilians or Atlanteans. In my opinion they are almost identical. Who asked: "Why?" Because in one, in another, we will look at technologies that are not available even to our civilization for the most part. And they are fundamentally similar to each other. Well, the difference between geoconcrete and geoplasticine is not fundamental for me, although the technologies are not comparable.

Let's go step by step.

1) Stone mining and processing.

I combined both processes here, since the answer to one question will give an answer to the other.

Manually, as the adherents of the version of mushrooms and Atlanteans say, it is impossible to extract such blocks of stone, as presented below.

Do you see these little people? They are not capable of such work.

Let's take a closer look at the walls of this obelisk. The weight of the finished obelisk must be about 1200 tons, made in granite. By the way, do not pay attention to the cracks in the obelisk itself. It split during the manufacturing process, because only the gods are omnipotent. So, we see neat (well, almost neat) grooves on the lateral surface. We would have seen the same furrows on the wall of the main mass from which this piece of stone was mined. These furrows are traces that were left by the mechanisms with which they cut trenches in granite.

What kind of mechanisms / technologies could do this?

Option one - some tricky bucket. Well, it looks like traces of an excavator bucket. Unfortunately, this option can be dismissed, because. there are quarry walls where the tracks form steps or are clearly not vertical (in some cases the slope reaches 30 degrees Celsius).

And in some cases, the traces are more like a dig.

In addition, you obviously cannot dig such a passage with a bucket (even if this passage is in sandstone, not granite).

And in general, the mechanism must be simply of incredible strength in order to cut granite in the same way as we are now sand. In addition, there should have been traces of granite "squeezed out" upward along the edges of the holes.

Well, let's add another version. This is a plasma / laser (or other kind) cutter that affects the rock with fire, sound, gravitational waves, thought force, etc. The version is good. The cutter can be reached anywhere and any way. Although it remains unclear why make a passage at an angle to the vertical, if you can humanly make an even vertical cut. And why sometimes make a cut with "holes", and sometimes leave a conditionally smooth wall. Well, as in the tunnel above. Different cutters? Why then use different cutters on the same object? Look, here the walls are smooth, and "hollow-shaped" go to the bottom.

Why then not do everything at once with a "smooth" cutter - after all, there would be less work on leveling later?

The previous pictures were from the territory of Egypt, but similar methods can be found among the Incas. In the image below, on the left side is a stone from Kachikata, and on the right side is a stone in Aswan.

Isn't it similar traces? So the same technology was used. True bad luck - the construction of structures by the Incas dates back to approximately 11-16 centuries AD, in contrast to Ancient Egypt. Therefore, either the structures were built at about the same time (and then the dating of the structures has a clear error of millennia !!!), or the reptilians or the Atlanteans existed on earth for a rather long period of time. I wouldn't bet on a mistake in the dates. In principle, during the indicated period of our era, no such work was already carried out in Egypt, at least there is no information about this for sure. And people already lived there. At what conditionally the same that live now. So they would have left written evidence of the presence of reptilians / Atlanteans at that particular time. Rather, we can conclude that the Atlanteans left Ancient Egypt, and after some time settled in the territory of Peru, and then left from there. Good version? Nothing worse than others.

However, the presence of the same "holes" in both Egypt and Peru does not answer the question of the difference in stone mining technologies during the same period and in the same place, i.e. simultaneously. (I'm talking about "hole-like" cuts and straight cuts of the rock.) It looks awkward.

Let's take another look at one of the photos already cited.

I circled another type of footprint. It seems that someone was quarrying the stone using another method - there are clear traces of something rectangular in shape stuck into the stone. The forklift type option does not work because traces within the same line differ in level. The traces themselves are located exactly in those places where mining was carried out by the aforementioned methods. Well, it turns out that the Reptilians / Atlanteans used as many as 3 technologies in the place where they could use one.

Very strange...

And there are still traces similar to cuts. Thus, a version of saws with a diamond working surface or other abrasive. (Sorry, I couldn't find a suitable photo). However, the use of a saw does not then explain the presence of "holes" and other traces in the extraction of stone. And even more strange to see also saws when there are cutters. However, cuts are found on individual stones, so it is impossible to simply discard the saw version in any design.

Another option is milling machines. This version explains both the "ladder", and smooth walls, and "hollow-shaped" walls, and cuts, and even a tunnel. But it does not explain why one option, then another, is used on one object. Well, the presence of traces of the "forklift" is also embarrassing. It would be redundant in this case. But this version is perfectly complemented by the presence of such ancient products:

Another option is acoustic waves. Explains a lot, but not the traces of the "loader" and the presence different surfaces on one object. And the accuracy of tuning such waves to the penetration depth is alarming - although the capabilities of these technologies are unknown.

As far as stone processing is concerned, polishing can be carried out really different ways available even now. Stone carving can also be done with current technology. Round holes found on ancient Egyptian stones are also fully explained by current technologies. Although there are doubts that modern methods could leave traces in the holes like this:

Perhaps there are enough options for now. Each of them has its pros and cons.

Of the pluses, one main one can be distinguished - with the help of such technologies it is possible to extract a stone and, moreover, process it.

Of the minuses of the versions:

Uncertainty about exactly what technologies were used (individual experts criticize each other so that feathers fly),

The use of several technologies (or performance techniques directly) at the same time in cases where one would be enough.

Let's move on to the next stages.

2) Delivery and construction.

Combined these points too. After all, it is obvious that if there is a technique / technology for lifting a massive load to a height, then there is an opportunity to transport this load from one place to another.

In principle, at the moment there is a technique that allows you to lift a load weighing about 2000 tons to a height of several meters. Made to order. But this technique is not capable of transporting cargo.

In principle, at the moment there is also equipment capable of transporting such a load, but it requires a fairly flat surface. And such a flat surface from quarries to construction sites is not observed in the vast majority of cases.

Here you can make a small digression.

On the territory of Ancient Greece, the stone that was in the immediate vicinity was almost always used. For them it was easy, because. Greece is almost 80% mountainous.

On the territory of Ancient Rome it was different. Granite, for example, was also imported from Ancient Egypt, including large blocks.

The Incas obviously used their local stone (they have a mountainous area), but usually it was necessary to lift it up the slopes.

In ancient Egypt, they also used their stone, but often delivered it from afar.

In general, we can say that the delivery of blocks or their blanks was absolutely necessary. If we take into account that the weight of individual products reached 1000 tons and more, then this would be a significant problem in our time.

If we talk about how intelligent mushrooms or Atlanteans could deliver stone blocks and products, then this could be done using various vehicles or through "weight loss" technologies. There is no particular controversy on this score, since few people are interested in developing ideas regarding transportation.

As for the construction itself, the huge blocks are presented exclusively in the form of building foundations / walls, i.e. this is the first or second row of stones. The higher the building, the smaller and smaller stones were used. Does this mean the technology is limited, or was that the original idea? We are unlikely to ever get an answer to this question within the framework of the two versions under consideration (meaning the version of the one who was the builder).

If the builders could transport giant blocks, then they could lift these blocks using almost the same technologies, especially if we are talking about "weight loss" technology.

However, in the construction technology itself there are several versions that you can focus on.

molten stone(magma), the shape of which is set using magnetic or other fields. To obtain raw materials, no special efforts are required, because. even the smallest stones (or even natural magma) can be used. Thus, the problem of extraction and transportation of stone disappears. But it is not clear how the stone was forced to harden in such bizarre forms, and why, if you can get by with more "correct" samples. And this approach does not quite explain the traces of stone processing, although they could have been processed additionally after manufacturing.

"geoconcrete"- this is a kind of concrete obtained from stone (the same granite), which, when solidified, gives complete identity to natural stone. That is, geoconcrete is poured into certain forms in which it solidifies in the required configuration, and then the resulting block is installed on the wall.

This approach almost completely removes the problem of mining, processing and transportation of blocks, because. even stone dust can serve as a source. However, questions remain.

Why are blocks made heterogeneous in shape and size? It's illogical and uneconomical to make a separate mold for each stone. And why did individual stones turn out so clumsy?

"Geoplastilin" is a kind of specific plasticine, which, when solidified, turns into a natural stone. Those. blocks were molded from geoplasticine and installed on top of each other. Plasticine under its own weight filled the joint with a neighboring stone, giving such a dense laying. Actually, geoplasticine removes the problem of individual preparation of the form for each block (which geoconcrete has). But this version does not explain why the plasticine did not float to the bottom of the block when it solidified. To circumvent the problem of slippage, there are versions about the local cancellation of the gravitational force on a specific block, which allows the block to freeze without experiencing gravity. But then it is not clear how plasticine could fill the joint with a neighboring stone.

Both geoconcrete technology and geoplasticine technology do not explain the main stage of work - namely, the presence of stone quarries. Why mine huge blocks if you can get by with crushed stone, which is later processed into concrete / plasticine?

There is another more logical scheme. It involves the installation of stone blocks without fitting, after which they are enclosed in certain forms. Then the entire wall/building is stripped of weight and the stone is forced to expand with some technology. Due to the expansion, the stone fills the gaps and acquires a characteristic swelling, stopped by the shape. After the end of exposure to the expander, gravity is returned and the stone wall becomes something like this:

This technology still requires both mining and transportation and some stone processing. And all sorts of costs, such as very "clumsy" blocks and inaccurate fitting, can be explained by the fact that they did not have time to apply the technology in these areas.

But such influxes of lava are explained by a breakthrough in the field that limits the magma, or destruction in the form in which the "expanding" stone is placed.

Here I have listed only some of the possible technologies that could be used by Reptilians or Atlanteans. It is not possible to view all possible versions, because almost every expert is ready to express his vision of the problem, and even give out several options for each action, respectively, and the number of versions tends to increase over time. In addition, for the most part, each subsequent version is usually a kind of semblance of those already mentioned, with some variations (for example, the use of nanothreads instead of a saw).

At the moment, none of the listed technologies of possible builders has been approved as unambiguously correct and final.

And what versions are you ready to put forward?

Polygonal masonry in Egypt. Presumably by the ancient Egyptians. And this is older than the Incas.

Japan

Russia. Kronstadt.

Admire? Such a laying is widespread practically

all over the globe - Mexico, Turkey, the Caucasus ... This is me still Roman

aqueducts are not included here as an example.

Let's now look at the definition of what is polygonal masonry.

The general definition of polygonal masonry sounds like

Polygonal masonry - masonry of the building wall, made of polygonal stones hewn to each other.

Here we can add that "completed often without a binder solution", if we are talking about the affairs of bygone days.

Polygonal

mortar masonry is recognized as one of the subspecies of rubble masonry, namely

dry masonry (if done without cement mortar).

Dry

masonry - a method of construction in which buildings or their elements

constructed of stone without the use of a binding solution.

The stability of dry masonry is ensured by the presence of a load-bearing facade made of

interlocking stones carefully matched to each other. This is the most

archaic of masonry techniques. Usually used for building

walls, but entire buildings and bridges built by such

method.

Here is an example of entire buildings built in just the above way.

(Thanks to Vzor for the provided picture and description.)

ancient

builders have calculated the best methods for laying stone without mortar and

supports, from the base to the final pom-pom stone at the top

sharp round roof. Buildings have been standing for several centuries, destruction

do not lend themselves to time. This is France, by the way.

In

of all these buildings, people are surprised how filigree precision of fit

stones, and their sizes, especially if we talk about the buildings of the Ancient

Egypt and the Inca Empire. And, as a consequence, the very possibility of extraction

and the processing of huge boulders and the construction of structures from them.

What versions are given to us by various sources? Let's look at them, summarizing a little similar options.

1) Made by hand

Mining,

processing, delivery and construction were carried out manually by people

(respectively, the Incas, ancient Egyptians, Romans, etc.) with

using the tools, technologies and devices that existed then.

This

the method is criticized by all and sundry. The main criticism is based on

that it is impossible to manually mine such blocks or process them so

exactly, neither transport nor build a structure out of them. Do it all

manually is simply impossible, especially with the then existing

technologies.

2) Made by reptilians, intelligent mushrooms, etc.

How

no matter how strange it looks, but if we take into account the criticism of point number 1, then

the only option left is - Extraction, processing, delivery and

construction was carried out by aliens from other worlds, because on earth could not

then there are technologies with which it would be possible to

do. So the aliens did it with turbo plasma cutters,

anti-gravity engines, geoconcrete, etc. alien technology,

which are beyond our understanding. This theory justifies

the presence of strange drawings of aircraft, humanoids in space suits

etc., which are found from time to time among various peoples. Also

this version fits smoothly on those traces in the quarries, on the stones that

seem strange.

3) Made by Atlantis

If not

believe in aliens, and realize the impossibility of such operations

manually, according to our knowledge of the ancients, then there remains only one

alternative - our ancestors knew how much more than we do about them

presenting. Accordingly, all this was done by the Atlanteans (someone

says that they were giants, someone hushed up the question of their size),

which possessed disproportionately greater capabilities than even ours

civilization now. (Or not Atlantes, but simply ancestors developed

better than us.) They did it with the help of ultra-/infra-sound,

stone softeners, magnetic fields and magma solidifying in them,

geoplasticine and some technologies that deprived objects of weight.

This version can be superimposed on finds of giant skeletons, legends

about the Atlanteans, etc. This theory also fits well into traces on

quarries, and on worked stones that seem strange.

4) Gift of the gods

When

you do not believe in the possibilities of the ancients, nor in intelligent mushrooms from Alpha

Centauri or Atlantis, then only faith in the Divine remains

intervention. Divine technologies are divine for that, what to understand

we are unable to do so. Therefore, these technologies can explain everything. Even

construction of the Alexander Column. (He is a god. Raised, changed

memory of people and added documents so that everything fits in the accounting department.)

I propose

postpone the divine version. No, not to postpone for later, but completely. She

is simply not interesting for consideration, tk. it can explain anything

without making any effort. Boring.

Other versions that are not

would fit into the above, were not found by me. If somebody

offer something, I'll be happy to consider and study.

So

I propose now to proceed to the consideration of these remaining three versions

in details. Let's start immediately with the second and third - i.e. work was

reptilians or Atlanteans. In my opinion they are almost identical. Who

asked: "Why?" Because in one, in another we will

look at technologies that are not available even to our civilization in

the majority. And they are fundamentally similar to each other. well no

fundamentally for me the difference between geoconcrete and geoplasticine, although

technologies are incomparable.

Let's go step by step.

1) Stone mining and processing.

I combined both processes here, since the answer to one question will give an answer to the other.

Manually, as the adherents of the version of mushrooms and Atlanteans say, it is impossible to extract such blocks of stone, as presented below.

Do you see these little people? They are not capable of such work.

Let's take a closer look

to the walls of this obelisk. The weight of the finished obelisk should be about

1200 tons, made in granite. By the way, do not pay attention to the cracks in

the obelisk itself. It split during the manufacturing process, because only the gods

omnipotent. So, we see neat (well, almost neat) furrows on

side surface. We would see the same furrows on the wall

the main mass from which this piece of stone was mined. These furrows

are traces left by the mechanisms with which they carved

in granite trenches.

What kind of mechanisms / technologies could do this?

Option

the first is a kind of tricky bucket. Well, it looks like traces of an excavator

bucket. Unfortunately, this option can be dismissed, because. there are walls

quarries, where the traces form steps or are clearly not vertical (in

in some cases, the slope reaches 30 degrees Celsius).

And in some cases, the traces are more like a dig.

In addition, you obviously cannot dig such a passage with a bucket (even if this passage is in sandstone, not granite).

And in general, the mechanism should be simply incredible

strength to cut granite as well as we now sand. Besides,

there should have been traces of granite "squeezed out" upward along the edges

holes.

Well, let's add another version. Is it plasma/laser (or

a different kind) a cutter that affects the rock with fire, sound,

gravitational waves, thought force, etc. The version is good.

The cutter can be reached anywhere and any way. Although it remains

incomprehensible, why make a passage at an angle to the vertical, if possible

to make a straight vertical cut in a human way. And why sometimes make a cut

"holes", and sometimes leave a conditionally smooth wall. Well, like in a tunnel

above. Different cutters? Why then use different cutters on one

object? Look, here the walls are smooth, and "hollow-shaped" go to the bottom.

Why then not do everything at once with a "smooth" cutter - after all, there would be less work on leveling later?

Previous

the pictures were from the territory of Egypt, but the Incas can find similar

methods. In the image below, on the left side, a stone from Kachikata, and from

right stone in Aswan.

Isn't it similar traces? So a similar

technology. True bad luck - the construction of structures among the Incas

refers to approximately the 11th-16th centuries AD, in contrast to the Ancient

Egypt. Therefore, either the buildings were built at about the same time (and then

dating of structures has a clear error of millennia !!!), or

reptilians or Atlanteans existed on earth for quite a long time

time interval. I wouldn't bet on a mistake in the dates. V

principle, during the specified period of our era, no similar work in Egypt

no longer conducted, at least there is no information about this for sure. And people

already lived there. At what conditionally the same that live now. Means

they would have left written evidence of the presence of reptilians / Atlanteans

exactly at that time. Rather, we can conclude that the Atlanteans are gone

from Ancient Egypt, and after some time settled in the territory

Peru, and then left from there. Good version? Nothing worse than others.

However,

the presence of the same "holes" in both Egypt and Peru does not answer the same

to the question of the difference in stone mining technologies during one period and in

the same place, i.e. simultaneously. (I'm talking about "hole-like"

cuts and straight cuts of the rock.) Looks awkward.

Let's take another look at one of the photos already cited.

I circled another type of footprint. It feels like

someone mined the stone using another method - obvious traces are visible

something rectangular in shape, stuck into a stone. Type option

forklift does not pass, because traces within one line

differ in level. The traces themselves are exactly in those places where

mining was carried out by the methods mentioned above. Well, it turns out

reptilians / Atlanteans used as many as 3 technologies in the place where they could

would use one.

Very strange...

And there are more traces

cut-like. Thus, a version of saws with a diamond

working surface or with other abrasive. (Sorry, I couldn't find a photo.

appropriate). However, the use of a saw does not then explain the presence

"holes" and other traces in the extraction of stone. And even more strange to see

also saws when there are cutters. However, cuts are found on separate

stones, so just discard the saw option in any performance

it is forbidden.

Another option is milling machines. This

version explains both the "ladder", and smooth walls, and "hole-shaped"

walls, and cuts, and even a tunnel. But does not explain why on one

The object uses one option, then another. Well, the presence of traces

"Forklift" is also confusing. It would be redundant in this case.

But this version is perfectly complemented by the presence of such products

ancient:

Another option is acoustic waves. Explains

a lot, but not traces of a "loader" and the presence of different surfaces on one

object. Yes, and the accuracy of tuning such waves to the penetration depth

alarming - although the capabilities of these technologies are unknown.

What

concerns exclusively stone processing, polishing can

carried out in really different ways, available now.

Stone carving can also be done with current technology. Round

holes found on ancient Egyptian stones are also quite

explained by current technology. Although there are doubts that

modern methods could leave such traces in the holes:

Perhaps there are enough options for now. Each of them has its pros and cons.

Of the pluses, one main one can be distinguished - with the help of such technologies it is possible to extract a stone and, moreover, process it.

Of the minuses of the versions:

Uncertainty about exactly what technologies were used (individual experts criticize each other so that feathers fly),

-

the use of several technologies (or directly

execution) simultaneously in cases where it would be sufficient and

one.

Let's move on to the next stages.

2) Delivery and construction.

merged

and these points too. After all, it is obvious that if there is a technique / technology

lifting a massive load to a height, that is, there is an opportunity to transport

this cargo from one place to another.

Basically, currently

there is a technique that allows you to lift a load weighing about 2000 tons on

several meters high. Made to order. But this technique is not

able to carry cargo.

Basically, there are currently

equipment capable of transporting such a load, but it requires enough

flat surface. And such a flat surface from quarries to places

construction in the general majority of cases is not observed.

Here you can make a small digression.

On the

the territory of ancient Greece almost always used the stone

which was in close proximity. For them it was easy, because.

Greece is almost 80% mountainous.

On the territory of Ancient Rome it was different. Granite, for example, was also imported from Ancient Egypt, including large blocks.

At

The Incas clearly used their local stone (they have the whole area

mountainous), but it was usually necessary to lift it up the slopes.

In ancient Egypt, they also used their stone, but often delivered it from afar.

V

in general, we can say that the delivery of blocks or their blanks was

definitely necessary. Considering that the weight of individual products reached

1000 tons and above, then this would be a significant problem in our time.

If

talk about how intelligent mushrooms or Atlanteans could deliver

stone blocks and products, then this could be done using various

vehicles or through "weight loss" technologies. On that

account of special disputes is not observed, since few people are interested

develop ideas for transportation.

Concerning

directly construction, then huge blocks are presented

exclusively in the form of foundations of buildings / walls, i.e. this is the first and second row

stones. The higher the building, the smaller the stones

were used. Does this mean the limitations of technology or it was

original idea? The answer to this question within the framework of the

two versions (meaning the version of the one who was the builder) we are unlikely

someday we'll get it.

If the builders could carry out

transportation of giant blocks, which means they could lift these blocks

due to almost the same technologies, especially if we are talking about "depriving

weight" technique.

However, in the construction technology itself there are several versions that you can focus on.

molten stone(magma), the shape of which is set using magnetic or other fields. For

obtaining raw materials does not require much effort, tk. can be used

even the smallest stones (or natural magma in general). So

Thus, the problem of extraction and transportation of stone disappears. But it's not clear

how they forced the stone to harden in such bizarre forms, and for what,

if you can get by with more "correct" samples. And this approach is not

completely explains the traces of stone processing, although they could already process

additionally after production.

"geoconcrete"is a certain

concrete obtained from stone (the same granite), which, when solidified, gives

complete identity of natural stone. Those. geoconcrete is poured into some

forms in which it freezes in the required configuration, and then

the resulting block is installed on the wall.

This approach is practically

completely removes the problem of mining, processing and transporting blocks,

because even stone dust can serve as a source. However, there remain

questions.

Why are blocks made heterogeneous in shape and size? This

after all, it is illogical and uneconomical to make a separate form for each

a rock. And why did individual stones turn out so clumsy?

"Geoplastilin" is a kind of specific plasticine, which

when solidified, it turns into a natural stone. Those. sculpted from

geoplasticine blocks and installed on top of each other. Plasticine under

filled with its own weight the joint with a neighboring stone, giving such a dense

styling. Actually, geoplasticine removes the problem of individual

preparing a form for each block (which geoconcrete has). But this

version does not explain why the plasticine did not float to the bottom of the block when

solidification. To circumvent the problem of slumping, versions are expressed about

local cancellation of the gravitational force on a specific block, which allows

solidify the block without experiencing gravity. But then it is not clear how

plasticine could fill the joint with a neighboring stone.

Like technology

geoconcrete, and geoplasticine technology does not explain the main stage

works - namely, the presence of quarries for the extraction of stone. Why mine

huge blocks, if you can get by with crushed stone, processed later in

concrete/clay?

There is another more logical scheme. She

involves the installation of stone blocks without fitting, after which they

put into some form. The entire wall/building is then stripped of weight and

Some technology causes the stone to expand. Through expansion

the stone fills the gaps and acquires a characteristic swelling, which is stopped

form. After the end of exposure to the expander, gravity is returned

and the stone wall becomes something like this:

This technology still requires both mining and

transportation and some stone processing. And any costs like

very "clumsy" blocks and inaccurate fit, can be explained

the fact that the technology in these areas did not have time to apply.

But

such lava flows are explained by a break in the field that limits the magma, or

destruction in the form in which the "expanding" stone is placed.

Here I have listed

only some of the possible technologies that could be used

Reptilians or Atlanteans. All possible versions cannot be viewed,

because almost every expert is ready to express his vision of the problem, and

then give out several options for each action, respectively, and

the number of versions tends to increase over time. Besides, in

for the most part, each subsequent version is usually some

similarity to those already mentioned, with some variations (for example,

using nanofilaments instead of a saw).

At the moment, none of

listed technologies of possible builders has not received approval,

as unambiguously true and final.

Before discussing the origin of megaliths, polygonal masonry, facing materials, etc., it is necessary to determine what we know about concrete technology in general and antediluvian technology in particular. And if the task is to find artifacts confirming this method in antiquity, then you need to project modern concepts on the concepts of the inhabitants of a vanished civilization. Perhaps it will be possible to unravel the secret of concrete. The famous alchemist Böttger did not succeed, although the question was blunt: if there are city walls, there is gold; if there are no walls, there is nothing. But now we have Saxon porcelain. Let's start with the main one.

Production of concrete blocks using antediluvian technology

Based on concrete technology in the modern sense. We are accustomed to "geometrically correct" shapes and flat surfaces. In this case, molding cells of arbitrary shape with a sand bottom are used. Sand serves to give individuality to the front side of the product. In addition, convex patterns and a typical texture of the product can be transferred with moistened sand. To prevent the solution from penetrating into the sand, a waterproofing film (polyethylene) is laid. The solution is poured arbitrarily, the deformation of the sand creates a unique pattern. The side walls of the concrete form are equipped with embedded elements to create spikes or grooves for spikes on the product, with the help of which the blocks are connected in the masonry.

The molding of the blocks is carried out in two stages: the molding of the main blocks and the molding of the fastening blocks. On a horizontal form, the main blocks are placed in the sand arbitrarily in a checkerboard pattern. The resulting voids are laid with a film and concrete is poured. With this technology, the fastening blocks do not have seams and voids at the joints. The pattern and configuration of the blocks in each case is unique and is selected depending on the particular location of the wall. After the concrete has dried, the blocks are removed from the mold and, after marking, transferred to the installation site. In this case, the effect of the "keystone" should be taken into account.

The assembly of the masonry is carried out on a previously prepared flat area with sand filling or on a strip foundation in the sequence according to the marking.

The article describes only one way to form blocks of polygonal masonry.

This technology is designed for the manufacture of straight walls on a flat surface. For bends or turns of the wall, it is necessary to develop other ways of forming curly and corner blocks. Most likely, you will have to develop a method for corrective filling in case of violation of the geometry of the wall during masonry.

The advantages of polygonal masonry: no masonry mortar, fast installation, seismic resistance, high vandal-proof properties, the possibility of repeated transfer.

Disadvantages of polygonal masonry: little knowledge, lack of application experience.

The discovery of this method makes it possible to restore antediluvian technologies and events. According to the legend of the Incas, mega-objects were erected in one night. Today, practice has shown that this is real and that the legends contain objective information.

The composition of concrete for pouring blocks

With the composition of concrete, everything is much more complicated. It is quite possible that it will not be possible to perfectly reproduce the blocks for objective reasons: over time, there has been a change chemical composition minerals, their physical properties, the atmosphere has changed, etc. In any case, it is necessary to continue research in this direction. The most probable variant of the concrete composition is based on feldspar (FS) rock. This is a very common breed, but there are not so many industrial deposits of it. This means that places of mass production of raw materials for concrete can be tied to these deposits and study the area, having the approximate characteristics of objects. PSH is mined from igneous and metamorphic rocks by the enrichment method, while waste is formed in the form of sand. Confuse volumes of sand on the surface of the earth and the question of its origin, I consider open. It is easier to extract PS from sedimentary rocks. When the PSh breaks down, clay is formed. Analyzing the structure of sedimentation and the formation of clayey rocks, it can be assumed that the breakup of PS was not always a natural process. Not all questions will be answered, but we need to continue to study historical materials, folklore, and conduct experiments. In the end, the knowledge gained can be of practical value.

Feldspar filler is produced from a variety of white feldspar, with a low content of free silicon and soluble salts. By its nature, feldspar is a chemically inert mineral.

The hard and angular feldspar particles create a rigid reinforcement, thereby effectively increasing the strength of architectural and industrial coatings. In industrial and repair compounds, feldspar increases the chemical resistance of coatings, even under extremely harsh operating conditions.

Possessing high hardness, feldspar filler makes it possible to create interior and exterior decorative coatings with high abrasion resistance, ensuring coating resistance to corrosion and polishing.

The low oil absorption of the feldspar filler makes it possible to significantly increase the fillability of the composition, without a significant increase in its viscosity. Due to the high percentage of filler introduced, dense coatings are obtained that are resistant to swelling, tarnishing and freezing.

Search for the remains of antediluvian production

Description of block production

So, what are we looking for, without which industrial production cannot do? concrete products? Repositories of binder (most likely in powder form) and filler. V modern form it looks like this.

Finished goods warehouse

For the preparation of a concrete solution, a concrete mixing unit (BSU) is required. Fantasies about levitation or anti-gravity are inappropriate in this process. Powders and solutions are mixed only mechanically.

For casting products, molds are needed - bulky devices that occupy a large area.

Forming process.

The article contains pictures of a medium-sized enterprise for the production of reinforced concrete products. The goal is to show an example of the organization of production and logistics. For the construction of mega-objects on all continents of the planet, this is indispensable. From historical documents we see an archaic (the word “antediluvian” suggests itself) production culture with low productivity.

Search for block production sites.

How to search for sites where blocks for polygonal masonry were produced? If we accept the version of the manufacture of the binder from potassium feldspar, then you need to find its deposit. For example, the US state of Maine. By studying the local architecture, one can be convinced of the wide application of this type of building material according to the technology of interest to us.

With a high degree of probability, it can be assumed that this production existed in this region in the recent past. So, there could be traces on the ground. In the future, old maps and modern satellite images will help us. The next picture shows a mining quarry. I do not know what is mined in it, but it fully corresponds to the parameters of the object.

Photograph of a suspected feldspar deposit.Further studies of the selected objects should be carried out directly on the ground.

When searching for materials for this article, a lot of related information was found from the global quarry to the colonization of the continent. But this is a subject for further study.

Why do we need a solution to the manufacture of polygonal masonry?

A civilization unknown to us from the past left traces on all continents in the form of architectural and construction technologies. At the same time, the structures erected on them stood for thousands of years, proving their effectiveness. In addition to technical mysteries, there are questions about the organization of construction of this scale and logistics.

It can be assumed that there was an organization whose activities included the development of deposits building materials, production of concrete structures according to the drawings of the customer and their assembly at the facility. Deposits and production facilities were available on all continents and were managed centrally. This proves the standard of technology and the scale of construction. Other structures were engaged in transportation. The scale of this production can be measured in kilometers of belt and screw conveyors, in thousands of cubic meters of concrete mixers, in hundreds of hectares of formwork, etc. And everywhere friction is formed on metal. There is a chance of discovering the remains of industries if you examine hundreds of deposits around the world and systematize the information received.

On the other hand, feldspar, on the basis of which concrete is made, under a certain impact, collapses and turns into clay. Today we will not know how many cities of that era became clay under our feet. The situation is similar with "colonial architecture". But that's another topic. The problem is, we've managed to forget this and more!

Recipe from a professional historian-archaeologist Yu.E. Berezkina with multiple hallmarks of quality:

1. The blocks of the bottom row are adjusted to the top ones by trial and error (that's right, the bottom ones to the top ones!)

2. The natural deformation of the stone fills all the cracks.

It's all so simple and uncomplicated.

I didn’t read Berezkin’s book, I didn’t check whether this nonsense was really written in it, but the approach is recognizable: “How to feed hundreds of thousands of Tatar-multi-headed horses in winter? It’s very simple - you take it and feed it.”

Further text taken from fabiy_maxim A Soviet scientist unraveled the mystery of polygonal masonry back in 1991

o tempora, o mores

Everything as usual. Numerous fans of alternative history run around like bitten and shout at all corners about the "civilizations of the gods", the unknown technologies of the "ancient civilizations" and the construction of the pyramids by aliens. With bated breath, they watch films by von Deniken and Andrei Sklyarov, discussing how some Incas, who owned only copper tools, processed giant stones and joined them together with filigree accuracy. Meanwhile, everything is extremely simple and uncomplicated.

As many history buffs know, in many ancient buildings, the so-called megalithic ones, the builders managed to fit stones to each other in such a way that even a piece of paper could not be inserted between them. Pairing is perfect. And not only that, as if mocking modern builders, ancient people managed in this way to customize not standard factory-made blocks, but stones of the strongest rocks with curvilinear surfaces, including. They built structures in this way without any cement, standing without damage in earthquake-prone regions of the planet. Well, to top it all off, this was done with a copper tool, which is much softer than the stone they process. Yes, and tossing stones weighing under a hundred tons, they also managed to easily.

Meanwhile, official science has long known the methods of building such structures. Anyone can verify this by reading the relevant literature. For example, the publication of the Academy of Sciences of the USSR, the book by Yuri Evgenievich Berezkin "The Incas. The Historical Experience of the Empire", which was published back in 1991. I must say right away that the respected Yuri Evgenievich Berezkin is not some kind of laboratory assistant of the history department who knows nothing about the Incas. He is a professional historian, archaeologist, ethnographer, specialist in comparative mythology, history and archeology of ancient Western and Central Asia, as well as the history and ethnography of the Indians (especially South America). Head of the Department of America of the Museum of Anthropology and Ethnography (Kunstkamera) of the Russian Academy of Sciences. Professor at the Faculty of Ethnology at the European University at St. Petersburg. Doctor of Historical Sciences.

Here is a quote from the above book:

It must be said that although the cyclopean buildings of the Incas are mentioned episodically in the "new" myths characteristic of our time (unknown highly developed technology, space aliens, etc.), these plots in this case did not receive much distribution. All too well known are the quarries where the Incas cut the blocks, and the paths by which the stones were transported to the construction sites. Only stable the legend about

as if a needle cannot be inserted between the plates - they fit so tightly. Though there are really no gaps between the blocks now

, the reason here lies not in careful fitting, but only in natural deformation of the stone, which filled all the cracks over time

. Inca masonry as such is quite primitive: the blocks of the lower row were adjusted to fit the upper ones, acting by trial and error.

I will allow myself to cite a number of photographs typed in Yandex under the tag "polygonal masonry" as an illustration of the opinion of a respected scientist

As they say: "May Vitzliputzli and Quetzalcoatl save us from the representatives of pseudoscience." Amen.

Substances and their physical properties

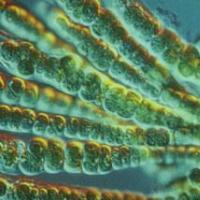

Substances and their physical properties Classification, structure, nutrition and the role of bacteria in nature

Classification, structure, nutrition and the role of bacteria in nature Bacteria - the most ancient organisms on Earth Bacteria - the oldest group of living organisms

Bacteria - the most ancient organisms on Earth Bacteria - the oldest group of living organisms Epithets, metaphors, personifications, comparisons: definitions, examples

Epithets, metaphors, personifications, comparisons: definitions, examples Bronchial asthma Bronchial asthma

Bronchial asthma Bronchial asthma Roman Empire Ancient History

Roman Empire Ancient History Flexible removable dentures: design, features and benefits Varieties of soft dentures with photos

Flexible removable dentures: design, features and benefits Varieties of soft dentures with photos