How to determine the volume of firewood? Taxation measurements and measuring instruments

Taxation measurements and measuring instruments

Units of measurement in forest inventory.

In forest inventory, the following units of measurement are adopted: for determining the length of ridges, logs, whips and the height of trees - a meter (m); diameter - centimeter (cm); cross-sectional area of tree trunks and logs - square centimeter and square meter(cm2, m2); volume - cubic meter (m3); weight - kilogram (kg); growing stock - cubic meter (m3); growth in volume - a cubic meter, in thickness - a centimeter and in height - a meter. The amount of harvested wood is taken into account in dense and folding cubic meters(sq. m3 and skl. m3), and the amount of wood on the vine - only in dense cubic meters. In folding cubic meters, firewood, brushwood and small business assortments (balance sheets, ore rack, etc.) are taken into account, while in addition to wood, the gaps formed between individual segments are included in the measurement; in dense - only wood of the corresponding assortments without gaps and voids.

Roulette.

To measure the length of felled trees, various materials, stacks of timber, as well as stacks of firewood and heaps of brushwood, as a rule, a tape measure is used (Fig. 1, a). Usually it is made from a linen ribbon, boiled in drying oil and covered with paint, about 1.5 cm wide and 5-20 m long. - red.The made braid is put into a special (flat round) leather case: one end is attached to the metal axis of the case, driven by the handle in a clockwise direction, the other is taken out of the case and a metal ring is attached to its end. from ring to axle.

Rice. 1. Measuring tools: a - a pen; b - measuring tape

Measurements with a tape measure are made by two workers: one takes the end of the tape measure with a ring, the second remains with a case. The number located at the exit of the braid from the case shows the length of the measured line. If the measurement is performed by one person, then the ring must be put on any object at the beginning of the line being measured (at the zero of the roulette). When unfolding the tape measure, care must be taken to avoid tearing off the tape from the axis, and when wrapping it, do not allow twisting, as this accelerates its wear and creates the possibility of breaks. Roulette is recommended to use in dry weather; in wet weather, it must be dried before rolling. A tape measure wrapped with wet tape quickly fails.

The downside of a tape measure is that it stretches out over time and can therefore give incorrect results. To eliminate this drawback, it is made two-layer with a laying between the layers of thin copper wire. In both cases, the length of the tape measure must be checked in order to make appropriate corrections. performance of work requiring special precision. Sometimes tape measures are made of steel: they do not stretch, but when rolled up they often break, the divisions on them are hard to see, and, moreover, they are much heavier than linen ones.

With care, a linen tape measure can last for several years. Most often, the first centimeters of tape and the place where the ring is attached to the tape measure wear out, but this can be easily fixed by sewing on the tape from the old tape measure.

Tape measures can also be used to measure small lines on the ground, such as construction sites.

Measuring pole, folding ruler.

You can also measure the length of felled trees and various timber products with a measuring pole and a folding ruler. Especially when measuring woodpile, it is convenient to use a measuring pole, which can be made from a thin, straight sapling. The felled tree is well dried and then planed, giving it a square or rectangular shape of a bar with a cross section of (2-3) X (3-5) cm. The length of the pole should be commensurate with the length of the most common woodpile. Poles with a length of 2-3 m are most convenient for work. On a made pole, notches are made with a knife or an ax every 10 cm, breaking down the extreme division into centimeters. For clarity, lines are drawn along the bottom of the 1st notch with a red pencil, 0.5-m - in blue, along the bottom of 10 and 1-cm - in black. In addition, numbers indicating the length in meters are put down in red pencil. For strength, the ends of the pole can be upholstered with metal plates or covered with tin.

The pole is placed horizontally on the woodpile and the length is measured, then, putting it on the woodpile, the height and, finally, the length of the logs. Multiplying the obtained values, they get the volume of the woodpile in folding cubic meters. For example, with a woodpile length of 4 and a height of 2 m, a log length of 0.5 m, the volume of the woodpile is 4X2X0.5 = 4 approx. m3.

The folding rule can be metal or wooden. Small divisions (up to 1 mm) are applied to one side of it, larger divisions (up to 1 or 0.5 cm) are applied to the second. The first side is used for measurements during work that requires great accuracy (for example, research), and the second - for household. The device of the folding rule is very simple: it consists of six plates fastened with pins. When folded, it is very portable and fits easily in your pocket. In order to avoid easy breakage, it must be used very carefully (a wooden meter is especially fragile). Sometimes measuring meters are made from a single elastic steel tape placed in a small metal flat round case resembling a miniature tape measure.

Measuring tape. To measure large lines on the ground during various economic activities (allocation of cutting areas, laying trial plots, etc.) and especially forest management (measuring clearings, sights, boundaries, etc.), measuring tapes are used (see Fig. 1.6). They are made from a thin steel tape 0.5 mm thick, 2-3 cm wide and 20 m long. There are metal handles at the ends of the tape. On the one hand, divisions are applied in meters, half meters and decimeters by attaching special metal plaques of various shapes to the tape, larger in meter and half-meter divisions. Sometimes numbers are put down on meter plaques - 1, 2, 3, etc. For ease of carrying and storage, the tape is wound on an iron ring between the walls of four bilateral protrusions attached to it, which, after winding the tape, are screwed on. Thanks to these screws and handles, which are wider than the band and the holes between the lugs, the band does not slip off the ring. Each ribbon is accompanied by a set of 11 sharp pegs 40-50 cm long with rings at the top, made of thick iron wire. The peg rings are put on a large iron ring and stored and carried in this form.

In the process of work, two workers unwind the tape, carefully pull it in the direction of the measured and fixed line. At the beginning of the measured line, one worker, having stuck a peg into the ground, applies a zero tape to it, and the other, facing the first one and slightly shaking and pulling the tape, sticks the second peg into the ground against the mark on the tape showing its end - 20 m. Then both go with the tape forward along the measured line. Having reached the second peg stuck into the ground, the first worker stops the second one and aligns the beginning of the tape with the peg set; the second again turns to face him and places the next peg, and the first at this time takes the second peg out of the ground and puts it on the ring on which the first peg was put on; the second peg means that one measurement has been made, i.e. the measured distance is 20 m. These processes are repeated until the entire line is measured. When measuring lines over 200 m, a small wooden stake is hammered in place of each 11th peg; the first worker passes all 10 pegs to the second, and the measurement continues. In order to avoid losing pegs, and hence incorrect counting, it is necessary to periodically check for their presence.

When the worker reaches the end of the measured line, he stretches the tape from the last peg to the pole placed at the end of the line, and counts meters and decimeters. According to the number of wooden stakes and iron pegs (without one) driven into the ground by the worker, as well as the meters and decimeters counted at the last measurement of the tape, the total length of the measured line is determined.

Example. If 4 wooden stakes are driven into the ground, the worker has 9 pegs left, and 7 m and 4 dm are counted on the last tape, then the length of the measured line is (4X200) + (8X20) + 7.4 m = 967.4 m.

Performing measurements without hanging lines can give errors, since in this case the line cannot be straight.

Measuring fork.

To measure the thickness (diameter) of felled and growing trees, as well as various round timber, a forest measuring fork is used. It is the main tool for taxation work. There are a lot of designs of measuring forks. The simplest of them consists of a thick ruler up to 1 m long with divisions. Attached at one end at a right angle wooden block(fixed leg) about 0.5 m long, a second bar of the same size (movable leg) is put on a ruler from the other end through a hole made in it. It should move freely on the ruler and at the same time always be parallel to the first bar.

Such a measuring fork has the disadvantage that with frequent use the movable leg soon loosens, loses its position perpendicular to the ruler. In addition, in wet weather it swells, which delays the movement of the movable leg, in dry weather it shrinks, as a result of which the movements of the movable leg become excessively free. All this causes measurement errors. To eliminate this drawback, the cutout in the movable leg must be larger than the cross section of the ruler; smooth running of the movable leg in any weather and maintaining perpendicularity are ensured by the use of various devices - screws, springs, rollers, wedges, etc.

In the manufacture of a measuring plug, the following requirements must be met: a right angle between the ruler and the fixed leg; easy and smooth sliding along the ruler of the movable leg, parallel to the fixed leg; leg length, slightly more than half the thickness of large measured trunks and timber; sufficiently thin ends of the legs for the convenience of slipping a fork under a lying tree; correct and clear divisions on the measuring ruler; contact along the entire length of the inner planes of the legs at full convergence; light weight of the fork and ease of handling.

As the State All-Union Standard, a measured forest wooden fork of an improved design was introduced (Fig. 2), which consists of a ruler and legs - movable and fixed. The movable leg has a device - a metal insert with a screw, which allows you to increase or decrease the hole in the leg. Thanks to this device, the movable leg of the measuring fork smoothly walks along the ruler in any weather, while maintaining perpendicularity to the ruler and parallel to the fixed leg.

To reduce the contact surfaces on the wide sides of the ruler, notches 1 mm deep were made for divisions of 0.5 cm with numbers every 2 cm, starting from zero on one side for more accurate measurements, on the other - 1 cm with numbers every 4 cm for the production of rounded conversions in steps of thickness 4 cm. With such recalculations and measurements, fractions of less than half of the thickness step are discarded, and more than half are taken as integers. To save the measurer from the need to round and speed up the calculation, divisions with rounding are applied to the ruler: the first step of thickness (4 cm) is marked in half (2 cm), and subsequent divisions are applied and indicated, counting from the first, in the usual order (through 4 cm) , as a result of which the mark 8 cm is placed where actually it should be 6 cm, etc. With this designation of divisions, the measurer always counts the measured diameter according to the last division, which he sees to the left of the movable leg of the measuring fork and which corresponds to the given diameter with the stipulated degree of rounding.

Rice. 2. Standard measuring wooden fork (I) and measurement with it (II): a - side for accurate measurements; b - for measurements in 4-cm thickness steps; c - incorrect; g - correct; 1 - barrel diameter, 2 - chord

Example. The movable leg goes over the number 12 by one division, therefore, the measurer marks the diameter of 12 cm, although it is equal to 2 + 8 + 1 \u003d 11 cm. +8+3=13 cm or rounded off 12 cm), i.e. until the movable leg reaches the number 16.

In this way, trees are counted in 4-cm thickness steps. As a result of rounding, errors are possible, but when performing recalculations a large number trees, as a result, these errors are reduced to a minimum, quite acceptable for forestry practice. When measuring a small number of trees and various round timber, use the reverse side of the measuring fork, which gives results without rounding to an accuracy of 0.5 cm.

When using a measuring fork, it is necessary to adhere to the following rules: apply a ruler to the barrel and smoothly, without pressure, enclose the barrel between the movable and fixed legs, taking into account the ability of the legs to spring, as a result of which pinching the barrel with a force between them or the ends of the legs can give reduced results due to the measurement of only the chord, and not the diameter (see Fig. 2); reading along the ruler must be carried out before removing the measuring fork from the tree; when measuring the thickness of a standing tree, the measurement site should be cleared of mosses and lichens; to obtain the most accurate results, it is necessary to measure not one diameter of the trunk (or parts of it), but two mutually perpendicular diameters or the largest and smallest diameters and take the average value, since the trunk, as a rule, is not round.

Measuring bracket.

The thickness of the log in the upper cut can be determined with a measuring bracket (Fig. 3). For its manufacture, a well-dried wooden block 50-80 cm long is taken and a ruler of rectangular section ZOH "Yu mm is cut out of it. the side is bent onto a ruler, and on the other side it remains in the form of a protrusion-hook 1.0-1.5 cm long, which serves to ensure that when a measuring bracket is applied to a cut of a log, the ruler does not slip and its beginning coincides with the edge of the cut (see Fig. Fig. 3) On both sides of the ruler, divisions are applied in the direction from the protrusion of the hook to the handle in centimeters and half centimeters with numbers every 2 or 5 cm.

Rice. 3. Measuring bracket

When measuring, the measuring bracket must always pass in the middle of the cut, and the protrusion of the hook rests against the edge of the cut, otherwise an incorrect result will be obtained. It is better to take two mutually perpendicular measurements with the output of the average. The count is recorded without removing the staple from the cut. For an accurate measurement, the log must be carefully debarked, otherwise the protrusion -; the hook may capture part of the bast, and the result will be exaggerated.

Altimeter.

To determine the height of a standing tree, many different devices and devices are used. The simplest and most accessible altimeter is an ordinary forest measuring fork (Fig. 4, a). When using it as an altimeter, a plumb line is attached about 6-8 cm from the end, and a zero line is marked on the movable leg at the same distance from the end, from which centimeter and half-centimeter divisions are applied on both sides. When combining the legs, the attachment point of the plumb line on the fixed leg and the zero division on the movable leg must match. The divisions on the movable leg for the convenience of readings when crossing them with a plumb line are applied at an obtuse angle to the ruler of the measuring fork.

When measuring, the measurer moves away approximately at a distance equal to the height of the tree, so that its top is clearly visible from this point. The distance from the tree to the measurer is precisely measured with a tape measure; then the movable leg is moved away from the fixed one by the number of centimeters corresponding to the number of meters to the measurer, and the movable leg is fixed with a screw; along the inner edge of the fixed leg they sight at the top of the tree and the centimeters are counted from the plumb line to the movable leg. The number of centimeters shown by the plumb line, replaced by meters, plus the average height of a person (to the eyes), taken as 1.5 m, is equal to the height of the tree. The measuring fork allows you to measure trees with an accuracy of approximately ± 0.5 m.

Example 1. The plumb line crossed the movable leg by 23.5 cm. The height of the tree is 23.5-4-1.5 \u003d 25 m. The measurement is correct if the tree grows on level ground, and if it is on a slope below the measurer, then first it is necessary to sight at the top of the tree and make a reading along the plumb line in centimeters, then to the base and make the same reading. In this case, the plumb line passes on the other side of the zero of the movable leg, i.e., in the direction of its end. Summing up both readings, we get a number equal to the height of the tree in meters. To obtain the height of a tree located above the measurer, the result of the second reading must be subtracted from the first.

Example 2. The reading when sighting the tree below the measurer at the top showed 17 and at the base 3 cm. Therefore, the height of the tree is 17 + 3 = 20 m.

As an altimeter, you can use a simple rectangular board about 10x15 cm in size, made of plywood or thin board. small size board allows you to carry it in your pocket (see Fig. 4, b). Its surface is divided by lines parallel to the edges into a series of small squares. A grid of squares can be pre-drawn with ink on parchment paper and carefully glued onto a board. In the upper right corner, at a distance of about 3-4 cm from the edge at point E, a plumb line is attached. Divisions are inscribed along the edges BD and CD: along the edge BD from top to bottom, and along the edge CD to the left and right of the line EO, crossing the plank from top to bottom through the point of attachment of the plumb line E.

Rice. 4. Tools for measuring the height of a tree: a - measuring fork; o - altimeter board; c - pendulum altimeter

To determine the height of a tree with such a board, measure the distance from the sighting point to the tree (as when working with a measuring fork) and, by the number of xmeters obtained, count the same number of squares from top to bottom along the edge. The line crossed at the end of the reading, parallel to the base of the plank, serves to read the height of the measured tree. Then they sight along the LS edge to the top of the tree. When the plumb line has calmed down, it is clamped by hand and the number of squares at the point of intersection of the plumb line with the previously found parallel line is determined (parts of the squares are determined by eye). This number plus 1.5 m (the height of a person to the eyes) is the height of the tree.

Example. The distance from the point of view to the tree is 18 M. Therefore, the height of the measured tree is measured by a line parallel to the base and passing through the number 18 along the BD edge (18 squares from top to bottom). Let's say that the plumb line crossed this line by 15.5 squares, then the height of the tree is 15.5 + 1.5 = 17 m.

If the place of measurement is uneven, the height of the tree is determined in the same way as when working with a measuring fork; for readings when sighting at the base of the tree, when it is below the observer, the right side of the board is used from the line crossing it from top to bottom through the attachment point of the plumb line E. The measurement accuracy using the board is approximately the same as when working with a measuring plug. In order to obtain greater accuracy, it is advisable to attach diopters to the upper edge of the LV of the board.

Of the special altimeters, the easiest to use and quite reliable in terms of measurement accuracy is the pendulum altimeter, proposed in 1949 by the tax collector N. I. Makarov (see Fig. 4, c). This is a thin metal plate, resembling a sector of a circle with a radius of 8-10 cm. At some distance from the corner of the sector, a metal pendulum is suspended, the sleeve of which ends on the outside with a special head - a button that presses the pendulum to the plate, and on the inside it has a nut, with pressing on which the pendulum begins to move. Two division scales are applied to the arc of the sector: the upper one is for reading the height of the tree when moving away from it at a distance of 10 m, the lower one is at 20 m. The plate, on which the pendulum is attached, has a sighting tube with a socket for viewing on one side and a small rounded hole for sighting on the top and base of the tree on the other side.

The height of a tree is determined as follows. If the height does not exceed 15 m, they depart from it by 10 m, and if it approaches 20 m, then by 20 m. Then in right hand they take an altimeter, covering the notch of the arc with the thumb, and the sighting tube with the index finger, point the latter to the top of the tree ^ and press the index finger of the left hand on the nut of the pendulum, which begins to swing freely; allowing it to calm down, the nut is smoothly released, as a result of which the pendulum in a vertical position is pressed against the plate. After that, the height of the tree is counted according to one of the division scales: 10 or 20, respectively. If the height of the tree, by preliminary determination, is more than 25 m, they retreat 30 m and, after sighting at its height, take readings on both scales. Then the obtained readings are summarized and 1.5 m are added, as a result, the height of the measured tree is obtained.

Example 1. When measuring a tree from a distance of 10 m, a reading on the 10th scale of 9.5 m was obtained. Therefore, the height of the tree is 9.5 + 1.5 = 11 m.

Example 2. When measuring a tree from a distance of 20 m, a reading on the 20th scale of 17 m was obtained.

Example 3. When measuring a tree from a distance of 30 m, a reading was obtained on the 10th scale 9 m and on the 20th 18 m. Therefore, the height of the tree is 9 + 18 + 1.5 = 28.5 m.

If the tree grows on uneven terrain, then it is necessary to sight 2 times: at the top and at the base (as when working with a measuring fork). A more accurate determination of the height of a tree is obtained by measuring from a distance approaching their actual height. In this case, the reading obtained on the upper scale is divided by 10 and multiplied by the distance from the tree to the point from which the sighting was made.

Example. The sighting was carried out from a distance of 14 m, a reading of 11 m was obtained on the upper scale. Therefore, the height of the tree

Х14+1.5=16.9 m.

Before starting work, it is necessary to check the serviceability of the altimeter. In a horizontal position (along the spirit level), the pendulum pointer should point to zero division. When the nut is pressed, the pendulum should swing freely, and when lowered, immediately stop moving, as it is pressed against the plate.

Incremental drill.

To determine the growth of a tree in thickness, a small tool called an incremental borer is used (Fig. 5). This tool consists of a metal tube with an internal diameter of 5-7 mm. There are drills various lengths, but usually 12 cm. One end of the tube is somewhat narrowed and has sharp edges with an external helical (also sharp) thread, the other has a quadrangular section and flat edges. With a square end, the tube is tightly inserted into another tube (hollow unscrewing, metal), which is both a handle and a tool case.

Before work, the thick bark of the tree must be somewhat cleaned, but not to the wood. Then, a drill is screwed in perpendicular to the surface of the trunk to the desired depth, after inserting a lance-shaped steel plate, serrated on one side, into the tube - a brush, with the teeth of which the column of wood is clamped in the drill and removed from the tree with it. It is necessary to take out the drill very carefully so as not to break this column, since the thickness of the annual layers is also measured on it with the help of a brush, on the reverse side of which divisions in millimeters and centimeters are applied. After work, the drill handle is unscrewed and a tube with a screw thread and a brush inserted into it is placed in it. In this form, the drill is convenient for carrying through the forest.

Stump resin- this is a naturally tarred sound part of the stumps and roots of conifers. Resin serves as a raw material for turpentine and rosin production. In our country, the harvesting and processing of stump resin from Scots pine and Siberian pine is carried out.

Stump resin resources are determined based on the number and diameters of stumps, using regional reference tables.

Using the initial data in Appendix 1 and the taxation characteristics of the units presented in Table. 2.17, as well as by the values of the average diameter and the number of tar stumps per 1 ha (Table 2.18), the stock of stump tar per 1 ha and the total area of the stand are determined (Table 2.19).

Table 2.17

Taxation characteristics of pine forest stands allotted for felling

| sq. no. | issue no. | S, ha | Compound | D cm | Bonitet | completeness | felling year | |

| 5,2 | 6S2E2B | 0,6 | ||||||

| 3,4 | 7S3B | 0,5 | ||||||

| 1,2 | 6S2B1E1Os | 0,6 | ||||||

| 6,8 | 6S3B1Os | 0,5 | ||||||

| 2,2 | 7S2B1Os | 0,5 | ||||||

| 4,1 | 6S4B | 0,4 | ||||||

| 5,0 | 6S1E3B | 0,5 | ||||||

| 3,8 | 7S1E2B | 0,5 | ||||||

| 2,9 | 8S2B | 0,6 | ||||||

| 4,2 | 8S1E1B | 0,5 | ||||||

| 2,4 | 7S3B | 0,6 | ||||||

| 6,3 | 6S2E2B | 0,5 | ||||||

| 2,2 | 8S2B | 0,4 | ||||||

| 6,4 | 7S1E1B1Os | 0,6 | ||||||

| 3,3 | 7S3B | 0,5 |

When determining the number of resin stumps, it is necessary to take into account the share of pine in the stand formula by multiplying by the participation factor. Also, the number of resin stumps depends on the felling age and is expressed by the following ratio:

Table 2.18

Determination of the average diameter and number of resin stumps per 1 ha, depending on the quality class and density of pine plantations

| Quality class | Wed D old, cm | The number of trunks (stumps) at fullness | Wed D stumps, cm | ||||||

| 1,0 | 0,9 | 0,8 | 0,7 | 0,6 | 0,5 | 0,4 | |||

| II | |||||||||

| III | |||||||||

| IV | |||||||||

| V | |||||||||

Example. Determine the stock of stump resin with an average stump diameter of 28 cm and their number per 1 ha - 325 pcs.

The stock of stump resin by digits of numbers and the corresponding diameter will be: for three hundred - 17 cl. m 3 (intersection of the number 3 in the quantity column and the column "hundreds"); for two tens - 1 cl. m 3; for 5 units - 0. Accordingly, the stock of 325 stumps will be: 17+1+0=18 skl. m 3.

Table 2.19

Determination of the stock of stump resin

| Wed D stumps, cm | Quantity | Wed D stumps, cm | Quantity | Stock of stump resin, skl.m 3 by digits of numbers | |||||||

| thousand | hundreds | dec. | units | thousand | hundreds | dec. | units | ||||

| - | - | - | |||||||||

| - | - | - | |||||||||

| - | - | - | |||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | - | |||||||||

| - | - | - | |||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | |||||||||||

| - | - | - | |||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | |||||||||||

| - | |||||||||||

| - | - | - | |||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | |||||||||||

| - | |||||||||||

| - | |||||||||||

| - | |||||||||||

| - | - | - | |||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | |||||||||||

| - | |||||||||||

| - | |||||||||||

| - | |||||||||||

| - | |||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | - | ||||||||||

| - | |||||||||||

| - | |||||||||||

| - | |||||||||||

| - | |||||||||||

| - | |||||||||||

| - |

According to the table 2.20 is the mass of stump resin harvested from the area of the allotment at a given humidity, per 1 ha.

Table 2.20

Conversion of the storage volume of stump resin into weight indicators

Based on the felling age index, the stump resin ripeness classes are determined for all sections, the characteristics of which are given in Table. 2.21 and the content of resinous substances per 1 hectare in the total mass of raw materials is calculated according to table. 2.22 subject to Appendix 19.

Table 2.21

Stump resin ripeness classes

Table 2.22

| Ripeness class | TUM | |||||||

| Bory | Subora | |||||||

| dry | fresh | wet | raw | dry | fresh | wet | raw | |

| I | 9,8 | 10,5 | 7,1 | 6,5 | 10,2 | 11,2 | 7,6 | 5,8 |

| II | 16,4 | 16,9 | 11,9 | 10,8 | 16,2 | 15,5 | 11,5 | 10,2 |

| III | 20,5 | 19,4 | 16,5 | 14,2 | 19,8 | 18,5 | 16,7 | 15,8 |

| IV | 23,8 | 24,5 | 22,2 | 20,1 | 23,5 | 22,9 | 21,0 | 19,5 |

Knowing the area of the section, the stock of stump resin is determined (cl. m 3 and kg) and the amount of resinous substances (kg) for all sections.

According to the results of all calculations, the table is filled. 2.23.

Table 2.23

Summary sheet for determining the stock of stump resin and the amount of resinous substances

| sq. no. | issue no. | S, ha | Ripeness class | Stock of stump resin, skl. m 3 | Pneumatic resin weight, kg | The amount of resinous substances, kg |

| 5,2 | ||||||

| 3,4 | ||||||

| 1,2 | ||||||

| 6,8 | ||||||

| 2,2 | ||||||

| 4,1 | ||||||

| 5,0 |

Tasks to complete practical work 2.10

1) Determine the average diameter of stumps and their number for each section.

2) Determine the stock of stump resin (cl. m 3 per 1 ha) for each section.

3) Find the mass of stump resin harvested from 1 hectare of the area of each section.

4) Determine the content of resinous substances in the stump osmol (kg / ha) for each section.

5) Find the total supply of stump resin, its mass, the amount of resinous substances for all sections.

2.11. Calculation of logging waste resources and dynamics of their formation during the year

An important direction at present is a more complete use of the logging fund, reducing wood losses during its harvesting and transportation. For various reasons, the logging fund allotted for felling is developed and used extremely irrationally. The value of wood losses and waste at all stages of production ranges from 1/3 to 1/2 of the total logging fund allocated for felling.

With the technology and equipment of logging currently used at the enterprises of the forest complex, waste is generated at the cutting area, loading point (upper warehouse) and timber warehouse.

The considered logging waste includes branches, branches and tops, fragments of trunks, waste from the processing of the dimensions of the cart, as well as residues from cutting the lengths into assortments (cutting off, peaks).

V general view volume of any wood waste V 0 T , can be determined by the formula:

where Vc- the volume of raw materials, relative to which the waste is determined, m 3; N- waste generation standard, %.

The volume of waste in the form of twigs, branches and tops at the cutting area and at the loading point is determined relative to the volume of timber removal. At a timber warehouse, the volume of exported wood, in particular the volume of crosscutting waste, is determined relative to the volume of wood to be crossed. Table 2.24.

Table 2.24

Consolidated standard for the formation of logging waste

| Region | Timber waste generation standard, % of timber removal | |||

| Branches, branches, tops on a growing tree | Fall of branches, branches, when felling, hauling | Consolidated standard of logging waste suitable for use | ||

| Used to strengthen logging trails and further as a fertilizer | Including used to strengthen the portages | |||

| Northwestern region | 13,3 | 8,1 | 2,8 | 5,2 |

| central District | 12,2 | 7,7 | 3,4 | 4,5 |

| Volga region | 12,2 | 4,4 | - | 7,8 |

| North Caucasus region | 16,6 | 5,7 | - | 10,9 |

| Ural region | 14,4 | 10,2 | 5,0 | 4,2 |

| West Siberian region | 12,2 | 10,9 | 5,8 | 1,3 |

| East Siberian region | 13,3 | 10,1 | 5,3 | 3,2 |

| Far East region | 15,5 | 11,8 | 6,2 | 3,7 |

The free average standard of logging residues suitable for use may vary depending on a number of factors. In summer, its value slightly increases (1.2 times), and in winter it decreases (up to 0.9 times). Its value is also adjusted depending on the degree of swamping of the forest fund allocated to the felling. When the swampiness of cutting areas is up to 20, up to 40, and up to 60%, correction factors equal to 0.8 are applied, respectively; 0.6 and 0.4.

The applied equipment and technology of work have a significant impact on the amount of logging waste generation. For example, the loss of stem wood harvested by machine is about 1.6-1.8 times higher than when cutting logging sites with machine systems using gasoline-powered saws. Wood waste in the cutting area in the form of damaged tree-lengths and their fragments are taken into account in the volume of actual use. According to the research of TsNIIME , the average standard for the use of stem wood relative to the volume of haulage can be taken as an average of 6.4% (in winter - 6.65%, in summer - 6.16%). The standards for the use of waste from bringing the dimensions of a timber truck to the requirements for the transportation of goods on public roads can be taken as 4% - when removing wood in whips, 9% - when removing wood from trees (in summer - 10%, in winter - 8%). The standard for the generation of bucking waste in the forest can be taken as for timber warehouses (Table 2.26), increased by 30% due to worse working conditions.

For a reasonable choice and operation of machine systems that produce process chips in a cutting area, it is important not only to know the total amount of waste, but also to take into account the dynamics of the formation of this waste throughout the year (by months, per shift).

Then, in general terms, the real annual volume of logging waste generated at the enterprise can be determined by the formula

![]() (2.67)

(2.67)

where Vi- the real volume of logging waste in i-th month, m 3 . In general, the value Vi can be calculated using the formula

where - the annual volume of logging operations of the enterprise, m 3; K i T and K i B- coefficients of unevenness, respectively, skidding and removal of wood in i-th month (Table 2.25), showing how the volume of a certain type of work differs in a particular month in comparison with the average monthly for the year; N ij - usage standard j-th type of logging waste in i-th month, %.

For specific production conditions and types of waste considered, formula (2.68) takes the form

where N i 1 , N i 2 , N i 3 , N i 4 - standards, respectively, for the use of waste in the form of: branches, branches, tops; fragments of trunks; wood formed during the processing of the dimensions of the cart; otkomlevok and visors; C s, C 3, C m- coefficients taking into account, respectively: the season of work; the degree of swampiness of cutting areas and the system of machines that harvest wood.

The replacement volume of logging waste generated after final felling, in m 3 in different months of the year, can be determined by the formula

where n pi- number of working days i-th month; k cm i- shift factor in i-th month.

The average shift volume of logging waste during the year is (2.7

where np the number of working days in a year; - the coefficient of change during the year.

Example(figures are conditional): a logging enterprise with an annual production volume of 200 thousand m 3 is located in the Komi Republic and carries out export in assortments; harvesting is carried out by a system of machines using gasoline-powered saws; the number of working days by month, starting from January, is: 24, 23, 24, 21, 23, 26, 25, 26, 24, 24, 20.25; the shift coefficient in all months is 1; the degree of swampiness of cutting areas - 20%.

The volume of logging waste suitable for use for technological and fuel needs will include branches, branches, tops, fragments of trunks, patches and peaks.

The real volume of logging waste generated in i-th month, is determined by the formula (2.68), using the data: tab. 2.24 ( N i 1, reduced for winter months by 0.9 times and increased by 1.2 times for summer months); tab. 2.25, option ( K iT and K iB); norms for the use of damaged stem wood: N i 2\u003d 6.4% (in winter 6.65%, in summer 6.16%), as well as the standards for the generation of cross cutting waste, taken from Table. 2.26 and increased by 30%.

Table 2.25

Monthly coefficients of irregularity of skidding K i T and removal K i B of timber

| Months | Options | |||||||||||

| a | b | v | G | d | e | |||||||

| K and T | K and B | K and T | K and B | K and T | K and B | K and T | K and B | K and T | K and B | K and T | K and B | |

| January | 1,15 | 1,18 | 1,22 | 1,41 | 1,28 | 1,73 | 1,08 | 1,12 | 1,10 | 1,15 | 1,13 | 1,20 |

| February | 1,30 | 1,33 | 1,28 | 1,39 | 1,32 | 1,72 | 1,04 | 1,12 | 1,20 | 1,25 | 1,16 | 1,23 |

| March | 1,38 | 1,41 | 1,33 | 1,40 | 1,66 | 2,01 | 1,21 | 1,25 | 1,30 | 1,35 | 1,28 | 1,28 |

| April | 0,95 | 0,69 | 0,83 | 0,76 | 0,88 | 0,87 | 0,98 | 1,00 | 1,00 | 0,60 | 0,95 | 0,73 |

| May | 0,77 | 0,64 | 0,74 | 0,70 | 0,61 | 0,46 | 0,82 | 0,80 | 0,70 | 0,80 | 0,84 | 0,93 |

| June | 1,00 | 0,92 | 0,95 | 1,00 | 0,72 | 0,63 | 0,96 | 1,01 | 0,90 | 0,90 | 0,95 | 1,05 |

| July | 0,95 | 0,99 | 0,92 | 0,90 | 0,78 | 0,63 | 0,94 | 0,98 | 0,90 | 0,95 | 0,90 | 0,87 |

| August | 0,92 | 0,99 | 0,94 | 0,98 | 0,87 | 0,67 | 0,92 | 0,92 | 0,90 | 1,00 | 0,92 | 0,98 |

| September | 0,91 | 0,88 | 0,87 | 0,72 | 0,86 | 0,60 | 1,00 | 0,94 | 0,95 | 1,00 | 0,91 | 0,93 |

| October | 0,77 | 0,89 | 0,87 | 0,64 | 0,89 | 0,51 | 1,00 | 0,95 | 0,90 | 0,95 | 0,96 | 0,96 |

| November | 0,90 | 1,02 | 0,98 | 1,00 | 0,91 | 0,85 | 0,99 | 0,92 | 0,95 | 0,90 | 0,97 | 0,91 |

| December | 1,00 | 1,06 | 1,07 | 1,10 | 1,16 | 1,30 | 1,06 | 0,99 | 1,10 | 1,15 | 1,04 | 1,03 |

Table 2.26

Bucking waste generation standard

Then the volume of logging waste generated, for example, in January, will be

and in August it will be

Similarly, the volumes of logging waste for other months are determined. Summing up their values for all months (formula 2.67), we find the real annual volume of logging waste at the enterprise, equal to 19646 m 3.

Determining the monthly volumes of logging residues using the formula (2.70), it is easy to obtain shiftable volumes of logging residues in these months. For example, in August, a shift will form

![]() waste

waste

Having determined the monthly and shift volumes of logging waste, we build a graph of the dynamics of their formation during the year (Fig. 2.9) based on Appendix 1.

Rice. 2.9. Dynamics of logging waste generation

Tasks for practical work 2.11

1) Determine the types of waste generated in the cutting area, and the area of their use.

2) Determine the actual annual volume of logging waste.

4) Build a graph of the dynamics of the formation of logging waste during the year.

Calculation for 1 tree

| No. pp | Name of works | Unit measurements | Discharge - a range of work | Deadline, months | Multiplicity | Scope of work | ||||||||

| Labor costs | Means of mechanization | materials | ||||||||||||

| Person-hour | Name, brand | Machine-hour | Name | Unit measurements | Quantity | |||||||||

| TNV 1987 1.2.11V-1 add. ETKS 1997 TNV 1987 1.2.11V-2 add. ETKS 1997 TNV 1987 1.2.11V-3 add. ETKS 1997 TNV 1987 1.2.11V-4 add. ETKS 1997 | Removal of trees on a stump by hand with delimbing and bucking for a short trunk with a trunk diameter at chest height: up to 0.2 m 0.2-0.3 m 0.3-0.4 m 0.4-0.5 m | skl. m 3 skl. m 3 skl. m 3 skl. m 3 | 3.64 2.66 2.11 1.85 | 6-2 hours drive 6-2 hours drive 6-2 hours drive 6-2 hours drive | 1-HP 1-HP 1-HP 1-HP | 0.758 1.60 3.66 6.63 | 2.75 4.25 7.723 12.26 | Chainsaw Gazelle Chainsaw Gazelle Chainsaw Gazelle Chainsaw Gazelle | 1.37 2.12 3.862 6.13 | - - - - | - - - - | - - - - |

| TNV 1987 1.2.11V-54 add. ETKS 1997 | collection of branches and logging residues after felling trees - with a trunk diameter of up to 0.2 cm (20%) - with a trunk diameter of 0.2-0.3 cm (30%) - with a trunk diameter of 0.3-0.4 cm (30%) - with a trunk diameter of 0.4-0.5 cm (20%) | 0.15 0.15 0.15 0.15 | 1-HP 1-HP 1-HP 1-HP | 0.758 1.60 3.66 6.63 | 0.11 0.24 0.549 0.99 | - - - - | - - - - | - - - - | - - - - | - - - - | ||||

| TNV 1987 1.2.11V-9-60 add. ETKS 1997 | Loading on vehicles and unloading branches and logging residues (Hvr x 2) - with a trunk diameter of up to 0.2 cm (20%) - with a trunk diameter of 0.2-0.3 cm (30%) - with a trunk diameter of 0.3-0.4 cm (30%) - with a trunk diameter of 0.4-0.5 cm (20%) | skl. .m 3 sk. m 3 skl. m 3 skl. m 3 | 1.08 1.08 1.08 1.08 | 1-HP 1-HP 1-HP 1-HP | 0.758 1.60 3.66 6.63 | 0.88 1.72 3.9528 7.16 | ZIL-MMZ ZIL-MMZ ZIL-MMZ ZIL-MMZ | 0.88 1.72 3.9528 7.16 | - - - - | - - - - | - - - - | |||

| Removal of branches and logging residues by road at a distance of up to 60 km | T | 0.96 | - | 1-HP | 7.5888 | - | ZIL-MMZ | 7.285248 | Waste collection voucher | T | 7.5888 |

TOTAL: 42.5848

Note: the calculation of the cubic capacity of cut trees must comply with the tables of timber volumes 19. 22. 183. 187. 206, published in the All-Union Standards for Forest Inventory. M. 1992

TECHNOLOGICAL SHEET 4.7

UPROADING STUMP MANUALLY

Calculation for 1 stump

| No. pp | Basis of standard costs | Name of works | Unit measurements | Norm of time per unit. measurements, man-hour | Discharge - a range of work | Deadline, months | Multiplicity | Scope of work | Required for work | |||||

| Labor costs | Means of mechanization | materials | ||||||||||||

| Person-hour | Name, brand | Machine-hour | Name | Unit measurements | Quantity | |||||||||

| TNV 1987 1.2.11b-3-48 add. ETKS 1997 | Manual removal of stumps up to 70 cm in diameter. Dig in the stump, cut the roots and clear the ground. Uproot, move to a distance of up to 5 m using a crowbar, horn and other devices. Fill the hole with earth | stump | 10.6 | 1-HP | 10.6 | - | - | - | - | - | ||||

| TNV 1987 1.2.11b-7-56 add. ETKS 1997 | Uprooting a free-standing shrub by hand. Dig, cut roots and move to a distance of 50 m with laying in a pile. Fill the hole with earth | bush | 0.36 | 1-HP | 0.36 | - | - | - | - | - |

TECHNOLOGICAL SHEET 4.8

WATERING PLANTS FROM HOSE

Calculation for 100 m 2

| No. pp | Basis of standard costs | Name of works | Unit measurements | Norm of time per unit. measurements, man-hour | Discharge - a range of work | Deadline, months | Multiplicity | Scope of work | Required for work | |||||

| Labor costs | Means of mechanization | materials | ||||||||||||

| Person-hour | Name, brand | Machine-hour | Name | Unit measurements | Quantity | |||||||||

| TNV 1987 1.2.1-6a-16.17 add. ETKS 1997 | Watering plants from a hose up to 40 m long at a rate of 5 l / m 2. Bring the hose, unwind and connect to the water supply. Water plants evenly. Roll up the hose and take it to the storage place | 100 m2 | 0.2 | U-1X | 0.2 | - | - | Water | l | |||||

| TNV 1987 1.2.1-6b-18.19 add. ETKS 1997 | Watering plants with a hose over 40 m long at a rate of 5 l/m 2 . Bring the hose, unwind and connect to the water supply. Water plants evenly. Roll up the hose and take it to the storage place | 100 m2 | 0.8 | U-1X | 0.8 | - | - | Water | l |

TECHNOLOGICAL SHEET 4.9

LOADING SNOW ON VEHICLES

Calculation for 1 car

| No. pp | Basis of standard costs | Name of works | Unit measurements | Norm of time per unit. measurements, man-hour | Discharge - a range of work | Deadline, months | Multiplicity | Scope of work | Required for work | |||||

| Labor costs | Means of mechanization | materials | ||||||||||||

| Person-hour | Name, brand | Machine-hour | Name | Unit measurements | Quantity | |||||||||

| Norma GUP Moszelenkhoz | Loading snow on vehicles with movement within the site up to 1 km with a body capacity of up to 6 m 3 | mash. | 1.0 | Water car Water loader 4 razr Working 3 razr. | Х1-Ш | 50.0 | ZIL-MMZ Loader | 50.0 | - | - | - | |||

| Norma GUP Moszelenkhoz | Snow removal by road up to 35 km | mash. | 2.4 | - | Х1-Ш | - | ZIL-MMZ | 120.0 | Snow removal ticket | T |

TOTAL: 50.0

TECHNOLOGICAL SHEET 4.10

REMOVAL OF GARBAGE, CUTTING RESIDUES,

WASTE EARTH, LEAVES, GRASS, SNOW, etc.

AT A DISTANCE OF 1 KM

Calculation for 1 t

| No. pp | Basis of standard costs | Name of works | Unit measurements | Norm of time per unit. measurements, man-hour | Discharge - a range of work | Deadline, months | Multiplicity | Scope of work | Required for work | |||||

| Labor costs | Means of mechanization | materials | ||||||||||||

| Person-hour | Name, brand | Machine-hour | Name | Unit measurements | Quantity | |||||||||

| Norma GUP Moszelenkhoz | Removal of garbage, logging residues, waste land, foliage, grass, snow, etc. by road at a distance of 1 km | T | 0.016 | - | 1-HP | - | ZIL-MMZ | 0.016 | - | - | - |

TECHNOLOGICAL SHEET 4.11

REMOVAL OF SELF-SEEDING OF TREE AND SHRUBS

Calculation per 1 ha

| No. pp | Basis of standard costs | Name of works | Unit measurements | Norm of time per unit. measurements, man-hour | Discharge - a range of work | Deadline, months | Multiplicity | Scope of work | Required for work | |||||

| Labor costs | Means of mechanization | materials | ||||||||||||

| Person-hour | Name, brand | Machine-hour | Name | Unit measurements | Quantity | |||||||||

| Norma GUP Moszelenkhoz | Self-seeding removal | 100 pieces. | 5-1h water 1 | 1-HP | 0.5 | 26.5 | Chainsaw | - | - | - | ||||

| TNV 1987 1.2.7-9-54 add. ETS | Collection of logging residues (0.3 cubic meters / piece) | 100 m 2 cleaning area | 0.31 | 1-HP | 0.31 | - | - | - | - | |||||

| TNV 1987 1.2.11V-9-60 add. ETS | Loading and unloading of logging residues (H time x 2) | skl.m 3 | 1.08 | 1-HP | 30.0 | 32.4 | ZIL-MMZ 45085 | 32.4 | - | - | - | |||

| Removal of logging residues by road at a distance of up to 60 km | T | 0.96 | 1-HP | 7.5 | - | ZIL-MMZ 45085 | 7.2 | Waste collection voucher | T | 7.5 |

When logging in winter time the yield of technical greenery is reduced by 20%. Weight loss during 3-day storage of raw materials is 10% for coniferous species, 30% for hardwoods.

stump wood. The stumps and roots of some conifers are used to obtain stump resin as a valuable raw material for rosin-extraction production. In some forest-deficient areas, they are used as fuel. The study of taxation properties and features of stump resin, the development of reference data on the accounting and inventory of raw materials of this forest product have recently been carried out by A.A. Smolenkov (1986) and A.P. Seryakov (1987).

Harvested by the uprooting method or the explosive method, the stump resin is folded into dense heaps of a rectangular shape. It is accounted for in storage m3. Depending on the diameter of the heart part of the stumps, the heap full-wood ratio increases in the range of tree thickness steps of 16–60 cm from 0.45 to 0.49. For the production taxation of resin raw materials in clearings, its value is taken equal to

A similar method of accounting can also be applied when estimating stocks of harvested stumps. To convert the volume into a dense measure, an average full-wood ratio of 0.5 is used.

More accurate data on the total wood content of these types of forest products can be found by xylometric or weight method.

3.5. Taxation of lumber

V as a result of longitudinal sawing of logs, lumber is obtained, which is divided according to the shape of the cross section into plates (cut into two symmetrical parts), quarters (cut into four symmetrical parts), beams, bars, boards, sleepers and slabs. When they are taxed on sawmills and woodworking enterprises use computer-aided calculations.

Bars are sawn timber with a width and thickness of more than 10 cm. According to the number of sawn sides, they are divided into two-, three- and four-edged. In turn, the four-edged bars in the shape of the cross-section can be acute and blunt-edged (wane).

Bars are lumber, the thickness of which does not exceed 10 cm, and the width is not more than twice their thickness.

Boards are also harvested with a thickness of not more than 10 cm, but their width exceeds the thickness by two or more times. The wide sides of the boards and bars are called the face, the narrow sides are the edges, and the corners are the ribs.

Lumber is edged if both edges are sawn at least half the length, and unedged - if there is no cut or it is less than half the length. In addition, there are clean-edged sawn products, which are obtained with a full cut of the edge. The unsawn parts of the edge are called wane, and the corresponding boards and bars are called wane.

A sleeper is a piece of log of a certain cross-sectional profile with a length of 2.7 m for a regular gauge railway and 2.5 m - for narrow. According to the section profile, two categories of sleepers are distinguished: A - sawn from four sides; B - sawn on both sides. Depending on the thickness and size of the beds, sleepers are divided into five types.

Transfer bars serve for laying under the railway track in the places of turnouts. They come in five types for the wide gauge and four for the narrow gauge. Assortment length 2.75…5.5 m with gradation

The croaker is cut outer part logs, in which the other surface remains untreated.

Depending on the quality of the wood, softwood lumber is divided into four grades, and hardwood lumber is divided into three grades. Broad gauge sleepers are divided into two grades. For narrow gauge sleepers, such differentiation is not provided.

The volumes of plates and quarters are determined according to special tables. In their absence, according to the tables of GOST 2708-75, according to the diameter in the upper cut and the length of the logs, the cubic capacity of the taxed assortments is found by a corresponding decrease in volumes.

The volumes of sharp-edged beams, beams and pure boards are calculated by multiplying their width a by the thickness b and length l according to the formula

where t is the wane chord length.

The cross-sectional area of the edged sleepers is

g a h |

||

and their volume |

||

Vgl, |

||

where a is the sleeper width; h is the sleeper thickness; t is the wane chord length; l is the length of the sleeper.

The cross-sectional area of a bar sleeper is calculated by the formula of a trapezoid and segments:

c t ; |

|||||

h is the sleeper thickness; с – segment base; t is the height of the segment. The cross-sectional area γ of bar sleepers (and transfer bars) is determined by

lyayut in the middle of the length of the assortment or as half the sum of the upper and lower sections.

To facilitate production calculations for these types of sleepers, special tables of volumes have been compiled. Sleepers are counted individually using templates that reproduce their cross-sectional profile.

where a is the width of the slab; b is the thickness of the slab; l is the length of the slab.

In this case, the cross-sectional area is set at 0.4 lengths from the butt end. In some cases, the slab is taken into account in the skl. m3. The coefficient of full-wood content of their stacks ranges from 0.48-0.74 and is determined according to GOST 5780-77.

The elements of the described lumber are shown in fig. 3.1. Allowances when determining the volume of lumber in

calculation is not accepted.

To determine the volume of unedged boards in accordance with OST 13-24-86, the following methods are used: piece, batch and sampling method. When the moisture content of lumber is more than 20%, correction factors are introduced into the accounting results according to the first method according to the standards of GOST 5306-83: for coniferous species - 0.96; for deciduous - 0.95.

The requirements for the packages are:

a) the boards on one side of the butt are aligned; b) the boards in the horizontal rows of the package are stacked close to each other

friend; c) the package has the same width along the entire length and vertical

sides.

The volume of the package in folding m3 is determined by multiplying its overall sides minus the dimensions of the gaskets and introducing corrections for protruding ends in the loose part of the package.

Rice. 3.1. Cross sections of some lumber: 1 - blunt beam; 2 - unedged sleeper; 3 - croaker

The package volume in a dense measure is found by introducing a stacking density coefficient according to OST, equal to 0.59 ... 0.75.

When evaluating large batches of unedged boards, their accounting is carried out by sampling. The sample sizes for determining the average volume of a board are provided for: for lumber of the same length - at least 3% of the delivered lot, but at least 60 boards; with an admixture of up to 15% shorter - not less than 4%, but not less than 80 boards; for lumber not more than 4 adjacent lengths - not less than 7%, but not less than 120 boards.

The percentage of lumber yield, according to TsNIIMOD, increases with an increase in the upper diameter of logs from 53% at d w/o = 14 cm to

64% with d in / about = 44 cm.

From 1 m3 of a sleeper log, on average, 6 ... 7 sleepers come out, making up 52 ... 60% by volume. In addition, boards (8 ... 15%) and slabs (7 ... 15%) are obtained. The minimum diameters in the upper cut for the production of category A sleepers are 23 cm, B - 24 cm.

When sawing logs, a significant amount of waste is generated. They are more and more widely used for the production of technological chips, in hydrolysis production, for heating, etc. These wood wastes are taken into account in skl. m3. Their full-wood coefficient is on average: sawdust - 0.35; cutting boards, beams - 0.58.

To account for woodworking waste, full-wood coefficients are used in accordance with TU 13-539-80.

3.6. Accounting for split, hewn, planed, peeled

and other timber

TO The group under consideration includes a rather large number of timber harvested by primary mechanical processing of wood.

TO small-sized wood raw materials include trunks with a thickness of 2 to 6 cm. They are harvested 1 ... 3 m long with a gradation of 0.5 m. tab. 3.7.

Table 3.7 - Full wood coefficients of small-sized wood raw materials

Full wood coefficients for the length of thin raw materials, m |

|||||

Deciduous |

|||||

Cooperage riveting of different sizes, depending on the intended purpose, is taken into account individually, in thousands of pieces or in sets (side and bottom). Its volume is determined in sq. m3 in three dimensions using special tables.

The sleigh skid is counted in pairs, the wheel rim - in pairs (on the front and rear wheels) or in camps (on all four wheels). Their volumes are determined by the trapezoid formula:

h l . |

||||

Blanks are pieces of trunks with a special shape of products given to them by hewing. They are accounted for in weight units.

A special place in the described group is occupied by planed and peeled plywood. It is accounted for in m2.

In addition, they make a whole range of products of local importance: bushings, knitting needles, shovels, rakes, etc., which are counted in pieces. In thousands of pieces, roofing and plaster shingles are also accepted.

Technological chips and chips are taken into account in skl. m3. Their full-wood coefficient is taken equal to 0.37 and 0.11, respectively. Special standards are provided for wood chips when transported by road and rail, for which the indicator in question varies from 0.36 to 0.43.

The useful yield from the raw materials of individual assortments is: cooper cage - 30 ... 40%, wheel rim - 20 ... 25%, sleigh runner - 65%, plywood - 50%, roofing and plaster shingles - 50%, etc. Therefore, it seems possible to calculate the need for raw materials for a particular production.

At present, it is technologically quite realistic to use the entire phytomass of trees. The organization of such a cycle should be based on the economic indicators of production.

Control questions

1. Give a classification of forest products based on their size, shape, nature of production use and accounting methods.

2. What methods of determining the volume of logs do you know?

3. Give a systematization of firewood according to its existing properties and characteristics.

4. On what factors does the coefficient of full-woodness of firewood depend?

5. What methods of accounting for brushwood, branches and tree bark are used in forestry?

6. Describe the main methods of taxation of lumber.

7. What are the features of accounting for split, hewn, planed and peeled timber?

8. What standards describe how to account for the main harvested timber?

Substances and their physical properties

Substances and their physical properties Classification, structure, nutrition and the role of bacteria in nature

Classification, structure, nutrition and the role of bacteria in nature Bacteria - the most ancient organisms on Earth Bacteria - the oldest group of living organisms

Bacteria - the most ancient organisms on Earth Bacteria - the oldest group of living organisms Epithets, metaphors, personifications, comparisons: definitions, examples

Epithets, metaphors, personifications, comparisons: definitions, examples Bronchial asthma Bronchial asthma

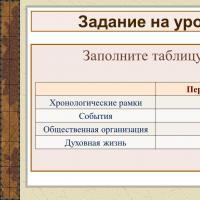

Bronchial asthma Bronchial asthma Roman Empire Ancient History

Roman Empire Ancient History Flexible removable dentures: design, features and benefits Varieties of soft dentures with photos

Flexible removable dentures: design, features and benefits Varieties of soft dentures with photos