Switching power supply on domestic circuit details. Simple switching power supplies. Schematic diagrams of switching power supplies

Do-it-yourself homemade switching power supply.

The author of the design (Sergey Kuznetsov, his website is classd.fromru.com) developed this home-made network power supply

for powering a powerful UMZCH (Audio Frequency Power Amplifier). Benefits of switching power supplies in front of conventional transformer power supplies are obvious:

- The weight of the resulting product is much lower

- The dimensions of the switching power supply are much smaller.

- The efficiency of the product, and, accordingly, the heat dissipation is lower

- The range of supply voltages (voltage surges in the network) at which the power supply can work stably is much wider.

However, making a switching power supply requires much more effort and knowledge than making a conventional low-frequency 50 Hz power supply. The low-frequency power supply consists of a mains transformer, a diode bridge and smoothing filter capacitors, while a pulse power supply has a much more complex structure.

The main disadvantage of switching network power supplies is the presence of high-frequency interference, which will have to be overcome if the printed circuit board is traced incorrectly, or if the component base is chosen incorrectly. When you turn on the UPS, as a rule, a strong spark is observed in the outlet. This is due to the large peak start-up current of the power supply, due to the charge of the input filter capacitors. To eliminate such current surges, the developers design various “soft start” systems that charge the filter capacitors with a low current in the first phase of operation, and at the end of the charge they organize the supply of the full mains voltage to the UPS. In this case, a simplified version of such a system is used, which is a series-connected resistor and a thermistor that limit the charge current of the capacitors.

The circuit is based on the IR2153 PWM controller in a standard switching circuit. Field-effect transistors IRFI840GLC can be replaced with IRFIBC30G, the author does not recommend installing other transistors, as this will entail the need to reduce the ratings of R2, R3 and, accordingly, to an increase in heat generated. The voltage on the PWM controller must be at least 10 volts. The operation of the microcircuit from a voltage of 11-14 Volts is desirable. Components L1 C13 R8 improve the mode of operation of transistors.

The inductors located at the output of the 10 μg power supply are wound with 1 mm wire on ferrite dumbbells with a magnetic permeability of 600 NN. You can wind on rods from old receivers, 10-15 turns are enough. Capacitors in the power supply should be low impedance to reduce RF noise.

The transformer was calculated using the Transformer 2 program. The induction should be chosen as small as possible, preferably no more than 0.25. Frequency in the region of 40-80k. The author does not recommend the use of rings of domestic production, in view of the non-identity of the ferrite parameters and significant losses in the transformer. The printed circuit board was designed for a transformer of size 30x19x20. When adjusting the power supply, it is forbidden to connect the ground of the oscilloscope to the connection point of the transistors. It is advisable to start the power supply for the first time with a 220V lamp with a power of 25-40W connected in series with the source, while the UPS cannot be heavily loaded. The printed circuit board of the block in LAY format can be downloaded or

I also made an inverter so that it could be powered from 12 V, that is, an automotive version. After everything was done in terms of the ULF, the question was raised: how to feed it now? Even for the same tests, or just to listen? I thought it would cost all the ATX PSU, but when you try to “heap”, the PSU reliably goes into defense, but somehow you don’t really want to redo it ... And then the idea dawned on me to make my own, without any “bells and whistles” of the PSU (except for protection, of course). I started with the search for schemes, looked closely at the schemes that were relatively simple for me. Finally settled on this one:

It holds the load perfectly, but replacing some parts with more powerful ones will allow you to squeeze 400 watts or more out of it. The IR2153 microcircuit is a self-clocked driver, which was developed specifically for operation in energy-saving lamp ballasts. It has very low current consumption and can be powered through a limiting resistor.

Device assembly

Let's start with etching the board (etching, stripping, drilling). Archive with PP.

First I bought some missing parts (transistors, irka, and powerful resistors).

By the way, the surge protector completely removed from the PSU from the disc player:

Now the most interesting thing in the SMPS is the transformer, although there is nothing complicated here, you just need to understand how to wind it correctly, and that's all. First you need to know what and how much to wind, there are many programs for this, but the most common and popular among radio amateurs is - Excellent IT. In it, we will calculate our transformer.

As you can see, we got 49 turns of the primary winding, and two windings of 6 turns each (secondary). Let's swing!

Transformer manufacturing

Since we have a ring, most likely its edges will be at an angle of 90 degrees, and if the wire is wound directly onto the ring, the varnish insulation may be damaged, and as a result, an interturn short circuit and the like. In order to exclude this moment, the edges can be carefully cut with a file, or wrapped with cotton tape. After that, you can wind the primary.

After it is wound, we wrap the ring with the primary winding with electrical tape again.

Then we wind the secondary winding from above, though it’s a little more complicated here.

As you can see in the program, the secondary winding has 6 + 6 turns, and 6 cores. That is, we need to wind two windings of 6 turns with 6 cores of wire 0.63 (you can choose by first writing in the field with the desired wire diameter). Or even simpler, you need to wind 1 winding, 6 turns with 6 cores, and then the same one again. To make this process easier, it is possible, and even necessary, to wind in two tires (bus-6 cores of one winding), so we avoid voltage distortion (although it can be, but small, and often not critical).

Optionally, the secondary winding can be insulated, but not necessarily. Now after that we solder the transformer with the primary winding to the board, the secondary to the rectifier, and I used a unipolar rectifier with a midpoint.

Of course, the consumption of copper is greater, but there is less loss (respectively, less heating), and you can use only one diode assembly with an ATX power supply unit that has expired, or is simply inoperative. The first power-up must be carried out with the light bulb turned on in the mains supply, in my case I just pulled out the fuse, and the plug from the lamp is perfectly inserted into its socket.

If the lamp flashed and went out, this is normal, since the mains capacitor was charged, but I didn’t have this phenomenon, either because of the thermistor, or because I temporarily set the capacitor to only 82 uF, or maybe it provides everything smooth start. As a result, if there are no problems, you can turn on the SMPS network. At a load of 5-10 A, below 12 V I didn’t sink, what is needed to power auto amplifiers!

- If the power is only about 200 W, then the resistor that sets the protection threshold R10 should be 0.33 Ohm 5 W. If it is in a break, or burns out, all transistors will burn out, as well as the microcircuit.

- The network capacitor is selected from the calculation: 1-1.5 microfarads per 1 W of unit power.

- In this circuit, the conversion frequency is approximately 63 kHz, and during operation, it is probably better for the 2000NM brand ring to reduce the frequency to 40-50 kHz, since the limiting frequency at which the ring operates without heating is 70-75 kHz. You should not chase a high frequency, for this circuit, and a 2000NM ring, it will be optimally 40-50 kHz. Too high a frequency will cause switching losses on the transistors and significant losses on the transformer, which will cause it to heat up significantly.

- If your transformer and keys heat up at idle with proper assembly, try reducing the capacitance of the snubber capacitor C10 from 1 nF to 100-220 pF. The keys must be isolated from the radiator. Instead of R1, you can use a thermistor with an ATX power supply.

Here are the final photos of the power supply project:

Discuss the article POWERFUL PULSE NETWORK BIPOLAR POWER SUPPLY

In most modern electronic devices analog (transformer) power supplies are practically not used, they were replaced by pulse voltage converters. To understand why this is so, it is necessary to consider design features, as well as the strengths and weaknesses of these devices. We will also talk about the purpose of the main components of pulsed sources, we will give a simple implementation example that can be assembled by hand.

Design features and principle of operation

Of the several ways to convert voltage to power electronic components, two of the most widely used can be distinguished:

- Analog, the main element of which is a step-down transformer, in addition to the main function, it also provides galvanic isolation.

- impulse principle.

Let's take a look at the difference between these two options.

PSU based on power transformer

Consider a simplified block diagram of this device. As can be seen from the figure, a step-down transformer is installed at the input, with its help the amplitude of the supply voltage is converted, for example, from 220 V we get 15 V. The next block is a rectifier, its task is to convert sinusoidal current to pulsed (the harmonic is shown above the symbol). For this purpose, rectifier semiconductor elements (diodes) connected in a bridge circuit are used. Their principle of operation can be found on our website.

The next block plays two functions: it smoothes the voltage (a capacitor of the appropriate capacity is used for this purpose) and stabilizes it. The latter is necessary so that the voltage does not “fall through” with increasing load.

The given block diagram is greatly simplified, as a rule, this type of source has an input filter and protective circuits, but this is not essential for explaining the operation of the device.

All the disadvantages of the above option are directly or indirectly related to the main structural element - the transformer. First, its weight and dimensions limit miniaturization. In order not to be unfounded, we give as an example a 220/12 V step-down transformer with a rated power of 250 W. The weight of such a unit is about 4 kilograms, dimensions are 125x124x89 mm. You can imagine how much a laptop charger based on it would weigh.

Secondly, the price of such devices sometimes many times exceeds the total cost of other components.

Impulse devices

As can be seen from the block diagram shown in Figure 3, the principle of operation of these devices differs significantly from analog converters, first of all, by the absence of an input step-down transformer.

Figure 3. Structural diagram of a switching power supply

Figure 3. Structural diagram of a switching power supply Consider the algorithm of such a source:

- Power is supplied to the surge protector, its task is to minimize network interference, both incoming and outgoing, resulting from operation.

- Next, a unit for converting a sinusoidal voltage into a pulsed constant and a smoothing filter come into operation.

- At the next stage, an inverter is connected to the process, its task is to form rectangular high-frequency signals. Feedback to the inverter is carried out through the control unit.

- The next block is IT, it is necessary for automatic generator mode, supply voltage to the circuits, protection, controller control, as well as the load. In addition, the task of IT is to provide galvanic isolation between high and low voltage circuits.

Unlike a step-down transformer, the core of this device is made of ferrimagnetic materials, this contributes to the reliable transmission of RF signals, which can be in the range of 20-100 kHz. A characteristic feature of IT is that when it is connected, it is critical to turn on the beginning and end of the windings. small size This device allows the manufacture of devices of miniature size, as an example, we can cite the electronic piping (ballast) of an LED or energy-saving lamp.

- Next, the output rectifier comes into operation, since it operates with a high-frequency voltage, the process requires high-speed semiconductor elements, therefore, Schottky diodes are used for this purpose.

- At the final phase, smoothing is performed on an advantageous filter, after which the voltage is applied to the load.

Now, as promised, we will consider the principle of operation of the main element of this device - the inverter.

How does an inverter work?

RF modulation can be done in three ways:

- frequency-pulse;

- phase-pulse;

- pulse width.

In practice, the latter option is used. This is due both to the simplicity of execution and the fact that PWM has a constant communication frequency, unlike the other two modulation methods. A block diagram describing the operation of the controller is shown below.

The device operation algorithm is as follows:

The master frequency generator generates a series of rectangular signals, the frequency of which corresponds to the reference one. Based on this signal, U P of a sawtooth shape is formed, which is fed to the input of the comparator K PWM. The second input of this device is supplied with the signal U US coming from the control amplifier. The signal generated by this amplifier corresponds to the proportional difference between U P (reference voltage) and U PC (control signal from the feedback circuit). That is, the control signal U US, in fact, is a mismatch voltage with a level that depends both on the current on the load and on the voltage on it (U OUT).

This implementation method allows you to organize a closed circuit that allows you to control the output voltage, that is, in fact, we are talking about a linear-discrete functional unit. At its output, pulses are formed, with a duration depending on the difference between the reference and control signal. Based on it, a voltage is created to control the key transistor of the inverter.

The process of stabilizing the output voltage is carried out by monitoring its level, when it changes, the voltage of the regulating signal U PC changes proportionally, which leads to an increase or decrease in the duration between pulses.

As a result, there is a change in the power of the secondary circuits, which ensures the stabilization of the output voltage.

To ensure safety, galvanic isolation between the supply network and the feedback is required. As a rule, optocouplers are used for this purpose.

Strengths and weaknesses of impulse sources

If we compare analog and pulse devices of the same power, then the latter will have the following advantages:

- Small size and weight, due to the absence of a low-frequency step-down transformer and control elements that require heat dissipation using large radiators. Through the use of high-frequency signal conversion technology, it is possible to reduce the capacitance of the capacitors used in the filters, which allows the installation of smaller elements.

- More high efficiency, since the main losses are caused only by transients, while in analog circuits a lot of energy is constantly lost during electromagnetic conversion. The result speaks for itself, an increase in efficiency up to 95-98%.

- Lower cost due to the use of less powerful semiconductor elements.

- Wider input voltage range. This type of equipment is not demanding on frequency and amplitude, therefore, connection to networks of various standards is allowed.

- Availability of reliable protection against short circuit, overload and other emergency situations.

The disadvantages of impulse technology include:

The presence of RF interference, this is a consequence of the operation of the high-frequency converter. Such a factor requires the installation of a filter that suppresses interference. Unfortunately, its operation is not always efficient, which imposes some restrictions on the use of devices of this type in high-precision equipment.

Special requirements for the load, it should not be reduced or increased. As soon as the current level exceeds the upper or lower threshold, the output voltage characteristics will begin to differ significantly from the standard ones. As a rule, manufacturers (recently even Chinese) provide for such situations and install appropriate protection in their products.

Scope of application

Almost all modern electronics is powered by blocks of this type, as an example we can give:

We assemble a pulsed power supply unit with our own hands

Consider a simple power supply circuit, where the above principle of operation is applied.

Designations:

- Resistors: R1 - 100 Ohm, R2 - from 150 kOhm to 300 kOhm (selected), R3 - 1 kOhm.

- Capacitances: C1 and C2 - 0.01 uF x 630 V, C3 -22 uF x 450 V, C4 - 0.22 uF x 400 V, C5 - 6800 -15000 pF (selected), 012 uF, C6 - 10 uF x 50 V, C7 - 220 uF x 25 V, C8 - 22 uF x 25 V.

- Diodes: VD1-4 - KD258V, VD5 and VD7 - KD510A, VD6 - KS156A, VD8-11 - KD258A.

- Transistor VT1 - KT872A.

- The voltage regulator D1 is a KR142 chip with the index EH5 - EH8 (depending on the required output voltage).

- Transformer T1 - a w-shaped ferrite core with dimensions of 5x5 is used. The primary winding is wound with 600 turns of wire Ø 0.1 mm, the secondary (terminals 3-4) contains 44 turns Ø 0.25 mm, and the last - 5 turns Ø 0.1 mm.

- Fuse FU1 - 0.25A.

The setting is reduced to the selection of R2 and C5 ratings, which provide excitation of the generator at an input voltage of 185-240 V.

The switching power supply is an inverter system in which AC voltage is converted to a constant, and then pulses of increased frequency are formed from it. Such a device is quite expensive and only wealthy people can buy it. All those who do not belong to this category try to make the device with their own hands. For this you will need necessary materials and a circuit of a switching power supply 12 V 5A.

General information

Before you make a switching power supply with your own hands, you need to study in detail its design features, principle of operation, advantages and disadvantages. Using this information, you can speed up the creation process, as well as make the device better and more durable.

Components

Most often, a home-made switching power supply is manufactured according to a standard scheme using some important elements. It is used to correct the input voltage when powering LED lamps or other lighting devices. The block design includes several components:

Principle of operation

The switching power supply is simple in its operation. It can be easily understood not only by a specialist, but also by a beginner who has basic knowledge in this area. Because of this, devices are considered the most affordable and are often used to achieve various goals. They work as follows:

- The AC input voltage is converted to DC.

- Then it takes the form of a rectangular pulse of high frequency and is fed to the transformer.

- There, with the help of negative feedback, the process of voltage stabilization takes place.

Feedback can be created in one of two ways. Both of them allow you to qualitatively perform the assigned functions and avoid the occurrence of unforeseen situations. Ways to organize feedback:

- Without creating a decoupling (a resistor voltage divider is used).

- With galvanic isolation (transformer winding output or optocoupler).

Similarly, the process of maintaining the output voltage.

Advantages and disadvantages

A do-it-yourself pulsed power supply unit, like any other device, has several advantages. Thanks to them, the design is very popular and is often used in a particular field of human activity. The benefits of a power supply include the following factors:

In spite of a large number of advantages, the design has several disadvantages. They must be taken into account, as they will avoid malfunctions and reduce the risk of poor-quality operation of the device. Among the shortcomings are the following:

- The presence of difficulties in self-adjustment device parameters.

- Strong impulse noise.

- The need to supplement the circuit with power factor compensators.

- The complexity of carrying out repair and preventive work.

- Low degree of reliability.

DIY manufacturing

In order for the device to work correctly and perform the functions assigned to it, a number of rules must be observed. With their help, you can achieve the desired result and reduce the likelihood of errors.

During the manufacture of a switching power supply, one should take into account not only the advice of parts manufacturers, but also the recommendations of specialists. They will help beginners avoid most common mistakes and get the job done in the shortest amount of time. Pro Tips:

- In most cases, the power supply circuit does not require special filters and feedback.

- Of the many field effect transistors it is recommended to buy IR type parts. They withstand high temperatures well and do not collapse under prolonged exposure to heat.

- If, in a self-assembled structure, the transistors become very hot during operation, then an additional cooling device (fan) should be installed.

Necessary materials and tools

Before proceeding with the manufacture of the device, you need to prepare all the necessary materials and tools. Thanks to this, it will be possible not to be distracted during work in order to find one or another object. In the process of creating the device will need:

In addition to the constituent parts of the structure, it is necessary to prepare various tools. With their help, the device will be assembled, so they must be of high quality and convenient to use.

Required tools:

- pliers;

- screwdrivers of different sizes;

- tweezers;

- soldering equipment;

- expendable materials for soldering.

Assembly process

After all the preparatory activities have been completed, you can begin to assemble the device with your own hands. The circuit of switching power supplies is drawn up in advance. This work can be done independently or with the help of a specialist.

The first option is much cheaper, but requires the master to have knowledge in the field of electronics and a lot of time.

Step-by-step instruction:

Device testing

In order to check the assembled pulsed energy source for operability, you need to perform a few simple steps. They will help to identify various problems and errors made during the build process. Procedure:

- The first short-term inclusion of the device in the circuit is performed.

- If everything is done correctly, then the light should light up, signaling the power supply to the device.

- Then you should leave the power supply in working condition for a few minutes.

- After this time, you must turn off the device and check the temperature of all its parts. Heating one or more elements will indicate a mistake made during the assembly process.

- At the second start, the voltage value is determined. You can perform this operation using a special tester.

- A working power supply is left for about 1 hour.

- After a specified period of time, the elements are checked for the degree of heating.

- If none of the cells has become hot, then all of them are checked for high current after the power is turned off.

Safety

During the operation of the impulse unit, it is necessary to adhere to simple rules security. They will help to avoid injuries of varying severity and reduce the likelihood of an emergency. Basic Precautions:

A pulsed energy source is a useful and necessary device that can not only be bought at ready-made but also make your own. The second option is more popular, as it allows you to get a high-quality device with minimal financial and time costs.

If you follow the advice of professionals and safety regulations, you can significantly reduce the risk of injury and avoid accidents.

!

In this article, together with Roman (the author of the YouTube channel "Open Frime TV"), we will assemble a universal power supply unit based on the IR2153 chip. This is a kind of "Frankenstein", which contains best qualities from different schemes.

The Internet is full of power supply circuits on the IR2153 chip. Each of them has some positive features, but the author has not yet met a universal scheme. Therefore, it was decided to create such a scheme and show it to you. I think you can go straight to it. So, let's figure it out.

The first thing that catches your eye is the use of two high voltage capacitors instead of one for 400V. Thus we kill two birds with one stone. These capacitors can be obtained from old computer power supplies without spending money on them. The author specially made several holes in the board for different sizes of capacitors.

If the block is not available, then the prices for a pair of such capacitors are lower than for one high-voltage one. The capacitance of the capacitors is the same and should be at the rate of 1 uF per 1 W of output power. This means that for 300 watts of power output you will need a pair of 330uF capacitors.

Also, if we use this topology, there is no need for a second decoupling capacitor, which saves us space. And that is not all. The voltage of the decoupling capacitor should no longer be 600 V, but only 250 V. Now you can see the sizes of 250V and 600V capacitors.

The next feature of the circuit is the power supply for the IR2153. Everyone who built blocks on it faced unrealistic heating of the supply resistors.

Even if they are set from a break, a lot of heat is released. An ingenious solution was immediately applied, using a capacitor instead of a resistor, and this gives us the fact that there is no heating of the element by supply.

The author of this homemade product saw such a decision from Yuri, the author of the YouTube channel "Red Shade". Also, the board is equipped with protection, but in the original version of the circuit it was not.

But after tests on the layout, it turned out that there was too little space to install the transformer and therefore the circuit had to be increased by 1 cm, this gave extra space on which the author installed the protection. If it is not needed, then you can simply put jumpers instead of a shunt and do not install the components marked in red.

The protection current is regulated using this trimming resistor:

The shunt resistor values vary depending on the maximum output power. The more power, the less resistance needed. For example, for power below 150 W, 0.3 ohm resistors are needed. If the power is 300 W, then we need 0.2 Ohm resistors, well, at 500 W and above, we put resistors with a resistance of 0.1 Ohm.

This block should not be assembled with a power higher than 600 W, and you also need to say a few words about the operation of the protection. She hiccups here. The trigger frequency is 50 Hz, this is because the power is taken from the AC, therefore the latch is reset at the mains frequency.

If you need a latched option, then in this case the power supply of the IR2153 chip must be taken constant, or rather from high-voltage capacitors. The output voltage of this circuit will be taken from a full-wave rectifier.

The main diode will be a Schottky diode in the TO-247 package, choose the current for your transformer.

If there is no desire to take a large case, then in the Layout program it is easy to change it to TO-220. There is a 1000 uF capacitor at the output, it is enough for any currents, since at high frequencies the capacitance can be set less than for a 50 hertz rectifier.

It is also necessary to note such auxiliary elements as snubbers (Snubber) in the transformer piping;

smoothing capacitors;

as well as a Y-capacitor between the grounds of the high and low sides, which dampens noise on the output winding of the power supply.

There is an excellent video about these capacitors on YouTube (the author attached the link in the description under his video (link SOURCE at the end of the article)).

You can not skip the frequency-setting part of the circuit.

This is a 1 nF capacitor, the author does not advise changing its value, but he put a tuning resistor in the driving part, there were reasons for this. The first of them is the exact selection of the desired resistor, and the second is a small adjustment of the output voltage using the frequency. And now a small example, let's say you are making a transformer and you see that at a frequency of 50 kHz the output voltage is 26V, and you need 24V. By changing the frequency, you can find a value at which the output will be the required 24V. When installing this resistor, we use a multimeter. We clamp the contacts into crocodiles and rotate the resistor knob, we achieve the desired resistance.

Now you can see the 2nd breadboards on which the tests were carried out. They are very similar, but the protection board is slightly larger.

The author made mock-ups in order to order the manufacture of this board in China with peace of mind. In the description under the author's original video, you will find an archive with this board, schematic and seal. There will be two scarves and the first and second options, so you can download and repeat this project.

After ordering, the author was looking forward to the board, and now they have arrived. We open the package, the boards are packed well enough - you won’t find fault. We visually inspect them, everything seems to be fine, and immediately proceed to soldering the board.

And now she is ready. Everything looks like this. Now let's quickly go through the main elements not previously mentioned. First of all, these are fuses. There are 2 of them, on the high and low side. The author used such round ones, because their sizes are very modest.

Next we see the filter capacitors.

You can get them from an old computer power supply. The author wound the throttle on the t-9052 ring, 10 turns with a wire of 0.8 mm 2 cores, but you can use a throttle from the same computer block nutrition.

Diode bridge - any, with a current of at least 10 A.

There are also 2 resistors on the board to discharge the capacitance, one on the high side, the other on the low side.

Social movements and their types

Social movements and their types Yamabushi-ninja teachers and their practices… Yamabushi and the secret of Shugendo numerology

Yamabushi-ninja teachers and their practices… Yamabushi and the secret of Shugendo numerology Secret rite on the Templar coin

Secret rite on the Templar coin How to cook beef heart salad, step by step recipe with photo

How to cook beef heart salad, step by step recipe with photo Carbohydrate-free diet - menu for the week: recipes for weight loss

Carbohydrate-free diet - menu for the week: recipes for weight loss Dynamic gymnastics for newborns

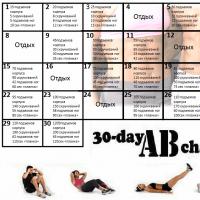

Dynamic gymnastics for newborns Exercises for the press at home

Exercises for the press at home