A house sheathed with a block house - Photo. Wooden block house: do-it-yourself house cladding Finishing the facade of the house with a pine blockhouse

Block house is one of the most popular finishing materials. The product on the front side has a convex shape that imitates a log. This lumber is considered to be one of the types of lining, since they have the same installation method - the "thorn-groove" technology.

Used in both external and interior decoration. The facade, finished with a blockhouse, looks like a house made of logs.

Characteristic

If we compare the block house with other boards for sheathing, then due to the arcuate profile, it has a large width. In terms of other parameters, it is similar to clapboard and imitation timber:

| Parameter | Characteristic |

|---|---|

| Material (raw material breed) | Spruce, pine, larch |

| Thickness | 22 - 42 mm |

| Length | 2 - 6 m |

| Width | 90 - 195 mm |

| Compound | tenon groove |

| Humidity | 10-12% |

After manufacturing, it is thoroughly dried in a drying chamber, then it is processed.

Block house in construction

In general, there are two types of block house - wide and narrow.

1. Wide - for exterior decoration - houses, cottages, baths. The house will look like it was built from a log.

2. Narrow - used in interior decoration. This is the decoration of such premises as country houses, cafe in a certain style. Also, this lumber is used for finishing saunas, gazebos and verandas.

It is interesting that the blockhouse can be painted in any color, to create an interesting, unusual interior. It is also possible to tint varnish.

Block house: price per m 2

Depending on your construction and finishing tasks, we may buy block house different sizes in any quantities.

The price of a product depends on its size. The larger the size, the greater the thickness of the lumber. And the greater the thickness, the higher the cost.

But there are other characteristics that affect the price - the type of wood, grade. Cheaper from pine and spruce, and if you want high quality, it will be more expensive - then you need to choose from larch or cedar.

Sold by square meters or cubes. In our company, the price of a block house is below the average on the market, as we work without intermediaries.

| Blockhouse size | Category | Quantity in m3, pcs. | Price rub./m 2 |

|---|---|---|---|

| Block house price Moscow | |||

| Block house 28×140×6000 | BUT | 5 | 500 rubles / m 2 |

| Block house 36×140×6000 | BUT | 3 | 590 rub./m 2 |

| Block house 36×190×6000 | BUT | 3 | 600 rubles / m 2 |

| Block house 45×190×6000 | BUT | 2 | 790 rub./m 2 |

| Block house 45×240×6000 | BUT | 2 | 790 rub./m 2 |

Material Features

Let's take a closer look at what the price depends on. Of course, from the type of wood that is used in the production of this material. The quality of processing and the quality of the finished material also affect the cost, in another way we call it a category. We sell several categories of blockhouses that meet recognized European standards.

- Category A - we allow the presence of knots, resin pockets (no more than 2), as well as through cracks - all this for every 1.5 meters,

- Category AB - knots (light, dark), cracks, cores are possible, but there should be no rot and through cracks - comparison on more than 50% of the material,

- Category C - in this option, we allow the presence of knots (the so-called live or dead), wane (this is part of the side surface of the log from which the lumber was made), it is possible to change the color of the board, as well as other points.

You can buy a block house from us inexpensively of any category.

Benefits of a block house

- Universal material for finishing.

Can be used for both exterior and interior decoration. Also suitable for finishing concrete bases, wooden, brick. - Lightweight, easy-to-use material, which provides ease of installation and is suitable for finishing surfaces of rooms.

It differs from other lumber for finishing in that it is very convenient to work with it in reality. The thorn-groove system makes installation easy, and the lightness of the material makes it possible to carry out work quickly and efficiently. In addition, under the blockhouse it is possible to lay any materials for thermal insulation. - Durability in use.

The service life of the product is affected by the humidity index. According to our standards, it does not exceed 10-12%. What gives such an indicator? The product will not crack, dry out under the influence of high and low temperatures, as well as their sudden changes. Withstands quite strong mechanical loads. The processing of the material makes it possible to be sure of the reliability of protection against insects and other environmental factors. - In addition to the beautiful unusual interior you get the scent of wood in your home.

Environmentally friendly, does not give any fumes and odors. On the contrary, the aroma of wood is natural. Deformations are excluded. - The only lumber that repeats the surface of the log.

The high demand for a blockhouse is not accidental, it is a worthy and high-quality lumber. At the same time, it is economical in comparison with a solid log, but it repeats its appearance very naturally. Fasteners are not visible, so the surface looks very natural. - Coniferous resin gives good natural waterproofing.

How to buy a block house?

You can buy lumber of the size and category you need by placing an order by phone. We sell wholesale or retail, delivery across Moscow or area is possible. We guarantee that the material will be all high quality, guaranteed to last a long time. We work without intermediaries, so we are responsible for each completed order. If you have any additional questions, please call us. We work every day, without days off. You can see the material at the warehouse in Moscow. In the contact section, we have indicated in detail the address, how to find us.

Block house - modern finishing lumber for external and internal wall decoration, imitating rounded logs. It is a panel of natural wood and is made from logs along with lining. Cutting a log using the square in a circle technology makes it possible to obtain four rounded blanks for panels, and boards or timber are produced from the remaining part with a rectangular section. This manufacturing method is suitable for industrial production of a diverse range of products in large volumes. A small batch of products is obtained from edged board, rounding its profile with milling machine. High-quality convenient docking, like that of the lining, is provided with a tenon-groove fastening. When assembled, the panels give the impression of a real log wall. They can be used for exterior and internal walls living quarters, cafes, country houses, loggias, baths, trading floors. This type of surface design saves time and money on plastering it.

Varieties of panels

Products are produced in three grades, and are also classified according to the type of raw material and size. Products of grade "A" may have a knot on the front side and no more than two shallow cracks per 1.5 m of length. Grade “B” is allowed to have 4 knots and one spot of a contrasting color. Wood grade "C" can have up to 5% of the surface with defects. Panels are made of coniferous and deciduous wood. The most common products are made of pine and larch. Their light wood has a beautiful texture. This material is easy to process, it can be tinted in any color. For external wall cladding, larch panels are more often used, since it is not subject to decay, is not afraid of temperature changes and is not affected by insects. Of hardwoods, most often produce products from alder, aspen, linden. Customers can choose the width of the product, which is from 90 to 180 mm. The standard panel lengths are 3 and 6 m. The thickness and radius of the arc are also different. Larger boards are best used for exterior walls or spacious rooms. For small rooms fit more flat options, which will create a spectacular relief surface without significant damage to space. It should be borne in mind that the panels are laid on the crate, which also reduces the footage.

Panel Benefits

The advantages of this type of panels are obvious. They are made from environmentally friendly natural raw materials. Walls with such finishes "breathe". The material is beautiful and durable. Coniferous varieties timber are quite affordable. Thanks to the antiseptic treatment, the material is not affected by fungus and mold. One of the most important points is that these products undergo high-quality drying and their moisture content is below 15%. This prevents the occurrence of deformation, cracking, twisting, reduces the weight of the boards. The material is lightweight and extremely easy to assemble. The tongue-and-groove fastening system ensures good fixation in conditions of optimal wood moisture. The disadvantages of wood are well known to everyone. First of all, it is low moisture resistance and all the problems associated with it. If there is a large difference between the temperature of the wall and the air, condensation may form under the panels.

Panels of this kind allow you to recreate an eco-friendly design in an already built house or in a standard apartment. They will fill the space with the aromas of wood, especially if they are made of coniferous species, and the owners will not have problems with cracking the material, draft, docking, sealing cracks, as happens with real logs.

A block house is a "new generation" in the world of profiled wall eco-panels, which are an unusual high-quality imitation of a rounded (milled) log, after installation of which a feeling of full presence in a wooden house is created in a living room.

To buy a block house in Moscow at a uniquely low price - CALL! Block house price per m 2 in Moscow varies from time to time; details can be obtained from our operators.

Based on the results of numerous studies for this type of building materials, our specialists have developed best dimensions in thickness and width, which is universal and is intended for further facing work both inside and outside your premises.

Block house siding is used for interior wall or ceiling cladding. Wherein:

- there should be a small air gap between the wall and the siding;

- wooden lath, intended for fastening, are attached to the walls every 50 cm (between them it is necessary to lay a heat or sound insulating layer, for example, mineral wool);

- profile boards are attached to mounting rails using special fasteners - metal brackets;

- before installing the products on the walls or ceiling, the boards must be pulled out of the plastic packaging and left to stand for several days in warm room;

- after installation work, it is necessary to paint the narrow block house for additional protection with a colored or colorless water-based varnish.

If you have a question, you can ask it right now on the site! We will be very pleased to answer and discuss with you all the details of construction!

Lumber is shipped by road and rail across Russia and for export. Registration of customs and other documents. Extensive experience in working with Central Asia (Kazakhstan, Uzbekistan, Tajikistan, Turkmenistan, Kyrgyzstan), Europe (the Baltic States, Germany, Poland, Hungary, Slovakia, etc.).

You can buy a block house with delivery in Russia right now. Discounts are possible depending on the volume of purchased products.

Send a request or ask a question about buying a block house:

Your request will be sent to our staff, who will promptly contact you by phone or e-mail. For a quick response, please fill out the form on the website.

A little about us:

"site" - an organization whose key area of activity is the sale of lumber. The organization was founded in 2010. The site company has its own production facilities for the production of high-class sawn timber. There are production warehouses in Moscow and Arkhangelsk.

Highly qualified employees of the company with high quality and well-established technologies provide services for timber harvesting, production and sale of lumber.

For all the time of work in the lumber market, the "site" has acquired a number of competitive advantages aimed at making cooperation with us the most convenient for our customers. Today we are developing dynamically, our production capabilities are expanding and the range of lumber offered is expanding.

All of us in childhood read Russian folk tales and watched their adaptations. And, of course, each of us has a memory bright pictures Russian tower and royal chambers. Yes, it was precisely such wooden buildings that ancient Russian architects created. And only thanks to them now almost everyone dreams of such a fabulous tower. With the advent of modern world the latest technologies wood processing, it became possible and accessible to everyone. And it is not necessary to rebuild the house, it is enough to use a block house for the exterior decoration of the house, and then your building will be filled with a fabulous Russian spirit.

It should be noted that the cladding of the facades with a block house not only resembles Russian buildings, but also goes well with modern ones. finishing materials. Combination with stone, brick or siding will create an original exterior for your home.

Block house- This is an imitation of a rounded log, equipped with a thorn-groove lock. For the manufacture of the block house are used tree species, whose characteristics are different high density and strength. Buy block house for exterior finish cheap in Moscow - not easy, but possible. This opportunity is offered to you by our company.

Photo 1. Finishing block house

There are several types of block house for exterior decoration. Of course, the most common is wood. Since it is environmentally friendly, and most close to the texture of a natural log plane.

Photo 2. Block house mounted on the facade

Sheathing with a block house is made according to a simple technology, which can be divided into several stages:

- Choice of panel size. course for facade works massive boards are suitable, for example, 190x36 or 140x28 mm. The length varies from 2 to 6 m. Using such a block house for exterior decoration, its price will be higher than on smaller panels. Of course, it is up to you to choose, but according to the rules of perception and indicators of practicality, it is recommended to use wider and thicker panels for decorating a house with a block house from the outside. At this stage, one should not forget about the grade of the block house. We have two varieties in the catalog: - narrow panels made from the top of a log. They will look great in interior decoration. AB - massive and wide boards, made mainly of pine. They are perfect for facade work.

- Painting and processing of panels. Experienced craftsmen recommend tinting and processing the block house before installation in order to have access to the end parts of the board, and to reliably protect the wooden structure from the external aggressive environment. We have professional equipment, which will help you to make the painting perfect, with even layers.

- Cleaning and leveling the wall under the block house. It is necessary to clean the walls of dirt, old paint, flying plaster, etc. until the surface is completely clean and even. If necessary, the walls are aligned.

- Sheathing with vapor barrier and waterproofing. Vapor barrier protects against condensate, which collects from the meeting of "opposite" temperatures, and waterproofing - from external atmospheric moisture.

- Sheath fastening. For the crate, you will need a reliable timber with a size of 40x40 mm. The size of the lathing bars is calculated depending on the thickness of the future thermal insulation. The crate is attached perpendicular to the future block house in increments of 50 cm.

- Installation of vapor barrier is carried out by laying the material in the gaps of the crate.

- Then comes the second layer of waterproofing. It can be fixed with a construction stapler.

- After that, another layer of the crate is mounted to the main layer, and subsequently to it - the panels of the block house.

- Block house for exterior decoration is laid from the bottom up, leaving small indents along the edges. The first board is leveled and set with the spike up. For finishing corners and window openings, additional wooden extensions are used. Turning to us, you will be pleasantly surprised by the price of exterior decoration with a block house by experienced craftsmen.

- Fasteners for solid boards, which are used in facade cladding, must be chosen reliable. We use special screws with Essve Corrseal 4.8x75 anti-corrosion coating

Photo 3. One of the stages of installation of a block house

Company " LesoBirzha" will help you realize all your planned projects. We have presented high-quality materials from Arkhangelsk wood, which you can order inexpensively at the specified contacts.

Understand what the cost of the panels depends on, make a purchase and pay for the order only after delivery. Also in our online store you can find out about all categories of block house.

21438 0

Block house is one of the many types of lumber used for sheathing exterior and interior walls. In appearance, it imitates a natural log, the connection is made in a tongue/groove.

Depending on the quality of the wood, it is divided into several varieties.

| Variety | Short description |

|---|---|

| Signs of diseases and malformations of wood are not allowed, healthy knots can have a diameter of not more than 15 mm, the number is not more than 1 piece / m. n. Rotten knots are prohibited. Cracks can only be at the ends. |

| There can be up to 2 healthy knots Ø 20 mm per linear meter, on the front side there can be shallow cracks no more than 30 mm long. Wormholes no more than 3 pcs. for the entire length of the board. |

| Light knots are allowed without restrictions on the number and size, dead knots are only not falling out. On the surface there may be narrow cracks up to 50 mm long. Wood may have blue spots and other natural malformations. |

Due to the fact that the assessment of the quality of a block house largely depends on subjective factors, manufacturers often offer mixed varieties in one batch. In such cases, lumber is designated AB or BC. A block house is made from several types of wood, the features of lumber have a great impact on the cost.

Larch is used to finish the most prestigious houses, often used when lining baths. The most common are softwood sawn timber. The price, taking into account the type and quality of wood, ranges from 400–1600 rubles/m3.

There is no single size standard, each manufacturer works according to its own specifications, which depend on the capabilities of its equipment. The main requirement during the selection is to buy materials from only one manufacturer.

Before starting the installation, it is recommended to hold the material a little, if you plan to sheathe the inner surfaces of the walls, then let it lie unpacked in the house for several days. The block house for exterior walls also needs to be unpacked and folded in a dark place.

The block house is installed only horizontally, in connection with this, the crate is made vertical. For fixing boards, several types of hardware are used.

You can fix the block house both in the spike and in the front surface. The second method is rarely used - it worsens significantly appearance, the imitation of a real timber is of poor quality.

Prices for a wooden block house

Wooden block house

Installation of a wooden block house with insulation

The most common cladding option for the facade walls of a building. It allows not only to significantly improve the appearance of the building, but also to increase its heat saving performance to the regulatory standards. Sheathing is used both during new construction and in the repair of old buildings. The relatively low weight of the structure does not require complex measures to increase the bearing characteristics of the foundation, the technology can be used on all types of walls: brick, foam concrete, wood, etc.

Step 1. Purchase materials. If you have big house, then it is recommended to buy a wide block house, it looks great on it. Accordingly, for small buildings, buy narrow lumber, due to this, the dimensions visually increase. Calculate the area of the walls, during the purchase, make a small margin of up to 5-7%.

Important. Remember that the block house has two widths: common and usable. Usable width does not include tenon dimensions.

For the crate under the insulation, bars are needed, the width should be the same as the thickness of the insulation.

It is better to insulate the wall with pressed or rolled mineral wool. The use of foam plastic is undesirable and is allowed only as a last resort during the sheathing of various outbuildings. The thickness of the insulation is at least 10 cm, otherwise its effectiveness will be insufficient.

Prices for mineral wool

The slats of the main crate should also be of the same height. The block house is fixed on a counter-lattice, slats with dimensions of 20 × 30 mm are suitable for it. For example, consider a house with wooden walls, we will fasten the elements with self-tapping screws or nails of the appropriate length. To fix the block house, small finishing studs about 2 cm long are also used. Finishing studs differ from ordinary ones in a small cap and the presence of an anti-corrosion coating. There are options for making finishing nails from stainless alloys.

Mineral wool must be protected from evaporation of the building (if the walls are wooden), for this, vapor barrier non-woven materials are used.

Step 2 Soak lumber with antiseptics.

If you want to additionally paint the boards, then it is better to do this even before the start of wall upholstery. Sometimes the corners and slopes of the house are sheathed with boards of a darker color - before starting work, they should also be painted.

Use only high-quality paints or wood varnishes for outdoor use. It takes a very long time to repaint buildings, it takes a lot of time to remove the old layer. It is much more profitable to immediately buy, albeit expensive, but high-quality materials.

The block house should be processed three times. Prime the first time, paint the second time and finish the third time after installation. The lacquered block house looks very nice, it is better to use these materials.

Step 3 Cover the wall with vapor barrier. The material is sold in rolls. Start fixing it from the bottom up, overlapping at least 10 cm. You can fix it with a stapler. Be sure to seal the seams with special or ordinary tape. Make sure that there are no wrinkles or sags on the surface.

Practical advice. If you are not sure about the weather, then do not sheathe the whole house at once, but in turn each wall. This will reduce the risk of surfaces getting wet during sheathing.

Step 4 Install the frame under the insulation. There are some nuances here. The fact is that in the future, a counter-lattice will be fixed to this main crate directly under the block house. This means that the distance between the vertical posts should not exceed 60 cm, consider this parameter when choosing a heater. Most manufacturers produce products with such dimensions.

Pay great attention to the frame near the window and doorways. In these places, you will have to fix the extra slats under the insulation with the expectation that they will come in handy during the creation of the counter-lattice.

The first frame must be precisely aligned vertically. How it's done?

- Check the position of the walls with a plumb line. Unscrupulous builders can overwhelm them a little, if such a problem is found, then the plane will have to be leveled due to the lining under the rails. Or vice versa, in some places, squeeze them into a cone.

- At a distance of no more than 10 cm from the corners, fix the extreme rails, once again check their horizontal position. We recommend using a plumb line, the level at a high height of the house can make noticeable errors. Pull the ropes between them at the top and bottom.

- Make a markup for the rest of the rails. We have already mentioned that you need to take into account the dimensions of the glass wool and the allowable distances for fastening the block house.

- Fix the slats to the wall one by one. First, put it against the wall, if necessary - reduce the thickness. Next, you should proceed depending on the wall, everything is fine - fix it, there are problems - align the slats with linings. According to this algorithm, collect the entire crate under the insulation.

The frame is easier to install on metal corners, special slots allow you to accurately install the elements vertically.

Step 5 Replace glass wool. It should fit snugly between the laths of the crate, gaps are strictly not allowed. And not only due to the fact that the heat saving indicator will decrease. Where there is no glass wool, condensation will constantly accumulate. Consequently - wooden structures wet, even the most effective impregnations will not be able to protect them from damage for a long time. In addition, moisture will get on the glass wool and significantly increase the thermal conductivity.

For fastening glass wool, you need to use special booster cuffs (rondos). They have a wide polyethylene cuff and a self-tapping screw.

You can find recommendations to cover the front surface with a windscreen. Although none of the true professionals can say why this is done and what a positive effect will result in the end. From wind and rain, the insulation perfectly protects the sheathing with a block house. But if you wish, buy a windscreen and fasten it with a stapler to the rails.

This completes the insulation work, start sheathing the outer walls of the house. Do not postpone further work for a long time, if rains are planned, then securely cover the surfaces with plastic wrap.

Prices for different types of bars

Block house wall cladding

Step 1. On the first main batten, install the slats of the counter batten. It is now easy to do this, all the laths of the crate are in the right position. We have already mentioned that slats 20x30 mm can be used for the counter-lattice.

Step 2 Beat off the line of the first row. This is very important point made mistakes are difficult to correct. Especially if you will do the corners in a professional way. On methods of finishing interior and outside corners we'll cover it a bit below. The line can be made with a laser level. If not, then use ordinary water. It is much easier to work with it, in addition, the possibility of error is completely eliminated.

Step 3 Cut off the protruding ends of the crate along the bottom line.

Important. When you seal the lower and upper parts of the cladding, be sure to leave air for natural ventilation of the structure.

Step 4 Place the first board exactly along the line and secure it with studs. They will have to be driven in from both sides of the block house. At the bottom into the groove, and at the top into the spike. Carnations drive in at an angle, work carefully, do not allow the spike or groove to be chipped.

Step 5 After the first row is done, continue laying in the same way. Often the length of the wall exceeds the length of the block house. How to deal with joints? There are two options.

- Simplest. Place the joints on the same vertical line. At the ends of the board, nails can be driven into the front surface, their length should be 2 cm longer than the thickness of the boards. Later, a vertical board about 20 mm thick and 10–15 cm wide is nailed to the junction. It can be varnished or painted in a dark color. All corners of the building, platbands and slopes are finished with the same boards. Advantages: work is simplified and accelerated. There is no need to precisely adjust each joint, measure the dimensions of individual pieces of the block house. Disadvantages - it is clear that the work was done by a fake master.

- Difficult way. Joints should not be placed on the same line, but in a checkerboard pattern. The house becomes much more attractive, but it will also take longer to work: all sections must be perfectly fitted, each piece of the block house is individually adjusted in length.

House after block house installation

Now we should talk separately about the decoration of external and internal corners. There are also two methods here. Simple - the block house is fitted end-to-end, and the corners are clogged with ordinary planed boards. Works quickly, no skill required. The disadvantage is that it is not very beautiful, and to put it mildly, the facade walls only remotely resemble natural timber. The question is, why buy an expensive block house in order to eventually spoil the appearance of the building? We will tell you how real professional builders do it.

Interior corner finishing

We immediately warn you that you will have to lose a lot of time, but the result will please you.

Step 1. Install the boards on one wall of the inner corner along the entire height. Constantly monitor their position. If in simple ways horizontal alignment is allowed due to a slight displacement of the block house at the junctions, this option requires special accuracy in all work.

Step 2 Make a template. It is made from pieces of thin plywood, fiberboard or thick cardboard. The length of the template should be equal to the width of the block house, the width of the template should be within 10 cm. Cut a rectangle of the correct shape from a piece, put it at the end of two boards so that the line of symmetry of the template is located exactly at the junction of the boards. With a pencil on the surface, draw the profiles of the front parts of the block house. The end result should look something like the letter M.

Step 3 Turn the board over with the convex face down, place the template on the flat back side and copy the outline. Make sure that the sharp ledge is located exactly in the middle of the board.

Step 4 Electric jigsaw carefully cut out the outline. The front side of the block house is semicircular, it is quite difficult to keep the board stationary. You can make a special fixture with a recess along the radius of the board, if you don’t want to do this, then use various improvised materials to fix the position of the board.

Step 5 Attach the board to the place of the upcoming joint. It will not be possible to adjust the connection the first time, you will have to do it in two stages. If you cut the profile for the template correctly, then the gaps in the connection will not exceed 3–4 mm, but they should also be eliminated.

Step 6 Insert the prepared workpiece and spike, slide it all the way into the sheathed wall surface.

Step 7 With a sharpened pencil, draw a new, more precise outline. To do this, the pencil must be pressed along the entire length to the front of the profile and slowly lead it along the surface of two block houses. The tip of the pencil at this time should draw a line on the workpiece. Due to such a simple operation, it will be possible to take accurate measurements to fit the inner corner.

Step 8 Again, lay the board on a flat place, hold it steady. Using an electric surface grinder, remove excess parts from the end of the block house. Working with a grinder is easy, but noisy and dusty.

Remove the burrs from the front side with a fine sandpaper. You can take the exact dimensions of the boards along the length only after fitting the connection in the corner, do not forget about it. Practice shows that already at the 5th or 6th connection, experience appears, work goes faster. It must be remembered that for such sheathing, you should buy materials from well-known manufacturers. The thickness, radius of the bulge and the width of the boards must be the same. Unfortunately, not all woodworking companies can meet high quality requirements.

That's all, we assure you that the connection will be perfect. Of course, it will take much more time.

Important. Be sure to re-impregnate the ends of the fitted boards with antiseptics. This applies to all cuts, not just corners.

Finishing of external corners

The prerequisites for sheathing the house are the same - the perfect accuracy of the position of the rows. If for the inner corners of the plane the connection of the block house on the adjacent walls occurs along the line of symmetry of the board, then the position of the locks for the outer ones should be at the same level.

The connection is made by sawing the ends at an angle of 45°. Depending on the parameters of the facade walls, this angle may slightly increase or decrease. There is no need to measure very precisely. There may be a gap on the back at the junction, the main thing is that it should not be on the front. Further, everything is unchanged - remove the burrs and protect the ends from rot.

Corners docked at 45°

We recommend this professional method of joining in the corners to be used when decorating the interior of the house. If outside it is allowed to use multi-colored boards to close simple joints, then designers prohibit their use during interior decoration.

Social movements and their types

Social movements and their types Yamabushi-ninja teachers and their practices… Yamabushi and the secret of Shugendo numerology

Yamabushi-ninja teachers and their practices… Yamabushi and the secret of Shugendo numerology Secret rite on the Templar coin

Secret rite on the Templar coin How to cook beef heart salad, step by step recipe with photo

How to cook beef heart salad, step by step recipe with photo Carbohydrate-free diet - menu for the week: recipes for weight loss

Carbohydrate-free diet - menu for the week: recipes for weight loss Dynamic gymnastics for newborns

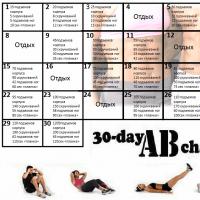

Dynamic gymnastics for newborns Exercises for the press at home

Exercises for the press at home