Characteristics, dimensions and prices of profiled sheet c8. Characteristics and dimensions of C8 corrugated board, types of polymer coatings, prices and fastening rules Working part of C8 corrugated board

Galvanized corrugated board under the brand name C8-150 is a universal type of profile, often actively used in the field of modern construction. This type of profiled sheet is highly economical in consumption, it can be used for wall cladding, erection of fences, installation of suspended structures. The product can be used even for the installation of roof coverings with an angle of 40 degrees, even despite its low load-bearing capacity.

Production of C8 corrugated board: main dimensions and quality requirements for finished products

Galvanized c8 has the following description: the sheet is prepared by cold rolling, which is reflected in the requirements of the state standard under the number 24045-94, as well as specifications 1122-079-02494680-01. To create products, thin-sheet steel with a thickness of 0.5-0.7 mm is used.

Cold-woven steel in coils (grade 01, 220-350) according to the state standard R 52246-2004, or sheets with zinc coating to protect the surface according to the state standard 14918 can act as the feedstock. In addition to the above, a polymer coating is distinguished (GOST R 52146-2004 ), paintwork (GOST 30246).

The production line for the creation of C8 includes the following types of equipment:

- an uncoiler that unwinds a roll of sheet steel;

- a forming machine (called a rolling mill);

- guillotine type scissors;

- receiving device;

- oil station;

- remote control equipped with a remote control system.

The process is fully automated at every stage of production. Shift personnel simply control the progress of the work, and also monitor the correct functioning of the equipment.

As for the dimensions of the product, it has the following features:

- the presence of corrugations on the surface, having the form of a trapezoid with a height of 8 mm, the width of the base will be 62.5 mm, and the distance between each next corrugation is 52.5 mm;

- modern rolling mills producing products of this type create finished sheets with dimensions from 0.5 to 12 meters.

The state standard regulates such requirements for the characteristics of the metal profile:

- Roof profile sheet: the front side may have scuffs small size that do not affect the integrity of the coating necessary to protect it from external influences.

- Deviations in height about a millimeter, width about 8 mm, length about a millimeter are allowed.

- The crescent should be more than a millimeter for every meter of length, provided that the length of the sheet does not exceed 6 meters, and also no more than 1.5 mm when the sheet is longer than 6 meters.

- An eight-millimeter sheet should have a waviness of flat sections of more than 1.5 mm and equal to 3 mm on the bends of the edge part.

The consumer must understand how the concept of professional sheet C8-1150-0.5 is deciphered:

- C - wall;

- 8 - the height of the trapezoidal part of the profile, measured in millimeters;

- 1150 - working width, which may be useful;

- 0.5 is the thickness of the metal of the original form from rolled steel.

Application of corrugated board C8

S8 1150 corrugated board can be used for different purposes. In load-bearing structures, this type of material is not used, because it is not able to withstand the proper level of load. In principle, this factor depends on the height of the wave, for this design it is the smallest, it is 8 mm.

This type of product is used for the following purposes:

- facade finishing;

- production of sandwich panels;

- creation of auxiliary buildings (warehouses, sheds);

- construction of fences, but only in those regions where there are no strong wind loads.

To solve the above problems, it is better to choose a product with a polymer coating. It is distinguished by high aesthetic appearance, high service life, especially in comparison with the galvanized variety.

Important! Polyester is able to extend the service life of the original material up to 30 years, approximately 2 times.

When a pural-coated product is used, its service life can reach 50 years. And plastisol makes it possible to obtain high resistance to mechanical damage, since this coating has a layer thickness of 200 microns.

This raw material is excellent for use in areas where hail often falls, dust storms occur, and other negative atmospheric phenomena that can damage the metal surface.

Polymeric coating of the PVDF type protects the raw material less from mechanical damage, but is chemically resistant to acids, alkalis, and other active components. Therefore, this material is used in regions where there are large industrial, chemical production, near busy highways, on the banks of salty reservoirs.

Important! The C8 design can be double sided allowing excellent performance from both coatings, greatly extending blade life.

Profiled S-8 - specifications and dimensions

Profiled s8 technical characteristics has the following:

- light weight facilitates installation work;

- weight of one square meter is 5.57 kg;

- cutting can have sheet sizes of 0.5-12 meters;

- the use of roofing material reduces the number of assembly joints to a minimum.

The calculation of the required volume of purchase is calculated by the formula: the mass of the sheet is multiplied by its area (useful width), then multiplied by the total number of coatings.

Dimensional characteristics of the material

Profile sheet C8 is prepared from rolled different thickness, however, the final dimensions, which are calculated during layout, do not change.

The total overall width of the C8 profiled sheet is 1187 mm. The useful width is 1150 mm. The length is 12 meters, after which the canvas is cut, with the help of which ready-made batches are formed, or left unchanged (in case the customer needs non-standard sizes). Finished products can have a length starting from 50 cm.

Lot weight calculation

Having specified the size of the profiled sheet, you need to understand the features of calculating the weight of the batch.

- When a large batch is shipped, the count is not based on the number of sheets. Precise parameters can be useful when you need to figure out the cross section rafter legs, or the thickness of the roof lathing.

- When the thickness of the original canvas is taken as a basis, a running meter may have a specific weight, depending on a number of parameters.

- Thickness of 0.4 mm with a linear meter weight of 4450 g, is the weight of a usable area meter of 3870 g.

- Thickness 0.45 has corresponding parameters 4930 and 4290 gr.

- An indicator of 0.5 mm is 5420 and 4720 gr.

- Indicator 0.55 - 5910 and 5150 gr.

- The thickest type is 0.6 mm - 6410 and 5570 mm.

Types of polymer coating applied to the material

Having specified the existing dimensions of the profiled sheet, it is necessary to consider the types of coatings offered by manufacturers applied to this sheet. It has aesthetic purposes, in addition, it enhances the protective properties of the product.

The material involves a double-sided application of a protective layer. The most commonly used types are:

- polyester: otherwise called polyester enamel. This type of processing is considered the most common, cheap, it is suitable for use in different climatic conditions. An important feature is the lack of fading in direct sunlight, as well as durability, providing a long service life in environmentally friendly areas. Such indicators are achieved on the condition that no one walks along the profile and seeks to scratch it;

- plastisol, polyvinyl chloride: here the layer is from 175 to 100 microns. Such a thick coating allows you to get the most reliable anti-corrosion protection. However, PVC fiber is not very resistant to heat, and fades quickly when exposed to the sun. Therefore, in the southern regions, its use is considered inappropriate;

- Pural is considered the most modern look spraying. Its thickness is fifty microns, which allows it to show high resistance to various influences. The coating does not lose its existing flexibility even when it is exposed to low temperatures, and also withstands heating up to 120 degrees.

Application area

Different sizes of corrugated board allow the use of products for the following construction purposes:

- roof, in the presence of a large slope angle, with a crate without creating gaps;

- facing the exterior of the facade of small buildings, for example, garages, pavilions, change houses);

- arrangement of frame walls;

- cladding of walls built of brick, aerated concrete blocks, concrete;

- creation of fences for the purpose of noise absorption along busy highways;

- creation of structures with multiple layers (sandwich panels) when it is necessary to equip an insulated roof;

- construction of partitions in industrial premises;

- arrangement of fireproof cut-off partitions (in order to achieve a high level of fire protection).

This kind of profile canvas allows you to speed up the construction works, as well as reduce financial expenses for installation. At the same time, there are no particular difficulties, and there is no need to attract highly qualified workers, use an expensive tool.

Profiled sheet marking

To deal with the labeling of paintings, you need to clarify the decoding of the designations used:

- C - scope - walls;

- number 8 - shows the height of the trapezoid, measured in millimeters;

- the width of the C8 corrugated board is 1150 mm, this indicator indicates the difference between the parameters of a full-size sheet minus the level of overlap that overlaps the corrugation of the adjacent row;

- a distance of 62.5 mm is maintained between the waves;

- the corrugation has a base width of 52.5 mm.

The profiled sheet is cut with a range of 0.5 - 12 meters. This makes it easy to bridge wide areas without the need for joints for mounting. Thanks to this technique, a highly reliable, hermetic coating is obtained. The light weight of this design makes it convenient to perform any installation work. The large thickness of the metal leads to an increase in the cost of any work.

One of the most common types of corrugated board is S8-1150 corrugated board.

C8 profiled sheeting is made from galvanized cold-rolled sheet steel and is characterized by a sheet thickness of 0.35-0.7mm and a profile height of 8mm. The metal sheet itself is protected by a zinc layer, and the zinc can be protected by a polymer layer.

Polyester is used as a protective polymer coating: glossy or matte. The choice of polyester colors is possible from a standard set or according to the RAL scale. This makes it possible to find options for shades that fit into the surrounding landscape and blend harmoniously with design solution houses or cottages.

For the manufacture of unpainted profiled sheet C8, galvanized sheet metal is used.

The affordability of corrugated board of this brand is explained by the low cost of production - the height of the profile is small, therefore, a smaller amount of metal is consumed per 1 m2 of material with the same sheet thickness as products of other brands.

The figure below shows the dimensions of the c8 corrugated board for the fence

C8 corrugated board is used for the construction of fences, as well as for cladding the facades of non-residential construction projects. A beautiful coating of durable polymer and the correct geometry of the wave provide the fence with an aesthetic appearance, protected by a solid fence made of profiled sheet, the territory is inaccessible to prying eyes.

C8 corrugated board is one of the most popular types of profiled sheet, the areas of use of which are practically unlimited in modern construction.

The main advantage of this brand of corrugated board is its low cost, which makes it difficult to find more economical material for wall cladding, fence construction and false ceiling installation.

Despite the low bearing capacity of the C8 profiled sheet, it is nevertheless often used for roofing installation - for example, for pitched roofs, the angle of inclination of which is more than 30-40 degrees.

Technical characteristics of corrugated board C8

The production of C8 grade corrugated board is carried out by the method of cold rolling of thin sheet steel with a thickness of 0.5-0.7 mm in accordance with the requirements of GOST 24045-94 and TU 1122-079-02494680-01.

As for other varieties of this building and finishing material, for the production of C8 corrugated board, both rolled cold-rolled steel (grades 01, 220-350 according to GOST R 52246-2004), galvanized according to GOST 14918, and galvanized steel with a polymer coating (GOST R 52146-2003) or steel with paintwork(GOST 30246).

The surface of the C8 corrugated board is a corrugated relief with 8 mm high trapezoids (which is reflected in the brand name), while the width of the base of the trapezoid is 62.5 mm, and the distance between two adjacent corrugations is 52.5 mm. In addition to the abbreviated nomenclature of corrugated board (C8), according to the requirements of GOST 24045-94, there is also an expanded marking of the profiled sheet.

For example, the designation “profiled sheet S-8-1150-0.5” means that we are talking about wall corrugated board with a trapezoid height of 8 mm, having a useful (working) profile width of 1150 mm and made of steel with a thickness of 0.5 mm. The working width of the corrugated board is determined as the difference between the total width and the value of the longitudinal overlap of the corrugated board with adjacent sheets.

The width and thickness of the steel used for the production of corrugated board are the determining factors for its weight, which is considered very small for this brand. For example, the mass of one square meter of profiled sheet C8-1150-0.6 is only 5.57 kg.

The dependence of the mass of one square meter of C8 corrugated board on its characteristics is presented in the following table:

|

Profiled brand |

Weight 1 p/m (1x1.25 m), kg |

Weight of 1 m² profiled sheet, kg |

This table is convenient to use, for example, when it is necessary to calculate the weight of a batch of purchased material: for this, the mass of a running or square meter of corrugated board should simply be multiplied by the length of a sheet 1 or 1.25 meters wide, or by the area of a sheet of arbitrary width, and then by the total number of sheets .

|

Profiled brand |

Sectional area, sq.cm |

Reference values per 1 m width |

Workpiece width, mm |

|

|

Moment of inertia |

Moment of resistance |

|||

But the most basic technical characteristic of C8 corrugated board is the ability to withstand loads of a certain magnitude. We have already mentioned that, although in most cases this brand of profiled sheet is used for the construction of fences, one should not neglect such an economical option for roofing.

The following table shows the maximum permissible uniformly distributed loads calculated for the most common profiled sheet support schemes - single-span, two-span, three-span and four-span.

|

Thickness of steel profiled sheetC8 |

Span, m |

||||

|

1 span |

2 spans |

3 spans |

4 spans |

||

The angle of inclination of the roof for cladding with corrugated board C8 must be at least 15 degrees, while the profiled sheet is mounted on a solid cladding.

We offer you to see how the production of C8 corrugated board is carried out at our enterprise:

Application of corrugated board C8

Profiled sheet grade C8 is usually not used to create load-bearing structures due to the high windage and the smallest of all possible wavelengths, which causes its limited ability to withstand the load. However, nevertheless, its scope is quite wide and includes the following areas:

- Finishing the facades of buildings

- Production of sandwich panels

- Construction of auxiliary facilities on summer cottages(sheds, warehouses, showers, utility rooms)

- Construction of fences in areas where strong and gusty winds are not typical

In particular, polymer-coated C8 profiled sheeting is relevant for solving these problems, since it is not only more aesthetically pleasing, but also has a long, trouble-free service life compared to the galvanized version. For example, if the service life of a C8 profiled sheet with a galvanized coating is approximately 10-15 years, then the polyester applied to its surface extends the service life to 2-3 decades. The use of pural as a coating can extend the life of C8 corrugated board even up to half a century.

You can learn more information about C8 corrugated board from the following video:

The popularity of the S-8 profiled sheet, the characteristics of which allow it to be widely used in construction, is explained by the cost-effectiveness and versatility of the material. It is used as a facing material, for the manufacture of barriers, fences. The sheet is valued for its strength, lightness, good rust protection and affordable cost.

Profiled C8, intended for roofing, may have roughness on the front side, abrasions and damage that do not have a big effect on the integrity of the protective coating.

The characteristics and dimensions of the material may be different, have slight deviations from the norm (width ± 8 mm, height ± 1 mm and sheet length ± 10 mm).

For the fence, C8 corrugated board should have a crescent shape of no more than 1 mm per 1 m of the length of the profile, while the length of the sheet should be up to 6 m. And with a length of more than 6 m - no more than 1.5 mm.

For the fence, C8 corrugated board should have a crescent shape of no more than 1 mm per 1 m of the length of the profile, while the length of the sheet should be up to 6 m. And with a length of more than 6 m - no more than 1.5 mm.

The waviness of the sheet on flat surfaces should be over 1.5 mm and 3 mm on the bends of its edge.

Galvanized profiled sheet C8 is marked in accordance with the requirements of GOST. concept "Professional sheet S-8−1150−0.5" can be deciphered as follows:

- C - wall;

- 8 (mm) - profile trapezium height;

- 1 150 - working width;

- 0.5 is the thickness of the metal of the rolled steel billet.

Professional sheet C8 is widely used in construction. Products differ in profile dimensions, appearance, external coating and other technical characteristics.

Rolled sheet C8 has a wide color scheme. When choosing a material, you can ask the sales assistant to show the catalog and clarify the color. Brown gamma has various shades. When mounting the sheet on a fence or on a roof, dark and neutral colors are chosen.

Advantages of a profile sheet

The advantages of C8 corrugated board include:

- light weight;

- ease of installation;

- wide area applications.

Due to its low weight, installation on a wooden frame is possible. Can be fastened with rivets, screws, self-tapping screws. Comfortable and simple circuit mounts. C8 corrugated board has fire-resistant properties, it is often used for lining the walls of a hot shop or chimney.

Sheet profile C8 is trapezoidal corrugated surface with a corrugation height of 8 mm and a trapezoid base of 62.5 mm. The distance between the waves is 52.5 mm, its width working surface equals the total width of the product without overlap on adjacent sheets.

If the total width is 1,200 mm, then the working part will be 1,150 mm, and the distance between adjacent corrugations (wave pitch) will be 115 mm.

If the total width is 1,200 mm, then the working part will be 1,150 mm, and the distance between adjacent corrugations (wave pitch) will be 115 mm.

The thickness of the profile sheet ranges from 0.4 mm to 0.6 mm.

Dimensions of profiled sheet cutting C8 can be from 0.5 to 12 m, which allows you to make fewer joints when installing roofing.

Depending on the thickness of the sheet, the weight of 1 m² of the product can reach 5.6 kg.

There are two types of C8 corrugated board: galvanized and polymer-coated, which performs a decorative role and serves as protection for the product. Thanks to the painting of the profile surface, you can choose any shade of the material.

Working width of corrugated board C8 is the area of the sheet without overlap.

The volume of purchase can be determined based on the area of the material.

Despite the complex manufacturing technology, cheap analogues of corrugated board have not yet been invented. A big plus is the ease of transportation and installation.

Before buying a profile, you need to ask the seller for a quality certificate, which can be viewed in the catalog without visiting the warehouse. Having carefully studied all the technical parameters of the purchased material, it can be argued that it is used not only for wall covering, but also for many other construction purposes.

, then you need to take into account the bearing capacity of the sheet. It may not cope with weight loads, bend under the weight of snow.

, then you need to take into account the bearing capacity of the sheet. It may not cope with weight loads, bend under the weight of snow.

It is necessary to cover the roof with a profiled sheet on structures whose slope does not exceed 45 °, otherwise the structure may collapse, which will entail high costs for the restoration of the roof. To increase the bearing capacity of the sheets, it is necessary to strengthen the crate and truss structure.

Profiled S-8 is recommended to choose polymer coated. Such a sheet is more durable and has an excellent appearance, giving individuality to the building. With the help of polyester, the service life is extended up to 30 years. If a pural is applied to the surface of the sheet, then the service life can last up to 50 years. Polymer-coated profiled sheet S-8 is more practical and has high wear resistance during operation. It can be used in regions with heavy rainfall and strong winds.

Decking is considered a demanded material used in various areas of construction. It is most often used to form roofing or fences. Often high-quality wall coverings are made from it. It is presented in different types, differing in profile, dimensions and technical characteristics. They can have a polymer coating, due to which not only their parameters are improved, but also painted in different colors and shades. An interesting choice is C8 corrugated board, created from high-quality galvanized steel.

Material production technology

Profiled sheet C8 is intended in most cases for the formation of wall coverings. For its manufacture, the method of cold rolling is used. For the process, high-quality galvanized steel blanks are used.

Important! To obtain really high-quality, durable and reliable material, large and proven manufacturers use GOST 24045-94.

For the production of corrugated board of this brand, a special production line is used. It includes several elements, each of which has its own purpose:

- a decoiler designed to insert a roll of steel, represented by a thin sheet, into it, and the raw material of grade 220 is considered optimal;

- the forming apparatus makes it possible to obtain the necessary structure, dimensions and relief from steel blanks;

- guillotine shears provide cutting of large sheets into small elements with the required dimensions;

- the paint shop is intended for painting finished sheets, and for this, high-quality polymer compositions are used, due to which an attractive material is obtained that is resistant to corrosion and other factors.

Important! Due to the use of modern production equipment, it is possible to achieve absolute automation of the process, therefore, the absence of defects and the high quality of the finished material are guaranteed.

C8 corrugated board can be made from various raw materials:

- cold-rolled steel, presented in the form of rolls, and it is allowed to choose a material grade from 220 to 350, and a protective zinc coating is additionally applied to the sheets;

- galvanized steel with a polymer coating on one or both sides.

Important! It is officially considered that this is a wall profile, therefore the profile has a small height of only 8 mm, and it also has a small bearing capacity, but this material is allowed to be used to create a roof covering, but only with advance careful and correct design of the truss structure.

Quality standards

C8 corrugated board is considered a popular material, as it has an acceptable cost, attractive appearance and good quality. Most often it is purchased for summer cottages or vegetable gardens, as interesting and high-quality wall coverings or fences are obtained from it.

Modern manufacturers are trying to produce really high-quality materials, devoid of any marriage or other shortcomings, but buyers often have to deal with fakes. In order not to buy low-quality or completely dangerous material for use, it is recommended to follow certain rules, as well as to know what errors may be on high-quality sheets:

- on the outside of the sheets, on which there is a decorative polymer coating, minor abrasions are allowed, but the integrity of this layer cannot be violated, as this will certainly lead to the onset of the corrosion process;

- profile height should be equal to 8 mm, and deviations from given parameter allowed only by 0.1 mm;

- the width of the sheet may differ from the declared parameters by only 0.8 mm, and the length cannot be more or less than 10 mm;

- the material of this grade cannot have waviness exceeding 1.5 mm at various flat places, and at different edges or folds this parameter cannot exceed 3 mm.

Important! Before directly purchasing the material, it is recommended that each buyer carefully study the accompanying documentation issued by the manufacturer, as well as check the markings that provide the necessary information about the profiled sheet.

It is advisable to make sure that the selected material exactly meets all the requirements of GOST. If there is a letter “C” in the abbreviation, then it means that the material is wall, but the number 8 indicates that the profile has a height of 8 mm.

Material technical parameters

Before buying this, it is important to study its parameters. Specifications C8 corrugated board is considered the most important to consider, as it makes it possible to understand in what conditions it is allowed to use the created coating, what is the service life of the material, and also what impacts it can easily cope with.

Important! This material belongs to the economy class, therefore it has an affordable cost and is often chosen by many owners of private or summer cottages.

All parameters of the C8 profiled sheet indicate that it should be used to form a wall covering or other similar structure. This is due to the low profile height, low weight, and the absence of any additional stiffening ribs. Its design is such that it can easily cope with dynamic wind loads.

The main parameters of the material include:

- the metal profile is intended for the formation of wall coverings;

- the height of its profile is 8 mm;

- its shape is represented by a trapezoid, in which the base is slightly wider than the top;

- the working width of the C8 profiled sheet is 1150 mm;

- the thickness of steel blanks that are used in the production process varies from 0.4 to 0.6 mm;

- weight of corrugated board C8 per 1 sq. m. reaches 5.6 kg / m2;

- length varies from 0.5 to 15 m;

- the optimal step for cutting sheets is 50 cm.

Important! A small mass of profiled sheet C8 is considered to be indisputable advantage, since this parameter greatly simplifies the procedure for transporting and installing sheets, so it is not required to spend a lot of money and effort on these processes.

Due to the fact that the profiled sheet has a speaking name, it is enough to simply determine what height the profile has, as well as what purpose this material is intended for. The greater the height of the profile, the higher the bearing capacity of the coating.

Social movements and their types

Social movements and their types Yamabushi-ninja teachers and their practices… Yamabushi and the secret of Shugendo numerology

Yamabushi-ninja teachers and their practices… Yamabushi and the secret of Shugendo numerology Secret rite on the Templar coin

Secret rite on the Templar coin How to cook beef heart salad, step by step recipe with photo

How to cook beef heart salad, step by step recipe with photo Carbohydrate-free diet - menu for the week: recipes for weight loss

Carbohydrate-free diet - menu for the week: recipes for weight loss Dynamic gymnastics for newborns

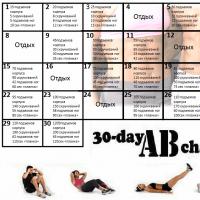

Dynamic gymnastics for newborns Exercises for the press at home

Exercises for the press at home