Do-it-yourself spiral staircase to the attic. Do-it-yourself attic stairs with a hatch - how to make it easier. Profile pipe ladder

Many owners of private houses, in order to get into the attic, use an attached or stationary ladder installed on the street. Of course, for security reasons, such a ladder is fully justified, and will never become superfluous. However, for use in the winter, and especially in cases where a utility room or even a full-fledged living space is equipped in the attic, it will be much more convenient to provide for the possibility of entering directly from the house.

But it often happens that the stationary design of the internal staircase requires a very large area, and therefore cannot be put into practice in a small house. And even if the area is sufficient, it hardly makes sense to “squander” it if the attic is not used constantly, but only from time to time. What to do? But there is a way out - this is a “transformer” structure, which is removed as unnecessary into the attic floor. So, the topic of this publication: do-it-yourself folding ladder to the attic - the most optimal an option for both large and small private houses.

General information about folding stairs to the attic

What do they say about the advantages and disadvantages of such structures?

Folding stairs, if their design is thought out, is safe and easy to use - very convenient. However, they also have their drawbacks, which you also need to know about in advance, proceeding to similar reconstruction of one of the rooms of the house.

So to advantages of folding ladder construction include the following points that will greatly facilitate the operation of the attic:

- The ability to safely enter the attic at any time, regardless of the season or current weather conditions.

- The compactness and ease of operation of a high-quality design allows all residents of the house to cope with the unfolding and folding of the stairs, since no great physical effort is foreseen.

- The folded design does not take up usable space both in the living room and in the attic. If there is no need, the ladder is most often removed into the opening of the attic floor, saving free space.

- The hatch in the ceiling, which is necessary to accommodate the staircase structure, with a high-quality finish from below, does not spoil the appearance of the ceiling surface at all.

- When purchasing a finished design, it is quite possible to choose a model with an electric drive. This, of course, is extremely convenient, since if necessary, bring the ladder into working condition or remove it - you don’t have to make any effort at all. However, to install this version of the stairs, you will have to invite a specialist. Yes, and there are such kits - quite a lot.

The disadvantages of installing this design in the attic floor include the following:

- Be that as it may, folding stairs, unlike, do not always meet the criteria maximum convenience in terms of the steepness of the rise, the number and size of the steps.

- Based on the first point, the second suggests itself - the ascent and descent of such stair structures still requires care and special precautions. This will especially apply to children, older people or people with some physical disabilities.

- No matter how tightly the hatch enters the opening cut under the stairs, it will still deprive the ceiling of tightness. Therefore, in order to prevent cold air from entering the living rooms from above (or, conversely, hot air during the summer heat), the attic room will have to be insulated. This, of course, leads to additional costs. True, you can consider this problem from the other side. If it is planned to equip a utility or residential space in the attic, then in it, one way or another, it is necessary to carry out thermal insulation work on the roof slopes and perform flooring with

Criteria that a folding ladder must meet

In order for the staircase to be used for a long time and be safe for its owners, it must meet certain criteria, regardless of its design and material of manufacture.

Prices for folding stairs

folding ladder

These product features include:

- The strength of the material of manufacture, all fasteners and connecting nodes.

- Lightweight construction. This is important not only for the ease of use of the stairs, but also so that when folded it does not give excessive additional load on the attic floor.

- Ease of operation - with the process of bringing the ladder into " combat readiness”and its folding should be handled by any adult member of the family.

- Hinged or other components and devices that fold the ladder should function easily, without even the slightest difficulty.

- If the staircase will be used constantly, due to the fact that it is supposed to place a frequently used room in the attic, then it is better to make the product yourself or order good master to be sure of its reliability, and therefore, of your personal safety.

Why is it better to make a ladder yourself?

Today, a considerable number of models from different manufacturers are presented on the construction market. They are usually quite convenient to use, but if they are not exploited very intensively. If the ladder is unfolded and folded several times a day, then a more durable mechanism will be required, since the proposed products may not withstand such intensive use due to the fact that each of them is designed for a certain “motor resource”.

Finished stairs almost always have a small angle of inclination relative to the vertical. That is, the manufacturer makes them too steep, so it is inconvenient to climb and descend on them, especially holding a certain load in one hand, and securing yourself with the other. The reasons, as you can see, are very significant, and therefore many homeowners prefer not to buy ready-made kits, but to mount them on their own according to their own drawings, calculating them for their own weight and equipping them with durable mechanisms.

The main types of folding stairs to the attic

Before purchasing or making a folding ladder, you need to decide on its design, since there are several of them. So, the following types of ladders have been developed and manufactured on an industrial scale and on their own: retractable, folding spring, telescopic, folding with a simplified design, simple folding compact ladders.

Retractable or retractable ladder

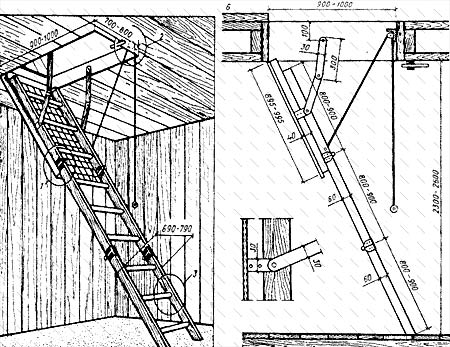

The retractable staircase design can consist of two or three sections, depending on the height of the attic floor.

- First option

The upper section of the structure, with the help of a metal flange, is fixed on a transverse board, forming an opening box, equipped in the attic floor. Each of the sections, when the ladder is folded, slides into the part located above, as if on a rail. The sections of the stairs assembled together are transferred to a horizontal position and stacked on the floors of the attic. The hatch in this design can be fixed to the uppermost and shortest section, and in this case, when the hatch is closed, the entire staircase will be hidden. The hatch can also be closed separately, that is, first a ladder is sent to the attic, and then the hatch is closed.

1 - Attic floor beam.

2 - Screw flange.

3 - Retractable sections of the stairs.

4 - Rotary mechanism.

This illustration shows how a retractable ladder works. However, it is quite obvious that it can only be suitable if the attic is not used as a living space and is visited quite rarely, and not constantly.

- Second option

Another version of a sliding ladder, consisting of two sections - a short one, fixed on the manhole cover, and a long one, which, after unfolding, will rest against the floor surface of the room .. This option is also suitable for an attic used as a utility room. So, if you need to get to the attic, the hatch opens, and with it the stairs also fall. Then, from the folded structure, its lower part is extended until it stops on the floor.

When unfolding the stairs, the passage to the attic is freed. In ready-made, factory-made versions of sliding or folding stairs, the hatch is equipped with its own thermal insulation. And a sealant is installed along the contour of the opening so that warm air from the room does not leave through the gaps around the ceiling hatch. One should not forget about similar methods of minimizing heat losses when making stairs on their own.

Folding ladder

A folding ladder differs from a sliding one in that its sections do not slide into one another, but are folded together. This is ensured by special hinged mechanisms installed in the span junctions. The addition of the structure occurs "according to the accordion principle." Top section fixed on the hatch panelGerman folding handrails are also installed, which make it easier to climb to the top floor or attic.

The advantage of this design is that it does not take up more space than an opening in the ceiling, as it is completely hidden in a special box that frames the opening hatch. Therefore, having climbed to the attic, the stairs can be raised so that it does not interfere on the lower floor, and in order not to accidentally step on the hatch, being at the top, you can provide an upper solid hatch or an opening fencing.

Prices for stairs

ladder

The diagram above shows finished construction, one of those that are offered in specialized stores. However, focusing on it, it is quite possible to make a staircase on your own. How to do this will be discussed in detail in the instruction table below.

The diagram shows a box framing the opening. It is equipped with an elastic rubber gasket, thanks to which the hatch tightly, without gaps, will be pressed against the inner walls of the box.

The hatch of the shown design is made of chipboard, but by making such a ladder on your own, it is quite possible to replace it with boards, assembling a shield from them. For this purpose, it is recommended to choose a light, porous wood, such as linden or pine.

Wooden steps are equipped with an anti-slip coating. With the independent manufacture of stairs, it is possible to cut recesses on the steps with the help of a milling cutter, in the form of two or three grooves running along the entire length of their surface.

The steps are fixed in the side posts of the ladder sections using a dovetail connection, which is more secure than straight spikes.

Metal scissor stairs

Another version of the folding structure is the so-called scissor ladder, which is made of metal. As a rule, aluminum is used for this purpose, due to its low weight. The design has proven itself quite well, especially for those cases when the attic has to be visited quite often.

The advantages of this type of stairs include its versatility. This means that the modules that form the steps can be stretched "to the full" if the room has a high ceiling, or compressed to a certain level, of course. The main thing is that the lower step rests on the floor. Thus, the staircase is designed for a certain, and very considerable range of ceiling heights.

In the folded state, such a ladder is quite compact and does not go beyond the box intended for it, which is installed in the thickness of the attic floor.

The disadvantage of such a scissor design can be considered that for its installation and addition it is necessary to make certain efforts. This may present a problem for some residents of the house who do not have the necessary physical data.

It is quite difficult to make such a staircase on your own, since the most precise fitting of metal parts is required, and the design itself is replete with swivel joints. Yes, this is unprofitable, since the material for self-manufacturing will probably cost no less than the cost of the finished product.

Every home needs more space. When all the rooms are functionally occupied, the owner of the dwelling begins to look for free space outside them. This is where a folding ladder to the attic will come in handy. It will allow to equip a workshop, a children's room, put a billiard table, a bar counter there. Preoccupied with this idea, the owner begins to wonder whether to buy ladder structure ready-made or make your own.

An example of a folding metal ladder to the attic

But first, he must familiarize himself with its various options in order to choose the right one.

Depending on the place of installation, attic entrances are internal and external. Folding attic stairs outside, as a rule, are not installed. And the stationary structure installed outside is not entirely comfortable in winter, but it does not occupy a single meter of usable living space; Another option is insulated.

To prevent metal parts from being exposed to the damaging effects of precipitation, they are most often made of galvanized metal or painted with special paint.

Attic stairs are made of wood and metal. Both options are fairly durable devices. However, they can creak or rumble, although not everyone finds these sounds annoying. In addition, they can be eliminated or at least muffled by using different rugs or anti-slip pads. Wood and metal are often combined to create very attractive multi-stage structures.

Stationary

A monolithic structure with steps, usually made of wood, with handrails and railings is installed on. With the active daily use of the attic, it is complemented by a door. You can’t do without it when it is equipped as a comfortable room in the house as or adults, a rest room, a workshop that you have to visit daily.

A variant of the device of a stationary wooden staircase to the attic

For a stationary device, a separate territory is sometimes assigned - a stairwell.

Folding loft ladders

You can also buy them or make your own. They are installed in rooms with limited space, when it is impossible to build a monolithic staircase structure. Folding attic stairs have several varieties, but they are not bulky, but light, but the weight does not limit strength, because hardwood and aluminum are used for manufacturing.

scissor

Such a retractable structure is attached to the hatch cover, and unfolds to the very floor according to the principle of a tram current collector or an accordion. This design is only metal, so over time, without proper lubrication, it begins to creak. It is used in a private dwelling with non-intensive use of the attic.

Scheme of operation of the scissor ladder to the attic

The load capacity is small, but the weight of an adult can withstand reliably.

telescopic

A ladder of several sections that are packed into one another is called telescopic. Usually it is made of aluminum, so it is light and strong. But such folding stairs to the attic are not very popular with consumers. More often they are applied to construction work in the form of ladders. When packed, they are so compact that they can be transported in the trunk of a car.

folding

This is one of the varieties of folding ladder devices, usually consisting of two sections. The first is rigidly attached to the base of the hatch. From below, a second one is attached to it with special hinges that allow it to be folded forward.

Drawing with the dimensions of the folding ladder

When there is no need for it, and the entrance to the attic is closed, then hinged design located in the attic. If you open it, it leans back and falls to the floor.

retractable

With a lack of space, a retractable staircase to the attic is installed. It can be made of wood or metal. Extends from the hatch, which is opened manually or by means of an electric drive.

The main requirements for such a design are compactness, strength, low weight. To achieve this, durable wood and light metal are combined in the manufacture.

screw

It requires more space than folding devices. May be with or without railings. It looks very light, no matter if it is made of wood or metal. original design, but the ascents and descents are difficult, and sometimes risky, especially for the inhabitants of the old house.

Such attic stairs are used in houses in which the exploitation of the attic is not so intensive. They can be arranged so that all steps are attached to a post that is in the center of the system. There are also such stair spirals, in which the steps are held by curved load-bearing bowstring beams.

Folding and can be bought without any problems at a building materials store that sells pine, oak, as well as metal, usually made of aluminum. The cheapest product made of pine, but in terms of strength is not inferior to other materials.

We should not forget that a ladder installation purchased in finished form needs proper care, which includes the treatment of wooden surfaces with fire impregnation, varnishing or paint.

Metal parts, hinges, rollers must be lubricated with machine oil.

But it is not always possible to find a suitable staircase on the market. Then the best option- do-it-yourself attic stairs, which can be made in accordance with your own wishes and tastes. How to do it? There is no shortage of relevant information on the World Wide Web today. All you need is a desire necessary materials, tools and creative enthusiasm.

Primary requirements

The attic staircase is a risk area, so it must meet the following requirements:

Stair details

The home master, who has decided to independently build a ladder structure, should familiarize himself with its components.

Structural elements of stairs to the attic floor

Then he will better understand the question of how to make the stairs to the attic in the best way.

Any attic staircase consists of details, the names of some of which may not have been previously known to the home craftsman. It would be nice to get a drawing on which they are depicted and signed.

These should include:

- Beams, which are called bowstrings and stringers;

- Railings, safety handrails;

- The edges of the steps, also having their own name: horizontal - tread, and vertical - riser;

- Flight of stairs.

Kosour

This is a solid beam in which cutouts are made for attaching steps from above, so that their ends are visible from the side. There are stair structures, in which it is one in the middle, and wooden planks are horizontally attached to it. But more often, the installation of an attic staircase for greater strength is carried out on two stringers.

Then, even visually, the whole structure looks solid, able to withstand heavy loads. The metal support is often made not in a straight line, but in a stepped shape. Making it at home is very problematic, it is easier to buy it ready-made.

bowstring

This is the name of the supporting inclined beam, and differs from the stringer one in that it hides the ends, and the steps are attached to it with the help of special grooves. Therefore, there must be two of them - on both sides staircase structure. Even a folding staircase to the attic cannot do without these beams, if it is made of wood.

With them, the stationary structure looks massive, soundly, while on the stringers it seems visually light and spacious.

Railings and handrails

It is necessary to find out if there is a difference between these concepts. A railing is a railing along the outside of a flight of stairs. From above, they are connected by handrails - this is component a fence against which they lean with their hands. Together, they ensure the safety of movement. These elements can be metal, wood, even glass. They look very attractive if they are made of stainless steel: no protective equipment is required, especially painting, and the service life is almost unlimited. But not every consumer decides to buy them because of the high price.

A variant of the device of the railing of the stairs to the attic floor

Railings need solid, reliable. If the attic stairs with a hatch, then they should end at its very base and not interfere with the functioning of its cover.

There are also some mandatory requirements for handrails:

- The width should allow a person to grab them with his hand in order to hold on tighter;

- Height - at the level of the belt of an adult, not lower;

- To avoid injury, do not sharp corners at their ends

- In appearance, they should form a single, harmonious ensemble with the entire staircase that adorns the house.

Rise and tread

The vertical part of each step is a riser. It closes the space between adjacent steps, and is also an additional support for them. Such steps are called closed, and open will be those that consist of only one horizontal plank for the feet - the so-called treads. Folding stairs to the attic are also equipped with these details.

Flight of stairs

This is an element that connects all the components into a single structure. It has a maximum of 18 steps, mounted on load-bearing beams - a bowstring or stringer. There are single-march stationary systems without turns from the floor to the entrance to the attic and multi-march systems with several spans. They must meet the same requirements that apply to all stair parts: strength, convenience, safety.

Construction of the staircase

The useful width of the march is determined by the distance from the finished wall to the inside of the handrail.

Currently, every developer is trying to make the most of the available area of his home. However, climbing into the attic without a ladder is almost impossible. Do-it-yourself attic ladder - best option for safe climbing to the attic.

The ladder to the attic can be located both indoors and outdoors. Of course, when the ladder is located inside, it is much more convenient to use it - you do not need to go out in the cold in winter or get wet in the rain in autumn.

There are several types of attic stairs, namely:

- folding;

- stationary;

- portable.

Stationary stairs with railings and wide flights are the most convenient, but their use is limited due to the impossibility of operation in small areas.

Portable ladders are used mainly as a temporary option and serve to access rooms that are rarely used. The main disadvantage of such a ladder is low security.

Folding attic stairs are the middle link between stationary and portable. In terms of convenience, they are almost as good as stationary ones, but they take up significantly less space. In terms of safety, they are significantly superior to portable designs.

The choice in favor of one or another type depends on several factors:

- the area of \u200b\u200bthe room where the staircase will be located;

- purpose of the attic;

- possible angle of inclination.

Standard sizes

There are a number of standards that an attic staircase must comply with:

- the optimal width of the march should be about 65-110 cm;

- the height should not exceed 3.5 m. This is due not only to the fact that the rigidity of the structure is significantly reduced, but also to the fact that a fall from such a height can lead to serious injury;

- the number of steps should usually not exceed 15;

- between the steps it is customary to make a distance of about 19 cm;

- the thickness of the steps is usually 18-22 mm;

- the standard tilt angle is 60-75 degrees. A small angle requires a lot of space, and a large one is dangerous during operation;

- folding ladder must withstand 150 kg load;

- steps should be installed parallel to the floor and should not be slippery.

Manufacturing process

Making attic stairs with your own hands is not at all as difficult as it might seem at first glance. Of course, you won’t achieve such beauty as industrial models, but it’s worth a try. Do-it-yourself drawings of attic stairs that you can make can simply be found on our website.

Luke - the basis of any attic stairs

You can make a hatch with your own hands using the following materials:

- bars 50 × 50 mm;

- plywood.

The order of work is as follows:

- determine the location and size of the future hatch;

Note!

7-8 mm should be added to the overall dimensions of the hatch so that the lid closes easily and without creaking.

- cut the timber into 4 parts of the required size;

- we cut grooves at the ends of the bars;

- lubricate the grooves with glue and connect the bars, reinforce the junction with self-tapping screws;

- so that the diagonal does not go away, we fasten the scarves;

- fix plywood;

- try on the hatch in the opening;

- to close the hatch well, we will cut the latch into the lid;

- to open the hatch we will use the handle, which is inserted into the hole and presses the latch.

Necessary tools and materials

For self-manufacturing stairs to the attic with your own hands, you must have the entire list:

- wood saw;

- foam gun;

- a set of screwdrivers or a screwdriver with a set of bits;

- various self-tapping screws, anchors;

- roulette;

- card loops;

- bars 20-30 mm thick.

These are just the basic tools that you will need for self-production, if you already have a ready-made attachment wooden staircase 30 cm longer than necessary to the level of the opening.

Simple design

As an example, consider how to make an attic ladder with your own hands.

The instruction will allow you to understand the principle of work:

- on the finished one-piece staircase made of wood, we fix 2 bars in width, on the lower and upper parts. Moreover, we fasten the upper bar to the hinges, and fasten the lower one rigidly;

- sawing the ladder into 2 parts. measuring 2/3 of the length. Top part will be longer, lower short;

- to stiffen diagonally, we fix 2 slats;

- we connect both parts of the stairs with loops;

- with the help of anchors we fix the upper bar under the hatch;

- so that the lower part does not open, it is fixed with a hook. The loop is located on the stringer above the cut.

- the finished staircase for the attic is pressed against the wall surface and fixed.

The main disadvantage that this design of the attic stairs has is its appearance and the fact that you can see all the fasteners and bars. However, even such a do-it-yourself ladder to the attic will greatly simplify the difficulties with climbing and descending from the attic.

Folding design on bowstrings

For the manufacture of the structure, several steps must be performed:

- divide the total height into 3 parts. The first part will correspond to the dimensions of the hatch, the second is slightly smaller, and the third will cover the remaining distance to the floor;

- we measure the angle of the hatch with the help of a bevel;

- we transfer the angle to the boards, thereby marking the steps;

- in place of the future hinge between the sections, we drill holes;

- we grind all edges;

- we cut the boards in those places where the hinges will be placed;

- cut and grind steps;

- under the steps we make small recesses in the bowstrings;

- we insert the steps into the recesses, putting them on glue and fastening them with self-tapping screws;

- connect the sections with special loops. To do this, be sure to place the sections on a flat surface;

Note!

Working at height is recommended with a partner.

This will not only help to avoid injury, but also greatly speed up the whole process!

The price of a ladder made by one's own hands is much lower than the price of a factory design, so if financial question is sharp - be sure to try to do everything yourself.

Output

Acquisition finished stairs the attic is the most simple option, however, in the presence necessary tools and initial skills is not at all difficult to do it yourself. In the presented video in this article you will find additional information on this topic.

Access to the attic (loft) requires a ladder. Since my attic room is not residential, i.e. " cold attic", then a stationary staircase was not supposed from the very beginning of construction.

However, access to the attic is necessary and this requires a hatch to the attic.

Having studied the proposals in the form of ready-made solutions in Moscow, I came to the conclusion that it is best to make a hatch to the attic with your own hands - it will be much cheaper.

A folding ladder with a hatch to the attic costs just not real money - compared to its cost price, it's just something ...

Trying to find information on the Internet, to my great surprise, it did not lead to anything - in the search results for queries:

- do-it-yourself hatch to the attic,

- do-it-yourself attic stairs, etc. opens a bunch of sites that contain almost the same article with an overview of stairs.

Or a reprint of an article published on the ForumHouse website by a user Alli58ru- "Do-it-yourself folding stairs to the attic" and the same picture is given:

I also came across one article where a man made a hatch to the attic with his own hands using barn hinges as hinges.

But this option does not suit me, like the one described in the article Alli58ru, since in these options there is a fairly large gap between the hatch cover and the box on the hinge side. Although in the version with barn loops this gap is smaller ...

I wanted to make such a hatch to the attic with a folding ladder so that:

- it was insulated (hatch thickness from 50mm,

- so that the hatch has a vestibule that would go a quarter in the hatch bun

- so that there are no gaps along the perimeter of the hatch, i.e. so that the hatch finish (in my case it will be either lining or imitation of timber) would go a little beyond the hatch on the sides.

In this case, the hatch should open normally.

To realize the normal opening of the hatch, which has a rather large thickness, you need to choose the right hinges for the hatch to the attic itself.

Alli58ru I used these loops:

By the way, on some sites they reprint the same picture with the dimensions for this loop - and the dimensions are not accurate.!

Having looked closely at the hinges on the factory attic hatches with stairs, I noticed such hinges:

Decided to experiment with them.

In theory, the following logical schemes for the operation of loops are obtained:

For samples, I collected several hinges from hardboard and wooden blocks.

Dimensions can be viewed directly on the hinges themselves.

1

In this embodiment, the manhole cover will bite right away - such a loop is not good ...

2

This is the option considered Alli58ru

3

This is the option I've settled on for now.

To test the operation of the attic hatch hinges, I whipped up an attic hatch box from a defective 90x60cm imitation timber.

The cover for the hatch was also assembled from the same imitation of a bar and fixed it on bars 30x40mm. The lid turned out to be crooked, but I didn’t care - I still had to check the operation of the hinges first.

Here is the hatch box. Inside the box, I screwed the strips that form a quarter to which the hatch cover should be pressed.

Laid the thickness of the hatch in 60mm:

I also made the hinges for this hatch from wooden blocks of this type:

I screwed these hinges to the hatch cover and to the sides of the box with self-tapping screws:

I installed the resulting test hatch to the attic on four legs 150 cm high.

View of the hatch from below. You can see the 30x40mm bars framing the hatch where you can place a heater to organize an insulated hatch to the attic.

Screwed the lock of the hatch in the closed position.

A box with a hatch to the attic is installed on legs.

Fully open sunroof:

Side view

Here you can see how far the back of the hatch recedes from the edge of the box forward when it is fully opened.

If the opening is limited in length and in the place where it will open, this must be taken into account.

Hinge with sunroof fully open

Front view

The beginning of the opening of the hatch. It can be seen that the hatch begins to open in such a way that it does not interfere with the outer skin and the box.

In this implementation, I found a problem, namely:

When opening the hatch, the hatch lining is biting against the box and the hatch does not open completely.

Perhaps this is due to the insufficient length of the levers in the hatch loop. Do not know.

The photo shows the problem area:

If the hatch lining is moved so that it is flush with the box, then the problem is solved. in this case, on the back side of the hatch (one hundred sides of the hinges), when it closes, there will still be no gap, as well as in the front, but in the area of \u200b\u200bthe hatch is fully opened, it will either be necessary to cut the frame of the hatch or somehow "play" with the loop and look for a way out. ..

While I have no solution - I had to leave the dacha.

I also figured out the moment for the attic hatch opening limiter at the desired angle.

So far I have made such a "crane":

In principle, you can make it so that it folds along the hatch box, and not on top. Until I finally decided.

In this loop, the load on the hatch that holds the weight of a person on the stairs is transferred to this node, and in the case of implementing the hinge for the hatch of the proposed Alli58ru there is a limitation in the loop itself. Those. the load is more distributed.

On the other hand, many factory attic stairs have this kind of hinges.

The next step I made this species metal loops.

It turned out this:

I will write a separate post about their manufacture a little later.

And finally, a few videos that I shot during testing:

This is the same hatch only with metal hinges (no sound):

Update:

I think that the problem with biting the outer trim of the hatch on the edge of the box can be solved precisely by lengthening the levers in the loop.

I "played" a little with the cardboard and the size of the levers in the loop and sort of found a solution.

Here's what happened:

Here I used a hatch pie like this:

- plywood 10-12mm

- on it a bar 40 mm high - then a heater there ...

- we fill the outer trim on the bar

I also immediately considered the option of using a 50mm bar instead of 40mm - it seems that it should also work as it should.

When opening the attic hatch, it turns out like this:

As can be seen from the figure, there should not be any biting between the trim and the bottom of the box. In theory for now.

It is also seen that with the hatch open, the ladder will move forward from the edge of the hatch by about 14-15 centimeters.

For small hatches, this can be critical.

Side view is like this:

And this is on cardboard:

And here I put this loop on cardboard on a sheet of paper to illustrate how the loop should behave when opened:

The new dimensions of the hinge arms are visible in the picture. It turned out that the dimensions were increased by only 10mm.

PS

But I have not yet been able to find a normal spring. Everywhere you can only buy springs 30cm long - like for doors - I don’t know if they will go for the hatch or not.

Are there any options at this moment? Are they sold somewhere?

I made new hinges from metal with slightly changed dimensions.

During testing, the outer finish of the hatch now does not touch the lower edge of the box.

Here's a video:

Drawings of the attic stairs are not particularly difficult. But a number of features for calculation and design should be taken into account. Then the resulting design will meet the basic requirements of safety and ease of movement between levels.

The name of the elements of the folding stairs to the attic

Before choosing a ladder, you should pay attention to a number of important points:

All these points will help you quickly navigate the choice of type of construction. There are the following classifications of stairs for the attic:

More common are aluminum structures. Metal and wood can be combined.

Technical requirements. Data and formulas for calculation

Attic stairs must meet the following specifications:

Ladder to the attic is easy to make. You should start with the calculations of the parameters and the drawing. To draw up a diagram not “by eye”, the following data will be required:

Schemes of folding stairs

Such designs do not require more space for arrangement, they can be organically fit into the interior or hidden in the attic. The proposed options will help to equip your home ergonomically.

Drawing No. 1

This view is a device of two folding sections.

This option is suitable for attic openings located near the wall.

When developing a drawing, the following points are taken into account:

This ladder is not particularly aesthetic, but when assembled it takes up almost no space.

Drawing No. 2

This option, like the first one, is attached to the wall, but through one bowstring. The requirements for it are somewhat different:

This staircase is a little more difficult than the previous version. But the following type of device gained great popularity.

Drawing No. 3

This type of construction, when folding and closing the hatch, is retracted into. Most convenient option, since it does not take up space in the residential part of the house. If the width for the previous design could be arbitrary, then for this type of staircase this parameter is associated with the dimensions of the opening. The main subtleties in the design and assembly:

Do-it-yourself attic stairs, the drawings of which are presented, are made simply. Some craftsmen and hinged mechanisms for the hatch do it themselves.

Social movements and their types

Social movements and their types Yamabushi-ninja teachers and their practices… Yamabushi and the secret of Shugendo numerology

Yamabushi-ninja teachers and their practices… Yamabushi and the secret of Shugendo numerology Secret rite on the Templar coin

Secret rite on the Templar coin How to cook beef heart salad, step by step recipe with photo

How to cook beef heart salad, step by step recipe with photo Carbohydrate-free diet - menu for the week: recipes for weight loss

Carbohydrate-free diet - menu for the week: recipes for weight loss Dynamic gymnastics for newborns

Dynamic gymnastics for newborns Exercises for the press at home

Exercises for the press at home