You spend a lot on heating, insulate the attic with mineral wool. Insulation of a non-residential attic of a private house Insulate the attic floor with a cold roof

Salvation from the harsh Russian climate for many people is warm dwelling. It is not always enough to insulate the foundation, basement and walls: if the roof of the house is cold, you need to properly insulate the attic. This procedure has a number of features that must be considered before starting work. Otherwise, all the means and efforts will be wasted, the result will not justify the efforts made.

Peculiarities

Regardless of the type of building and its number of storeys, work with floors must be carried out according to strict rules.

- It is required to provide a margin of safety covering its own weight and design load.

- Under full design load, no deformation or deflection should occur.

- It is necessary to ensure the level of sound insulation prescribed by the regulations or special recommendations for building projects.

- It is supposed to maintain the fire resistance limit established by regulatory documents.

When insulating attics, any of these requirements may be violated due to ignorance, carelessness or deviation from standard technology. The rest of the nuances already belong to one group of floors.

Types of floors

From the attic, the main part of the house can be separated by attic and interfloor floors. The difference is that in the first case top part buildings are not heated, and in the second it is turned into a residential attic.

By design, the bearing segments of the floors are beamed and beamless. The former are formed by beams and filling, the latter are homogeneous, made in the form of slabs or panels.

Beam ceilings in a private house they are created in such a way that the main elements are at the same distance. chief structural material is a tree. Metal and reinforced concrete are practically not used.

Wooden blocks are quite light, but have a serious disadvantage - the maximum length is limited. In the interfloor version, they can be used if the span is not longer than 5 m. For an unused attic, you can increase the allowable value by 1 m.

Sometimes you need to make the span even bigger. Then you need to apply metal constructions. In the summer country house this solution is not used for obvious reasons. Most often, the flooring that is placed on top of the beams simultaneously acts as a ceiling (for the lower floor) and as a floor (for an attic or a simple attic).

In addition to the beams and flooring, they also install a run-up and a layer of insulation.

Houses resembling a rectangle in shape overlap parallel to the shortest wall. Strictly defined distance and section of the structure help to avoid deflection of beams in a loaded state. These indicators are interrelated.

Under a cold roof, it is required to lay beams with a gap greater than under the attic(this is due to the difference in load). Regardless of the specific option, it is necessary to insulate the ceiling in such a way as to guarantee the protection of the rafters from water ingress. On top of the protective layer, it is required to create a vapor-tight material.

materials

Proper insulation always starts with drying the attic by opening the windows. It is important to take into account the nuance: they work with the floor of the attic, and not with the ceiling of living rooms.

The range of heaters is large, in any hardware store you can find a lot of varieties. They are divided into three main groups - bulk, rolled and made in the form of plates. Each of the varieties is suitable for solving strictly defined tasks.

Bulk products optimally combined with wooden beam ceilings, helping them to "breathe". But mounting polystyrene foam is not very convenient.

Roll options are highly environmentally friendly.

Plate, despite its heaviness, it is well combined with concrete ceilings (for example, foam concrete), which themselves differ in density.

Insulation from the inside of the room (from the side of the ceiling) is rarely practiced in a cold attic, which is associated with several problems:

- lowering the level of the room;

- invariable violation of the already created finish and the need for its repair;

- different environmental and sanitary safety of heat-insulating materials.

Installation of thermal protection from inside the room can be done cheaply or with maintaining the proper level of comfort. We have to abandon mineral wool, keep a gap from thermal insulation to exterior finish (this is necessary for ventilation). Internal insulation is the best option heat preservation when arranging a false ceiling.

If the insulation is carried out with extruded polyurethane foam or expanded polystyrene, pre-installation of the crate is necessary, on top of which drywall is fixed. The thickness of the timber is selected 0.2 - 0.3 cm more than that of the insulating layer itself, the installation step is 0.1 - 0.2 cm narrower than the foam. It is recommended to use mineral wool only in the most extreme cases: it is highly toxic.

Much better ecowool, obtained from cellulose with the addition of substances reducing the risk of ignition. Such material perfectly restrains extraneous sounds. If you use reeds, you can not be afraid of fire.

It's time to figure out what features each of the coating groups has, and what other materials belong to them.

Bulk

The use of bulk type of heaters began in ancient times. Their main options are:

- expanded clay;

- sawdust;

- linen fibers;

- reed stems.

Each variety has its own differences and performance characteristics. Ease of obtaining, availability and almost zero price of sawdust have a downside (they have a number of serious drawbacks).

Mice easily settle in sawdust. This can be prevented by adding slaked lime and carbide. To keep warm, a layer of 10 - 20 mm is enough, but this impressive quality is crossed out by high combustibility.

Expanded clay is compatible with wooden and concrete floors: when it is covered, a full-fledged floor covering is created. The thickness of the layer ranges from 20 to 25 mm, under it there should be a concrete screed of about 5 mm.

in rolls

The undoubted advantages of any roll insulation are the convenience of its use and the ease of accurate installation of blocks. This allows you to do the work yourself.

In most cases, despite all its shortcomings, mineral wool is used. Before laying the material, you will have to make a high-quality vapor barrier with glued seams for greater tightness.

If algae is safe, you can't say that about glass wool. Water resistance is devalued by a serious inconvenience during work: you have to protect yourself from small, prickly and dangerous fibers. After some time, the material becomes caked and largely loses its positive qualities..

In the form of mats and plates

Slab insulation is distinguished by reliable blocking of air intake. It should not be used in houses natural material . More often in the manufacture of plates using expanded polystyrene, reeds, ecowool. seaweed.

The technology provides for installation strictly on flat surfaces with preliminary placement of vapor barrier films. Even the smallest irregularities need to be eliminated. It is easy to make a full-fledged floor above the stove, which allows you to create residential attics even from the initially coldest attics.

sprayable

A real technological breakthrough was the use of sprayed heaters. It is important to carefully approach their selection and take into account all the features, including the advantages and disadvantages of the coating being created.

The main positive aspects when using penoizol for insulation are:

- exceptionally high level of thermal protection;

- excellent absorption of extraneous sounds;

- solid vapor permeability (absence of condensate);

- the possibility of application in places that are inaccessible or inaccessible for other insulation products;

- ease of installation over all existing building materials.

The last point does not mean that careful surface preparation can be neglected.

Only careful degreasing of the base guarantees decent adhesion and stable performance of the material of its main function.

Regardless of the option chosen preparatory work more or less the same.

Preparation for work

Before work begins in the attic wooden house you need to check the joints of the ceilings. It is important to consider: there should be no gaps and cracks on the base. Any gap is blocked using lime mortar and tow.. Frame elements are impregnated with antiseptic compounds and flame retardants.

If ventilation products have not been created before, the time has come to make them.

If you plan to make insulation according to a roll scheme, you need to equip the floor slabs with logs (special bars). To fix them, screws for concrete or dowels can be used.

When it is planned to turn the attic into an attic, the heating pipes must be insulated. The following types of technical wool are best suited for them:

- glass;

- mineral;

- slag;

- stone;

- basalt.

For your information: the cheapest options should be used in areas with mild winters. If the frosts are hard enough, you will have to buy a more expensive and reliable insulation.

It is necessary to clean the surface as much as possible from the slightest traces of dust and other contaminants. All plots heating systems overlap with protective materials at least twice.

Features of the combination of heat and vapor barrier

Vapor barrier in combination with thermal insulation is always made extremely tight. The rolls are overlapped up to 0.2 m, glued. A prerequisite is the overlap on the wall, followed by pressing with plaster. Preference should be given to materials that have a foil surface that effectively reflects infrared rays.

Floor cleaning

This moment cannot be underestimated. It is worth using the house for several months without visiting the cold attic, as an amazing amount of dust, dirt, and cobwebs accumulate there. It is necessary to remove all things, even the smallest and most insignificant, remove all debris before starting work.

Warming

It will not be possible to disassemble the laying technology of all possible coatings. You need to stop at one option. For example, such as mineral mats.

First you need to remove the board run and attach a vapor barrier layer to the beams. For fastening membrane films, it is worth using staples 14 - 16 mm, driven into the base with a stapler. The gaps of the structures are filled with mats, which are fixed with the help of transverse rails with a section of 20x50 mm. These slats will help hold the extra vapor barrier.

Then you need to make a boardwalk with your own hands and equip the ceiling. Materials that form a kind of shell (for example, penofol) are better suited to protect ventilation pipes from the cold. It is better than polyethylene foam, it does not so much absorb dust, which is inevitably present in any room.

If the ventilation pipe passes through the main wall, it must be placed in a heat insulating sleeve. When ventilation duct goes through the room, you need to lay the material where freezing begins to be felt. Ventilation protection is done before covering the rest of the building.

A typical pie involves stacking:

- solid board 25x100, 30x100 mm;

- a two-layer membrane that protects against wind;

- timber 5x5 cm across the overlapping beams (the distance between the blocks should be 59 cm);

- beams based on a double beam 5x20 cm;

- new timber 5x5 cm;

- vapor barrier (best with aluminum foil);

- boards on the overlaps of the vapor barrier.

In attics, one has to deal with the problem of a freezing wall or even several walls at the same time. Only the simultaneous insulation of the structure both outside and inside the building will help eliminate this trouble. Minimum Thickness the inner layer should be from 20 cm. This is the rare case when there is nothing better than a simple mineral wool.

Foreword. The attic protects the house from cold, moisture and the scorching rays of the sun. In addition, the heat from the house leaves it through the attic to a greater extent. Therefore, the question is “what is the best way to insulate the attic in a private house?” - the owner decides in the first place. We will also consider the issue of attic insulation in a private house with our own hands in this article and show a video lesson from Isover.

How to insulate the attic floor of a private house

Often the attic, due to its disorder, remains unused. But it is from the attic that you can make an excellent rest room or bedroom, if you correctly approach the choice of insulation and equip the attic for living quarters yourself. These issues can be resolved independently, or you can invite a team of builders who, for the insulation of the attic of a wooden house, as well as ventilation devices attic floor can offer several options.

Gables and attic floors are insulated using various types of insulation. But more often, three types of insulation are used for attic thermal insulation. Consider the advantages and disadvantages of each:

– Organic derivatives (polyurethane foam);

– Heaters based on mineral wool;

- Bulk heaters such as expanded clay.

We analyze the better to insulate the attic of a private house

Insulation with polyurethane foam (PPU) attic

Polyurethane foam is the most popular insulation for roofs, gables and attic floors. Among its advantages are called low thermal conductivity with a small thickness. Its use is especially relevant here, because. the load on the supporting structures is reduced and a significant part of your attic space is saved.

PPU is applied by spraying, which creates a monolithic structure that perfectly protects housing from cold and moisture, as well as preventing heat from escaping from the house. Polyurethane foam does not absorb moisture and is resistant to mold, prevents the penetration of insects and rodents.

Insulation of the attic with polyurethane foam enhances the strength of the entire roof due to the creation of a single sprayed structure, without cracks and cracks. Also, PPU has high strength and wear resistance - the service life exceeds 30-40 years. PPU does not require the creation of moisture and vapor barrier, since it itself perfectly performs the functions of its moisture protection.

Warming with mineral wool of the floor of the house

Mineral wool is suitable for insulating attic floors and attic floors, as well as for insulating walls and roofs. However, mineral wool insulation implies the creation of external wind and moisture protection with the help of waterproofing. Mineral wool has a structure that perfectly transmits steam, therefore, from the side of the room, the insulation must be protected with hydro-, vapor barrier.

Mineral wool is laid in the form of rolls or mats. Usually mineral wool is laid between the rafters, and on the floor - between the lags. Inevitably, seams form between fragments of material and structures. They must be carefully foamed and sealed with adhesive tape. For middle lane Russia requires a layer of insulation of at least 200 mm.

Mineral wool has a considerable weight - the load on the supporting pillars and floors is significantly increased. Therefore, before insulating the attic with this material, you should make sure that the supporting structures and the roof are reliable. You ask - and this is all that can be used to insulate the attic? And how was the attic floor insulated before the invention of polyurethane foam and mineral wool?

Expanded clay insulation of the attic floor of the house

Expanded clay is a bulk insulation, it is perfect for insulating an attic floor, because it creates a ventilated space, while retaining heat. Expanded clay is light, in terms of flammability, it is safe and environmentally friendly. Thanks to the manufacturing technology, expanded clay is strong and durable, resistant to moisture, high and low temperatures.

Expanded clay differs in the size of granules. Attic insulation with expanded clay is often carried out in the floor area. From the inside, expanded clay needs a vapor barrier coating. The material needs a frame, and this "eats" part of the attic space. A special “box” is usually created on the floor, where expanded clay is poured, and a wooden floor is laid on top.

More often, expanded clay insulation and attic insulation with sawdust complement mineral wool or polyurethane foam, especially for horizontal surfaces. You should not choose only one option than to insulate the attic in a private house - you should correctly combine materials. For horizontal surfaces, it is better to use bulk insulation, they are cheaper and more convenient in the device.

Insulation with sawdust and foam attic

Insulation with sawdust can be used as one of the ways to insulate the attic. But this method is no longer in demand today as it used to be. The main disadvantage is the flammability of the material, which is not suitable for the roof of the house. Attic foam insulation is easy to implement, but it also has a significant drawback - a fire hazard and the release of toxins during combustion.

Comparison table of thermal conductivity of materials

Video: how to insulate the attic in a private house

When providing insulation of a private house and insulation of the roof along the rafters, one must not forget that Special attention should be given to such a place as an attic.

Development of attic floor insulation with mineral wool

Warm air tends to rise to the top, and therefore, in a temporarily unheated room, heat can escape through the space of a cold attic. Therefore, the issue of attic insulation must be addressed without delay.

1 Why is attic floor insulation necessary?

Insulation of the cold floor of the attic with stone or mineral wool, by and large, is necessary in little used premises, which are properly equipped with special roof ventilation.

The attic, or rather its ceilings, perform the function of a kind of boundary between heat and cold. In such places, attic floors are exposed to intense moisture due to the formation of condensate.

However, it is possible to properly insulate the floors in the attic of the house with mineral wool with your own hands. The very process of insulating the floor in the attic with mineral wool is the creation of a durable thermal insulation coating, which will have a low degree of thermal conductivity.

The very technology of mineral wool insulation of floors in the attic, as well as Energoflex thermal insulation for pipes, implies strict adherence to its stages and requirements.

By itself, this technology is quite simple and understandable. Good thermal insulation attic floor with mineral wool helps to close unwanted gaps.

To do this, the insulation must be laid tightly. In most cases, mineral wool is used to insulate the attic of a house.

The presented insulation is the most suitable for this type of work, it can also be used to insulate the floor surface in the living quarters of the house.

With the organization of good insulation with mineral wool, the most optimal temperature will be maintained in the living quarters.

If the procedure is not performed correctly, then moisture rising from the floor of the house will lead to the formation of condensate.

It will accumulate on the ceiling, and then seep through the floors. The resulting temperature difference in those areas where attic floors adjoin the walls of the house initiates the formation of mold and microscopic fungi, which can be the causative agents of allergic diseases.

1.1 Attic insulation requirements

The process of insulating the floor of the attic and insulating the roof of the house with your own hands, or rather the level of its quality, has a direct impact not only on the size of heat loss, but also on the duration of the operational life of the entire roof structure and roof coverings.

The fact is that the water vapor inside the heated room diffuses to the attic of the house. In order for the applied insulation to provide a high degree of calculated efficiency of the heat-insulating layer, it must always be dry.

Based on this, the insulation must be protected from excessive moisture by vapors of ascending heated air using a special vapor-tight material.

If the attic is well insulated, then it will not only provide high-quality thermal insulation, but will also help to increase the operational life of the entire roof structure.

If there is no vapor barrier, then steam will penetrate through the unprotected attic ceilings and condense on the ceiling surfaces.

This will lead to the fact that moisture will drain onto the rafters, which, under its influence, will slowly begin to rot from the inside.

As a result, the probability of destruction of the entire roofing pie increases. The thermal insulation performance of the structure is also reduced due to the fact that the tightness of the vapor barrier layer has been broken.

Before you insulate the attic, you need to drain the layer and remove moisture from the entire attic space. To do this, ventilation should be done through windows. They can be:

In order to ensure maximum ventilation intensity, the indicator of the total area of all ventilation openings should be equal to 0.2-0.5% of attic floors.

If all the work is carried out correctly, then in the winter, icicles will not form on the roof. The very process of warming the attic space is carried out not from the living quarters, but from the floor of the attic.

So it is most convenient to lay insulation, the choice of which depends on the technology used and design features buildings.

1.2 Features of insulation of beam ceilings

When implementing such an insulation scheme using mineral wool, heat is stored in the space between the beams. Their usual height is almost always enough for this, however, if necessary, several bars are stuffed on top.

Insulation of the ceiling with mineral wool from the side of the attic

The lower part of the ceiling is sewn up with molded material, as when insulating the attic of a private house. For this, lining or drywall sheets can be used.

On top of the beams, a subfloor covering is laid. It can be a tongue-and-groove board, plywood sheet or OSB board. Mineral wool is adjusted to a special vapor barrier prepared in advance.

An alternative to it can serve as an ordinary film made using polyethylene. If the vapor barrier material is foiled, then it is laid with a shiny surface down.

The intermediate distance between the beams is filled with mineral wool with the desired thickness parameters. The surface of the beams must be equipped with an additional insulating layer.

This will block the so-called cold bridges and significantly reduce the overall level of heat loss. If high quality timber was used to create the beams, then finishing material creep directly on their surface.

Mineral wool is placed between them, as when insulating the roof with PPU, and the attic floor is laid on top. The use of this technology is especially important in houses that are made of logs or beams.

It is important to protect the mineral wool with a high degree of reliability from the ingress of the smallest drops of moisture, this is especially true if the roof has minor coating defects, due to which leaks occur.

The layer of mineral wool must be reliably protected from the effects of wind from the side of the eaves. For this, mineral wool slabs with a high degree of density are used.

2 Why is mineral wool used for attic insulation?

In most cases, when insulating attic floors, the choice of the consumer falls on mineral wool. Its advantage lies in the fact that its installation does not require special skills.

Mineral wool has excellent thermal insulation properties. Its structure consists of thin vitreous fibers, the length of which ranges from 2 to 60 millimeters.

Attic insulation with mineral wool

High soundproofing characteristics are provided due to the presence a large number air pores.

These pores are located in the space between the fibers and can occupy 95% of the total volume of the insulation. Mineral wool is presented in three varieties, it can be basalt glass and stone.

Basalt wool is made using molten basalt rocks, to which binders are added.

This may be a carbonate-type rock, which regulates the level of acidity of the substance, which entails an increase in the service life of the insulation. Glass wool exhibits high heat-resistant properties and is able to withstand temperatures up to +450 degrees Celsius.

2.1 Technology of insulation of attic floors with mineral wool

During work related to mineral wool, it is important to comply with all safety requirements and regulations.

This is due to the fact that in the process of cutting and laying such material, the air is filled with tiny particles that can enter the respiratory organs and thus cause harm to human health.

When carrying out installation, be sure to take care of the availability of personal protective equipment. Goggles, a respirator and thick rubber gloves should be available.

The process of warming attic floors begins with the selection of the necessary tools and additional materials.

The essence of the insulation technology lies in the fact that the insulation must be carefully laid in the space between attic floors or beams.

To enhance the thermal insulation qualities, reliable vapor barrier should be used. Warm and moisture-saturated air will continuously rise from the living rooms and go up through the ceiling.

There in roof space, it will collide with a layer of insulation. Due to the fact that mineral wool is generally recognized as a vapor-tight material, it will take all the outgoing moisture into itself.

If it is left without the necessary access of air and sunlight, it will gradually shrink and, in the end, will lose all its heat-insulating qualities.

Attic cold interfloor overlapping 20 cm min.

In order to avoid such destructive consequences, it is necessary to lay a vapor barrier material under a layer of mineral wool.

Before starting the main work, it will be necessary to carefully calculate the required amount of insulation.

The amount of wool purchased depends on how many layers you plan to use when covering the attic. In addition, the thermal insulation thickness parameter directly depends on the climatic conditions in the region.

Insulation of the ceiling of a cold attic with mineral wool

Warming the ceiling of a cold attic with mineral wool - advantages. Features of warming the floors of cold attics with mineral wool.

Insulation of the attic floor in a private house - effective ways to keep warm

Warming the attic floor of the house allows you to save more heat inside the room, and not spend it on heating a cold attic. Well, if it is used as a utility room (technical attic) or as an attic, but if not? Then it is pointless to spend resources on heating an unheated attic space.

That is why it is worth making the insulation of the cold attic ceiling using heat-insulating materials. You can perform insulation from the side of the attic or from the side of the room (inside / outside). It is best to do this during the construction period of the building, or immediately before the final finishing of the room. But even during the operation of the house, there is no reason not to insulate the ceiling from the attic.

The thickness of the attic floor insulation is standardized using SNiP II-3-79 "Construction Heat Engineering". V this manual contains detailed recommendations regarding the choice and formulas for calculating the resistance to heat transfer of various thermal insulation materials. The calculations take into account not only the type of material, but also the average annual temperature, duration heating season, wall material of the house.

The attic floor insulation technology depends on the material chosen.

Comparative characteristics thermal insulation material with equal thickness

In this article we will consider the most popular heaters.

Attic insulation with mineral wool

Mineral wool is a heater, the fibers of which are arranged in a certain way. Namely, this randomness leads to the fact that an air cushion is formed between the fibers, which informs the insulation of its properties. However, the same feature of cotton wool increases the ability to absorb moisture. To avoid this, you need to know how to properly install mineral wool.

Benefits of mineral wool:

- high density;

- long service life;

- Fire safety;

- ease of installation;

- the use of mineral wool for insulation of horizontal surfaces does not lead to its caking, slipping and, as a result, the formation of cold bridges.

Among the disadvantages: the ability to absorb moisture.

Mineral wool attic insulation technology

There are three main ways to lay cotton wool: continuous, in grooves or in cells (see photo). The choice of method depends on what load will fall on the floor in the future. The most stable frame is obtained in the latter case.

Attic insulation with mineral wool

Attic insulation with mineral wool

First stage

It starts with laying the vapor barrier film. The film will allow you to remove the steam that rises from a warm living space to a cold attic. To lay the film correctly, you need to carefully read the markings applied to it. Be sure to observe an overlap of 100 mm.

Technology of insulation of the attic floor with mineral wool If insulation is made along wooden beams, then the film should go around all the protruding elements. Otherwise, the beams may rot.

Technology of insulation of the attic floor with mineral wool If insulation is made along wooden beams, then the film should go around all the protruding elements. Otherwise, the beams may rot.

At the junction of the film and walls or other protruding surfaces, it is necessary to raise it to a height equal to the thickness of the insulation plus 50 mm. and glue it with tape or wrap it on the insulation plate.

Second phase

Insulation (wool) is being laid. This is a fairly simple process. Slabs or strips are easily cut with a construction knife to the desired size.

When laying the sheet, make sure that there are no gaps left or that the mineral wool material is not strongly squeezed. Both will lead to a decrease in the quality of insulation. Common Mistakes on the picture.

a) insufficient thickness of the heat-insulating material;

b, c, d) the thickness of the attic floor insulation is incorrectly selected.

Useful tips for installing mineral wool

- insulation with foil will increase the resistance of the material to heat loss. The sheet is laid with the foil side down.

- the insulation should not protrude beyond the beam. If such a situation exists, the beam needs to be lengthened wooden beam or additional lath up to the thickness of the insulation.

- a thin insulation laid in two layers retains more heat than one thick one. In this case, the plates must be laid in a checkerboard pattern.

- if there are speakers in the attic structural elements, for example, a chimney pipe, you need to raise the insulation to a height of 400-500 mm. and fix it.

Third stage

Waterproofing flooring is carried out if the attic is not supposed to be used, and the truss system is not protected waterproofing film. If roofing material separated from the attic with a film, then you can proceed with the final stage.

Draft floor. It is laid over the insulation and serves as the basis for the final finish.

Insulation of the attic floor with foam

The process according to the installation technology is similar to the insulation of the attic floor with polystyrene foam.

The advantages of these materials:

Among the disadvantages: flammability.

Attic floor insulation technology with polystyrene foam or polystyrene foam

The process of installing rigid foam-based insulation is more than simple and can be done by hand. The work can be divided into two stages:

- surface leveling. To ensure high-quality insulation, there should be no significant irregularities on the floor of the base. You can eliminate such differences by performing a screed with a sand-cement mortar.

- slabs are laid butt-to-butt or between beams. The presence of a bar increases the strength of the floor.

Insulation of the attic floor with foam plastic Draft coating

Insulation of the attic floor with foam plastic Draft coating

Styrofoam must be protected from destruction with a film in a non-residential attic. In a frequently used or residential attic, you need to somehow move, so it is better to equip an OSB subfloor or a sand-cement screed over polystyrene foam or polystyrene foam.

Attic insulation with sawdust

Sawdust is finely chopped wood.

- naturalness;

- no toxic impurities;

- light weight;

- material availability.

Attic insulation technology with sawdust

- before proceeding with the insulation with sawdust, they need to be prepared. Namely, mix cement and water with sawdust in a ratio of 10:1:1.

- Pour the attic floor with the finished mixture and level it. It is worth noting that it is possible to use sawdust as a heater without using a frame only in a non-residential attic. Otherwise, when walking on the floor, sawdust will be compressed, and the concrete screed will collapse.

- build a cellular structure from a bar. Pour a solution with sawdust into each cell. The advantage of this method is that a subfloor can be laid along the timber. And the attic will be usable

Attic insulation with sawdust

Attic insulation with sawdust

Insulation of the attic floor with expanded clay

Expanded clay is obtained by firing clay.

The disadvantage is associated with the difficulty of lifting expanded clay to the height of the attic.

Expanded clay is usually used if it is necessary to insulate the attic floor over the slabs.

Expanded clay attic insulation technology

The work is carried out in three stages:

- the plate is inspected for cracks and cracks. They are sealed with mortar or covered with thick paper. The protruding elements do not create difficulties with backfilling of expanded clay.

- mount a crate from a bar. A rough floor will be laid on it in the future.

- loose insulation is poured onto the stove and leveled with a conventional rake. Layer thickness 250-300 mm. You can move around expanded clay without restrictions.

Insulation of the attic floor with expanded clay Advice: when filling expanded clay, it is better to combine granules of different sizes (diameters). This way you can avoid the appearance of voids.

Insulation of the attic floor with expanded clay Advice: when filling expanded clay, it is better to combine granules of different sizes (diameters). This way you can avoid the appearance of voids.

At the end, a subfloor is mounted or poured with a sand-cement screed.

Please note that attic insulation hardwood floor has some quirks:

- the tree is subject to decay, which means that the steam rising up must pass freely. Improper installation of films or the use of non-breathable materials, such as roofing felt, will lead to the destruction of wood in the future.

- using foil insulation, you need to place it with the foil down. So the wood will be protected from water ingress and at the same time, it will not accumulate steam moisture.

attic insulation mistakes

attic insulation mistakes

- "Correct" - use a superdiffusion membrane or vapor barrier film

- "Wrong" - to lay a special film without marking or even a regular film

The scheme of insulation of the attic floor for heaters of various types is given below.

Attic floor insulation scheme - 1

Attic floor insulation scheme - 1  Attic floor insulation scheme - 2

Attic floor insulation scheme - 2

Conclusion

In this article, we focused on the main stages and features of warming the attic floors of a private house using heaters various kinds. We hope that this information will be useful to you.

Insulation of the attic floor with mineral wool, polystyrene foam, sawdust, expanded clay

How and how to insulate the attic floor with your own hands. Overview of insulation and installation methods. Insulation of the attic floor with mineral wool, sawdust, polystyrene foam and expanded polystyrene, as well as expanded clay

Thermal insulation of cold attic floors: materials and methods

To understand why it is necessary to insulate the ceiling of a cold attic, let's clarify a little why an attic is needed in a private house and what its purpose is. Our ancestors built houses that could stand for more than 100 years, while it was warm inside, and the wooden structure of the roof always remained dry.

In the past, they mainly built gable roofs with a slight slope. This was done so that in winter the snow could remain on the roof. Thus, snow was used as a natural insulator. One or two windows were made in the attic and kept closed in winter so that the compressed air acted as a heat insulator. In the summer, however, the situation was somewhat different. Attic windows were opened at night so that the air cooled down, and during the day, in hot weather, they were closed so that the air would not get too hot, thus regulating its temperature.

When snow fell in winter, it lay down as a continuous cover on the roof, becoming at the same time a natural insulation. Even in severe frosts, the temperature in the attic did not fall below zero. Thus, the air in the attic and the insulation of the ceiling made it possible to maintain the temperature in the house at the level of +20-25 °C. The roof slopes were not insulated so that the snow lying on the roof would not melt. The truss system remained open, making it possible to inspect and repair it if necessary. Therefore, in a cold attic, only the ceiling is insulated.

If the roof slopes are insulated, then the attic becomes a heated room, i.e. attic, which has a completely different functional purpose.

Now it remains to figure out how to insulate the attic floor in a private house, and what materials are used for thermal insulation.

Materials for insulation of the attic floor

There is a wide range of insulation materials on the market. To make a choice, it is necessary to take into account the conditions in which the heat-insulating material will be used:

- The material must retain its properties when temperature conditions from -30 to +30 °С. Should not freeze in severe frosts and should not emit harmful substances in hot weather.

- It is necessary to choose a fire-resistant insulation if there is electrical wiring in the attic.

- It is better to choose a material that is moisture resistant so that when wet it does not lose its thermal insulation properties.

- The insulation should not quickly caking in order to fulfill its purpose as long as possible.

Before deciding on the type of material for insulating the floor of a cold attic in a private house, it is necessary to consider what material the floor is made of. If the attic floor is made of wooden beams, then slab, roll and bulk insulation can be used. In the case when the attic floor is made of concrete slabs, then they resort to the use of heavy bulk or dense slab heat insulators. Their use makes it possible to make a cement screed on the floor.

Materials produced in the format of plates and mats:

- mineral wool (mineral wool) in mats;

- Styrofoam;

- extruded polystyrene foam;

- seaweed;

- straw.

- mineral wool;

- glass wool;

- stone wool;

- algae ladders;

Bulk materials for attic floor insulation:

- expanded clay;

- ecowool;

- reeds;

- sawdust;

- straw;

- slag;

- buckwheat tyrsa;

- foam granules.

Attic floor insulation wooden house must be made with ecological, natural and breathable material.

Attic floor insulation wooden house must be made with ecological, natural and breathable material.

How to properly insulate the attic floor with mineral wool

Mineral wool is a common and modern heat insulator. Available in rolls or slabs (mats). It does not rot and does not burn, rodents and various kinds of microorganisms are also not afraid of it.

Warming the ceiling of a cold attic with mineral wool begins with laying the lining material on the floor. For budget option glassine is laid on the floor, but more expensive and quality option- flooring made of vapor barrier film. The film is laid with an overlap, and the joints are glued with adhesive tape or fixed with wooden slats, which are fixed with a construction stapler.

The width of the insulation is selected based on the requirements of thermal engineering standards for each region. Mineral wool is laid between the lags tightly and without gaps. The joints are glued with adhesive tape. After the insulation is laid, they simply put it on the logs flat boards, thus forming the floor in the attic. Such a simple solution for creating a floor allows the mineral wool to "breathe" and ventilate normally if moisture gets on it. To prevent moisture from entering the mineral wool, waterproofing material is laid under the roof.

Mineral wool is laid in personal protective equipment: tight clothing, goggles, gloves, respirator.

Insulation of attic floor slabs with extruded polystyrene foam

Expanded polystyrene or polystyrene are not very dense materials, so they are used when the attic floor is a construction of logs and beams. If it is necessary to insulate the plates, use the insulation of the cold attic ceiling with extruded polystyrene foam. This material is stronger and therefore denser than conventional foam. Before laying it, the surface of the plates should be leveled. On the warm side of the floor, vapor barrier is not required, since concrete slabs have almost no vapor permeability.

A vapor barrier film is laid on the leveled concrete slabs. Next, slabs of extruded polystyrene foam are laid in a checkerboard pattern. Joints are blown out mounting foam. After the foam dries and hardens, the heat-insulating plates are poured with a concrete solution 4-6 cm thick. When the screed dries, it is already suitable for use as a floor. Although you can go further and put any floor covering on the screed.

Thermal insulation of a cold attic with ecowool

Ecowool is a cellulose, light and loose insulation, consisting mainly of waste paper and newspapers. Other components - borax and boric acid are used as flame retardants.

Before insulation, it is necessary to put a film on the floor. The procedure for laying ecowool is carried out using a special blowing machine. A layer of insulation is applied as a continuous cover, without creating gaps. Since ecowool contains a large amount of air, a layer of 250-300 mm is usually enough.

Do not forget that over time, shrinkage of the material will occur. Therefore, apply a layer of ecowool 40-50 mm more.

Do not forget that over time, shrinkage of the material will occur. Therefore, apply a layer of ecowool 40-50 mm more.

After the insulation of the cold attic ceiling with ecowool is completed, it must be moistened. It can be done plain water or prepare a solution of 200 gr. PVA glue on a bucket of water. Soak a regular broom in this solution and moisten the cotton well. After drying, a crust is formed on the surface of the cotton - lingin, which will not allow the cotton to move.

As you can see, there are plenty of ways to insulate the floor in the attic. Which one to apply depends on each specific situation. Most importantly, follow the right technology insulation installation! Then your house will always be warm, and the materials used will last for many years.

Warming the ceiling of a cold attic with mineral wool, how to insulate the floor of the attic

How to make floor insulation in a cold attic. Insulation of the attic floor with mineral wool and extruded polystyrene foam. How to properly insulate the floor in the attic.

How to perform attic insulation in a private house with your own hands as efficiently and inexpensively as possible

I decided to dedicate this article to those people who want to insulate the attic of the house on their own without large financial costs. Next, we will get acquainted with heat-insulating materials suitable for these purposes and the nuances of their installation.

Stages of work

Insulation of the attic in a private house is conditionally divided into:

Floor insulation

Floor insulation can also be divided into several steps:

Stages of thermal insulation of the floor

Preparation of materials

First you need to decide on the choice of thermal insulation material. There are quite a few options. However, our task is to insulate the ceiling with minimal financial costs.

- sawdust - thermal conductivity is 0.07 - 0.095 W / mºС. The main advantage of sawdust is that if there are woodworking enterprises nearby, they can be purchased very cheaply or even for free.

Wood sawdust is an excellent natural insulation

The only thing to keep in mind is that before using the sawdust, it is necessary to dry it and also treat it with an antiseptic composition. Also, slaked lime mixed with carbide can be used to protect sawdust from biological influences.

If sawdust has traces of fungus damage, they cannot be used for insulation;

Reed insulation mat

- reeds are another natural material that can be obtained for free. The thermal conductivity of the reed does not exceed 0.042 W / (m.K).

Reeds for thermal insulation are harvested in late autumn with the onset of the first frost, when the stems remain almost completely without foliage. Moreover, only mature plants can be used. Such stems are easily identified by a light yellow tint.

Penoizol is applied in liquid form

- penoizol - is a modified foam that is applied to the surface in the form of foam. Within a few days, the foam hardens.

Penoizol has a lower thermal conductivity than all the materials described above - 0.028 - 0.040 W / (m * K). In addition, penoizol is not subject to biological influences, does not burn and is not afraid of moisture.

The disadvantage of this material is that the insulation of the attic with foam insulation requires certain equipment. Accordingly, it will not be possible to cope with the work on your own. The cost of the material with the work of specialists is 1450-1500 rubles per cubic meter.

True, you can use dry penoizol in bags, but in this case its price will increase to 2000-2300 rubles per cubic meter;

Expanded clay for floor insulation

- expanded clay is an environmentally friendly and fireproof natural material that is sold in the form of durable granules. The cost of expanded clay starts on average from 1000 rubles per cubic meter, which allows it to be classified as budget heaters.

The disadvantage of expanded clay is a higher thermal conductivity of 0.1 - 0.18 W / (m * K). So for high-quality thermal insulation of the ceiling, expanded clay must be poured with a layer of at least 20 cm.

- mineral wool is also an environmentally friendly and fireproof material with low thermal conductivity (0.038 to 0.055 W / m * K). As a rule, mineral wool is sold in the form of mats or rolls. Its main disadvantage is the rather high cost - from 2300-2500 rubles per cube of basalt mats.

True, you can use stone wool in rolls, the cost of which starts at 1,500 rubles per cubic meter. But, this material is less environmentally friendly than basalt wool.

Recently, cellulose-based insulation - ecowool - has become widespread. This material is treated with an antiseptic and flame retardant, therefore it is fireproof and not subject to biological influences. The cost of ecowool is 1200-1500 rubles per cubic meter.

Everyone should choose the best way to insulate the attic in a private house, depending on the needs and availability of a particular heat insulator.

In addition to thermal insulation, you will need other materials:

- vapor barrier membrane;

- boards, OSB sheets or other material that can be laid on floor beams;

- antiseptic impregnation for wood.

Floor preparation

It is possible to start warming the attic floor only after the following preparatory work has been completed:

- if there is flooring on the floor beams, it must be dismantled;

- then wooden beams be sure to treat with antiseptic impregnation. Instructions for the use of such compounds are available on the packaging;

- if there is no roll-up (filing) of the overlap, it must be done. To do this, boards can be nailed to the beams from the inside, i.e. from the side of the room.

This completes the preparation.

Floor insulation

Insulation of the attic floor is carried out as follows:

- a vapor barrier membrane must be laid on the logs and the roll. The stripes should overlap each other. For reliability, the joints should be glued with adhesive tape;

- Now the insulation is being installed. Mineral mats must be positioned so that they fit snugly against the floor beams and against each other. The same applies to roll material;

Example of laying mineral wool

- on top of the floor beams and thermal insulation with their own hands, another layer of vapor barrier is laid and glued with adhesive tape;

- then boards or other material are laid on the floor beams. If the attic will be used as a living space, you can install logs to level the surface and lay a subfloor on top.

If the house has a concrete floor, to insulate the attic, you need to lay mineral mats or extruded polystyrene foam on the slab, and pour the screed. At the same time, the insulation on both sides must be covered with a waterproofing film, especially if mineral mats are used.

I must say that the ceiling can be insulated not only from the outside, but also from the side of the room. True, in this case, the choice of insulation is limited, since it will not work to use bulk materials.

Ceiling insulation with mineral mats

As an example, consider how to insulate the ceiling in a private house with an isover, i.e. mineral mats:

- First of all, you need to dismantle the reel. In this case, it is desirable to lay boards on top of the beams and fix them;

- then a vapor barrier membrane is attached to the beams and boards. To fix it, you can use a stapler;

- now mineral mats should be laid in the space between the beams. To fix them, you can use slats located across the beams. Also, nails are often nailed to the beams, between which threads are pulled;

Fastening the vapor barrier with a stapler

- after that, you need to attach another layer of vapor barrier to the beams;

- at the end of the work, you need to roll up, after which you can deal with the arrangement of the ceiling.

Roof insulation

In most cases, roof insulation is not required. But, if you are going to use the attic as a living space, then this procedure is indispensable.

Do-it-yourself roof insulation in a private house can also be divided into several stages:

Stages of attic insulation

Preparation of materials

Since it is inconvenient to use bulk materials for roof insulation, you can use mineral mats. To save even more, you can make mats from reeds.

In addition to the insulation, you will need the following set of materials:

- vapor barrier;

- nails and threads;

- wooden slats;

- antiseptic impregnation.

Treatment of rafters with an antiseptic

Roof preparation

Before proceeding with the insulation of the roof, you need to perform some preparatory work:

- inspect first truss system for its integrity. If any parts are cracked or rotten, they must be replaced or repaired.;

- if the thickness of the insulation exceeds the thickness of the log, they must be increased. To do this, nail bars or boards of sufficient thickness to them;

- then all wooden structures must be treated with an antiseptic composition to protect them from biological influences.

Roof insulation

Do-it-yourself roof insulation in a private house is carried out as follows:

- The vapor barrier membrane must not touch the roof waterproofing. To provide space between these materials, nails must be nailed to the rafters, and threads must be pulled in a zigzag pattern between them;

Fastening the vapor barrier to the rafters

- then fix the vapor barrier membrane to the rafters with a stapler or small nails. Let me remind you that smooth side the vapor barrier must face the insulation. Glue the joints of the film with adhesive tape;

Warming the space between the rafters with mineral wool

- now you need to lay the insulation in the space between the rafters. To ensure that there are no cold bridges in the thermal insulation, place the mats close to the rafters and to each other . If the cracks are nevertheless formed, they need to be filled with scraps of insulation..

To fix the thermal insulation between the rafters, you can also nail carnations and pull threads between them;

- after laying the insulation, you need to fix another layer of vapor barrier on the rafters;

- at the end of the work, you need to complete the crate using slats or boards about 2 cm thick, to which finishing materials can be attached.

Warming of gables

Now it remains only to insulate the gables, if, of course, they are available. I must say that it is more expedient to insulate them from the outside in parallel with the insulation of the entire facade. However, if the facade is not insulated, then thermal insulation must be made from the inside.

To do this, we need the same materials as for finishing the roof. The only thing besides them is to prepare bars or boards. Their width should correspond to the width of the insulation.

Insulation work resembles the thermal insulation of ordinary walls:

- to provide a ventilation space between the walls and the insulation, you need to fix the slats on the gables in a horizontal position. The vertical step should be about half a meter, and horizontally - a few centimeters.

Scheme of mounting rails on the gables for arranging the ventilation gap

Keep in mind that the slats must form an even vertical plane. Therefore, if the gables are uneven, the rails must be aligned during installation;

- further, a vapor barrier membrane is attached to the rails. During installation, make sure that the film does not sag;

- then vertical racks (beams or boards) are installed. To fix them, you can use self-tapping screws and metal corners. Make the distance between the racks a couple of centimeters less than the width of the mats;

An example of laying mineral mats in the space between the uprights

- now the space between the racks must be filled with insulation. If the racks are installed correctly, the mats will go in tightly, and their additional fixation will not be required;

- then attach a vapor barrier to the racks;

- at the end of the work, mount the crate.

Now all that's left is finishing. The choice of finishing materials depends on the purpose of housing and the attic itself. If, the house is used for permanent residence, and the attic will be heated, you can sheathe it with drywall and use any finishing materials.

Finishing a cold attic should be done with materials that are not afraid of low temperatures. Therefore, from the use of wallpaper and plastic panels better to refuse.

Insulating your own attic, as you can see, is not at all difficult. Therefore, you can safely get to work, the only thing I recommend is also to watch the video in this article. If you don't understand any of the nuances, please contact me with questions in the comments, and I will be happy to help you » width="640" height="360" frameborder="0" allowfullscreen="allowfullscreen">

Insulating your own attic, as you can see, is not at all difficult. So you can safely get to work.

Do-it-yourself attic insulation in a private house: the better to insulate, video and photo

Do-it-yourself attic insulation in a private house: the better to insulate, video and photo

May 25, 2018 No comments

When insulating a house, special attention should be paid to the attic or attic, since it is through this space that the house loses most of its heat.

The reason lies not only in the fact that this is facilitated by a large roof area. It is known that warm air is lighter and, when heated, it rises to the top, namely to the attic, from where it penetrates through uninsulated structures.

As a result, if the attic is not insulated, you will have to constantly heat not only your house, but also the surrounding space. In addition to heat leakage, this will lead to high humidity in the house, the floors in the rooms will always be cold and, as a result, mold will appear in the house.

There are several options for insulating an attic or attic.

In non-residential premises, it is possible not to fully insulate the entire system, to insulate the floors well enough so that air from the lower floors does not penetrate into the attic, and cold from the attic does not seep into warm rooms.

Before starting work, it is necessary to decide what material will be used, how much of this material will be required, and what additional fastening materials and tools will be needed to mount the structure.

Calculations should be made to determine the amount of heat loss through the attic, on the basis of which it is possible to determine the thickness of the layer of insulation material.

Sometimes a lot of insulation is required, so it is better to choose a material that is not very heavy so as not to overload the entire structure. For example, expanded clay is a rather heavy material and before using it, you should make sure that it does not damage the supporting structures of the house.

In addition, the heat-shielding qualities of the attic floor must be maintained both in winter and in summer in order to avoid both heat loss and overheating of the interior of the house.

In order for the insulation to last as long as possible and all financial and physical costs justify themselves, it is important to do right choice in favor of high-quality material and competently carry out its installation. So, for example, in a loose heat insulator, regular air circulation occurs (convection cell).

Convection loose ceiling insulation

It turns out that moving air constantly draws out the heat retained by the insulation, and the lower the air temperature in the attic, the more intense the convection and heat removal from the insulation. At the same time, the flow of heat into the insulation through the ceiling increases.

Gradually, the throughput of the insulation increases, and the resistance to heat movement decreases, and as a result, the effectiveness of thermal insulation is significantly reduced. To avoid this, it is necessary to carefully consider the insulation scheme, use high-quality material and conscientiously install it.

Useful advice

To insulate the attic floor, you can use foam plastic, expanded clay or polyurethane foam as a heat-insulating material. In the first three cases, you will additionally need waterproofing material (for example,), mounting, foam for sealing joints and cracks, as well as floor covering (these can be ordinary boards, wood boards, etc.). For spraying polyurethane foam, a special installation is required.

Thermal insulation with mineral wool

First of all, you should prepare the surface of the attic floor - remove debris and dust. Then the floor of the attic must be covered with a waterproofing film.

Once in a humid environment, mineral wool loses its thermal insulation properties, so it is better to spread the film for moisture insulation with a margin, bringing its edges to the walls or side beams and fastening it with a construction stapler.

The next step is the device of a wooden crate (frame).

To do this, wooden planks must be fixed on top of the film in such a way that insulation boards can be laid between them. If wooden beams are laid on the floor of the attic, mineral wool can be placed between them. With significant heat loss through the ceiling, it will be necessary to lay several layers of insulation.

The last layer of wool must necessarily cover the beams. If this is not done, the wooden beams will become cold bridges through which heat will continue to leave the room.

All cracks and voids should be filled with pieces of insulation or filled with construction foam, and the joints between the mats should be sealed with adhesive tape.

Then a second layer of vapor barrier film is laid, since the mineral wool must be protected on both sides.

This will better protect the insulation from damage when walking on it. If the attic will not be used, it is enough to nail a few boards along which you can move around, like along paths.

Mineral wool prices

Expanded clay is used to insulate attic floors in cases where heat losses in the house are insignificant and you can get by with a small amount of insulation so as not to weigh down the supporting structure.

Expanded clay has many advantages over other heaters: it is inedible for rodents, durable and, since it is a bulk insulation, it easily fills all the bumps and hard-to-reach places on the surface. So that when insulating with expanded clay there are no voids, granules of different sizes should be used.

In addition, expanded clay is not afraid of moisture, so it does not need to be protected from it and spent money on the purchase of waterproofing material.

However, the thermal insulation characteristics of this material are relatively low, therefore, for greater efficiency, it will still be necessary to pour a sufficiently thick layer, which will increase the load on the floors of the house. In this case, it is recommended to combine expanded clay with mineral wool, which will make it possible to make the insulation multi-layered, somewhat facilitating it due to lighter mineral wool.

Expanded clay insulation technology simple enough:

on the attic floor cleared of debris, you need to pour a layer of insulation, and then cover it with a cement-sand mortar screed. In the attic, which is planned to be used as a living space in the future, you can lay a laminate or linoleum on top of the finished screed, or limit yourself to flooring from boards or wood boards.

If there are communication pipes in the attic, they can also be insulated with expanded clay, which will provide the necessary ventilation in such places and protect the structure from ignition if the pipes become very hot.

When combining expanded clay with mineral wool, an insulating film will be required to protect the structure from moisture. First, the floor is covered with a vapor-proof material, then a layer of expanded clay is poured, on which the crate and mineral wool slabs are laid, and another layer of film is laid on top.

After that, you can make flooring from boards or other flooring material.

Insulation with foam

This material, when insulating cold (non-residential) attics, is most in demand in comparison with others. In this case, both plates and bulk foam can be used. In any case, this material will not make the structure heavier, even if the layer is thick enough. Installation of foam insulation is very simple and quite feasible alone. The plates are easily cut with a knife, and if necessary, for better joining, they can be cut right inside the crate.

If the old-style foam was dangerous for its flammability, then non-combustible types of this material are currently being produced. It is quite cheap and, in terms of environmental friendliness, will not pose a great danger, since the attic space in this case will be non-residential.

Attic floor insulation technology with foam boards similar to the installation of mineral wool. First, the ceiling should be protected with waterproofing.

To do this, you can use glassine, after cutting it into strips so that the material fits between the beams. When laying on the floor, it should be led onto the beams by 5 cm, and then fix the ends on the ends of the beams with the help of wooden slats or construction stapler.

After that, the foam boards must be cut with a knife so that they fit between the ceiling beams.

After laying the heat insulator, the remaining gaps and voids should be filled with mounting foam. The upper edges of the floor beams must be covered with insulation.

A second layer of waterproofing is laid on top of the structure, and then the floor covering (boards, fiberboard or chipboard, linoleum, etc.) can be laid.

The number of layers of insulation directly depends on the heat loss of the house. Foam layers can be alternated with mineral wool or expanded clay. In any case, the main thing is quality installation the whole structure.

Insulation with sprayed polyurethane foam

Today, it has become possible to perform thermal insulation using the PPU spraying method using special kits - disposable 2-component installations for insulation and sealing of various structures. And although this material is not cheap, it fully justifies itself.

Polyurethane foam is applied directly to the ceiling by spraying from above - either between the logs of a wooden attic floor, or on a concrete slab or screed, if it is capital. It is important to spray PPU continuously to get a uniform seamless layer of the required thickness without cold bridges.

The foam easily penetrates even into inaccessible cracks and recesses, quickly hardens and forms an even water, vapor and heat impermeable layer.

The processed polyurethane foam surface does not require additional floor covering and you can walk on it without fear of damaging or violating the integrity of the structure. However, if the attic or attic is planned to be used as a living space, it will be necessary to cover the floor with wood boards, boards, linoleum, etc.

The thickness of the sprayed PPU layer is determined based on specific conditions (heat loss at home) and the requirements of SNiP. On average, to achieve effective thermal insulation of the attic floor and attic, a layer of polyurethane foam with a thickness of 7-9 cm is required.

If access to the attic floor is limited, spraying can be applied from below to the ceiling inside the living space.

Useful advice

The method of insulation of the attic floor by spraying PPU is very effective, therefore, it has recently become more and more popular. Such insulation is durable, resistant to impact chemical substances, microorganisms and temperature changes, inedible for rodents.

The weight of the insulation is small, so the supporting structures are not overloaded and even acquire additional adhesion rigidity. Due to the fact that the insulation layer is very thin, neither the total area nor the volume of the attic or attic is reduced.

One of the few disadvantages of this type of thermal insulation is its cost, but in any case, it is better to do the job well once than to return to this problem again and again. It should also be recalled that this material, suitable for arranging a cold attic, does not “breathe” and therefore is not very suitable for residential premises.

Video: Insulation of a non-residential attic of a private house

When providing insulation for a private house, one should not forget that special attention should be paid to such a place as the attic.

Warm air tends to rise to the top, and therefore, in a temporarily unheated room, heat can escape through the space of a cold attic. Therefore, the issue of attic insulation must be addressed without delay.

1 Why is attic floor insulation necessary?

Insulation of the cold floor of the attic with stone or mineral wool, by and large, is necessary in little used premises, which are properly equipped with special roof ventilation.

The attic, or rather its ceilings, perform the function of a kind of boundary between heat and cold. In such places, attic floors are exposed to intense moisture due to the formation of condensate.

However, it is possible to properly insulate the floors in the attic of the house with mineral wool with your own hands. The very process of insulating the floor in the attic with mineral wool is the creation of a durable thermal insulation coating, which will have a low degree of thermal conductivity.

The very technology of insulating the floor with mineral wool in the attic, as well as implies strict adherence to its stages and requirements.

By itself, this technology is quite simple and understandable. Good thermal insulation of the attic floor with mineral wool helps to close unwanted gaps.

To do this, the insulation must be laid tightly. In most cases, mineral wool is used to insulate the attic of a house.

The presented insulation is the most suitable for this type of work, it can also be used to insulate the floor surface in the living quarters of the house.

With the organization of good insulation with mineral wool, the most optimal temperature will be maintained in the living quarters.

If the procedure is not performed correctly, then moisture rising from the floor of the house will lead to the formation of condensate.

It will accumulate on the ceiling, and then seep through the floors. The resulting temperature difference in those areas where attic floors adjoin the walls of the house initiates the formation of mold and microscopic fungi, which can be the causative agents of allergic diseases.

1.1 Attic insulation requirements

The process of insulating the attic floor and, more precisely, the level of its quality has a direct impact not only on the size of heat loss, but also on the duration of the operational life of the entire truss structure and roofing.

The fact is that the water vapor inside the heated room diffuses to the attic of the house. In order for the applied insulation to provide a high degree of calculated efficiency of the heat-insulating layer, it must always be dry.

Based on this, the insulation must be protected from excessive moisture by vapors of ascending heated air using a special vapor-tight material.

If the attic is well insulated, then it will not only provide high-quality thermal insulation, but will also help to increase the operational life of the entire roof structure.

If there is no vapor barrier, then steam will penetrate through the unprotected attic ceilings and condense on the ceiling surfaces.

This will lead to the fact that moisture will drain onto the rafters, which, under its influence, will slowly begin to rot from the inside.

As a result, the probability of destruction of the entire roofing pie increases. The thermal insulation performance of the structure is also reduced due to the fact that the tightness of the vapor barrier layer has been broken.

Before you insulate the attic, you need to drain the layer and remove moisture from the entire attic space. To do this, ventilation should be done through windows. They can be:

- Skating like;

- eaves;

- slotted;

- Auditory.

In order to ensure maximum ventilation intensity, the indicator of the total area of all ventilation openings should be equal to 0.2-0.5% of attic floors.

If all the work is carried out correctly, then in the winter, icicles will not form on the roof. The very process of warming the attic space is carried out not from the living quarters, but from the floor of the attic.

So it is most convenient to lay insulation, the choice of which depends on the technology used and the design features of the structure.

1.2 Features of insulation of beam ceilings

When implementing such an insulation scheme using mineral wool, heat is stored in the space between the beams. Their usual height is almost always enough for this, however, if necessary, several bars are stuffed on top.

The lower part of the overlap is sewn up with the help of molded material as with. For this, lining or drywall sheets can be used.

On top of the beams, a subfloor covering is laid. It can be a tongue-and-groove board, plywood sheet or OSB board. Mineral wool is adjusted to a special vapor barrier prepared in advance.

An alternative to it can serve as an ordinary film made using polyethylene. If the vapor barrier material is foiled, then it is laid with a shiny surface down.

The intermediate distance between the beams is filled with mineral wool with the desired thickness parameters. The surface of the beams must be equipped with an additional insulating layer.

This will block the so-called cold bridges and significantly reduce the overall level of heat loss. If a high-quality timber was used to create the beams, then the finishing material will spread directly onto their surface.

Mineral wool is placed between them as with, and the attic floor is laid on top. The use of this technology is especially important in houses that are made of logs or beams.

It is important to protect the mineral wool with a high degree of reliability from the ingress of the smallest drops of moisture, this is especially true if the roof has minor coating defects, due to which leaks occur.

The layer of mineral wool must be reliably protected from the effects of wind from the side of the eaves. For this, mineral wool slabs with a high degree of density are used.

2 Why is mineral wool used for attic insulation?

In most cases, when insulating attic floors, the choice of the consumer falls on mineral wool. Its advantage lies in the fact that its installation does not require special skills.

Mineral wool has excellent thermal insulation properties. Its structure consists of thin vitreous fibers, the length of which ranges from 2 to 60 millimeters.

High soundproofing characteristics are provided due to the presence of a large number of air pores.

These pores are located in the space between the fibers and can occupy 95% of the total volume of the insulation. Mineral wool is presented in three varieties, it can be basalt glass and stone.

Basalt wool is made using molten basalt rocks, to which binders are added.

This may be a carbonate-type rock, which regulates the level of acidity of the substance, which entails an increase in the service life of the insulation. Glass wool exhibits high heat-resistant properties and is able to withstand temperatures up to +450 degrees Celsius.

2.1 Technology of insulation of attic floors with mineral wool

During work related to mineral wool, it is important to comply with all safety requirements and regulations.

This is due to the fact that in the process of cutting and laying such material, the air is filled with tiny particles that can enter the respiratory organs and thus cause harm to human health.

When carrying out installation, be sure to take care of the availability of personal protective equipment. Goggles, a respirator and thick rubber gloves should be available.

The process of warming attic floors begins with the selection of the necessary tools and additional materials. Can't do without:

insulation

- Boards and plywood;

- vapor barrier film;

- Mineral wool (excellent);

- Waterproofing;

- adhesive tape;

- Roulettes;

- Knife;

- Construction stapler;

- spatula.

The essence of the insulation technology lies in the fact that the insulation must be carefully laid in the space between attic floors or beams.

To enhance the thermal insulation qualities, reliable vapor barrier should be used. Warm and moisture-saturated air will continuously rise from the living rooms and go up through the ceiling.

There, in the roof space, he will collide with a layer of insulation. Due to the fact that mineral wool is generally recognized as a vapor-tight material, it will take all the outgoing moisture into itself.

If it is left without the necessary access of air and sunlight, it will gradually shrink and, in the end, will lose all its heat-insulating qualities.

In order to avoid such destructive consequences, it is necessary to lay a vapor barrier material under a layer of mineral wool.

Before starting the main work, it will be necessary to carefully calculate the required amount of insulation.

The amount of wool purchased depends on how many layers you plan to use when covering the attic. In addition, the thermal insulation thickness parameter directly depends on the climatic conditions in the region.

2.2 Proper insulation of the attic floor (video)

Substances and their physical properties

Substances and their physical properties Classification, structure, nutrition and the role of bacteria in nature

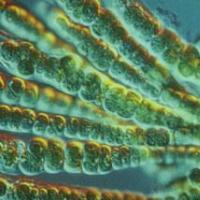

Classification, structure, nutrition and the role of bacteria in nature Bacteria - the most ancient organisms on Earth Bacteria - the oldest group of living organisms

Bacteria - the most ancient organisms on Earth Bacteria - the oldest group of living organisms Epithets, metaphors, personifications, comparisons: definitions, examples

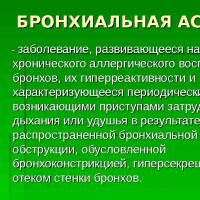

Epithets, metaphors, personifications, comparisons: definitions, examples Bronchial asthma Bronchial asthma

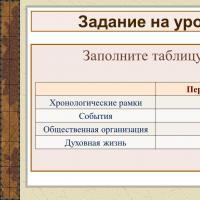

Bronchial asthma Bronchial asthma Roman Empire Ancient History

Roman Empire Ancient History Flexible removable dentures: design, features and benefits Varieties of soft dentures with photos

Flexible removable dentures: design, features and benefits Varieties of soft dentures with photos