Floor insulation in the apartment on the ground floor. Insulation of floors in an apartment: materials and methods What material to insulate the floor in an apartment

The floor differs from other building envelopes in that it is constantly under load from the weight of residents, furniture and equipment.

Obviously, this should be considered before planning in an apartment with your own hands.

Foamed polymers are used in construction practice, this is an extensive group, which includes:

- polyethylene foam;

- polypropylene, etc.

Flaws:

- combustibility: when burning, they also emit super-toxic smoke;

- interest from rodents: use styrofoam as food.

If it is decided to make the floor concrete, then it is better to cast the base not from pure concrete, but from expanded clay - sawdust - or polystyrene concrete. Then the EPPS is laid on top.

Do-it-yourself floor insulation technology

The wooden floor is insulated in this order:

- dismantle the finishing floor, exposing the logs, and inspect all lumber for damage and rotten areas. If necessary, beams and boards are changed, not forgetting to treat the new wood with fire protection;

- nails are nailed to the lags on the side below or bars are screwed with self-tapping screws. A more expensive option is to attach steel corners, but there will be more space for insulation. That is, it can be laid in a thicker layer;

- low-grade lumber is laid on bars or corners - sorted, slab or unedged board;

- in the case of using mineral wool or other moisture-absorbing material, a dense polyethylene film (waterproofing) is laid. In the gaps between the lags, it is pressed in so that it touches the unedged board. The material is placed with a 10 cm approach to the walls;

- lay the insulation in the gaps between the lags on the bedding boards. The thickness of the layer is selected so that there is a gap of 20 mm between the heat insulator and the boards of the finishing floor;

- in the case of mineral wool, polyethylene is again spread on top;

- they lay the boards of the finishing floor so that there is a gap of 1-1.5 cm between their ends and the wall. Subsequently, it will be closed with a plinth;

- cut waterproofing.

The concrete floor is insulated like this:

- knock down the old screed;

- close up cracks in the concrete base, eliminate other defects;

- insulation is laid - extruded polystyrene foam or expanded clay. The latter is leveled by the rule according to the lighthouses;

- a wire mesh (reinforcement) is laid on top of special bosses or fragments of bricks;

- on the walls, at the level of the future screed, a damper tape is glued. It will allow the screed to transform in volumes when the temperature changes without the occurrence of internal stresses;

- install beacons;

- pour the screed and level it over the beacons;

- beacons are knocked out of a frozen screed with a chisel or cut out with a grinder. The recesses remaining from under them are filled with a solution.

It remains to lay on a screed or other finishing flooring.

A lot of articles have been found on the Internet about the insulation of a concrete floor, where it is recommended to lay Penofol under the screed. This is an unfortunate option: Penofol - foamed polyethylene, soft roll material. It is not only under load, even under the weight of the screed, it will flatten to a thickness of 1 mm and cease to perform its functions.

When is it necessary to insulate the floor on the 1st floor?

Floor insulation is used in the following cases, if:

- there is no basement (floor on the ground);

- there is an unheated basement;

- the floor is located above the arch;

- below is a non-residential premises: a shop, a hairdresser or, for example, a workshop.

It is imperative to insulate the floors on the ground and above the arch. In the first case, high heat losses are due to good thermal conductivity of the soil, especially clay soil - it retains moisture well. In the second - a draft, which is usually observed in an arched opening.

If the 1st floor is located above a heated basement and the same temperature is maintained there, it is pointless to insulate the floor. It is also impractical to do this on interfloor ceilings, if the dwelling is located below.

Related videos

How to insulate the floor in an apartment with extruded polystyrene foam:

Uninsulated floor is not only discomfort when walking barefoot, but also overspending on heating. Therefore, it is strongly recommended to allocate funds and time for this event. Basically, they are insulated with extruded or granulated polystyrene foam, and with a significant ceiling height - with expanded clay.

The floor is the coolest surface in the room. Even at relatively warm air temperatures, the floor can remain cold. There is nothing strange in this. Let's remember the laws of physics: cool air always goes down, and warm air goes up. But that's not all. Cold penetrates into the floor coverings of our apartments through interpanel joints, corner cracks, and damp basements. Through a poorly insulated floor, up to 20-30% of the heat can leave the room! At the same time, heating bills increase, and the rooms are still cold. In this case, it's time to start thinking about how to insulate the floors in the apartment. This will help reduce heat loss and create a more comfortable indoor climate.

Choosing an insulating material

The floor is insulated with materials with high thermal insulation properties that prevent heat from escaping outside the room. For these purposes, the most popular are:

- Bulk materials(expanded clay, wood concrete, shavings) - have good thermal insulation qualities, are relatively inexpensive;

- Mineral wool and glass wool- effective in terms of heat and sound insulation, fireproof, not susceptible to infection by fungi and rodent attacks, hygroscopic (require mandatory vapor barrier);

- Styrofoam and expanded polystyrene- materials are moisture resistant, not subject to deformation, do not ignite, conduct heat poorly, muffle sound noises.

It is impossible to say which of these materials is the best. You need to choose based on your financial capabilities and the functionality of the insulated room.

Wooden base insulation

The traditional way of warming is laying the selected type of heat insulator in the space between the lags.

Scheme of warming a wooden floor along the logs

To do this, perform the following steps. The first step is to remove the old floor covering, open the floor. A vapor barrier layer is laid, for example, a polyethylene or polypropylene film. Unfold the material and lay the strips on top wooden frame floors, overlapping them by 15-20 cm. The joints are securely insulated with special adhesive tape. When laying, a vapor barrier film is placed on the walls to a height of 3-5 cm.

Laying a vapor barrier film is necessary so that moisture does not penetrate into the insulation layer

A heater is laid between the lags. When using expanded clay, it is evenly poured between the lags, leveling to one level with the rule. sheet or roll insulation laid close to the lags, without cracks.

Formation of an insulating layer of mineral wool

On top of the insulation (if mineral wool or glass wool was used), another layer of vapor barrier is created.

The second layer of vapor barrier protects the insulation from steam penetrating into the ceiling from the room

Expanded polystyrene is an affordable insulation that does not absorb moisture and is quite easy to install. You can read more about the use of such material in our article:.

Lay over insulated floor wooden planks, dense plywood, OSB or GVL sheets.

If necessary, install the finish coating: laminate, parquet, linoleum, carpet, etc.

concrete floor insulation

In most cases, the floors in the apartments of urban high-rise buildings are reinforced concrete slabs. The concrete floor itself is very cold, but if you add to this the gaps between the slabs, insufficiently tight joints between the walls and the floor, then it becomes truly icy. Therefore, the insulation of the concrete surface is a top priority for residents. multi-storey buildings who seek to increase the comfort in their apartments.

Each master involved in insulation derives his own formula for the ideal insulating "pie" on concrete slabs. Consider the most popular of the possible options.

Option number 1 - insulation + screed

It is possible to significantly improve the thermal insulation properties of a concrete floor by laying insulation between the floor slab and the cement leveling screed. In this case, the floor insulation in the apartment is performed as follows. The first step is to remove the old floor covering, remove the screed. The surface of the slab is cleaned of debris, dust, and irregularities from the remnants of the cement screed are eliminated.

Warming the floor in the apartment with thermal insulation material and reinforced screed

Then perform vapor barrier. A polyethylene or polypropylene film is laid on the concrete base, overlapping the strips by 15-20 cm and leading 3-5 cm onto the walls. The overlap joints are insulated with special adhesive tape. Styrofoam is laid on the vapor barrier film minimum thickness 50 mm, density 25 mm. Instead of foam, you can use expanded polystyrene, mineral wool, etc. Insulation sheets are laid as close as possible to each other so that cold bridges do not form in the seams. After that, another layer of vapor barrier is laid. If foam or polystyrene foam was used as a heater, then this step can be skipped.

Now stacked metal mesh with square cells (cell side - 50-100 mm). The mesh will act as a frame for the cement screed, making it more durable. A cement screed with a minimum thickness of 50 mm is poured over the mesh. A thinner screed will be unreliable - after a while it will begin to crack and crumble. The cement screed should dry, it will take about two weeks. After that, to strengthen the top layer, it is necessary to cover it with a primer. After all this, any decorative coating is laid on the screed.

Expanded clay is well suited for warming concrete floors. You will learn about how to properly use such a heater in the material:.

Option number 2 - insulation along the lags, without the use of wet processes

This option is similar to the insulation of a wooden floor. The difference is that logs are initially provided in the thickness of the wooden floor, between which it is convenient to lay any type of insulation. In case of concrete floors these lags will have to be designed independently.

Insulation of the concrete floor along the logs eliminates wet processes and does not weigh down the floor

The technology of concrete floor insulation along the logs:

1. First of all, they clean the concrete slab from the old screed, debris and dust.

2. Arrange waterproofing. It is convenient to use ready-made waterproofing polymer-bitumen solutions, which are applied to the concrete surface with a roller or brush. Another option is to use a vapor barrier film for these purposes, which is laid out on the floor with an overlap, leading to adjacent walls. If you want to save money, then the most acceptable material for hydro and vapor barrier will be ordinary polyethylene film.

3. Lags are installed at a distance of no more than 0.9 m from each other, if you take a step more, then the floors will sag. Instead of a log, if bulk material is supposed to be used for insulation, metal beacons are attached to the floor.

Installation wooden lag on the concrete floor

4. Lay the selected insulation. Suitable for both mineral wool and polystyrene, and any variant of loose thermal insulation materials. Insulation in the form of sheets or rolls, laid out tightly, without gaps between the lags. Bulk material (for example, expanded clay) is poured between beacons and leveled to one level with a metal rule.

5. Lay the floor. To do this, you can use sheets of plywood, GVL, OSB, chipboard with a thickness of 10-15 mm. It is safer to lay them in two layers so that the seams of the lower sheets overlap with the panels of the upper sheets. Thus, the floor covering will be seamless, which will eliminate the possibility of cold bridges. After laying, the layers of sheets are connected to each other and to the lags (beacons) using self-tapping screws.

Laying sheets of dense material (plywood, GVL, etc.) on logs

6. Suitable for any floor finish.

In a short video, you will clearly demonstrate the process of warming along the lags:

Features of floor insulation by spraying

In addition to the above methods of insulation, there is another, professional one - spraying a thin layer of polyurethane foam (PPS) on the base of the floor. As a result, a monolithic, devoid of seams, surface with a thickness of 50-100 mm is formed on the floor. The technology for applying PPS involves the use of special equipment and some skills, so this work can only be done by specialists.

Equipment used for spraying high pressure, which allows you to apply the material to the floor in the form of an aerosol liquid. In a matter of seconds, this liquid spray layer turns into rigid polyurethane foam. The efficiency of the resulting heat-insulating layer surpasses any other heaters - PPS has a lower thermal conductivity than mineral wool, foam plastic, expanded clay, foam concrete, etc. In addition, polyurethane foam is absolutely moisture resistant, therefore it does not need additional hydro and vapor barrier. This material does not require floor preparation before application, is not damaged by rodents, does not rot, does not burn. The service life of the heat-insulating layer of PPS is estimated by the manufacturers of this material at 30-50 years.

Polyurethane foam - effective method creating a warming and waterproofing coating in the apartment

Alternative ways of warming

If the heat loss through the floor is small, then you can use simpler methods of insulation. Their essence is to use a material with a low coefficient of thermal conductivity as a floor covering.

The simplest thing is to lay carpet or carpet on the existing floor. Products made of natural wool with a long pile have the greatest warming properties.

Another option is to use thickened linoleum on a warm substrate (felt, jute) or on a foam base. Similarly, it is possible to “insulate” a laminate by laying a thickened cork, polyethylene or expanded polystyrene underlay under it.

Thus, in order for the floor to maintain a comfortable temperature even in winter, it is not necessary to use additional heating systems and “warm floor” structures. In most cases, to increase the floor temperature by several degrees, it is enough to properly insulate it with the help of available materials.

Residents of block houses, apartments located above unheated basements or from the end side are “chased” by the discomfort associated with cold floors. And not only that - often they witness the freezing of joints and corners, the formation of condensate in the room, which sooner or later leads to damage to the flooring and swelling of the furniture. How can you make the floors warmer, what materials to use when insulating the floors in the apartment?

Thermal insulation material

All heaters can be classified by origin into several groups. Moreover, each material, in turn, is distinguished by its installation technology.

- Heaters of mineral origin. This group includes cement mortars with various modifying additives, mineral wool, expanded clay.

- Wood chip- Chipboard, sawdust, plywood, ecowool.

- polymer group- polystyrene and its types ( solid slabs), penofol, polyurea penoizol (liquid polymers).

- Silicate - glass wool.

There are, of course, among them favorites.

Most often, floor insulation in an apartment is performed using materials such as:

Mineral wool. It is distinguished by high heat and effective sound insulation, resistance to moisture, fire, etc. When choosing mineral wool, the density should not be lower than 125 kg / m3, otherwise either the loose wool will be practically pressed down by the weight of the screed and partially lose its heat-insulating properties, or the screed will operation of the floors will begin to "walk", which in the future will lead to the destruction of the final floor covering. Mineral wool is produced in the form of:

- boards with high hydrophobic properties;

- they are quite effective for single-layer floor insulation;

- flexible mats, which are distinguished by increased elasticity and strength, on the one hand they are covered with a special perforated paper.

Expanded clay. The insulating layer of expanded clay is scattered before the screed is completed. based on the specifics of the project. If it is thick enough, it is recommended to shed it with cement "milk" and lay a reinforcing mesh. As a result, the base will not be “loose”, which will ensure the absence of “play” of the screed and cracks in the future.

Styrofoam. The salient features include:

Styrofoam. The salient features include:

high level of thermal insulation, low cost and durability. Its more often, with a heating system, above the basement. Expanded polystyrene allows laying on any surface: concrete, wood, metal or ceramic tiles. It is especially effective on concrete floors. Its installation is incredibly simple - the insulation is fixed to the base of the floor, a reinforcing mesh is laid and poured with an ordinary concrete screed.

Penoplex . Modern insulation, which in its structure represents expanded polystyrene. With its help, thermal insulation of various structures is performed. The material is distinguished by moisture resistance, low thermal conductivity, and durability. Penoplex insulate the surface of any configuration. The thermal insulation of the floors is carried out along the lags when laying the base, followed by pouring the concrete mixture.

How to properly insulate the floor in the apartment

Let's imagine two main schemes for performing thermal insulation of floors in an apartment.

First of all, all existing structures are removed up to the overlap. Rigid insulation boards are installed on the cleaned and leveled surface. If the thermal insulation material is hygroscopic, an additional vapor barrier layer is required. On top of them, a screed (thickness 4 cm) is made, on which a reinforced wire mesh is laid.

To increase the resistance of the coating to thermal expansion, it is necessary to exclude the possibility of its contact with the walls, for example, lay a thin layer of polyethylene foam.

After that, in accordance with the accepted technology, a finishing coating is laid. The resulting design is able to withstand significant floor loads that are possible in an apartment.

An easier option in terms of loads on the floor slabs is the laying of thermal insulation between the logs, laid in increments of 60 cm. They are installed directly on the concrete floor slab. A vapor barrier layer is laid on top of the log, and a continuous “rough” coating is laid on it under the finish.

In houses of old buildings, insulation is placed between the floor beams.

Some simple ways to insulate

Izolon. Isolon, sold in rolls, is laid on the cleaned surface. It is glued with special adhesive tape to prevent its displacement during operation. The topcoat, say, a laminate, is laid directly on the heat-insulating layer. This method is very simple, but quite effective.

Expanded polystyrene or screened polyethylene foam. A high-quality polyethylene film is laid on the prepared surface with an overlap (15 cm), so that it goes onto the walls by at least 2 cm. The joints are carefully glued. Next, a heater is placed, and on top - a mounting grid. The resulting structure is poured with a concrete screed of 60–80 mm.

Fiberboard sheets. Sheet material is laid on the prepared surface and covered with a vapor barrier on top: plastic wrap or special foil.

Floor insulation will not be complete if you do not take care of the insulation of pipe connections and various electrical or water communications.

Water floor. A layer of waterproofing is laid on the surface, then a foil insulation is laid. Next, lay with a snake metal-plastic pipes usually 20 mm in diameter. They are attached to the floor using special plastic cuffs, and the ends are connected to the riser. Performing a system health check is mandatory for at least 20 hours. The pipes are left to cool for a couple of days and the screed is poured.

Warm electric floors are mounted in much the same way as water floors, only floor heating passes through electrical cable. Warm floors are also good because the heating temperature can be adjusted. In addition, the room warms up evenly, since the heat is evenly distributed over the floor surface and rises evenly.

Thermal insulation of building envelopes most often includes wall decoration. However, insulation is also required for vertical surfaces such as floors. It will be especially important to carry out such work if there is an unheated basement under the apartment. Although the inhabitants of the upper floors of block buildings also face problems with cold floors, observing the freezing of corners and the formation of condensate in the premises. Before you insulate the floor in the apartment, you should choose the right material that will be used for this.

The choice of insulation

Heaters used for thermal insulation of floors, by origin are:

- chipboard (ecowool, plywood);

- polymeric (polystyrene, penoizol);

- mineral (mineral wool, cement mortars, expanded clay);

- silicate (glass wool).

The decision on which type of insulation material to choose depends on various factors. For example, some of them will better insulate a wooden floor, while others are not suitable for such a base at all, and still others can be used for any surface.

It is also worth paying attention to the thickness of the insulation, which can sometimes significantly reduce the height of the room.

Mineral wool and fiberglass insulation

Possessing good parameters of heat and sound insulation, mineral and glass wool allow you to insulate structures made of any material. In addition, their installation does not require special skills. And the service life of both insulation reaches 50 years. Mineral wool and fiberglass are often used for thermal insulation using logs, as well as laying under the subfloor.

Among the shortcomings of the materials can be noted:

- relatively high thickness;

- low mechanical strength;

- high water absorption. Moreover, in mineral wool it is 2 times more compared to glass wool.

Penoplex or expanded polystyrene

For polymeric materials such as expanded polystyrene and foam plastic, the following are characteristic:

- high thermal insulation properties;

- affordable cost;

- long operational period.

They are well suited for providing over basements or cold grounds. Although they have a number of disadvantages - the inability to use wooden floor without prior preparation, increased flammability and brittleness. In addition, moisture ingress leads to the appearance of mold and fungi on the surface of materials, therefore, after installing polystyrene foam or foam plastic, it must be carefully protected with additional waterproofing.

Application of polyurethane foam

It can be attributed to the most modern methods of insulation of structures. It is suitable for mounting on any type of surface, including wood, concrete and even tiled floors.

And for such a heater, a device for vapor and waterproofing is not required. The disadvantages of the method are the too high cost of both the material itself, and the performance of work (which cannot be done by hand), and further finishing of its surface.

Gypsum fiber boards, which are also called "dry screed", are a universal technology with a minimum increase in its thickness (up to 25 mm).

This results in a smooth finish that is compatible with all finishes, including electric floors.

Another advantage of choosing this particular method is the high speed of work - up to 5 square meters. m per hour.

And among the shortcomings can be called:

- relative high cost;

- the impossibility of an independent device.

Thermal insulation with expanded clay

One of the most inexpensive ways insulation is laying on top of the expanded clay floor. This material protects well from the cold, and absorbing moisture, it does not lose heat-insulating abilities.

At the same time, to ensure sufficient insulation, a large thickness of the insulation layer is required - up to 20 cm.

You can also make the room warmer with the help of self-leveling floors - special mixtures for leveling and warming. They are used in cases where it is required to ensure a minimum increase in the thickness (up to 50 mm) of a concrete structure.

At the same time, the heat-insulating properties of such floors are lower than those of most other materials, and making them yourself will not work without experience.

Stages of work

The choice of a specific insulation technique depends mainly on the location of the apartment. So, for premises on the ground floor, the work will be the most difficult - due to the high heat transfer and the likelihood of dampness (especially if there is a basement under the first floor). And for housing located above, it will take less time and materials.

Warming of the first floor

Before carrying out work on the insulation of the floor of the first floor, it is necessary to check the possibility of laying heat-insulating material from the basement side. If this can be done, it is possible to reduce the heat transfer of the floor without spending a lot of money. The ceiling of the non-residential premises of the basement is insulated with inexpensive mineral wool, after which the thermal insulation of the floors of the apartment will require less investment and is carried out in the same way as for housing on the upper floors.

Mineral wool in the basement is placed in a metal crate, arranged according to the principle plasterboard ceilings with vapor barrier. The device of a wooden frame in this case is undesirable due to high humidity premises, which will lead to a decrease in the service life of the tree and, accordingly, the entire insulating frame. True, metal profiles will not save mineral wool from damage, the condition of which should be checked before the start of the heating season.

If it is impossible to get to the floor from below, better insulation is carried out from the side of the apartment.

Before starting work, you should check the condition of the existing concrete screed under the main cover (which in any case will have to be removed). If it is damaged, the floors should be overhauled, and then the insulation should be continued in the following sequence:

- perform a vapor barrier over the base;

- pour a second screed (for example, from plastic concrete) with a thickness of 3–4 cm;

- install a crate;

- put a heater in its cells (for example, mineral wool or polystyrene);

- lay plywood 12–16 mm thick on the crate;

- restore the floor covering (parquet, linoleum, tiles) using the appropriate technology.

Top floor features

For all other floors, except for the first, it is much easier to insulate the floors. This is done by removing the old flooring, laying insulation, installing a layer of plywood on top and returning the original coating to its place.

The device of the floor over the plywood base can be performed with the preliminary creation of an additional base or without it (for example, when laying linoleum).

Features of the device "warm floors"

Warm floors, regardless of the location of the apartment, necessarily require the creation of a vapor barrier and screed with a thickness of 2–2.5 cm.

It is also desirable to lay on top of aluminized mats designed to prevent heating of the lower rooms. Features of the installation of the "warm floor" itself depend on its variety.

When installing a water floor, 20 mm pipes are laid on top of the metallized material, placing them in a snake.

With the help of cuffs, the system is attached to the floor, and its ends are connected to the riser.

Before the final introduction of the "warm floor" into operation, it must be checked within 15-20 hours. Only then can the screed be poured.

Electric heating

"Warm floor" electric type can be mounted in the same way as water - except that this does not require testing.

The advantages of such a system are simple temperature control and uniform heating of the room, the heat in which is evenly distributed first over the surface above the heating cable, and then rises.

It happens that the floors in the apartment need to be insulated. How to do this so that it turns out to be of high quality and durable, while not expensive? Let's compare heaters and their prices. Consider the technology of work, on the correct implementation of which much depends.

Why are the floors in the apartment cold?

Perhaps the apartment is located on the 1st floor or above the driveway, or there are unheated rooms from the bottom. One way or another, but at the same time, the floors need to be insulated, because no one likes the cold under their feet, and heat loss significantly reduces the contents of the wallet.

An ordinary reinforced concrete slab and a screed on it easily conduct energy through themselves, as a result of which the cold from below almost unhinderedly affects the flooring and the entire apartment. On the way of cold, you need to create a barrier of heat-insulating material. Such an obstacle will reduce the rate of energy transfer tenfold.

It is important to use a heater, which is commonly called effective, and the thickness of its layer should not be small so that the heat-insulating barrier really saves heat well.

What kind of floor insulation should be used? Consider the most popular options.

Floor heaters

To insulate floors in an apartment, the following heaters are most often used.

- Polyfoam - the main advantage in low cost, as well as in the efficiency of insulation - 0.04 W / mS. At the same time, foam plastic is not allowed in places where there are rodents; it must be closed from the room with a slow-burning barrier.

- Mineral wool - can vary significantly in its qualities. Expensive samples are dense, heavy and strong, they can be under a screed, they do not shrink. Cheap loose cotton is prone to shedding. But, as a rule, mineral wool is not environmentally friendly, except for the most expensive samples, it accumulates water, requires closure from the room with dense vapor barrier layers with ventilation from the outside. The coefficient is at the level of 0.045 - 0.05 W / mS.

How much do floor heaters cost?

Styrofoam will cost the cheapest, its square meter with an average thickness of 10 cm will cost about 120 - 140 rubles.

Mineral wool is budgetary, not dense, it will cost 150 - 180 rubles / m².

Expanded clay, on average - 1500 rubles. per meter cubic

And extruded polystyrene foam 8 cm thick - 330 rubles. per square meter.

If we need to insulate the floors in a room of 20 square meters, then we will have to spend only for the insulation.

- Expanded clay, taken with a layer 20 cm thick - 6000 rubles.

- Styrofoam, 10 cm - 2800 rubles.

- Mineral wool, 10 cm - 3600 rubles.

- Extruded polystyrene foam 8 cm - 6600 rubles.

But you need to look at how much the accompanying structures will cost, and all the work as a whole, which will turn out to be much more expensive than the heat insulator itself. It is clear that it is pointless to save on the thickness of the insulation - these are pennies, the lack of which will entail incomparably greater losses in the future.

Creating insulated floors with screed

If the base allows the placement of a cement screed, then you should take advantage of this and get the most reliable, strong and durable subfloor with it. On a sand-leveled base, extruded polystyrene foam from 8 cm thick is laid, and if a water-heated floor is planned, then it is recommended from 12 cm thick. Expanded polystyrene sheets are stacked with a tenon-groove, all cracks are sealed with fragments of material on glue.

Along the perimeter of the room, an edge tape is installed on the walls, or a heater 1–1.5 cm thick, which will separate the screed from the walls. The insulation layer is covered with polyethylene, which will prevent the mortar from adhering to the heat insulator. Then reinforcement is placed on small supports - a mesh with a cell of 10 cm. Now the place for laying the cement-sand (concrete B20) screed is ready, which is prepared and laid according to classical technology. The result is the best insulated base for floors - a floating screed.

Also, the screed is made directly on the expanded clay layer. But the requirements for reinforcement and thickness remain. Here the screed will also serve as a vapor barrier for the thermal insulation layer.

Floors on the crate

There are special metal systems raised floors that rest with legs on the base. But they are expensive, so they often use dry wooden beam thickness from 80 mm.

Typically, the crate is placed so that there is 600 mm between the bars, which corresponds to the standard thickness of the insulation. It is recommended to put the crate on stands made of wood, which significantly reduces cold bridges.

An edge tape is also used, the space between the bars (and possibly under the bars is laid in a solid insulation - expanded clay, foam plastic, mineral wool.

From above, the insulation layer is separated by a continuous vapor barrier - a special construction film, which is laid with overlaps, glued, screwed onto the walls. It is also recommended to leave a gap of up to 20 mm under the flooring.

Flooring is best made from dry cheap boards, which, compared to plywood, do not emit formaldehyde. Further, on such a flooring, you can put a coating of laminate, linoleum or parquet board. And in the case of using foam plastic, it is necessary to lay low-combustible cement-fiber or gypsum-fiber boards with a total thickness of 3 cm or more.

What Not to Do

- Use materials of dubious environmental friendliness, such as OSB ...

When laying synthetic insulation, it must be separated from the living space with a vapor barrier.

- Use materials of dubious environmental friendliness, such as OSB ...

- Reduce the layer of insulation.

If the thickness turns out to be small, the effect will not be noticeable, even "by eye", therefore, the time and money spent will be in vain.

What questions arise when insulating floors from the inside

In most cases, the floors in the apartment are insulated from the inside, since it is often impossible to do this from the outside, problematic.

In doing so, the following questions need to be taken into account and addressed:

- the height of the room should not be less than 2.4 meters, otherwise the ceilings will seem low, overhanging.

- raising the floors may disturb the location of the radiators and interior doors, which will have to be solved by rewiring.

- materials used for the construction of insulated floors must be environmentally friendly, allowed for indoor use.

- heaters, as materials with dubious environmental friendliness, except for expanded clay, it is desirable to separate from the living space with a reliable

vapor barrier.

Is it possible to insulate from the outside

Sometimes it is possible to insulate the floors in the apartment from the outside, which is the preferred option. In addition to the above issues, other problems related to internal insulation will also be solved.

- The possibility of wetting the insulation at the dew point with a loss of thermal insulation efficiency, in the presence of intense steam movement through the layers.

- Cooling and freezing of the ceiling and adjacent load-bearing structures in a wet state.

- Decreased efficiency of heat insulator application due to incomplete overlap of cooled structures…etc.

In some cases, there is access to the ceiling from the outside, for example, from the basement, which can be used and a layer of thermal insulation applied to the slab.

It is possible to insulate the floors from the outside with the help of polystyrene foam using the wet facade technology. The process will be cheaper, since most likely there will be no requirements for surface design - only a primer.

Substances and their physical properties

Substances and their physical properties Classification, structure, nutrition and the role of bacteria in nature

Classification, structure, nutrition and the role of bacteria in nature Bacteria - the most ancient organisms on Earth Bacteria - the oldest group of living organisms

Bacteria - the most ancient organisms on Earth Bacteria - the oldest group of living organisms Epithets, metaphors, personifications, comparisons: definitions, examples

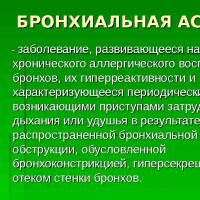

Epithets, metaphors, personifications, comparisons: definitions, examples Bronchial asthma Bronchial asthma

Bronchial asthma Bronchial asthma Roman Empire Ancient History

Roman Empire Ancient History Flexible removable dentures: design, features and benefits Varieties of soft dentures with photos

Flexible removable dentures: design, features and benefits Varieties of soft dentures with photos