The pitch of the rafters of a gable roof. How to determine the distance between the rafters of a mansard roof? How far to lay rafters

The service life and final reliability of the roof are in the correct preparatory work, to which the correctly chosen distance between the rafters can be attributed. It is from this element of the supporting frame that the distribution of the load on the supporting frame directly depends, an error in the calculations of which can lead to deformation and collapse of the entire roof. So, the calculation of the total distance between the truss elements is one of the most important tasks in planning and calculating the load-bearing house.

Basic calculation technology

Rafter pitch is the exact distance between two legs of one truss truss. Most often, in private construction, the distance between the legs is about one meter, but the exact figures should come from a detailed calculation of the bearing capacity of the selected type of roofing system. In order to independently perform such a calculation, you must adhere to the following scheme of actions:

- Having measured the eaves of the roof structure, it is necessary to determine the total length of the roof slope.

- The resulting value must be divided by the selected and most optimal step of the rafters. In other words, if exactly one m is chosen in the rafters, then the length of the slope must be divided by this unit of measurement.

- One is added to the result, after which you can round the finished value. It is this method that allows you to determine the number of roof trusses on one roof slope.

- Now it’s worth dividing the length of the roof slope by the resulting number of trusses, which will allow you to determine the pitch of the rafters.

It is worth recalling that this method of calculating such a building element as the pitch of the rafters cannot be considered extremely accurate, because in such calculations it is necessary to take into account the features of the selected roofing material, which can be a problem in the absence of proper experience in this matter. It is for this reason that methods will be described below that will allow you to choose the right rafter pitch for popular roofing materials.

Ceramic tiles and rafter installation

The main feature of the manufacture and installation of a truss bearing system for ceramic tiles is the extremely large weight of the roofing material, which in its totality is ten times greater than the weight of any roofing material.

As a rule, this type and size of roofing material provides for up to 60 kg per square m of the truss bearing system. All this becomes the reason for the use of only dry lumber on the roof, which eliminates the possibility of further deformation during drying and pressure.

When using a wooden beam on the roof, the cross section of which is 150x50 mm, the step between can vary from 70 to 120 cm.

In addition, the distance between the rafters may depend on the overall slope of the roof.

Do not forget about the length of the legs themselves rafter type. The longer this length is, the smaller the distance should be between the legs of the rafters, otherwise the supporting frame of the roof will be deprived of maximum strength and stability.

Experts recommend using no more than 80 centimeters of pitch between trusses if the roof slope is up to 45 degrees. Special attention should be paid to the lathing system when using ceramic roofing material on the roof.

To determine such a step, it is necessary to take into account the characteristics of each individual element of the roofing material, namely each tile. In order to perform the correct calculation of the crate step for such material, it is necessary to subtract the length of the lowest row and the distance between the last bar and the row of the crate from the pitched length.

As a rule, all varieties of such roofing material have a length of no more than 40 cm. When laying tiles, they are overlapped, which takes up to 9 cm from the bottom row. In other words, the correct step in this calculation is from 31 to 35 cm.

Metal tiles and laying methods

As a rule, the use of metal tiles in private construction is considered the most common, for which there are a number of reasons and positive characteristics of this roofing material on the roof.

If we compare such a roofing type material with the one described above, then several striking differences can be noted, each of which can be safely considered a positive feature of the material. First, it is worth recalling the simplicity and speed of installation of such material, which is made in a sheet type, allowing you to cover a significant area of \u200b\u200bthe roof at a time.

The second feature of metal tiles on the roof can be considered the extremely low weight of the material, which has a positive effect on installation, work on the roof and the load on the supporting frame of the roofing system.

This feature can be considered the most important, because it is responsible for the lower costs of labor and time in organizing the truss carrier system. When using this roofing material, the pitch of the rafter bearing legs is from 60 to 95 cm, because the reduced weight and size of the roof does not require high load resistance parameters.

With such indicators, it is worth using thermal insulation material, whose thickness is not less than 15 cm, which fits between the rafters. When arranging ,thickness insulating material should or may be larger, because it is necessary for arranging a residential floor in the attic. This also affects such an element as the thickness of the material that is used to make the rafter load-bearing legs.

All this indicates the absence of significant differences in the truss system for metal roof tiles. This roofing material provides standard knowledge about the construction of truss and roofing systems, which is simply necessary to install. The main difference of such a system may be the fastening of the upper type support to the ridge run, and not through the ridge type beam itself.

The free space at the top of the system, obtained through the installation of rafter legs, is ideal for ventilation of the entire under-roof space, which is often covered with condensate in metal roofing material.

In the event that changes are made to the roof of the old wooden house, it is necessary to completely remove the Mauerlat, replacing it with a common crown of the upper type. In such a crown, it is necessary to put marks and make selections with the desired step, into which the elements of the rafter bearing legs will be installed. This allows you to more accurately calculate the pitch of the rafter bearing legs and install them.

Decking and determining the distance between the racks

When using such a roofing material as corrugated board, the calculation of the correct pitch of the rafter bearing legs is 60-90 cm, which practically coincides with all the types of structures and roofing materials described.

If necessary, put more distance between the elements of the rafter legs, it is necessary to insure the transverse elements of the crate with a greater thickness and cross section. This will strengthen the entire supporting structure, which will extend the life of the entire roof. The step between is about 50 centimeters, when using a board that is at least 10 centimeters in size.

When it comes to such a moment as calculating the sheathing on the truss system, you should not forget that the last board should be 1.5 centimeters thicker than all the other elements of the system. Before installing the elements of the crate, it is worth remembering the presence of a chimney and a special system that should be on each roof. This will save time on calculation and rework. truss system, and crates in general.

Ondulin and construction installation methods

As in the cases described above, ondulin provides for the calculation of the pitch of the rafter bearing legs from 60 to 100 cm, which makes such sizes standard when using the most popular roofing materials.

The truss trusses themselves are made of lumber with a section of 200x50 millimeters, which is quite enough to ensure that the strength and reliability of the truss system are at the maximum level, and it is easy to install them. It is immediately worth noting the fact that the described roofing material needs a continuous lathing system, which will allow the material to qualitatively resist the loads from snow thicknesses, as well as solar exposure.

In some cases, you can also use a thinned type of crate, the calculation of which is quite simple, if used for this. wooden beam, the step between the elements of which is no more than 30 cm. As a rule, this option is more expensive than necessary for the installation of a continuous crate. In other words, it is irrelevant to use the thinned type of system in this case.

Slate and truss structure under it

As a rule, slate coating is considered the most common in our country. The reason for this indicator can be considered the extremely low cost of the material, the simplicity and speed of installation, as well as the possibility of replacing individual sheets in case of damage to individual sections of the roof.

The distance between the rafters for this type of roof should be 80 cm. It is this distance that is considered the most optimal solution when combining the load from the weight of slate sheets.

The crate in such a system needs a thinned type using a board or timber of any type, but of a certain section, which should not be less than 30 mm. Such a thickness of a board or timber is needed for high-quality and correct distribution weight from the roofing material itself, as well as from winter precipitation.

Do not forget about the constant margin of safety when organizing the truss system, which may be required in case of unforeseen circumstances associated with mechanical loads and bad weather. All other features of the truss and crate system do not have any special differences from the options listed above. In other words, for all other types of coatings, we determine the distance in the same way as for the above roof.

The reliability of the roof and its service life mainly depend on how correctly the calculations are made.

One of the most important parameters of the rafter system is how far apart the rafters are located.

After all, the distribution of the load on the frame depends precisely on this desired parameter.

If the calculation is made incorrectly, then deformation may occur and the roof will collapse.

Therefore, it is extremely important to perform an accurate calculation of the interval between when drawing up a roof project.

Basic provisions of the calculation

The pitch of the rafters is the distance from one rafter leg to the other.

In the construction of roofs of private houses, this value is 1 meter.

But this figure is approximate.

To get the exact size of the interval, it is necessary to calculate the bearing capacity of the truss system of the selected type.

To perform the correct calculation, the following scheme should be used:

- first you need to determine the length of the roof slope;

- now the resulting figure should be divided by the value of the approximately selected rafter pitch. If you previously chose its value of 1 meter, then you need to divide by 1.

If 0.8 was chosen, then it should be divided by 0.8, etc.;

- after that, one is added to the result obtained and the resulting value is rounded up. This action is necessary in order to get the exact number of rafters that will need to be installed on one slope;

- the total length of the slope must be divided by the number of rafter legs obtained in the previous calculation. And we get the exact distance between them.

To better understand everything, let's look at an example.

By measuring the length of the roof slope, we got 27.5 meters.

We choose a step of 1 meter to make it more convenient to count.

Further calculations will look like this:

Now we add the unit 27.5 m + 1 = 28.5 m.

We round up to the nearest value and get the number 29.

That is, 29 rafter legs must be installed on one slope of our roof.

Now we divide the length of the roof by their number: 27.5 / 29 \u003d 0.95 m.

So, in our case, the step of the rafter legs should be 0.95 meters.

This is a general calculation.

In which the peculiarity of a particular roofing material is not taken into account.

And he can significantly change this parameter.

When you know what kind of material you will use on the roof, some changes will have to be made to the calculation procedure.

Optimal and minimum value

The step is the unit of account.

After all, it depends, first of all, on the load on the roof frame and the section of the rafter legs.

You can take a thick board for their construction and make the interval between them 120 cm.

At this distance, the crate may begin to sag.

Yes, and how to lay the heater?

Indeed, for most materials, the width is 1 meter.

So they take an approximate step of 1 meter when calculating.

The minimum distance between is 70 cm.

And to obtain the optimal value for each material, it is necessary to perform a calculation.

Determining the pitch for a pitched roof

Shed roofing is the simplest.

Indeed, in the truss farm of such a roof there are only rafter legs.

There are no struts, racks, braces in its design.

Such a roof is usually arranged on garages, outbuildings, baths.

In order to determine the pitch of the rafters on a pitched roof, you can use the table:

As can be seen from the table, the rafter step depends on their length and cross section.

Distance between rafters for a gable roof

A gable roof is much more common than a shed roof.

And to explain such popularity is simple: the design is very simple, but for all its simplicity, the gable roof is distinguished by its reliability.

Its design is easy to adjust to any climatic conditions and any roofing material.

When calculating the pitch of the rafters of a gable roof, everything is performed according to the general calculation system (see above).

If the slopes have the same length, then it is enough to perform calculations for one slope.

If the slopes are of different lengths, then the calculation is performed for each slope.

It should be remembered that the limit values \u200b\u200bof 70 and 120 cm.

What is the step depending on the material of the roof

Ondulin

If ondulin is used as a roofing material, then the rafter system is constructed from pine boards with a section of 50 x 200 mm, and the rafters should be located at a distance of at least 60 cm and not more than 90 cm from each other.

A crate of timber with a section of 40 x 50 mm is laid on top.

metal tile

Metal roofing during construction country houses used most often.

Because this material is much lighter than ceramic or cement tiles.

Although according to appearance very similar to her.

A small one makes it possible to use boards of a smaller section when creating a truss system, and use thinner bars for the crate.

Reducing the size of the elements of the rafter leg system, in turn, reduces the load on the walls of the building and its foundation.

During the construction of the rafter system under the metal tile, the rafters are mounted in increments of 60 - 95 cm.

The cross section of the material is 50 x 150 mm.

According to experts, if a heater having a thickness of 150 mm is placed between the rafters, then the most comfortable living conditions will be created in the attic.

To ensure ventilation of the space where the insulation is laid, when installing the rafter system, holes will be drilled near the upper roof with a diameter of 12 mm.

The technology for manufacturing a truss system for metal tiles does not differ significantly from the technology for manufacturing a frame for other roofing materials.

Its only difference is the installation at the top.

The upper support is mounted not on the side of the ridge beam, but on the ridge run.

The presence of a free zone between the rafters allows the air to fully circulate under the flooring, which helps to protect against the formation of condensate.

Ceramic tiles

System design under ceramic tiles has its own characteristics.

After all, clay is used to make such a roofing material.

And this is very heavy material.

If we compare metal and ceramic tiles, the latter weighs 10 times more.

Accordingly, the truss system is significantly different.

For 1 square meter the roof surface has a load of 40 - 60 kg, depending on the manufacturer and brand of the product.

The rafters for such a frame system are made from wood that has been dried for a long time.

Such wood should have a moisture content of no more than 15%.

A beam with a section of 50 x 150 or 60 x 180 mm is used.

So more reliable.

And the distance between can be 80 - 130 cm.

The exact value can be called if the angle of inclination of the slopes is known.

If the angle of inclination is 15 degrees, then the pitch of the rafters will be 80 cm.

And if the angle of inclination, for example, is 75 degrees, then the step can be larger - 130 cm.

More than 130 cm interval between the rafters do not.

Also, when calculating the pitch of the rafters, their length is taken into account.

The larger the dyne, the smaller the distance between them.

The shorter the rafter legs, the greater the distance can be.

If the angle of inclination is 45 degrees, then the roofer can safely move along the roof if the pitch of the rafters is 80 cm.

Decking

When creating a rafter system for corrugated board, the minimum distance between is 60 cm.

The maximum value is 90 cm.

If for some reason the pitch of the rafters was more than 90 cm, then it becomes necessary to install large cross-section boards.

The rafter legs themselves can have a section of 50 x 100 or 50 x 150 mm.

Slate

Despite the appearance a large number new roofing materials, asbestos-cement slate remains one of the most popular.

If it is planned to lay slate on the roof, then the rafters should have a section of 50 x 100 or 50 x 150 mm.

The distance between them is made not less than 60 and not more than 80 cm.

The crate is made from a bar having a section of 50 x 50 mm or a board with a section of 25 x 100 mm.

When device any building structure It should be remembered that there are still unforeseen situations.

And, therefore, at and distances between them, it is necessary to provide a margin of safety.

Video about the installation of the truss system.

The gable roof is the most popular design in private housing construction. truss system gable roof must provide a support platform for the installation of the roof. Properly calculated pitch of the rafters of a gable roof allows you to ensure the strength and stability of the structure to all external loads, create a durable and reliable roofing. This article discusses the design features of the truss system, the calculation and installation procedure. This information will allow you to correctly understand the methodology for creating a gable roof so that you do not ask unnecessary questions to workers during construction.

The distance between the rafters for a gable roof

Among people employed in the construction of a private or country house, there are constant discussions about the most successful roof design and the number of supporting elements. In order to understand these opinions and take one side or another, it is necessary to consider the general structure of the roof.

There are two types of rafter construction:

hanging.

Layered.

They are used on relatively small houses with a length of supporting elements of not more than 6 m. The structure consists of a number of truss trusses having the shape of an isosceles triangle. The trusses are installed on a strapping made of timber (Mauerlat), interconnected by batten strips. The bearing capacity of hanging rafters is relatively small, but the simplicity of design, economy and high speed of installation are their advantages. There are quite a few options for implementing hanging rafters, which is explained by the prevalence of small buildings that do not need a complex and massive roof structure.

Design layered truss system somewhat more difficult. Along the perimeter of the ceiling of the upper floor, a strong timber is laid - Mauerlat. Two (or more) vertical racks are installed along the longitudinal central axis, the height of which determines the angle of inclination of the slopes. A ridge run is installed between the posts, which runs along the entire length of the roof and serves as a reference line for the rafter legs. Each of them has two points of support - at the bottom it is a Mauerlat, and at the top - a ridge run.

For the formation of additional support, which excludes sagging of the supports, struts are used - inclined strips attached to the rafter legs at an angle close to a straight line and abutting in the lower part against the central lower bar - lying.

The step lag for the roof is the distance between two adjacent rafters. It is determined by the number of lags evenly distributed along the length of the longitudinal axis of the roof. The main supporting structures for the roof are rafters and lathing, forming inclined surfaces with a given geometry and area. The angle of inclination determines the wind and snow loads, and, with an increase in the angle, the wind load increases, and with a decrease, the snow load on the roof.

On our website you can find the most . In the filters, you can set the desired direction, the presence of gas, water, electricity and other communications.

What determines the pitch of the rafters

Consider the factors that determine the step between the rafters gable roof, details. It must be immediately taken into account that the number of rafters determines the bearing capacity. Reducing their number complicates the installation of insulation, contributes to the sagging of the laths of the crate and the roof installed on them.

At the same time, too frequent placement of rafters also creates difficulties in the installation of insulation. It has to be adjusted in width, which creates waste, i.e. waste of material. Therefore, the size of the heat insulator is often used as a criterion for determining the pitch of the rafters. For example, many types of mineral wool are 60 cm wide, which is quite suitable for most gable roof designs.

In addition, the pitch of the rafters directly depends on their number. This is a calculated value, which is determined based on the bearing capacity of the supporting elements. The loads acting on the roofing, as well as the weight of the roofing itself, are quite large, so a stable and durable structure is needed to accept them. It should be borne in mind that the type of rafter system also matters, since layered rafters are much heavier than hanging rafters, they form a noticeable load on the walls and foundation of the house.

Wind and snow loads are external factors that affect the roof structure. The weight of snow in winter can crush or even break a roof if its design is not properly designed. The SNiP applications contain special data on the average annual amount of snow in different regions. Some of them have up to half a ton of snow per square meter.

In addition to snow, wind creates serious loads. At the same time, if the snow load is static, then the wind effects are sudden and uneven. The wind can rise at any time of the year, both in winter and in summer, which makes us take it seriously. When choosing the angle of inclination, you should find out the strength and direction of the prevailing winds in the region, find out about the possibility of hurricane gusts. Available in SNiP applications.

All these factors determine the parameters of the truss system and the distance between the individual supports.

The dependence of the pitch of the rafters on the material of the roof

There are a large number of types roofing. Most of them are noticeably outdated and little used in modern construction. The most popular today are:

profiled sheet.

metal tile.

It should be noted that profiled sheet and corrugated board are one group of profiled coating. Some sources consider them to be different names for the same material, others separate them by wave height. The profiled sheet has a higher wave height, and the corrugated board is somewhat flatter. The first type can be used not only as a roof covering, but also as a material for the construction of fences, fences, metal garages, etc.

The corrugated board has a smaller wave and is intended for laying as a roof. Both materials have a common specific feature - profiling is performed only in the longitudinal direction, which expands their capabilities and allows you to make roofs for round roofs and canopies.

The step of the rafters of the gable roof under the corrugated board is selected taking into account this feature of the material. If the value is too high, it will be possible for the roof to sag between the rafters. In addition, there will be an excessive load on the battens, which may not be ready for it. An important parameter also becomes the area of the slope. Rafter pitch shed roof under corrugated board is much less than that of a gable roof, since the length of the supporting elements and the magnitude of the load in it increase significantly and require an increased number of supports.

The metal tile looks like a canvas made of natural ceramic tiles. In all its operational qualities, it is very similar to corrugated board or profiled sheet, but physically it has an important feature - the presence of not only longitudinal, but also shear waves. This allows you to slightly increase the step between the rafters of a gable roof under a metal tile, or be guided when choosing the size of a heat insulator.

When using slate or ondulin, the pitch of the rafters is taken according to the degree of rigidity of these materials. Alternatively, increase the density of the lathing, or install a solid version of thick plywood.

Method for calculating the distance between the rafters

There are two calculation options:

Engineering calculation using appropriate formulas and techniques.

Using online calculators, giving an answer after entering their own initial data.

The first method is only suitable for a professional roof system designer. For an unprepared person, it is extremely difficult to perform such calculations, since various specific data, coefficients, tabular values are needed, which are difficult to find and must be used correctly. Calculations obtained using online calculators are also not recommended for use in real construction, but as an option to refine or verify the results of calculations performed by specialized organizations.

Video description

In the video you can see what the step of the rafters should be:

Conclusion

In conclusion, it should be recalled that all design and calculation activities must be carried out by trained and specially trained specialists. The pitch of the rafters is an important and crucial value that determines the bearing capacity of the roof. The damage caused by the inability to take on existing loads is quite serious and can call into question the possibility of living in a house, so it is necessary to take this issue as seriously as possible.

The distance between the rafters is one of the key parameters that affect the strength of the structure. Competent calculation of the installation step of the rafters allows you to build a roof that is resistant to high operational loads.

Roof loads and rafter system calculation

The development of a single-pitched or dual-pitched roof project begins with the choice of the type of truss system, the angle of inclination of the slopes (roof height) and materials for the construction of the structure. The calculation of the distance between the rafter legs is carried out taking into account the loads that the roof will experience during operation. Permanent loads include:

- the weight of the materials from which the truss system is made;

- roofing weight;

- weight of roofing cake materials (waterproofing, vapor barrier, insulation);

- the weight of the finishing elements of a residential attic or attic.

In addition to permanent loads, the roof also experiences temporary ones, which include:

A step is the distance between the rafters of one slope. Performing the calculation of a single-pitched, gable or complicated roof, usually adhere to the following scheme:

- the length of the future roof slope is measured;

- the resulting value is divided by the optimal numerical value of the pitch of the rafters;

- one is added to the obtained value, the result is rounded off;

- the length of the roof slope is divided by the rounded result.

The final result will determine how far the rafter legs should be placed. The determination of the step cannot be extremely accurate, since it is necessary to take into account a number of additional factors, including the width of the insulation, the installation features of the crate under different kinds roofing material. If a roof with a chimney is being designed, the pitch can be adjusted according to its location so that it is not necessary to remove part of the rafter in the future and install a supporting structure, such as a special rafter system.

The distance between the rafters under the slate

Slate is a traditional roofing material. Its advantages include such characteristics as resistance to external influences (excluding mechanical ones) and low cost. Slate allows you to create a roofing, the repair of which can be reduced to the replacement of individual elements. Slate is heavy and requires the installation of a sufficiently powerful truss system. The calculation of the distance at which it is necessary to put the rafters under the slate is carried out taking into account the cross section of the beam for the manufacture of rafter legs.

The optimal solution is to install the system under the slate, in which the gap between the rafters must be at least 800 mm. In order for the slate structure to withstand not only the weight of the material, but also increased external loads, the crate is made of timber or boards with a cross section of at least 30 mm. When calculating the rafter system for slate, it should be read that this material has rather large restrictions on the choice of the angle of inclination of the slopes.

Rafters for metal roofing

Metal tiles are actively used as a practical and aesthetic roofing material when arranging a shed, gable, hip or complex roof. The frame for the metal tile is built according to standard principles. To calculate at what distance it is better to place the rafters, it is necessary to take into account the loads and the angle of the roof. The metal tile is characterized by a relatively small weight, so it can serve as a replacement for the old roofing of slate or ceramic tiles. In this case, the rafters do not need to be strengthened or the pitch of their installation changed.

The standard step of rafters for metal tiles is 600-900 mm. The cross section of the elements can be 50-150 mm - this is enough to create a reliable frame for a metal tile. But if it is planned to use insulation, the layer of which in areas with low winter temperatures should be 200 mm, it is recommended to use a 200x50 beam for rafters under metal tiles so as not to mount an additional system that holds the insulation. The gap between the rafters under the metal tile is best adjusted to the width of the sheet or roll heat insulator.

Decking: rafters and crate

The professional flooring belongs to easy and convenient roofing materials in application. Galvanized or covered with a decorative protective layer corrugated board can be used for installation pitched roof utility room or garage, and for the gable roof of a residential building. How to calculate the distance required to install the rafters under the corrugated board?

To ensure the necessary rigidity of the structure, it is enough to install the rafters under the corrugated board in increments of 600-900 mm. In this case, it is necessary to pay attention to the angle of the roof. The calculation shows that with high external loads, it is better to lay the corrugated board on the system with a minimum step. But if the distance between the rafters under the corrugated board is close to the maximum, and the angle of the roof slope is small, then the structure is strengthened by using a more frequent crate. In this case, the step of the crate under the corrugated board should be about 50 mm, the width of the elements should be at least 100 mm.

Rafter system for soft roofing

Soft roofs include bituminous and bitumen-polymer roll materials, roofing membranes, as well as soft tiles. A soft roof is characterized by a relatively low weight and no need to install a massive truss structure.

The minimum distance between the rafters is 600 mm, the maximum is 1500 mm. When installing the support under soft roof it is important to take into account the angle of inclination of the slopes: the smaller the angle, the smaller the distance between the supports for a continuous crate should be. The choice of step is also influenced by the thickness of the material for the crate - the thicker the plywood or OSB sheet, the greater the installation step of the rafter legs can be.

Ondulin: calculation of rafters

Ondulin (bituminous slate) is laid on a flat, continuous crate made of sheet material. This allows the roofing to successfully resist wind and snow loads. The crate under the ondulin rests on the rafters, which should be located in increments of 600 - 1000 mm, depending on the angle of inclination of the gable or shed roof.

Rafters for ondulin are made of timber with a section of 200 × 50 mm. When choosing at what distance to put the rafter legs for the structure under the ondulin, it is recommended to take into account the width of the insulation material in order to simplify its installation. This calculation reduces financial expenses for roofing.

Sandwich panel roof

Sandwich roofing is most often erected on sip-panel houses or hangar-type buildings. A feature of the sandwich is its bending rigidity, which makes it possible to dispense with the installation of traditional rafters. Small spans from the ridge of a gable roof to the upper part of the wall (or the distance between the supporting structures of a shed roof) allow the installation of a sandwich without additional supports.

If the span exceeds 4 meters, additional girders must be installed. To install a sandwich roof on a residential building, a traditional rafter system is often installed, but in this case the rafters can be positioned with a large step - they serve as a support for the girders. The distance between the rafter legs is selected based on the length of the available material for the runs and the length bearing walls. Technical specifications sandwich allow the roof to withstand high operating loads.

Polycarbonate: erection of the supporting structure

Polycarbonate has recently been actively used as a roofing material. First of all, polycarbonate is in demand in the construction of gazebos, sheds, winter gardens. The crate and truss system for polycarbonate can be made of wood or metal.

Polycarbonate varies in weight depending on the thickness of the sheet. The crate for polycarbonate is recommended to be done in increments of 600-800 mm. The crate (wooden or metal) is mounted on rafters, which can be straight or arched. Usually the gap between the rafters for polycarbonate is from 1500 to 2300 mm. In order to correctly calculate at what distance it is better to bleed the rafters, it is necessary to take into account the glazing area, the dimensions and thickness of the sheets, and take into account that polycarbonate is attached with gaps for thermal expansion.

The distance between the rafters of a gable and single-pitched roof

Find out what distance between the rafters you need to make for a gable and shed roof. The maximum distance between the rafters for metal tiles, ondulin and soft roofing.

What is the distance between the rafters of a gable roof

Roof erection - The final stage any construction. This structural element is a load-bearing structure that takes on all the loads, and then evenly distributes them over the surface of the load-bearing walls of the house.

gable roof

A gable roof is rightfully considered the most common option for arranging suburban housing. And there is a perfectly logical explanation for this. It's no secret to anyone that simpler design, the easier it is to build and the higher its reliability and performance.

The gable roof has a triangular shape and consists of two pitched planes connected in highest point ridge run, and the same number and shape of gables.

In principle, the construction of a gable roof is not considered such a complicated operation. But, despite all the simplicity, it requires the most responsible and thoughtful approach.

Structurally, a gable roof has two slopes located at a certain angle relative to the wall elements of the house, providing it with a natural removal of precipitation from its surface. Also, gable roof structures can be attic or attic type.

As a rule, gable roofs are installed on one-story, architecturally simple structures. A huge plus is that the rafters in this case will not be particularly difficult to install.

The angle of inclination of the roof slopes of the gable roofs

The angle of inclination of a gable roof cannot be less than 5 degrees, and in some cases it can even reach 90 degrees. Only with such an angle of inclination of the roof slopes, the rafters will be able to adequately cope with the function assigned to them.

The choice of the angle of inclination of the slopes for gable roof influenced by a huge number of factors, such as climatic features, the type of roofing material chosen and architectural style building.

For example, sloping roofs are ideal for building in areas where strong gale-force winds constantly blow, but steep-sloped structures are a great option for areas that receive an impressive amount of rainfall.

Also, the angle of the roof affects its cost, this is due to the fact that much more roofing material will go to the roof with a small angle of roof slopes than with a large one.

However, this is not the only important parameter in the construction of a gable roof. Equally important in the formation of a gable roof is correct installation and fastening of the truss system, as well as the step size between its elements.

Also, the quality of the structure is affected by the fastening of the rafters to the Mauerlat and the ridge run. Particularly reliable fastening can be formed with the help of cutting and additional fixation of the joints with bolts.

The distance between the rafter legs (otherwise, the pitch of the rafters) is considered one of the most important parameters when installing a roof, which affects its strength characteristics.

A correctly calculated step between the rafters of a gable roof allows you to form a roof that is resistant to the high loads that it will be subjected to during operation.

Let's take a closer look at what the distance between the legs of the rafters should be.

Rafter spacing for a gable roof

The distance between the rafters of a gable roof is calculated at the time of design. Correcting any mistakes made at this stage is quite problematic, and therefore if you are not confident in your own abilities, then it is better to entrust its implementation to professional architects.

Reliable rafters are the basis of any roof of the house.

The rafter step is calculated taking into account the loads to which the structure will be subjected during operation, and the angle of inclination of the roof slopes.

With a competent calculation, the presence or absence of an insulating layer, cross-section structural elements truss system, type of lathing and roofing. It is necessary to correctly calculate the load, as this will help not to make a mistake when choosing a rafter section.

The rafter step is the distance between two adjacent truss trusses.

Step-by-step instructions for calculating the pitch of rafters for a gable roof:

- We calculate the estimated length of the roof slopes.

- The resulting number is divided by optimal dimensions step.

- Add one to the resulting number and round the result.

- We divide the length of the slopes by the rounded result.

As a result of these simple calculations, you will get the distance at which the rafters should be installed.

The step between the rafters cannot be calculated exactly, since in order to obtain more accurate data, it is necessary to take into account a huge number of parameters, ranging from the width of the insulation layer, the type of roofing material, and even the distance between the elements of the gable roof lathing. Rafters installed correctly will serve you faithfully for decades.

Step of rafters under asbestos-cement slate

An important parameter of asbestos-cement slate is its significant weight, due to which it requires the installation of powerful rafters that can withstand heavy loads. The distance between the rafters is selected based on the section of the timber used to make the rafters.

It is equally important that the gable roof rafters are properly fastened, as this will provide it with a high degree of reliability and a long service life.

The optimal step between the rafters when using asbestos-cement slate should not be less than 800 mm. Thanks to this, the rafters will be able to easily cope with the task assigned to them.

Rafters for metal tiles

We will not talk about all the advantages and disadvantages of this material, a lot has already been said about this. Let's take a better look at what should be the step between the supporting structural elements. Rafters for metal tiles are installed in accordance with existing norms and requirements.

Due to its low weight, this coating can be used to cover roofs on which ceramic tiles or asbestos-cement slates have previously been laid.

The size between the rafters in this case ranges from 600 to 900 mm, and the cross section of the lumber is 50 by 150 mm. Such a step between the rafters will allow you to create the most reliable supporting frame for the roof.

However, in areas characterized by snowy winters, it is preferable to equip the distance between the rafters of 200 mm, and for the manufacture of structural elements, use a beam with a cross section of 50 by 200 mm.

In order not to mount a special system to support the insulation, you can adjust the distance between the rafters to the width of the thermal insulation material.

Rafters for ondulin

Ondulin or flexible tiles should be laid on a solid, perfectly even crate, and it is better if it is made of some kind of sheet material, which will allow the roof to endure all loads.

The lathing is attached to the rafter legs, located in increments of 600 to 1000 mm, depending on the angle of inclination of the roof slopes of the gable roof.

The correctly chosen distance between the elements of the truss system guarantees the entire supporting frame a high degree of strength and durability of the entire structure.

What is the distance between the rafters of a gable roof, YouSpec Building Encyclopedia

The correctly chosen distance between the elements of the truss system guarantees the entire supporting frame a high degree of strength and durability of the entire structure.

The distance between the rafters: the correct calculation

The reliability of the roof and its service life mainly depend on how correctly the calculations are made.

One of the most important parameters of the rafter system is how far apart the rafters are located.

After all, the distribution of the load on the frame depends precisely on this desired parameter.

If the calculation is made incorrectly, then deformation may occur and the roof will collapse.

Therefore, it is extremely important to perform an accurate calculation of the interval between the rafter legs when drawing up a roof project.

Basic provisions of the calculation

The pitch of the rafters is the distance from one rafter leg to the other.

In the construction of roofs of private houses, this value is 1 meter.

But this figure is approximate.

To get the exact size of the interval, it is necessary to calculate the bearing capacity of the truss system of the selected type.

To perform the correct calculation, the following scheme should be used:

- first you need to determine the length of the roof slope;

- now the resulting figure should be divided by the value of the approximately selected rafter pitch. If you previously chose its value of 1 meter, then you need to divide by 1.

If 0.8 was chosen, then it should be divided by 0.8, etc.;

- after that, one is added to the result obtained and the resulting value is rounded up. This action is necessary in order to get the exact number of rafters that will need to be installed on one slope;

- the total length of the slope must be divided by the number of rafter legs obtained in the previous calculation. And we get the exact distance between them.

To better understand everything, let's look at an example.

By measuring the length of the roof slope, we got 27.5 meters.

We choose a step of 1 meter to make it more convenient to count.

Now we add the unit 27.5 m + 1 = 28.5 m.

We round up to the nearest value and get the number 29.

That is, 29 rafter legs must be installed on one slope of our roof.

Now we divide the length of the roof by their number: 27.5 / 29 \u003d 0.95 m.

So, in our case, the step of the rafter legs should be 0.95 meters.

This is a general calculation.

In which the peculiarity of a particular roofing material is not taken into account.

And he can significantly change this parameter.

When you know what kind of material you will use on the roof, some changes will have to be made to the calculation procedure.

Optimal and minimum value

The step is the unit of account.

After all, it depends, first of all, on the load on the roof frame and the section of the rafter legs.

You can take a thick board for their construction and make the interval between them 120 cm.

At this distance, the crate may begin to sag.

Yes, and how to lay the heater?

Indeed, for most materials, the width is 1 meter.

So they take an approximate step of 1 meter when calculating.

The minimum distance between the rafter legs is 70 cm.

And to obtain the optimal value for each material, it is necessary to perform a calculation.

Determining the pitch for a pitched roof

Shed roofing is the simplest.

Indeed, in the truss farm of such a roof there are only rafter legs.

There are no struts, racks, braces in its design.

Such a roof is usually arranged on garages, outbuildings, baths.

As can be seen from the table, the rafter step depends on their length and cross section.

Distance between rafters for a gable roof

A gable roof is much more common than a shed roof.

And to explain such popularity is simple: the design is very simple, but for all its simplicity, the gable roof is distinguished by its reliability.

Its design is easy to adjust to any climatic conditions and any roofing material.

When calculating the pitch of the rafters of a gable roof, everything is performed according to the general calculation system (see above).

If the slopes have the same length, then it is enough to perform calculations for one slope.

If the slopes are of different lengths, then the calculation is performed for each slope.

It should be remembered that the limit values for the pitch of the rafter legs are 70 and 120 cm.

What is the step depending on the material of the roof

If ondulin is used as a roofing material, then the rafter system is constructed from pine boards with a section of 50 x 200 mm, and the rafters should be located at a distance of at least 60 cm and not more than 90 cm from each other.

A crate of timber with a section of 40 x 50 mm is laid on top.

metal tile

Roofing from metal tiles is most often used in the construction of country houses.

Because this material is much lighter than ceramic or cement tiles.

Although in appearance it is very similar to her.

The light weight of the metal tile makes it possible to use boards of a smaller section when creating the rafter system, and to use thinner bars for the crate.

More about the counter-lattice under the metal tile.

O hip roof with hanging rafters on the link. Also about the design of hanging rafters.

About the price of Viking metal tiles here. Specifications, photos, reviews.

Reducing the size of the elements of the rafter leg system, in turn, reduces the load on the walls of the building and its foundation.

During the construction of the rafter system under the metal tile, the rafters are mounted in increments of 60 - 95 cm.

The cross section of the material is 50 x 150 mm.

According to experts, if a heater having a thickness of 150 mm is placed between the rafters, then the most comfortable living conditions will be created in the attic.

To ensure ventilation of the space where the insulation is laid, when installing the rafter system, holes will be drilled near the upper roof with a diameter of 12 mm.

The technology for manufacturing a truss system for metal tiles does not differ significantly from the technology for manufacturing a frame for other roofing materials.

Its only difference is the installation at the top.

The upper support is mounted not on the side of the ridge beam, but on the ridge run.

The presence of a free zone between the rafters allows the air to fully circulate under the flooring, which helps to protect against the formation of condensate.

Ceramic tiles

The design of the system for ceramic tiles has its own characteristics.

After all, clay is used to make such a roofing material.

And this is very heavy material.

If we compare metal and ceramic tiles, the latter weighs 10 times more.

Accordingly, the truss system is significantly different.

There is a load of 40 - 60 kg per 1 square meter of the roof surface, depending on the manufacturer and brand of the product.

The rafters for such a frame system are made from wood that has been dried for a long time.

Such wood should have a moisture content of no more than 15%.

A beam with a section of 50 x 150 or 60 x 180 mm is used.

And the distance between the rafter legs can be 80 - 130 cm.

The exact value can be called if the angle of inclination of the slopes is known.

If the angle of inclination is 15 degrees, then the pitch of the rafters will be 80 cm.

And if the angle of inclination, for example, is 75 degrees, then the step can be larger - 130 cm.

More than 130 cm interval between the rafters do not.

Also, when calculating the pitch of the rafters, their length is taken into account.

The larger the dyne, the smaller the distance between them.

The shorter the rafter legs, the greater the distance can be.

If the angle of inclination is 45 degrees, then the roofer can safely move along the roof if the pitch of the rafters is 80 cm.

Decking

When creating a rafter system for corrugated board, the minimum distance between the rafter legs is 60 cm.

The maximum value is 90 cm.

If for some reason the pitch of the rafters was more than 90 cm, then it becomes necessary to install large cross-section boards.

The rafter legs themselves can have a section of 50 x 100 or 50 x 150 mm.

Despite the emergence of a large number of new roofing materials, asbestos-cement slate remains one of the most popular.

If it is planned to lay slate on the roof, then the rafters should have a section of 50 x 100 or 50 x 150 mm.

The distance between them is made not less than 60 and not more than 80 cm.

The crate is made from a bar having a section of 50 x 50 mm or a board with a section of 25 x 100 mm.

When constructing any building structure, it should be remembered that there are still unforeseen situations.

And, therefore, when calculating the sections of the rafters and the distance between them, it is necessary to provide for a margin of safety.

The distance between the rafters: shed, gable roof

One of the most important parameters in the calculation of the truss system is the distance between the rafters. After all, it depends on him how strong and stable it will be.

Substances and their physical properties

Substances and their physical properties Classification, structure, nutrition and the role of bacteria in nature

Classification, structure, nutrition and the role of bacteria in nature Bacteria - the most ancient organisms on Earth Bacteria - the oldest group of living organisms

Bacteria - the most ancient organisms on Earth Bacteria - the oldest group of living organisms Epithets, metaphors, personifications, comparisons: definitions, examples

Epithets, metaphors, personifications, comparisons: definitions, examples Bronchial asthma Bronchial asthma

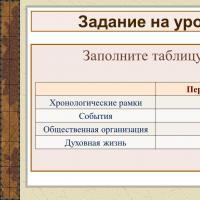

Bronchial asthma Bronchial asthma Roman Empire Ancient History

Roman Empire Ancient History Flexible removable dentures: design, features and benefits Varieties of soft dentures with photos

Flexible removable dentures: design, features and benefits Varieties of soft dentures with photos